Oil immersion device for manufacturing auto parts

A technology for spare parts and oil immersion, which is applied to the device and coating of the surface coating liquid, which can solve the problem of inability to immerse auto parts in oil, reduce the efficiency of auto parts immersion in oil, and the oil immersion device cannot meet actual needs, etc. problem, to achieve the effect of improving sufficiency, fast and fully immersing oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

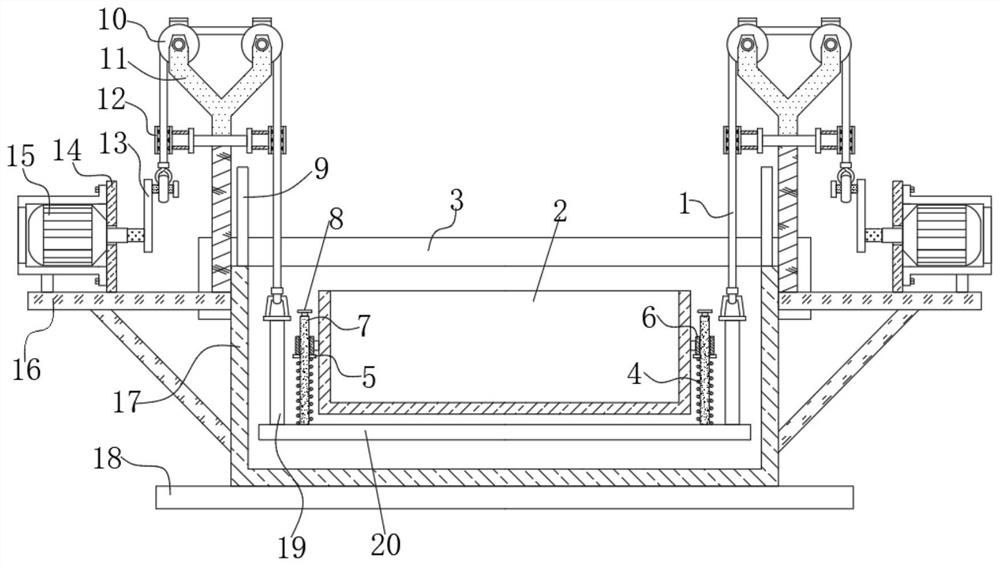

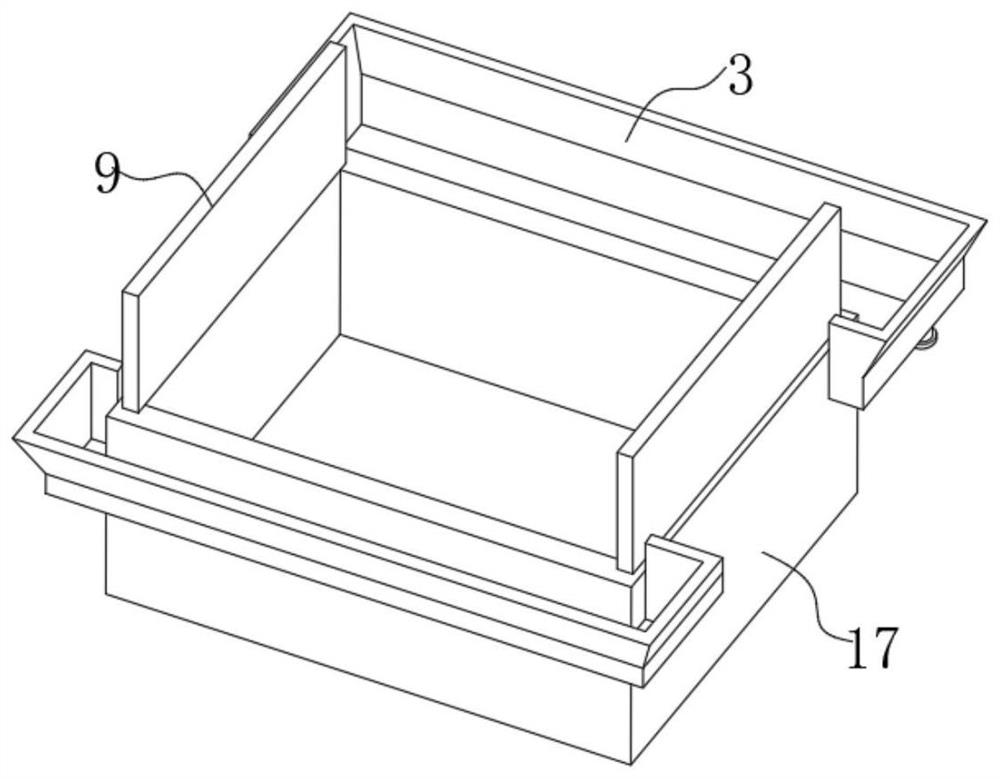

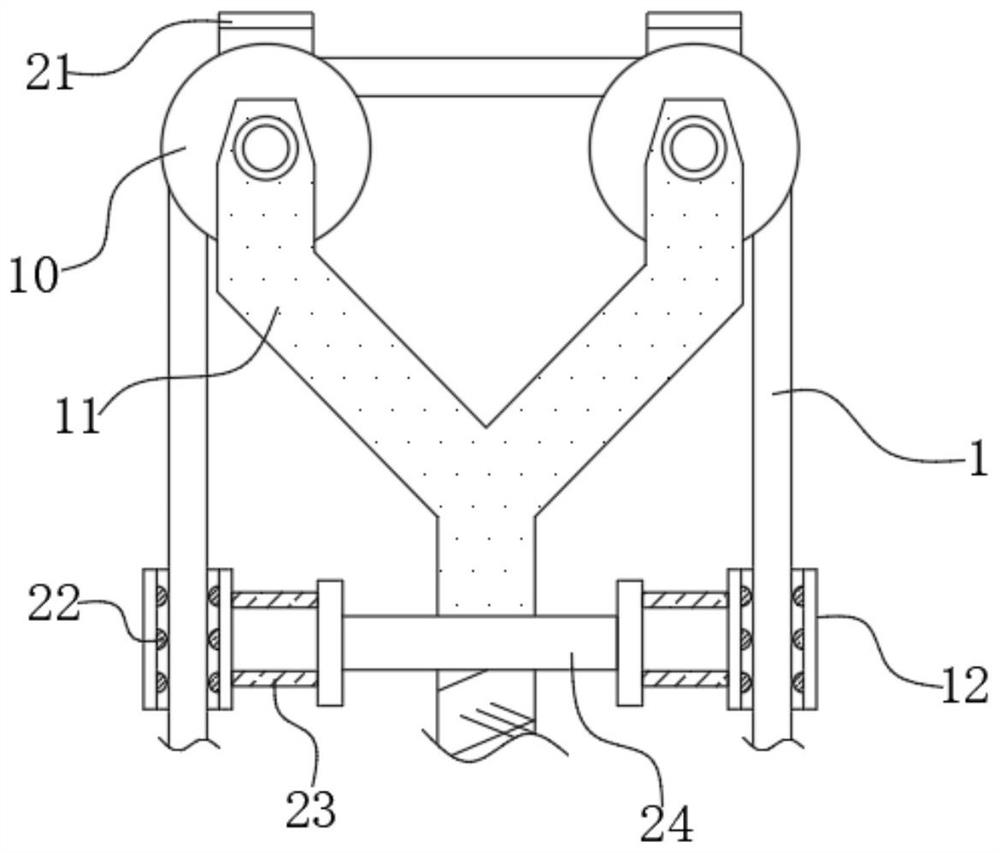

[0026] refer to Figure 1-3 , an oil immersion device for the manufacture of auto parts, comprising an oil immersion tank 17, lifting mechanisms are provided on both sides of the oil immersion tank 17, and a holding mechanism is arranged between the two lifting mechanisms. When immersing in oil, the lifting mechanism drives the holding mechanism The mechanism moves up and down so that the auto parts can be better immersed in oil. The holding mechanism includes a support plate 20. The top outer wall of the support plate 20 has multiple rows of through holes. The top outer wall of the support plate 20 is close to the four corners. Both are welded with a vertical rod 19, and the top of the vertical rod 19 is welded with a hanging ring. The side view structure of the hanging ring is an isosceles trapezoid, and the top outer wall of the supporting plate 20 is welded with two round rods 7 near the edges of both sides. The outer wall of the round rod 7 is sleeved with a spring 4, an ...

Embodiment 2

[0036] refer to Figure 4 , a kind of oil immersion device for the manufacture of auto parts. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, the bottom inner wall of the cage 2 is welded with multiple rows of standpipes 26, and the top of the standpipe 26 is welded with The tapered plug 25 and the arc-shaped outer wall of the standpipe 26 are welded with multiple groups of annularly distributed leakage holes 27 .

[0037] During use, multi-row standpipe 26 makes auto parts be separated, avoids auto parts clumping, and the tapered plug 25 at the top of stand pipe 26 can prevent auto parts from accumulating on its top, and the outer wall of stand pipe 26 has leakage Hole 27, so it does not affect the flow of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com