Self-reset shock-absorption and anti-collapse structure for frame structure

A frame structure and self-resetting technology, which is applied in earthquake resistance, building components, building structures, etc., can solve the problems of energy consumption, shock absorption and continuous collapse resistance of the frame structure at the same time, and achieve simple structure, easy construction and installation, transmission and transmission. force mechanism clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

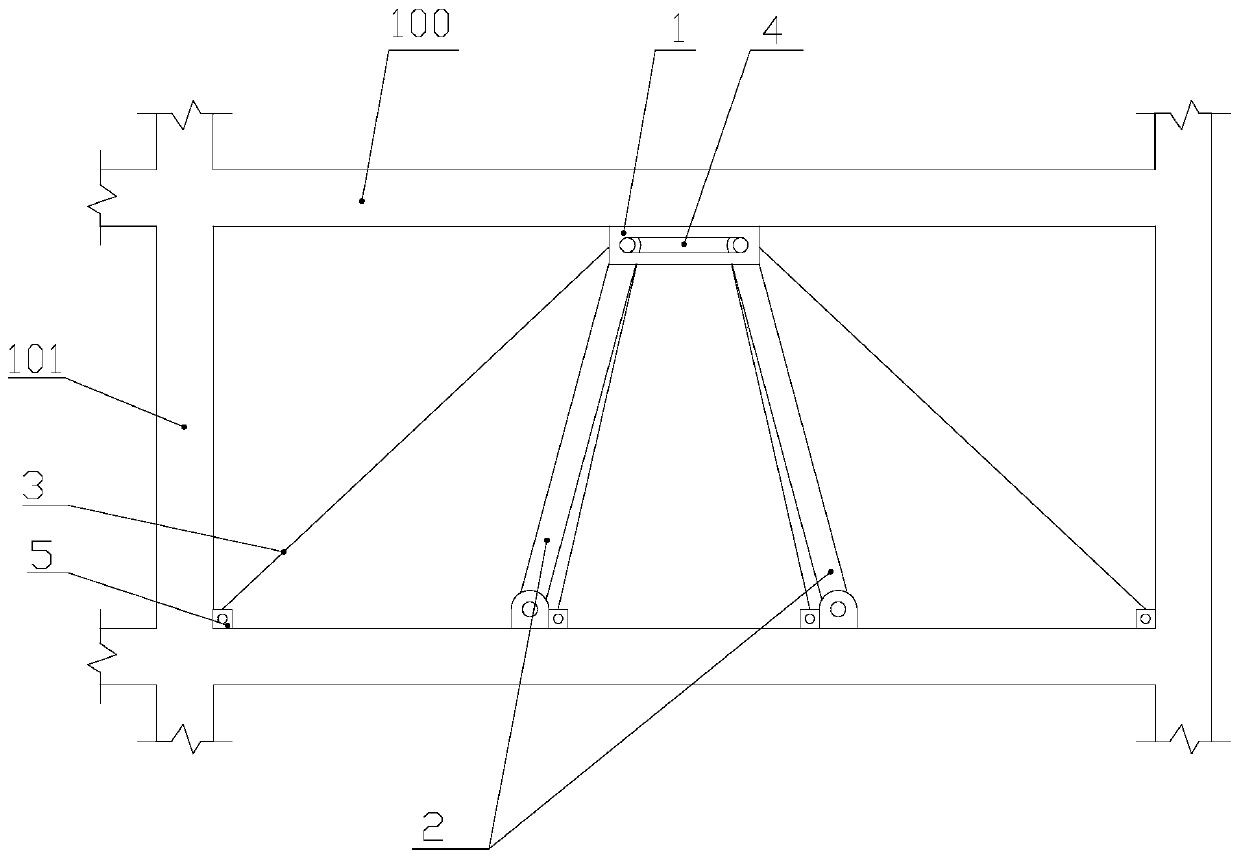

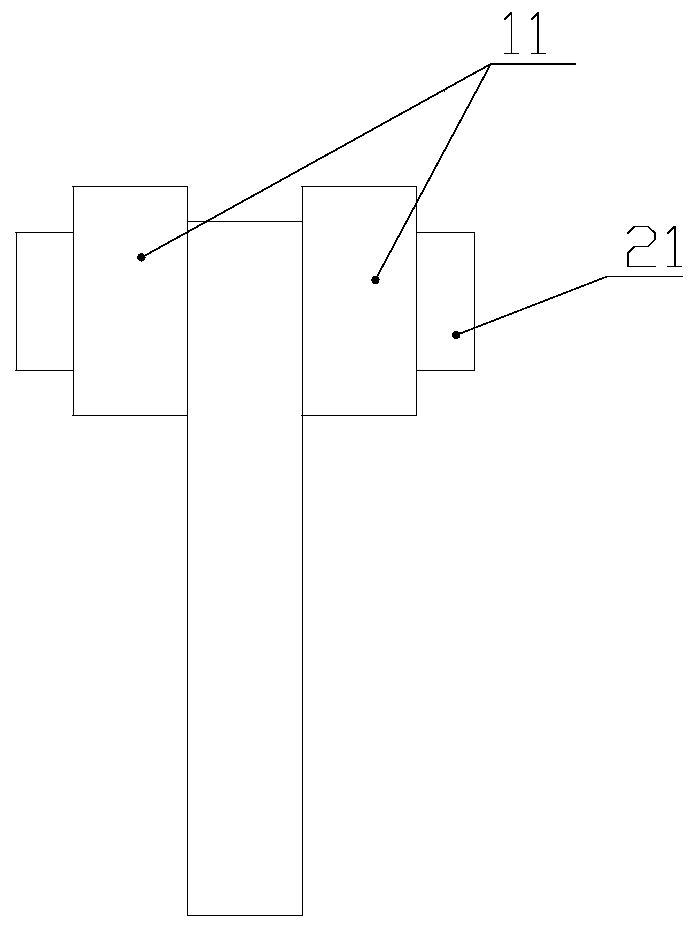

[0018] Specific implementation mode one: combine Figure 1~2 Describe this embodiment, a self-resetting shock-absorbing and anti-collapse structure for frame structures, which is arranged in the enclosed area of two beams 100 and two columns 101 of the frame structure, and it includes a sliding support 1, two metal pillars 2 and several SMA wires 3, the sliding support 1 is fixedly connected to the beam 100 above, and the sliding support 1 is horizontally processed with a long hole 4, and the lower ends of the two metal pillars 2 are respectively connected to the beam 100 below Hinged, the upper parts of the two metal pillars 2 are slidably connected with the sliding support 1 through the long holes 4, and the top of each metal pillar 2 is respectively wound with several SMA wires 3, and the two ends of each SMA wire 3 are respectively located on the other side. Both sides of the wound metal pillar 2 are fixedly connected to the beam 100 below. There is a hinge between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com