A rollover self-unloading compression garbage truck and its self-rescue device

A compression type, garbage truck technology, applied in the directions of garbage storage, transportation and packaging, can solve the problems of changing the center of gravity of the vehicle, low safety of use, and overturning of the vehicle, to prevent the overturning angle from being too large and improve the safety of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

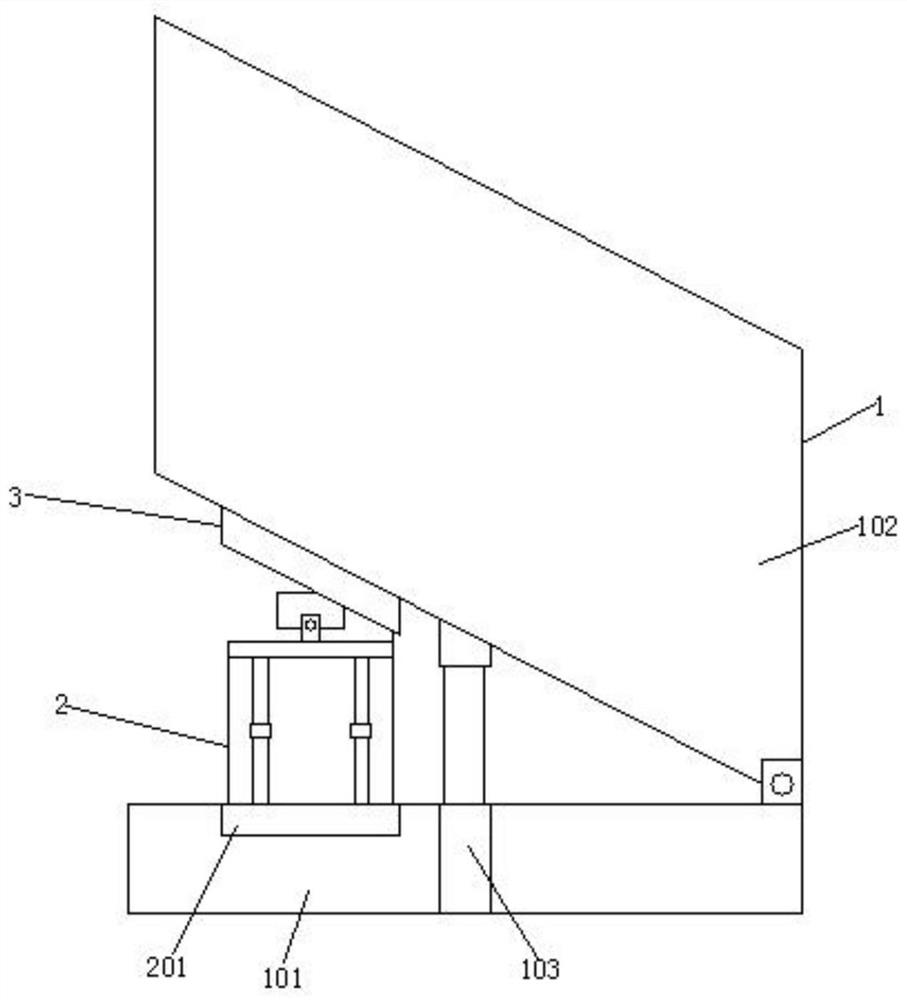

[0028] Such as Figure 1-7 As shown, the present invention provides a technical solution: a rollover self-unloading compression garbage truck and its self-rescue device, including a self-unloading mechanism 1, the self-unloading mechanism 1 includes a base 101, a compartment 102 and a hydraulic telescopic rod 103, A limit mechanism 2 is installed above the base 101 , and an installation mechanism 3 is installed at the bottom of the compartment 102 .

