Ladle-deslagging overturn table

A technology for subcontracting tables and ladles, which is applied in mechanical cleaning, casting molten material containers, manufacturing tools, etc. It can solve the problems of limited turning angle, heavy equipment weight, and potential safety hazards, and achieves high safety, strong versatility, The effect of lowering the height of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

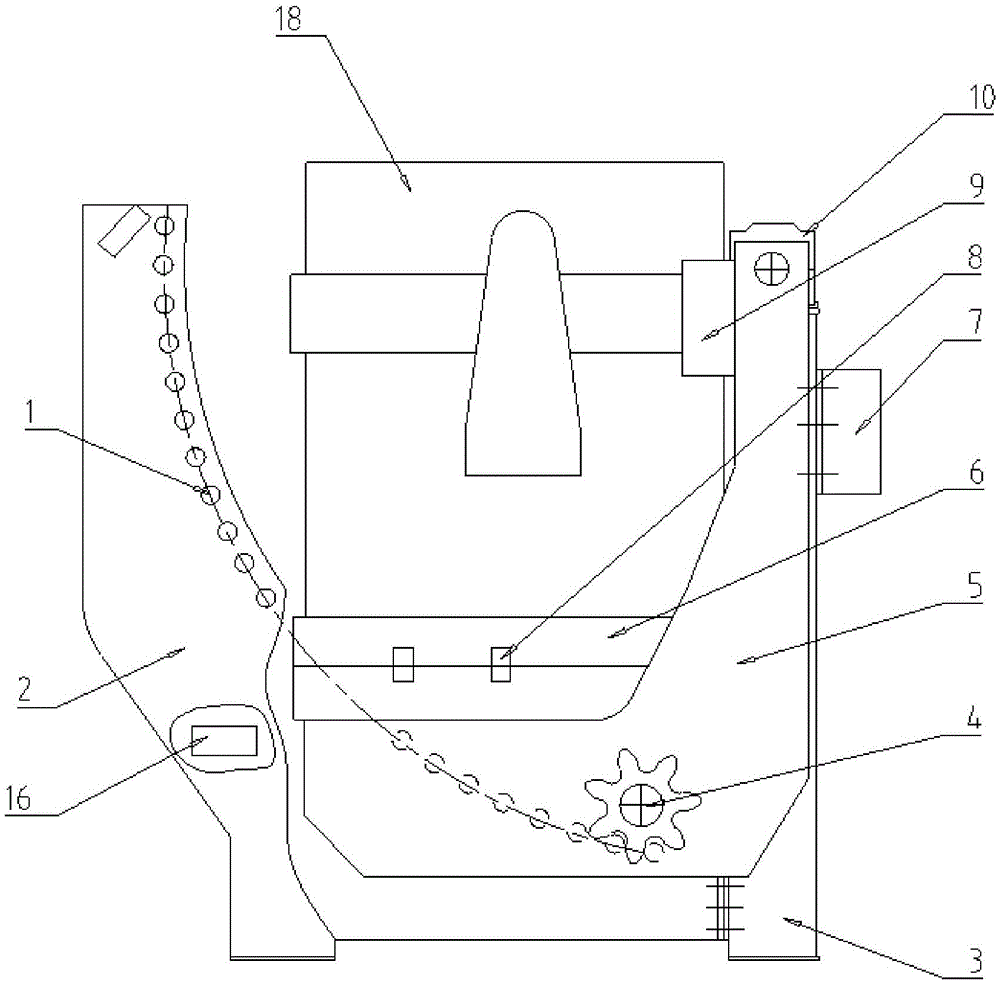

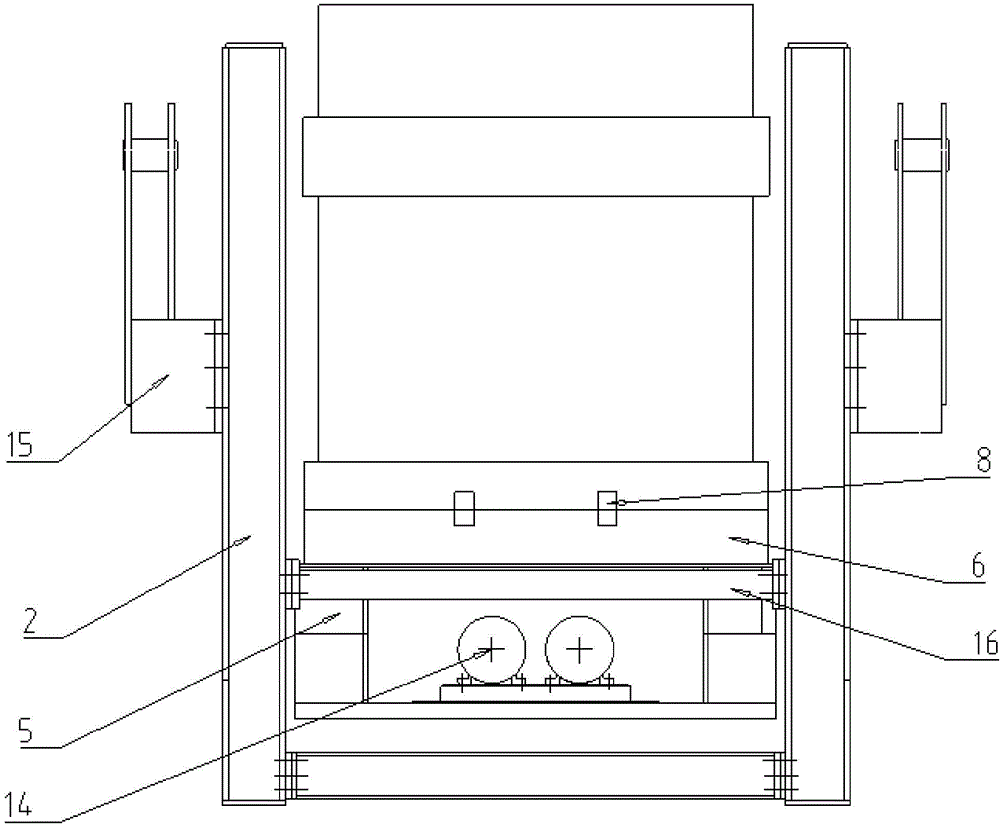

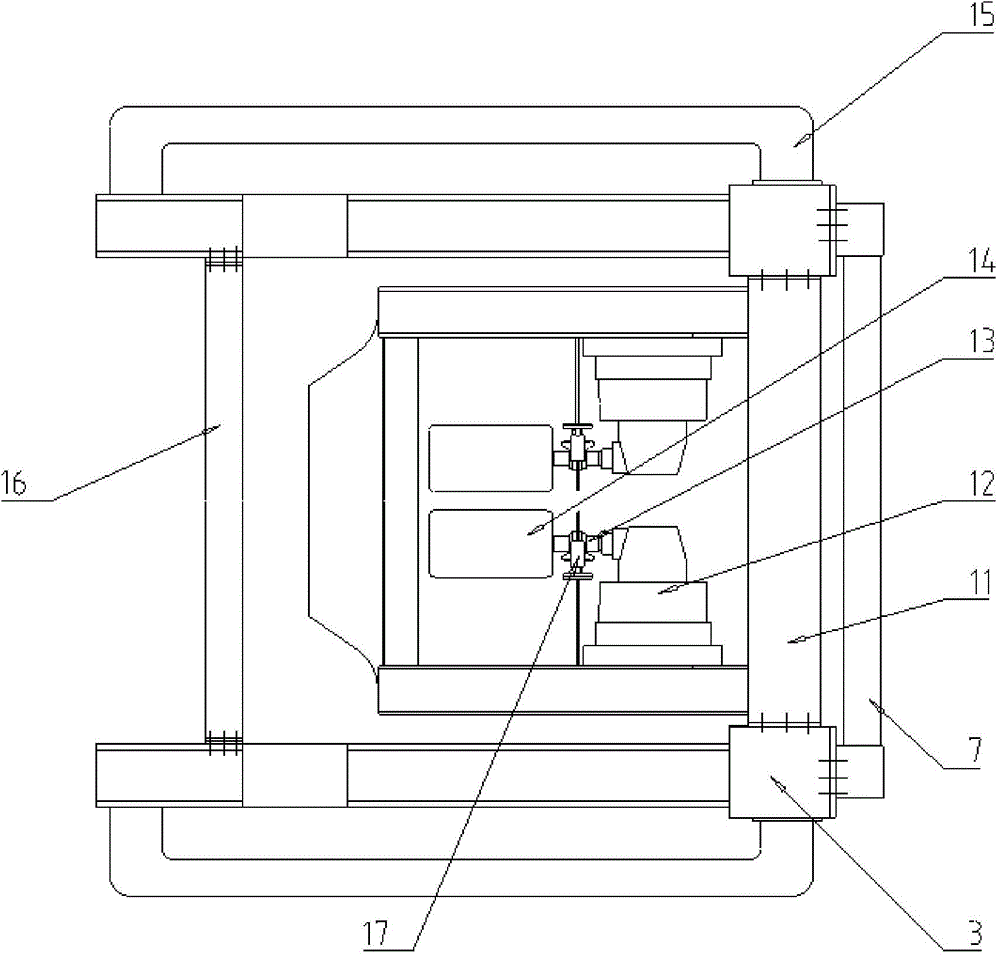

[0018] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, a ladle steel slag cleaning subcontracting platform includes a pin shaft 1, a pin ring gear 2, a column 3, a pin gear 4, an L-shaped tipping frame 5, an adjustment pad 6, an upper connecting beam 7, a V-shaped seat 9, Bearing housing 10, lower connecting beam 11, planetary reducer 12, coupling with brake disc 13, driving motor 14, hanging beam 15, pin ring gear connecting beam 16 and brake 17, pin shaft 1 is connected to the pin gear by bolts On the ring 2, the pin gear rings 2 on the left and right sides are connected through the pin gear ring connecting beam 16, the pin gear gear 2 is connected to the column 3 through bolts, and the pin gear ring 2 is connected to the column 3 through the hanging beam 15, and the upper connection The beam 7 connects the columns 3 on the left and right sides by bolts, and the lower connecting beam 11 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com