Automatic charging pile charging control method, control equipment and storage medium

A charging control method and automatic charging technology, which is applied to battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of easily damaged electrodes and external discharge, and achieve the effect of avoiding easy damage and external discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

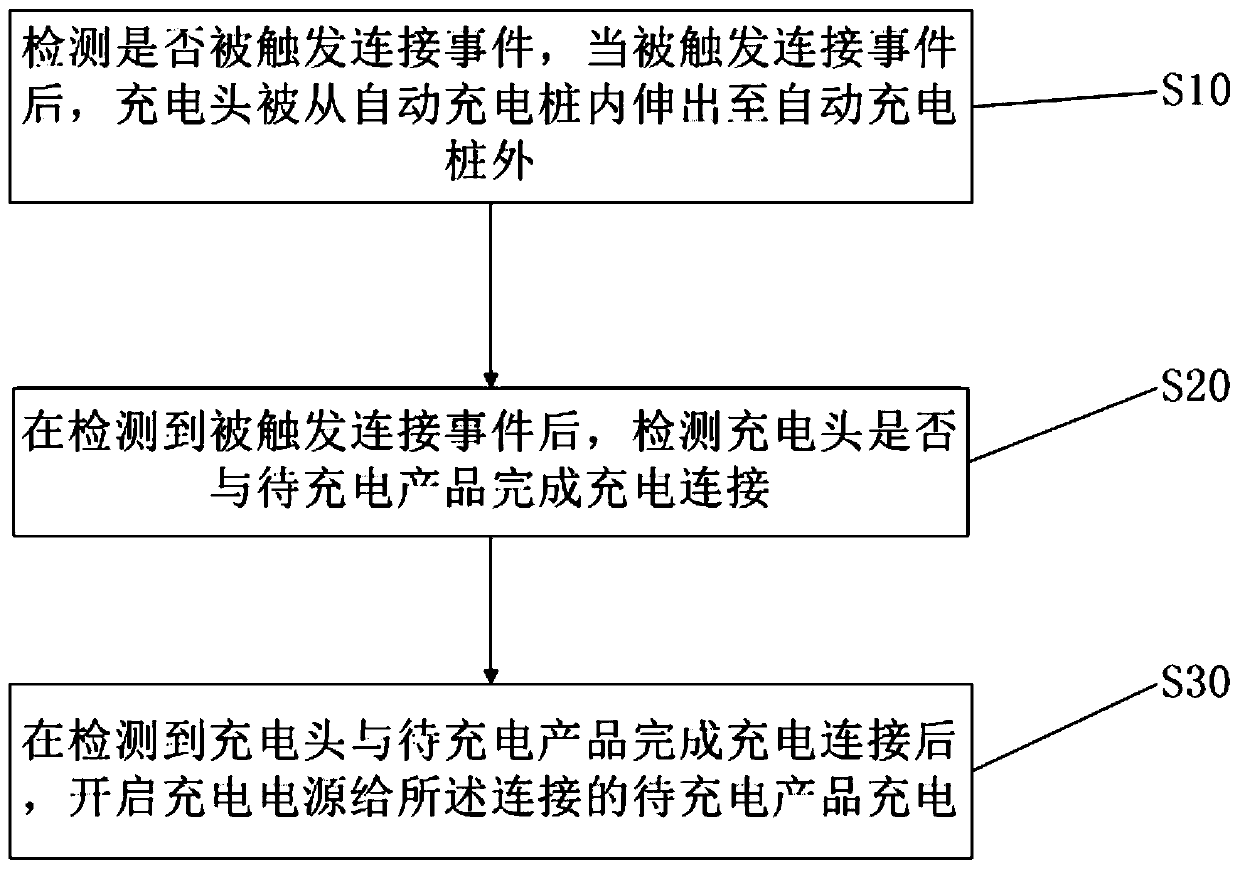

[0033] This embodiment discloses a charging control method for an automatic charging pile. When the automatic charging pile is not in use, the charging head is located in the automatic charging pile. When the automatic charging pile is in use, the charging head extends out to connect with the product to be charged to complete charging. Such as figure 1 As shown, the automatic charging pile charging control method includes the following steps:

[0034] Step S10 , detecting whether a connection event is triggered, and when the connection event is triggered, the charging head is extended from the automatic charging pile to the outside of the automatic charging pile.

[0035] Specifically, the automatic charging pile is provided with a charging head control mechanism for extending and retracting the charging head, and the automatic charging pile is provided with related detection components to detect in real time whether the charging head control mechanism is triggered to The con...