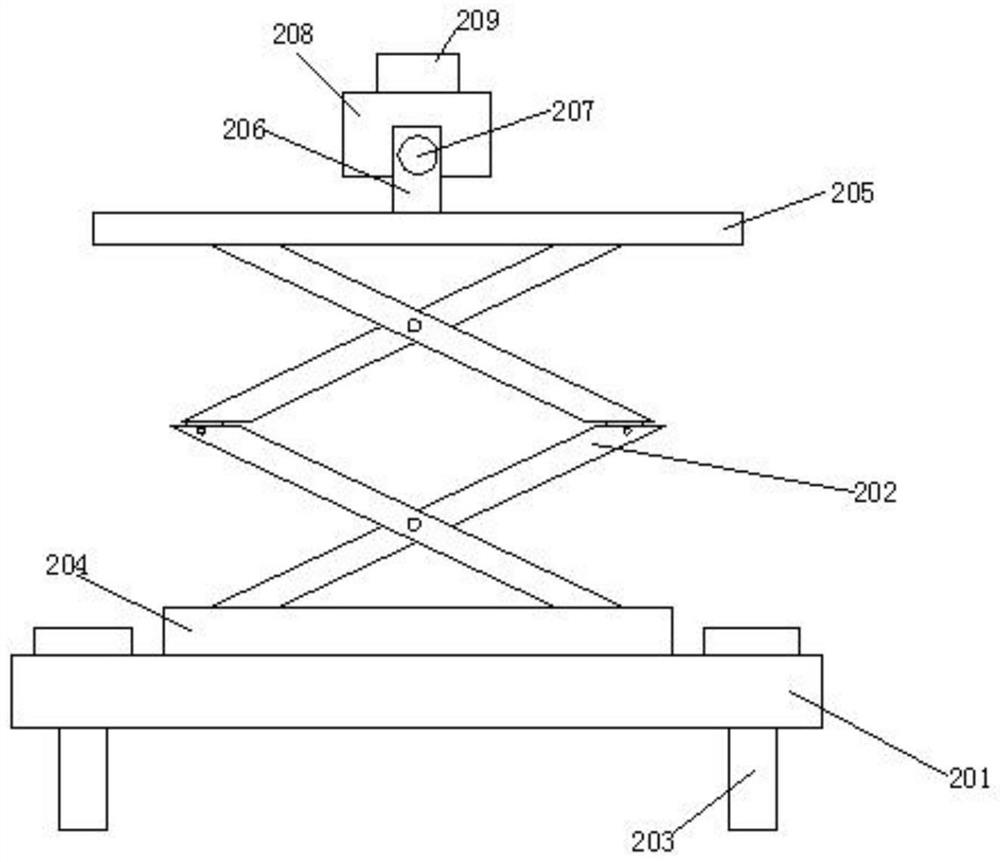

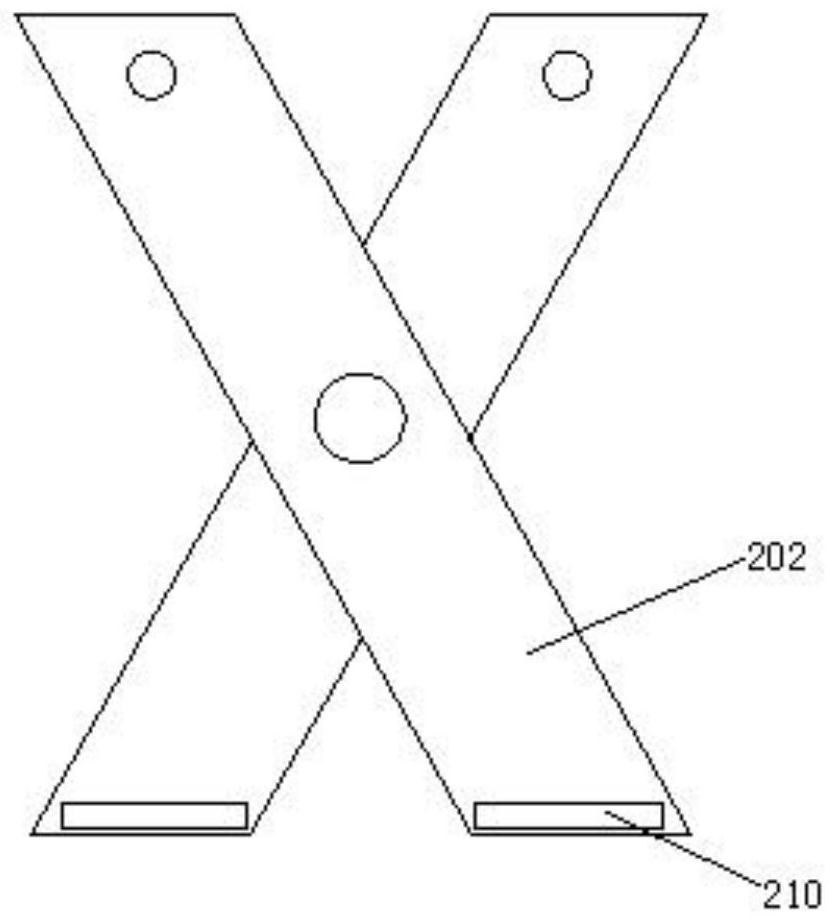

[0029] The limit mechanism 2 includes a connecting plate 201, a lifting frame 202, a No. 1 bolt 203, a No. 1 U-shaped plate 204, a No. 2 U-shaped plate 205, a pole 206, a shaft pin 207, a connecting block 208, a clamping block 209, No. 1 slider 210 , slide rail 211 and concave hole 212 .

[0030] A lifting frame 202 is installe...

Embodiment 2

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0040] Such as Figure 1-7 As shown, the present invention provides a technical solution: a rollover self-unloading compression garbage truck and its self-rescue device, including a self-unloading mechanism 1, the self-unloading mechanism 1 includes a base 101, a compartment 102 and a hydraulic telescopic rod 103, A limit mechanism 2 is installed above the base 101 , and an installation mechanism 3 is installed at the bottom of the compartment 102 .

[0041] The limit mechanism 2 includes a connecting plate 201, a lifting frame 202, a No. 1 bolt 203, a No. 1 U-shaped plate 204, a No. 2 U-shaped plate 205, a pole 206, a shaft pin 207, a connecting block 208, a clamping block 209, No. 1 slider 210 , slide rail 211 and concave hole 212 .

[0042] A lifting frame 202 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com