Chip-on-film and display device

A chip-on-chip film and chip technology, which is applied in the field of chip-on-chip films and display devices, can solve problems such as abnormal function of the display panel, misplaced connection between output pins and binding pads, etc., to improve production yield and reliability, and prevent functional abnormal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

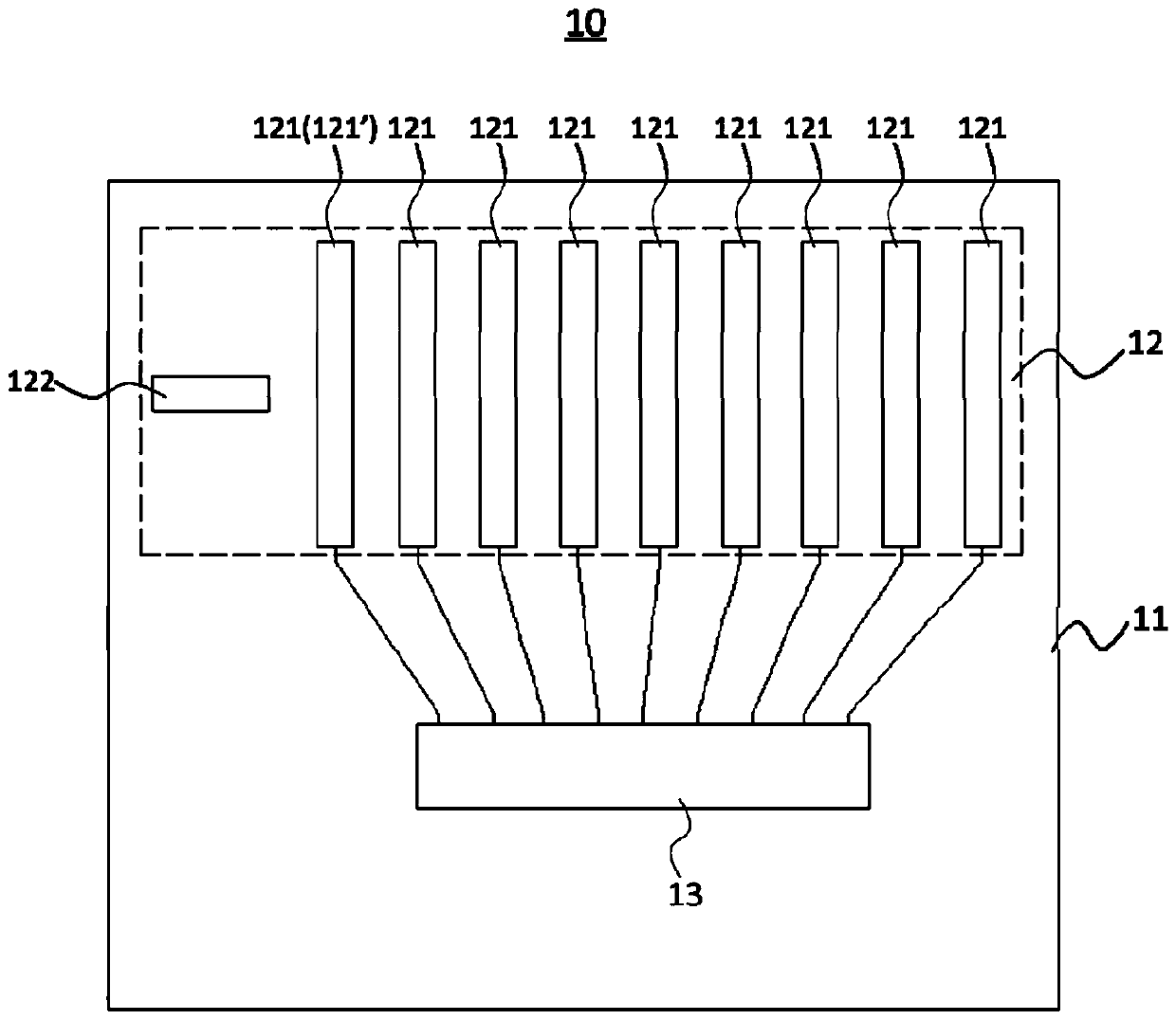

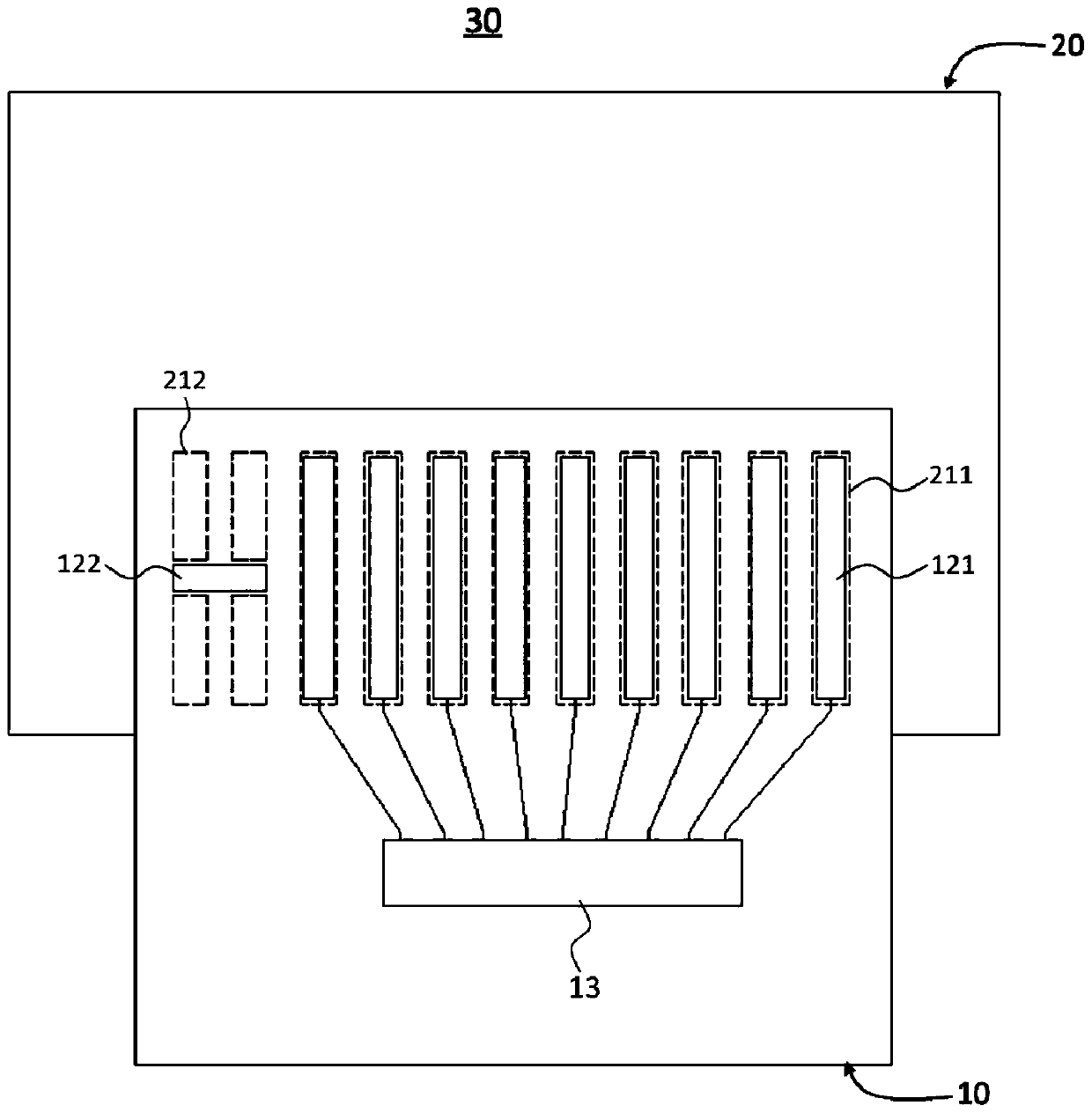

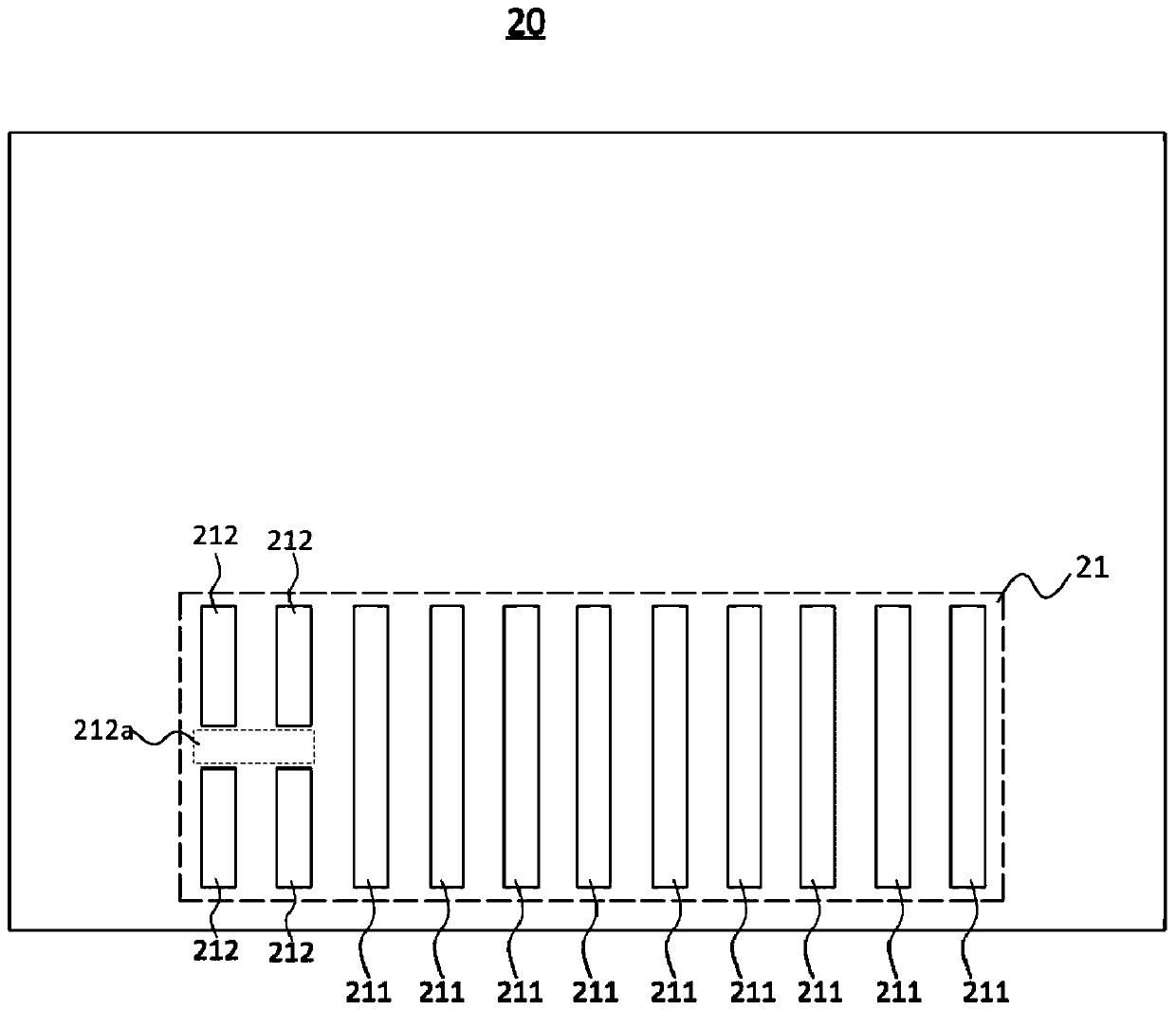

[0025] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

[0026] An embodiment of the present invention provides a chip-on-film, by setting horizontal pins disconnected from the longitudinal pins on the side of the longitudinal pins of the chip-on-film, and implementing the chip-on-film through the horizontal pins Accurate alignment with the display panel solves the problem of difficult alignment in the bonding process of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com