Pre-alignment device and method

A pre-alignment and assembly technology, applied in sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve problems such as inability to absorb warped sheets and meet the pre-alignment and positioning requirements of large warped sheets , to achieve the effect of improving the pre-alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

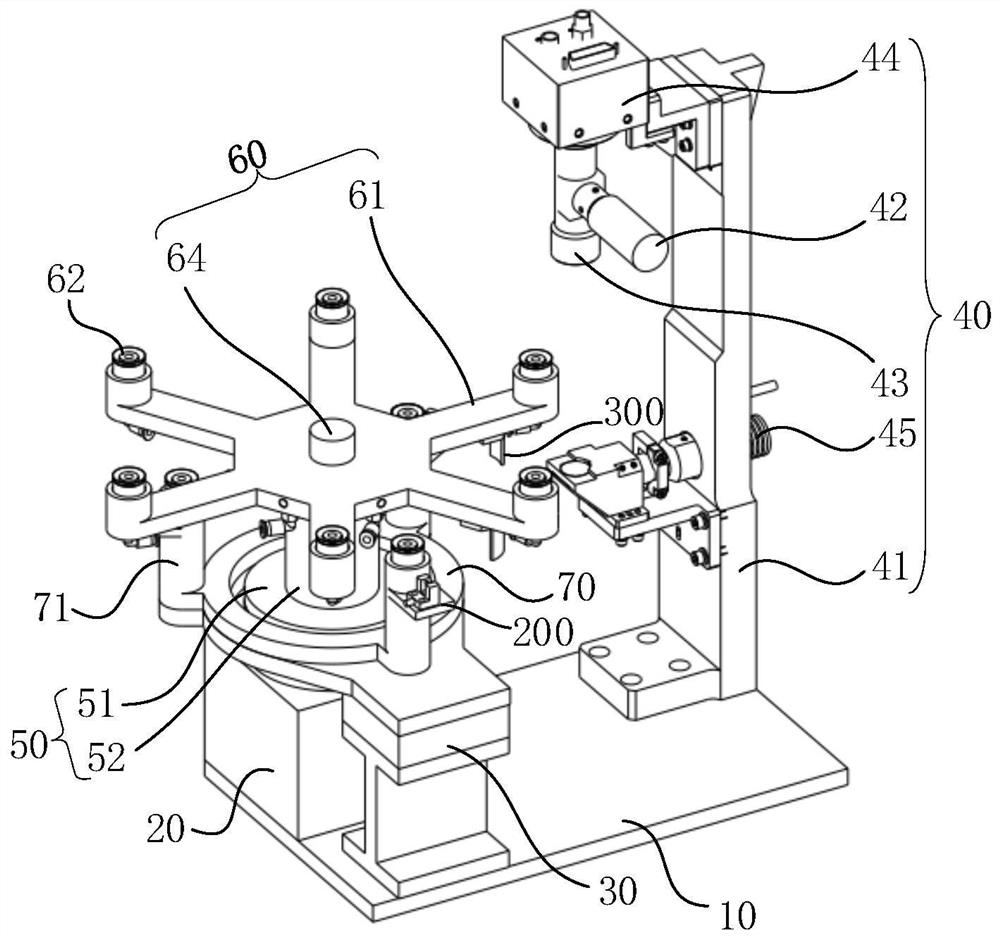

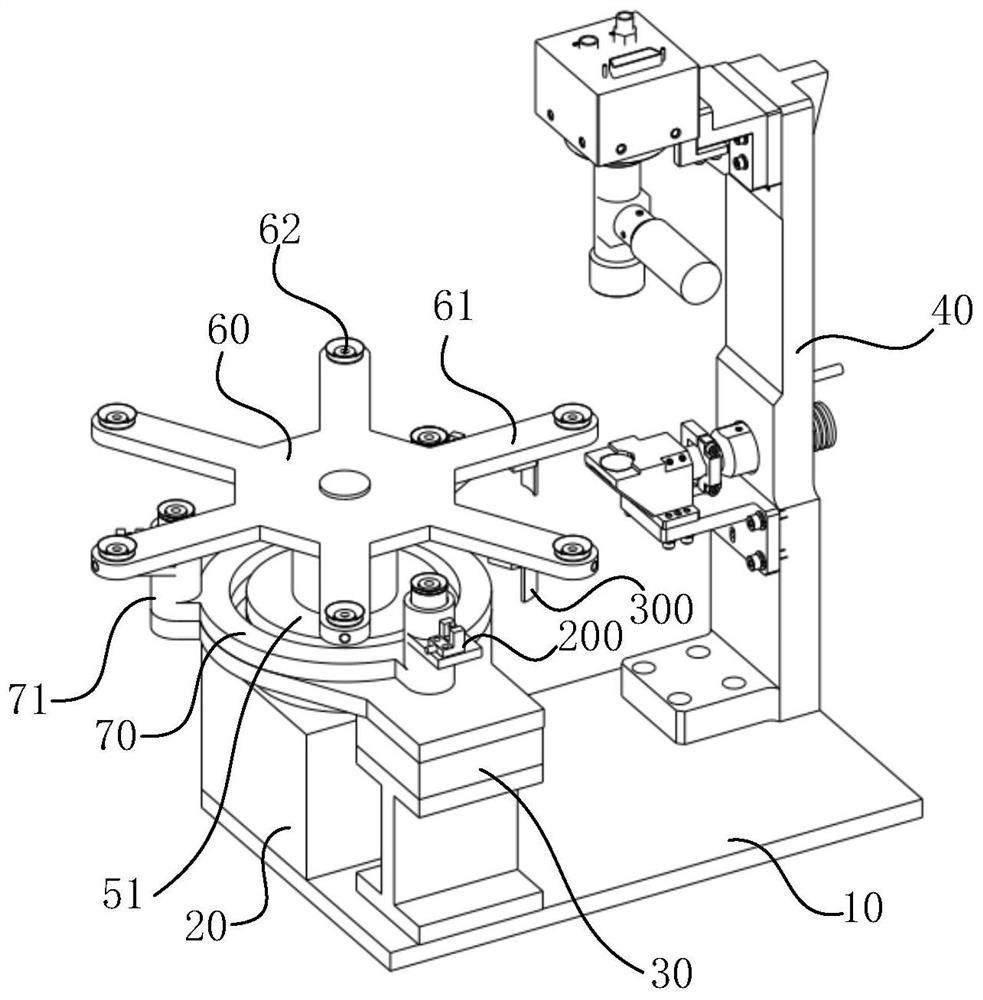

[0054] The technical solutions of the present invention are further described below in conjunction with the accompanying drawings and through specific embodiments.

[0057] The rotating shaft assembly 50 can drive the claw plate 60 to rotate, and the lifting shaft 20 can drive the claw plate 60 to lift and lower in the vertical direction.

