Curtain wall panel hanging assembly and using method thereof

A panel and curtain wall technology, applied in the field of curtain wall panel mounting components, can solve the problems of rapid installation of panels in place, deformation or displacement of the main structure or supporting structure, cracking and damage, etc., to achieve convenient adjustment and replacement, simple structure and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A curtain wall panel mounting assembly.

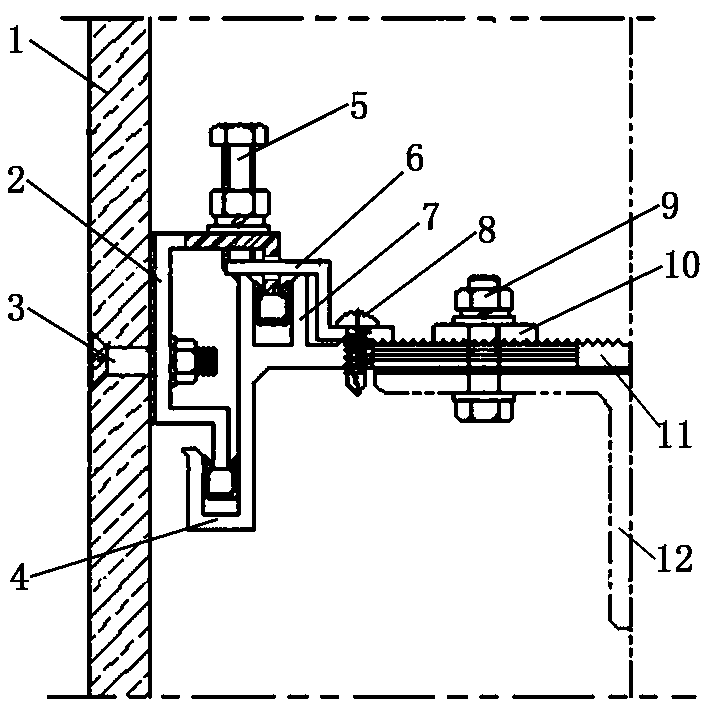

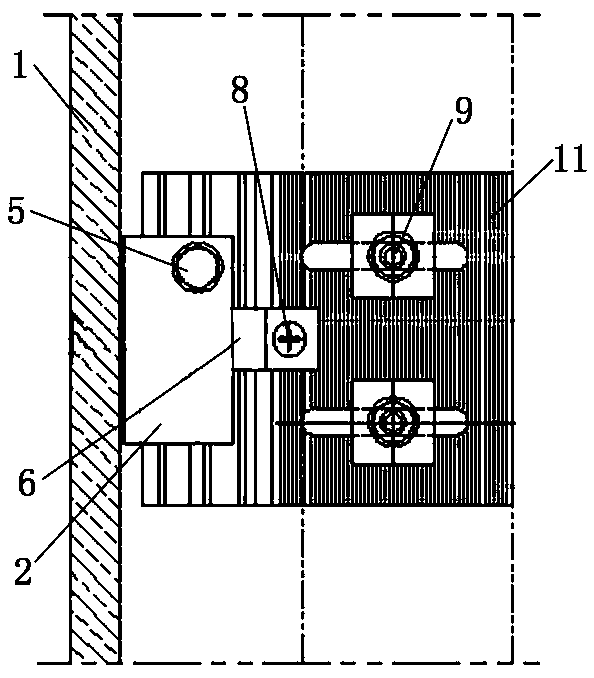

[0024] Such as figure 1 , figure 2 As shown, the curtain wall panel hanging assembly of the present invention includes a hanging seat 11, a hanging piece 2, a fastening screw 3, a fixing bolt 9, a height adjusting bolt 5, and a Z-shaped limiting piece 6.

[0025] The hanging base 11 is a horizontal and straight board body, and its rear end is a straight edge, which is used for fixed connection with the supporting beam 12 by a fixing bolt 9. A vertical vertical board is provided at the front edge of the hanging base 11, and U-shaped grooves are respectively provided at the upper and lower ends of the vertical board. The U-shaped grooves extend along the length of the hanging base 11 and are opened upwardly. The grooves are arranged up and down, wherein the upper U-shaped groove is located on the rear side of the vertical plate, which is the rear U-shaped groove 7, and the lower U-shaped groove is located on the front s...

Embodiment 2

[0031] Embodiment 2: A method of using a curtain wall panel hook assembly.

[0032] Such as figure 1 , figure 2 As shown, the method for using the curtain wall mounting assembly of the present invention includes the following steps:

[0033] a. According to the size of the cement fiber board to be installed, a number of panel hooking components are prepared. The structure of the panel hooking component has been described in detail in Embodiment 1, and will not be introduced here too much.

[0034] b. Fix the pendant 2 in the assembly on the curtain wall panel 1 to be installed by the set screw 3, and make the length direction of the U-shaped groove of all the pendants 2 be arranged in the same direction.

[0035] c. Install the hanger 11 in the assembly on the supporting beam 12 of the curtain wall panel 1 to be installed by fixing bolts 9, and make the position of the hanger 11 correspond to the position of the hanger 2 on the curtain wall panel 1 to be installed one by one.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com