Dustproof puncher for chemical anchor bolt

A kind of technology of chemical anchor bolt and puncher, applied in the field of puncher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

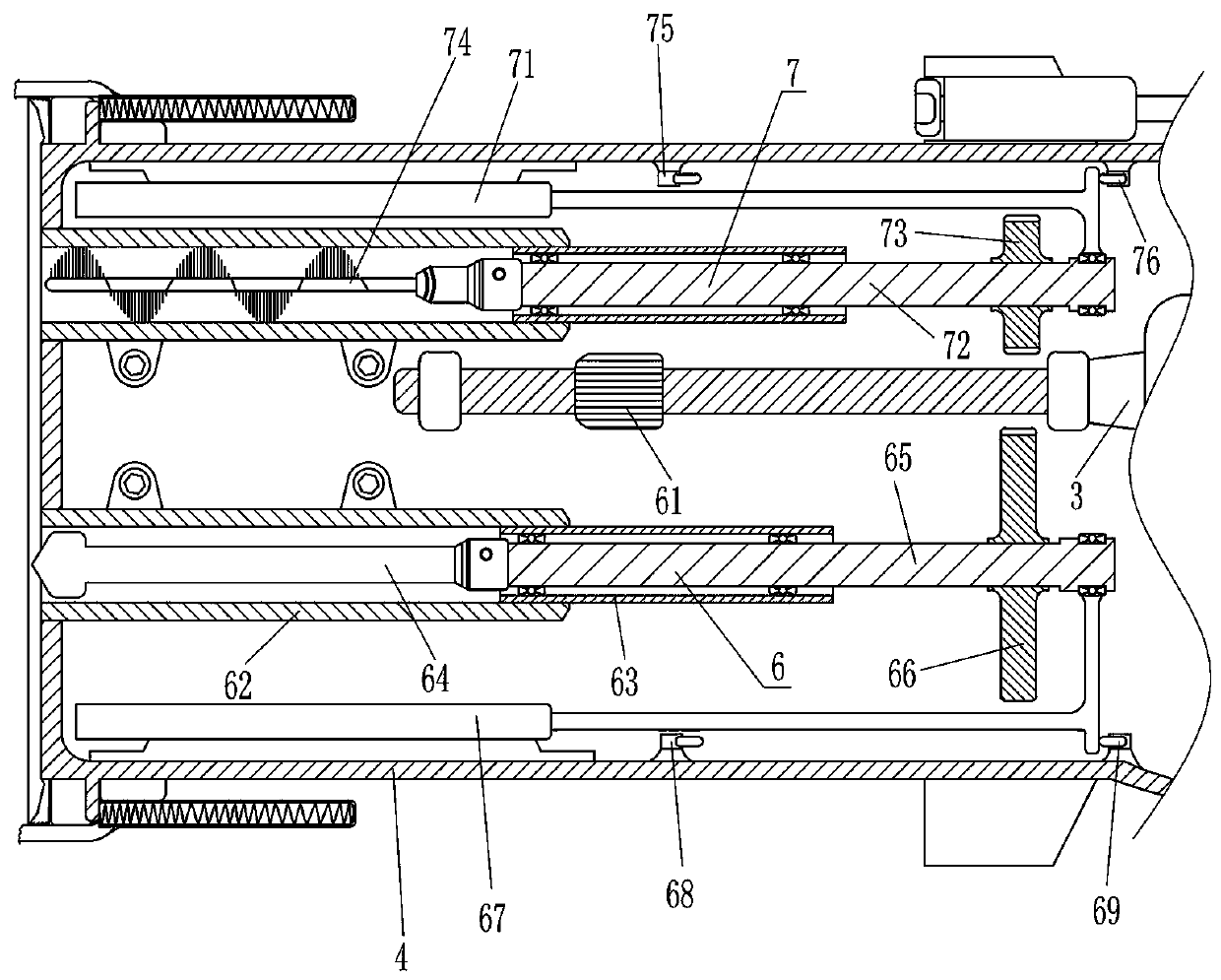

[0025] A chemical anchor bolt dustproof hole puncher, such as Figure 1-2 As shown, it includes a handle 1, a driving motor 3, a mounting plate 4, a punching mechanism 6 and a hole cleaning mechanism 7, the top of the handle 1 is provided with a mounting plate 4, the right part of the mounting plate 4 is equipped with a driving motor 3, and the left side of the mounting plate 4 The upper part of the side is provided with a start key 2, the bottom left part of the mounting plate 4 is provided with a punching mechanism 6, the punching mechanism 6 is used to install and punch holes, and the upper left part of the mounting plate 4 is provided with a hole cleaning mechanism 7, and the hole cleaning mechanism 7 is used for Clean the inside of the hole.