Embodiment 2

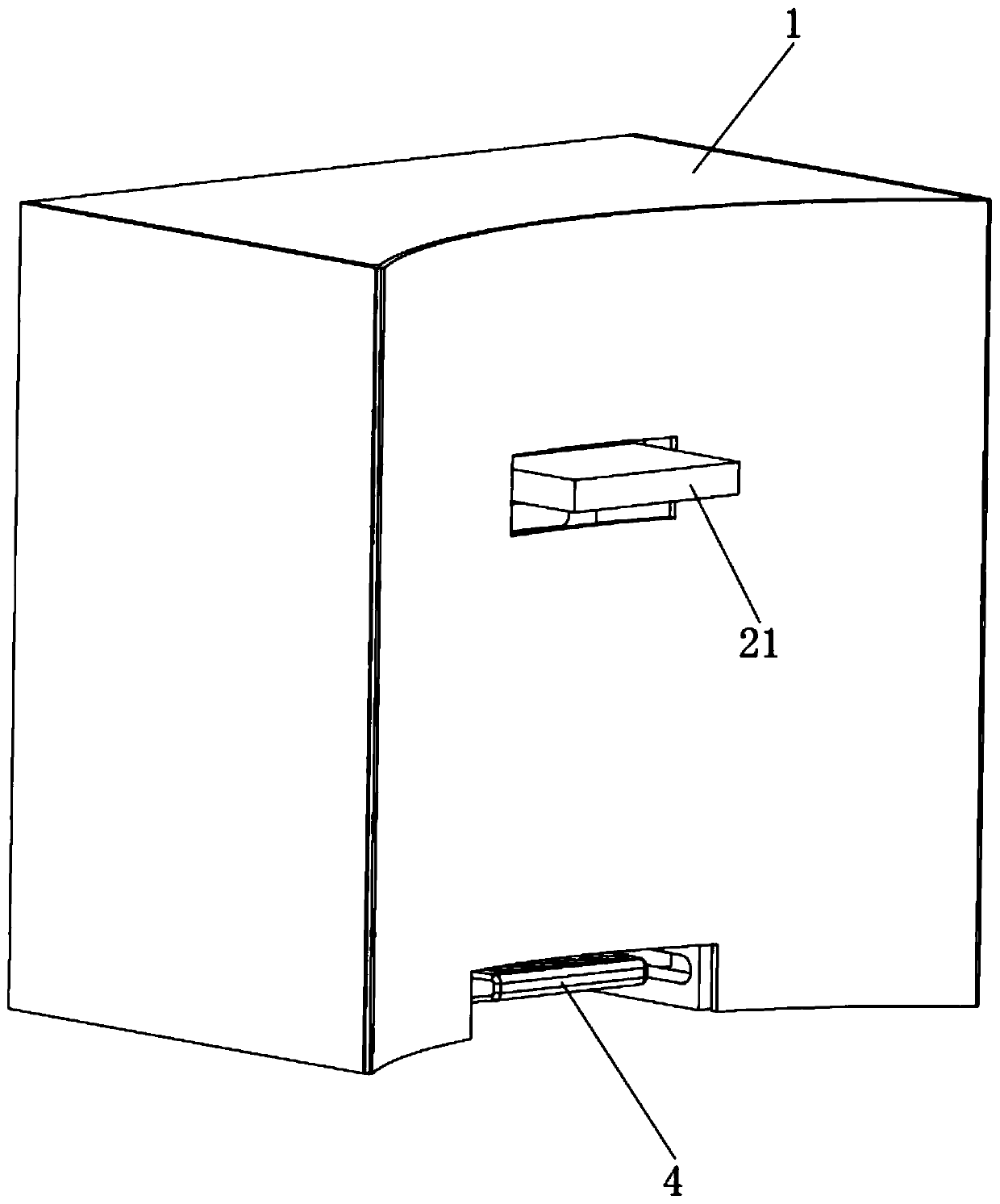

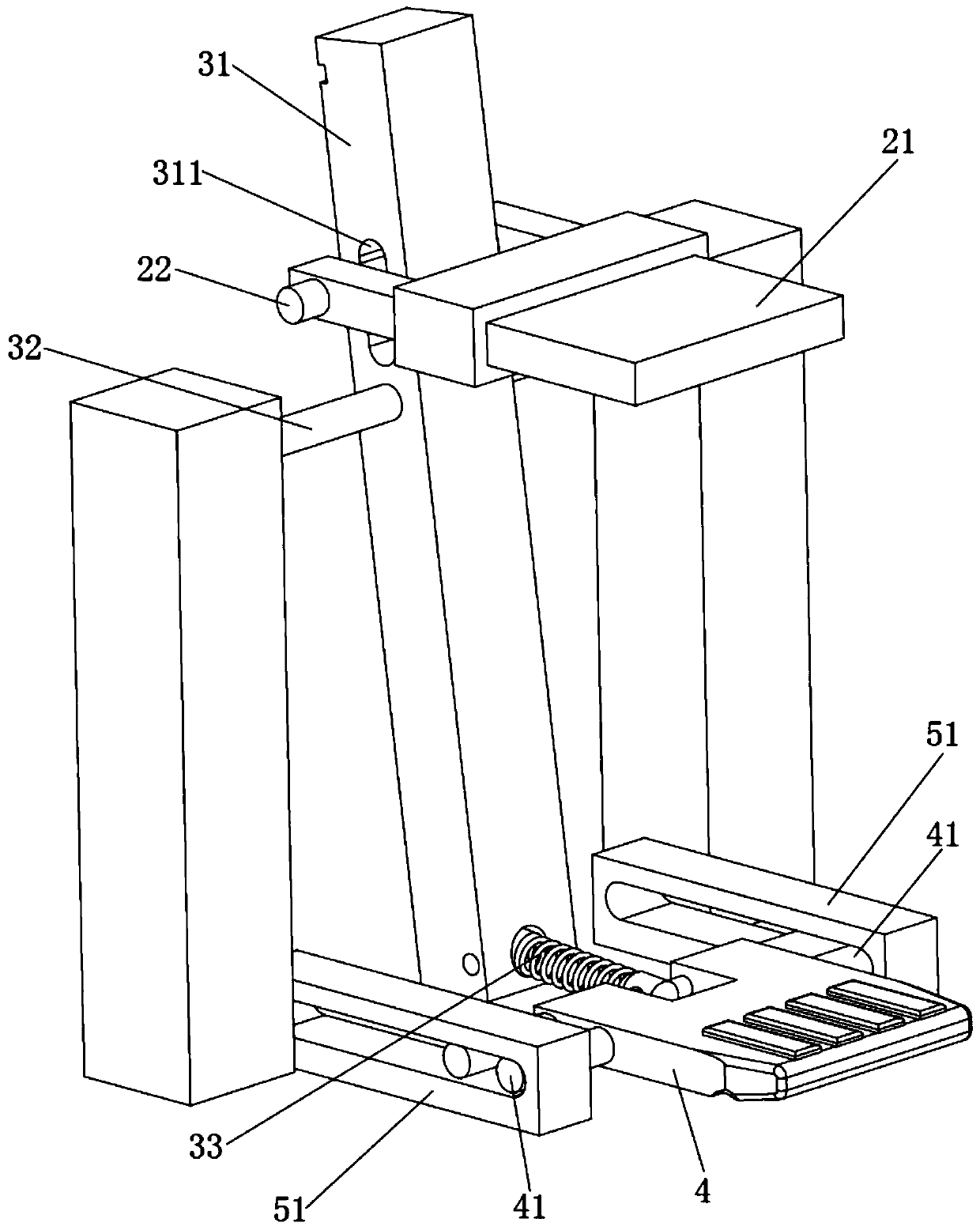

[0043] This embodiment discloses an automatic charging pile applying the charging control method of the automatic charging pile in Embodiment 1, and the charging head control mechanism of the automatic charging pile is a purely mechanical mechanism. Such as figure 2 As shown, the automatic charging pile includes a charging pile body 1. A trigger device, a linkage device and a charging head 4 are installed in the charging pile body 1. One end of the trigger device extends out of the charging pile body 1, and the other end is connected to the charging pile through the linkage device. The first 4 linkage. When the automatic charging pile is not in use, one end of the trigger device extends out of the charging pile body 1, and the charging head 4 is stored in the charging pile body 1. When the mobile robot that needs to be charged moves close to the charging pile body 1 One end of the trigger device outside the charging pile body 1 is triggered by the mobile robot to move into t...

Embodiment 3

[0052] Such as Figure 6 As shown, the automatic charging pile charging control method in this embodiment further includes the following steps on the basis of the first embodiment:

[0053] Step S40, turn off the charging power supply after the charging is completed.

[0054] Specifically, after the charging of the product to be charged is completed, the automatic charging pile is controlled to turn off the charging power supply, which saves power and can effectively prevent the charging head from discharging to the outside.

[0055] Step S50, detecting whether the charging head is disconnected from the charging connection.

[0056] Specifically, it is detected whether the charging head is disconnected from the charging connection by the product through the relevant detection parts on the charging head, that is, whether the product has left the automatic charging pile.

[0057] S60, after detecting that the charging head is disconnected from the charging connection, detectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com