Cabinet with rotatable interlayer

A rotary and interlayer technology, applied in the direction of casing/cabinet/drawer parts, elastic/clamping device, bendable lead device, etc., can solve the problems of increasing maintenance difficulty and reducing maintenance efficiency, and achieve reduction The difficulty of maintenance, the improvement of maintenance efficiency, and the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

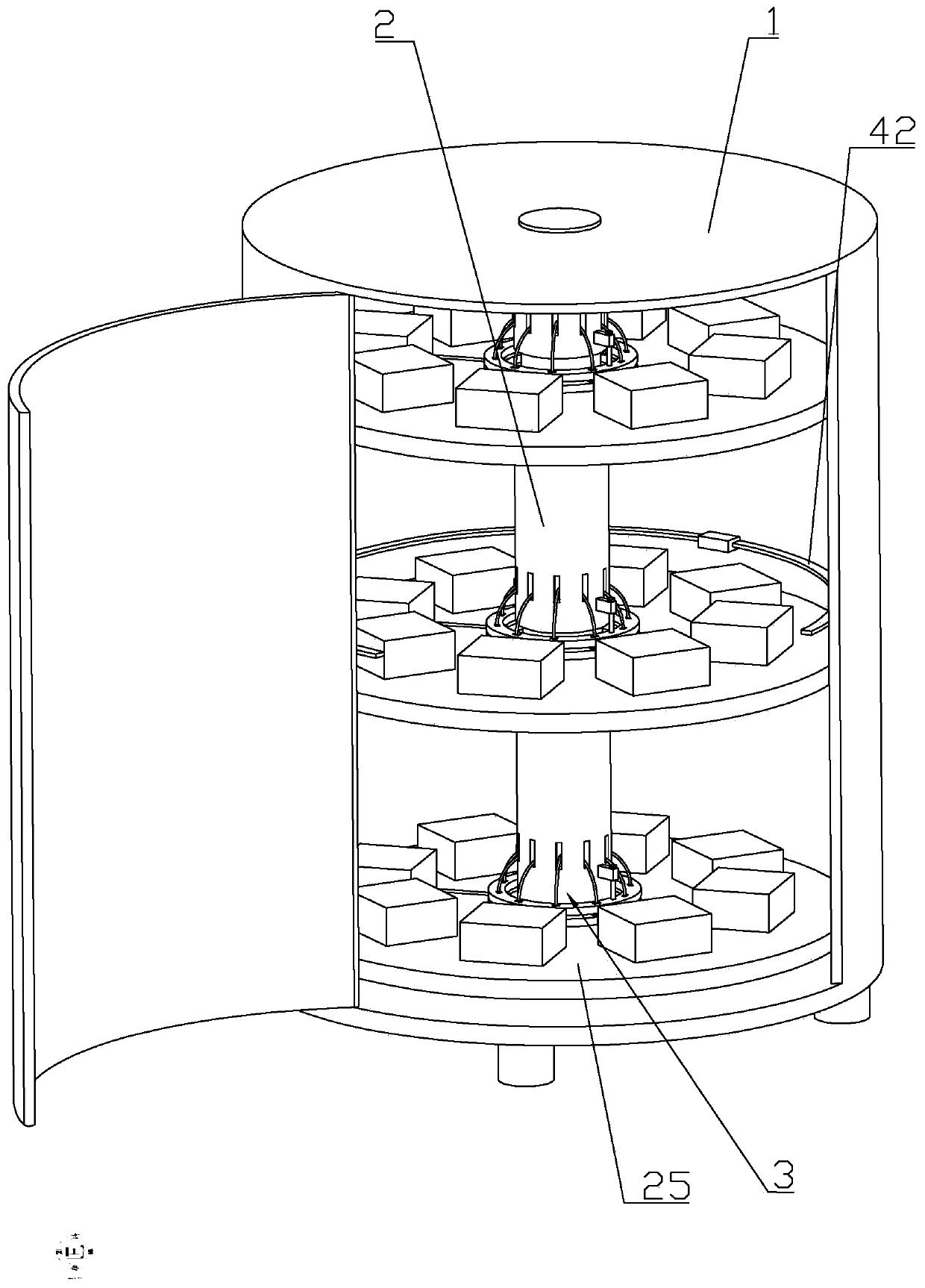

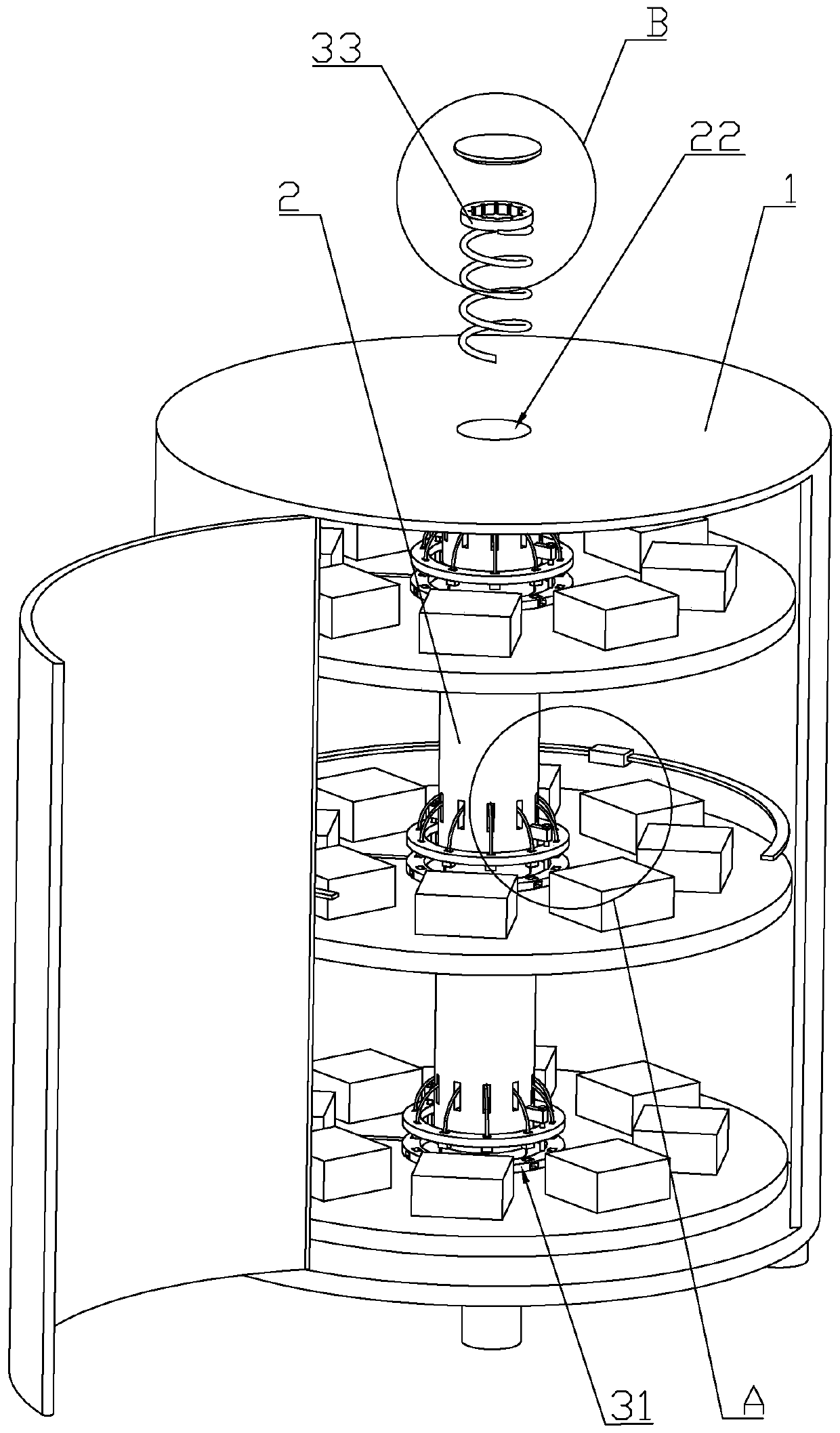

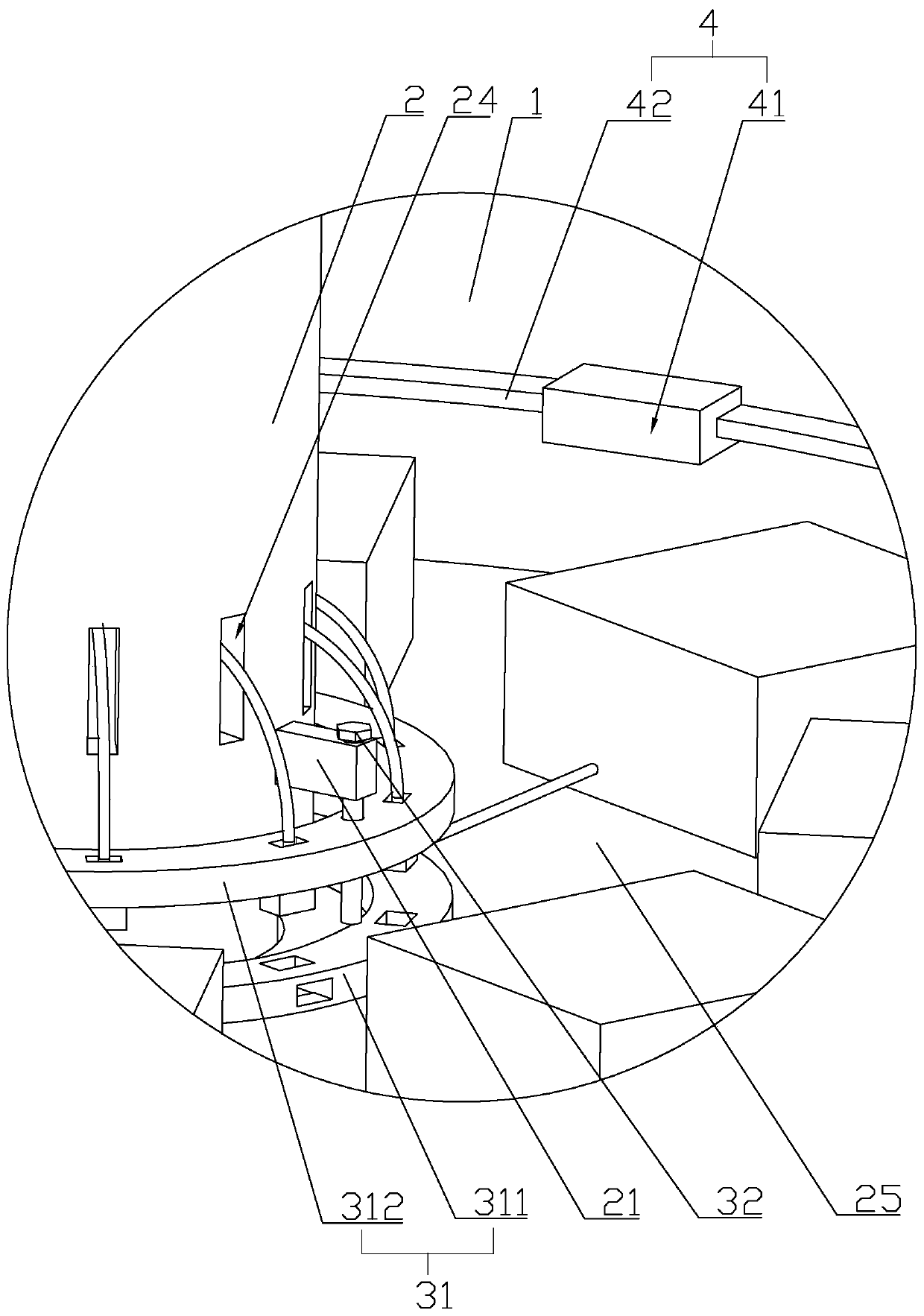

[0049] Embodiment one: refer to figure 1 , figure 2 , is a mezzanine rotatable cabinet disclosed by the present invention, including a cabinet body 1, a main shaft 2 vertically arranged in the cabinet body 1, a plurality of interlayers 25 which are rotatably sleeved on the main shaft 2 to