[0026] The punching mechanism 6 includes a first gear 61, a guide cylinder 62, a conduit 63, a drill bit 64, a first transmission shaft 65, a second gear 66, a first electric push rod 67, a first travel switch 68, and a second trave...

Embodiment 2

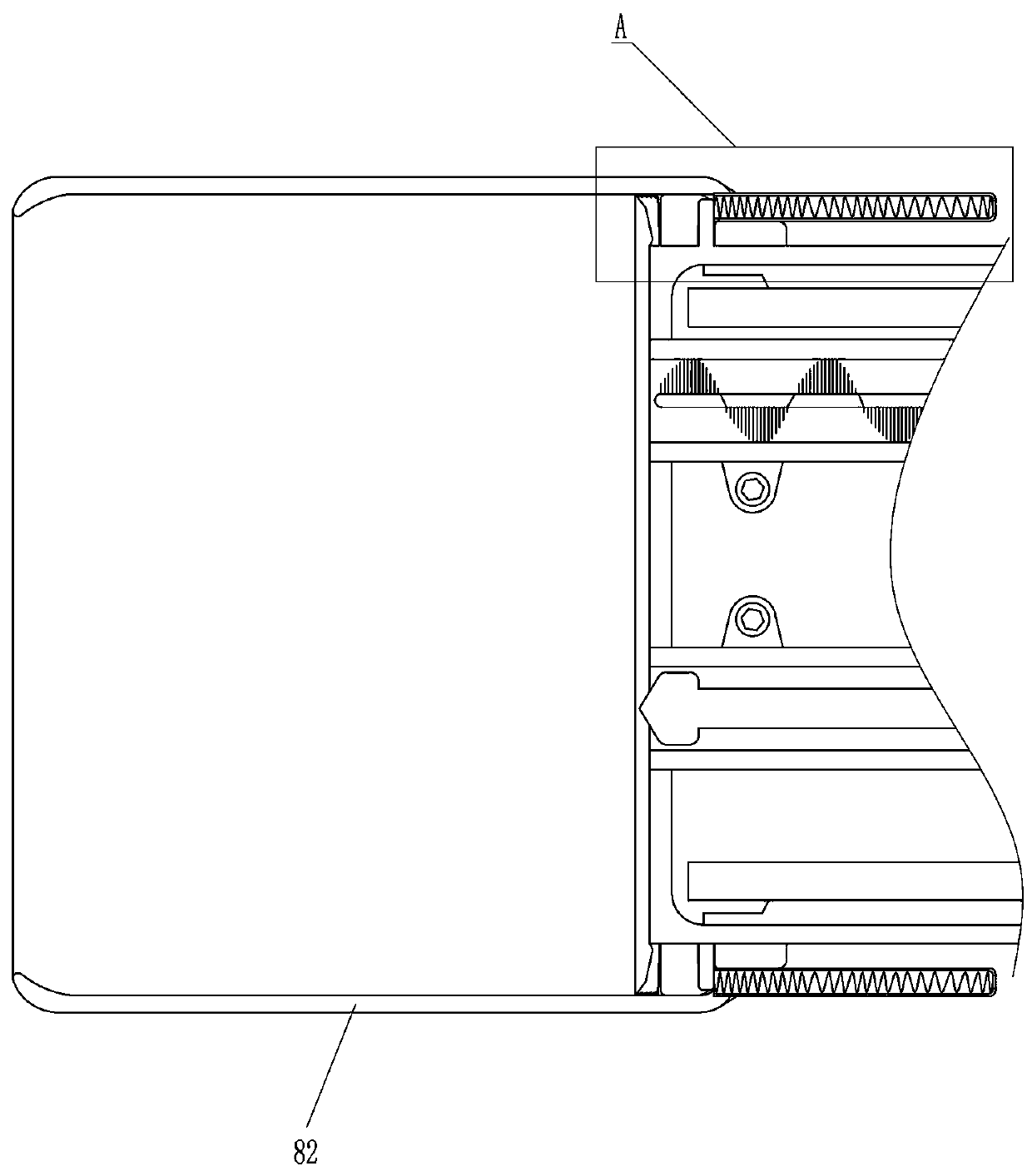

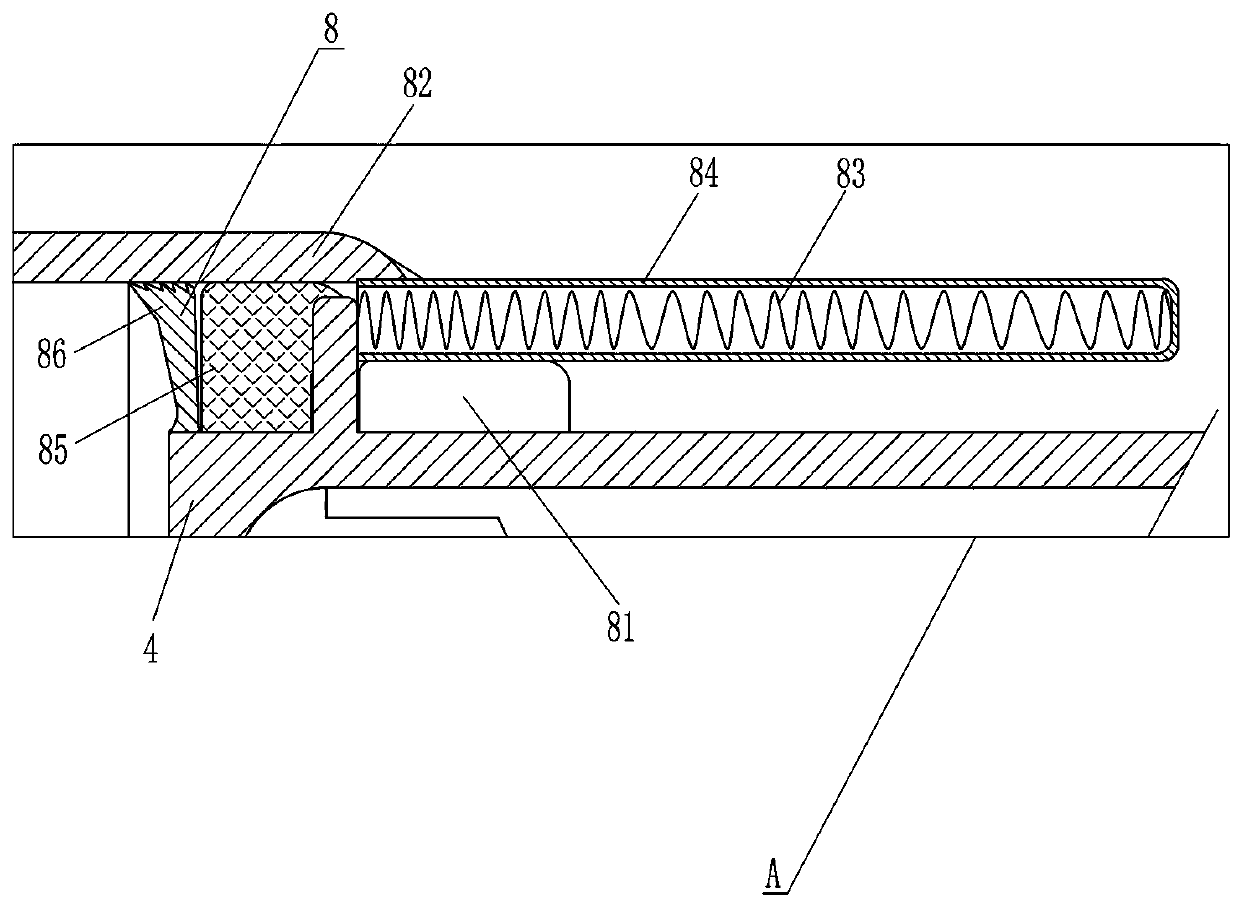

[0033] On the basis of Example 1, such as Figure 3-6 Shown, also include dustproof mechanism 8, dustproof mechanism 8 includes sliding ring 81, dustproof cover 82, spring 83, protection tube 84, sponge ring 85 and dustproof pad 86, mounting plate 4 left parts are covered with sliding Ring 81, the upper and lower sides of sliding ring 81 are all provided with protective tube 84, and spring 83 is all provided with between the inner right end of protective tube 84 and mounting plate 4, and the left part of mounting plate 4 is covered with dust cover 82, and dust cover 82 The upper, lower, and right sides are fixedly connected to the outer sides of the protection tubes 84 on the upper and lower sides, and the outside of the left part of the mounting plate 4 in the dust cover 82 is provided with a sponge ring 85 and a dust pad 86, and the sponge ring 85 is located at the dust pad 86 Right.

[0034] Also comprise limit mechanism 9, limit mechanism 9 comprises adjusting nut 91, adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com