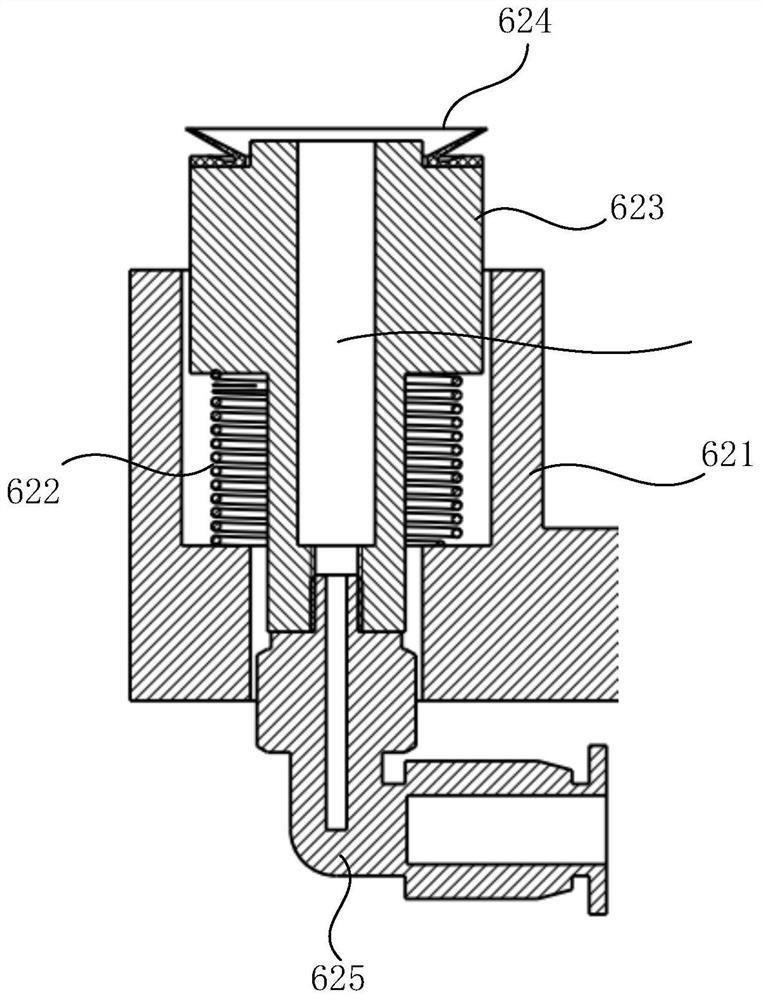

[0062] As shown in FIG. 2, in one embodiment, the first adsorption component 62 includes: a rigid support 621, an elastic member 622, a spring

[0064] As shown in FIG. 3 and FIG. 4, in yet another embodiment, the first suction assembly 62 includes a rigid support 621 and a rubber suction

[0065] In one embodiment, the above-mentioned pre-alignment device further includes a sensor 200 and a blocking plate 300, and the sensor 200 is provided with

[0067] In one embodiment, as shown in FIG. 1 and FIG. 3 , a rigid support block 64 is provided at the central position of the claw plate 60 . Tool

[0068] In the above-mentioned embodiment, six claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com