Turnover device for balance shafts

A technology for balancing shafts and appliances, which is applied in the manufacture of tools and tool storage devices, etc., which can solve problems such as noise generation, bump damage, and engine performance, so as to avoid bump damage, save space, and ensure appearance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

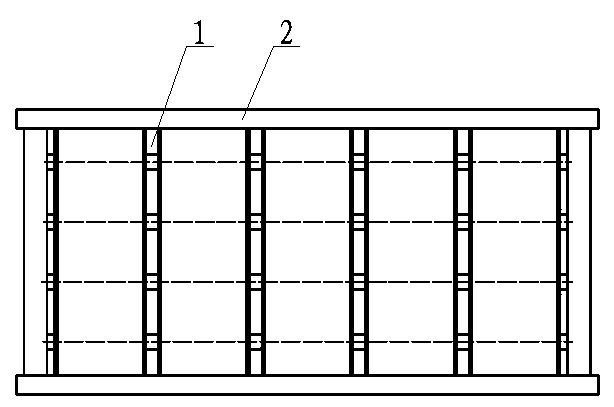

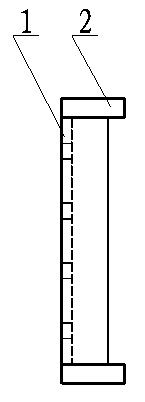

[0009] Such as figure 1 , figure 2 A balance shaft turnover device shown, it includes a V-shaped groove insulation board 1 and a wooden bracket 2, the V-shaped groove insulation board 1 is vertically arranged on the inner frame of the wooden bracket 2; the V-shaped groove insulation board 1 is a rectangular bar body, and a plurality of V-shaped grooves are evenly arranged on it, which is used for placing and taking workpieces at any time; the wooden bracket 2 is a square frame, which plays an overall fixing role.

[0010] Before use, you only need to determine the axial position of the V-groove insulating plate 1 on the wooden bracket 2 according to the axial length of the workpiece. Using this turnover device, you only need to place the two shaft ends of the workpiece on the V-shaped groove insulating plate In the V-shaped groove of 1, because the workpieces do not touch each other and are piled up by the wooden bracket 2 when they are stacked up and down, there will be no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com