Deceleration strip for bridges and roads

A technology of speed bumps and roads, which is applied in the field of transportation facilities, can solve problems such as unfavorable drivers driving safely, affecting driver experience, etc., and achieve the effect of avoiding bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

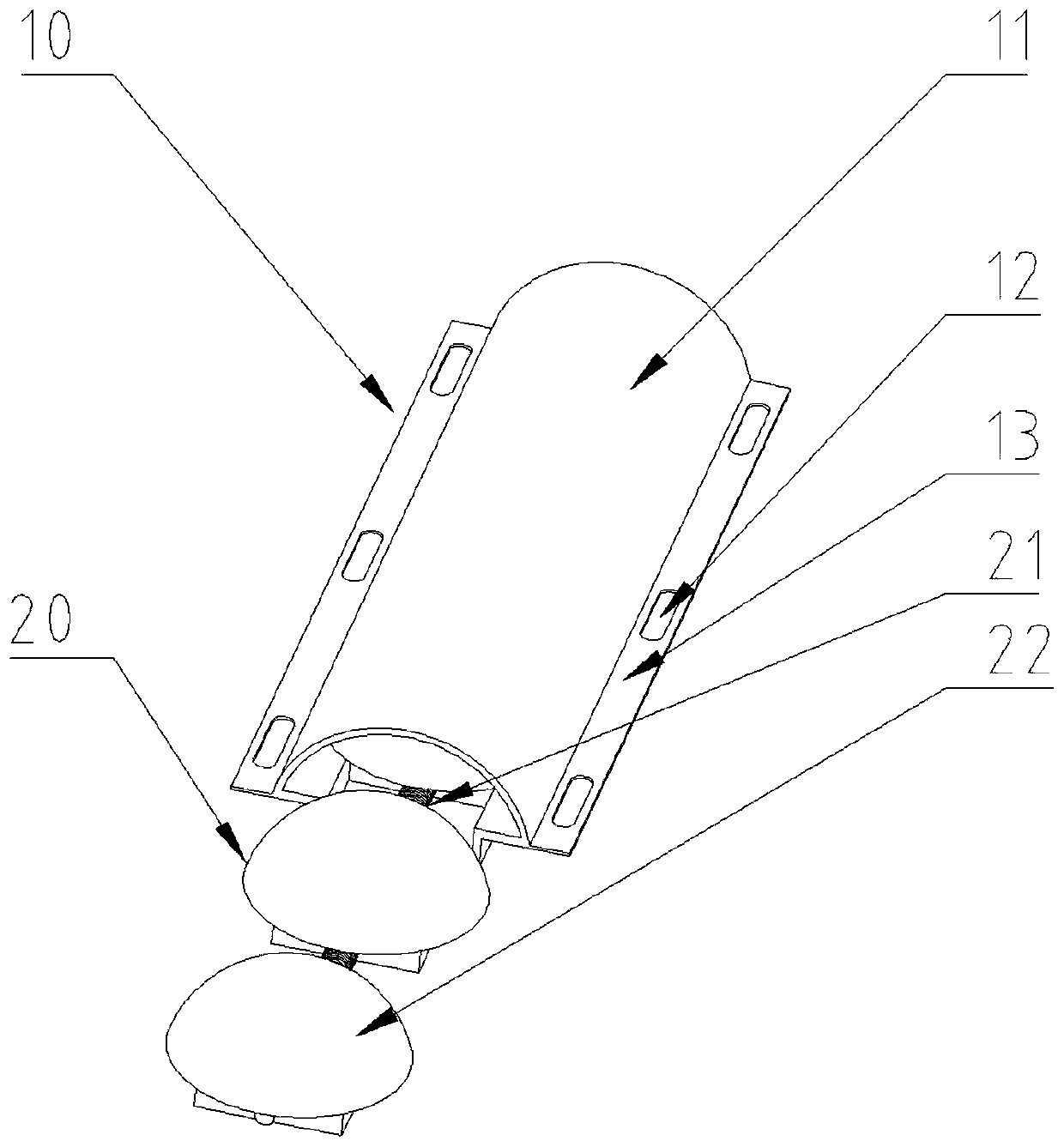

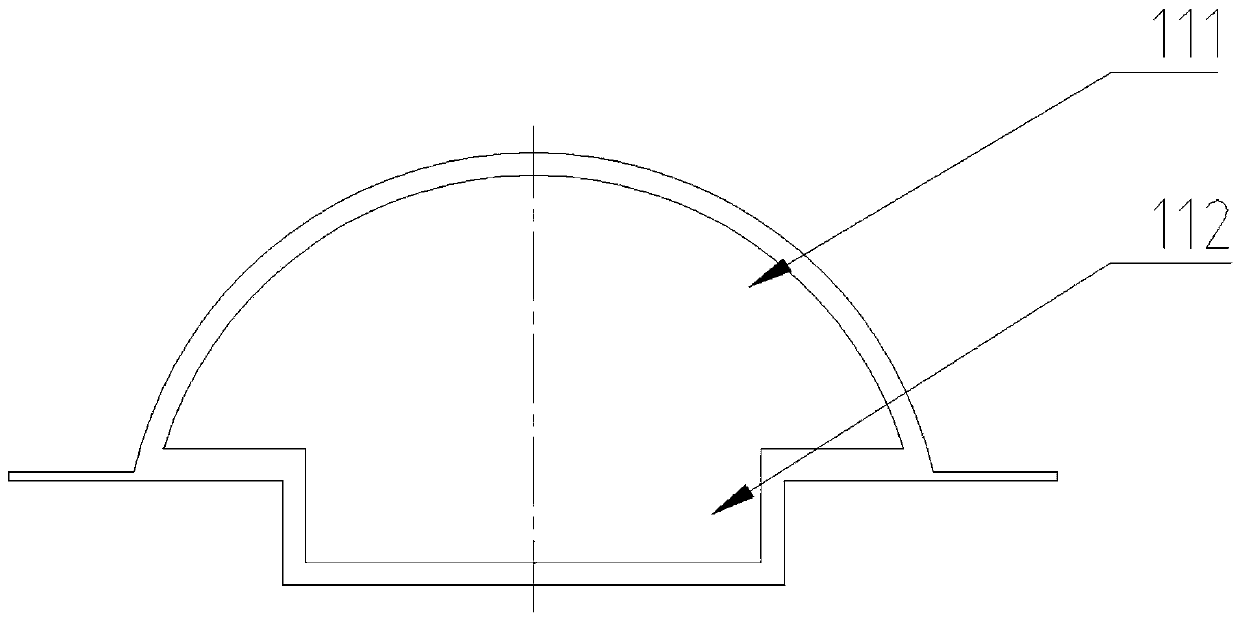

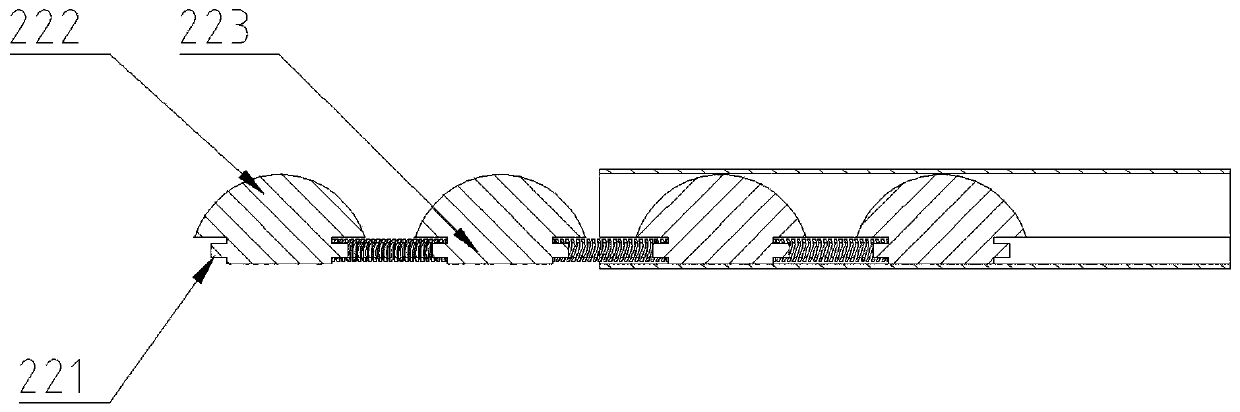

[0019] see Figure 1-3 , a deceleration belt for bridge roads, including a protection mechanism 10 and a movable mechanism 20, the protection mechanism 10 includes a housing 11, a mounting hole 12 and a mounting plate 13, and the housing 11 includes a housing upper end 111 and a housing lower end 112. The upper end 111 of the housing is in the shape of a circular arc. Through the structure of the transition between the arc and the ground, in addition to making it easier for vehicles to pass by, it also makes the movable block that matches it in the upper end 111 of the housing The space between the upper ends 222 is more likely to be squeezed away by the wheels of the vehicle. At the same time, the arc structure can also minimize the damage to the tires under high-speed impact, especially in the hot summer. The temperature rises and expands, causing the pressure in the tire to rise. At this time, if a sharp object is encountered during high-speed operation and local stress co...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the material of the lower end 112 of the housing is stainless steel, and there are no installation holes 12 on both sides of the lower end 112 of the housing. The example is poured together with the concrete.

[0028] The working principle of the present invention is:

[0029]The present invention protects the movable mechanism 20 from being polluted by rainwater and dust through the housing 11 made of flexible material, and the movable block 22 can slide in the lower end 112 of the housing, when the automobile passes the deceleration belt at a slow speed The tires of the automobile squeeze the movable blocks 22 away from each other, so that the tires are in direct contact with the ground, and there is no bumpy feeling when driving. After passing by, the movable blocks 22 return to their original positions under the action of the spring 21. And when automobile passes by at a high speed, there is no time to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com