carry parts, and arranged on A sorting mechanism 3 for sorting wires in the cabinet body 1. Both the cabinet 1 and the main shaft 2 are cylindrical and hollow inside, the central axis of the main shaft 2 coincides with the central axis of the cabinet 1, and the outer wall of the main shaft 2 is provided with an annular groove along its circumference. There are a plurality of them and they are evenly spaced along the axial direction of the main shaft 2 . The interlayer 25 is in the shape of a ring, and a plurality of interlayers 25 are evenly spaced along the height direction of the cabinet body 1. Various parts are installed on it, and the various parts are distributed around the main shaf...

Embodiment 2

[0067] Embodiment two: refer to Image 6 , a sandwich rotatable cabinet, which differs from Embodiment 1 in that: a drive motor 34 is provided on the support rod 21, the drive motor 34 is fixed to the support rod 21 by screws, and its output shaft is fixed coaxially with the screw rod 32.

[0068] The implementation principle of this embodiment is: when the interlayer 2525 needs to be rotated greatly to make the faulty part face the maintenance personnel, the maintenance personnel only need to start the driving motor 34 . At this time, the driving motor 34 drives the screw rod 32 to rotate, and the screw rod 32 drives the receiving part 312 away from the socket part 311, so as to facilitate the separation of the wires passing through the main shaft 2 and the wires on the parts, reduce manual operations, and facilitate maintenance personnel to repair parts. Reduce potential safety hazards such as electric shock and improve safety.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap