Gear ring eccentric rotating continuously variable transmission system

A technology of infinitely variable speed and eccentric rotation, which is applied to gear transmissions, belts/chains/gears, mechanical equipment, etc. It can solve problems such as large torque, inability to achieve zero-speed output when the internal combustion engine does not stop, and small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

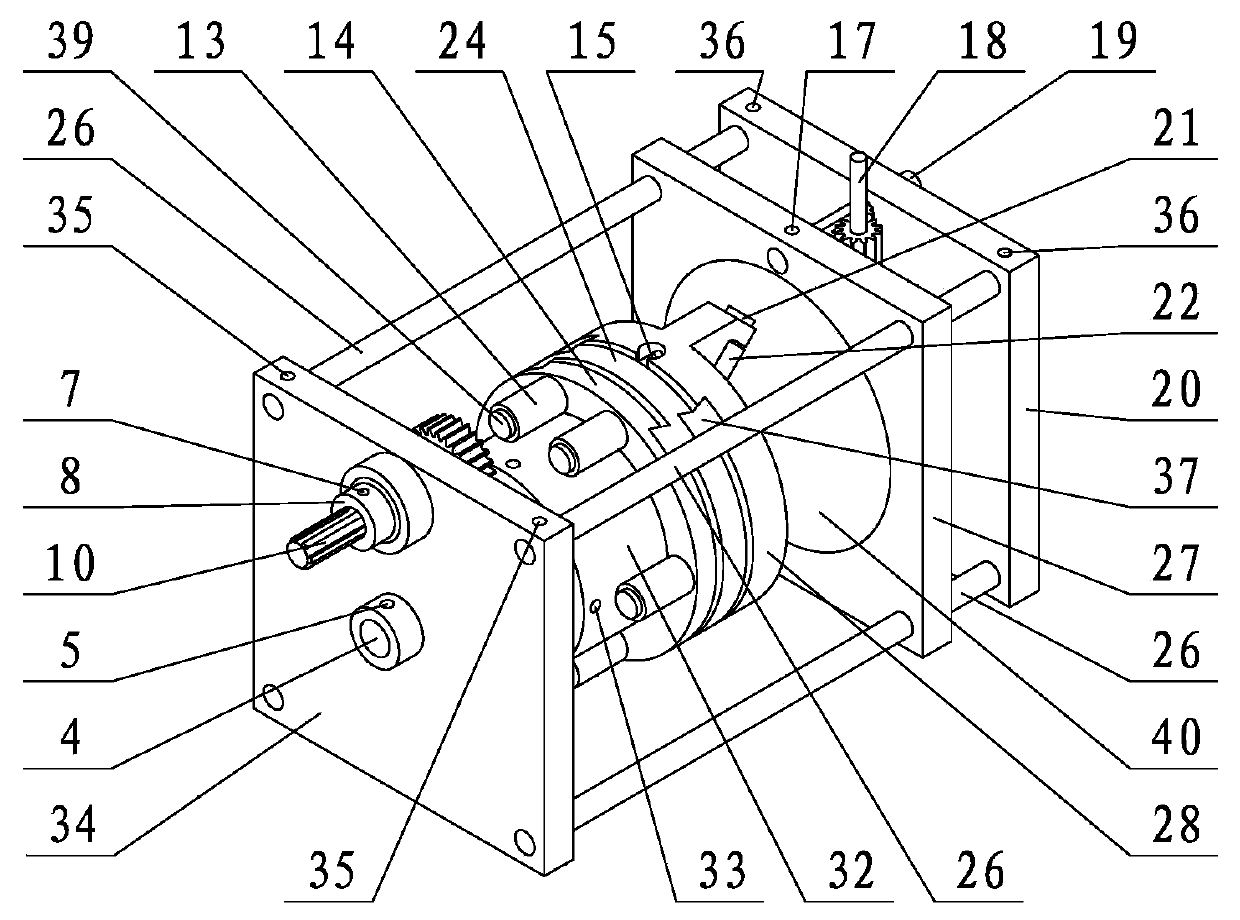

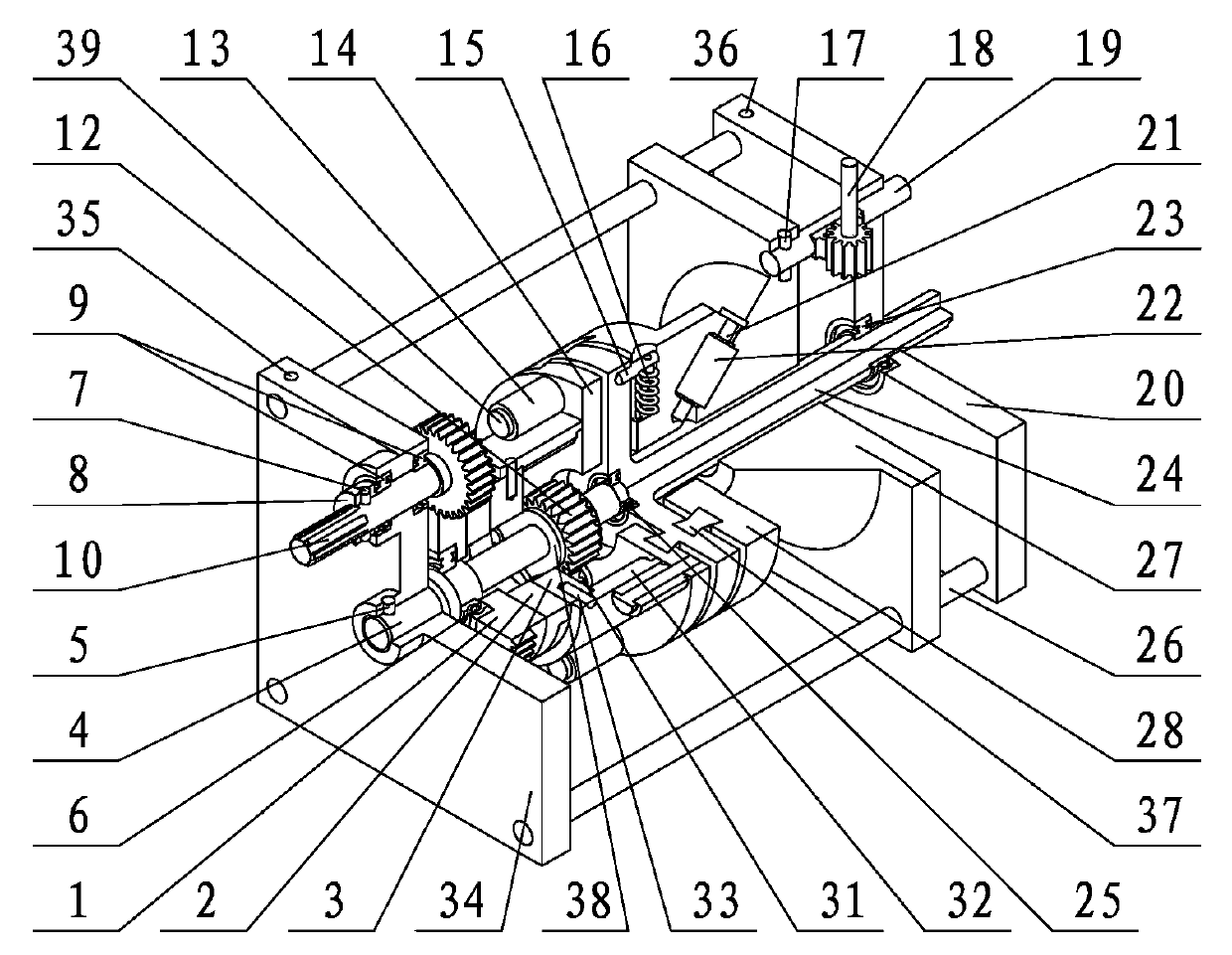

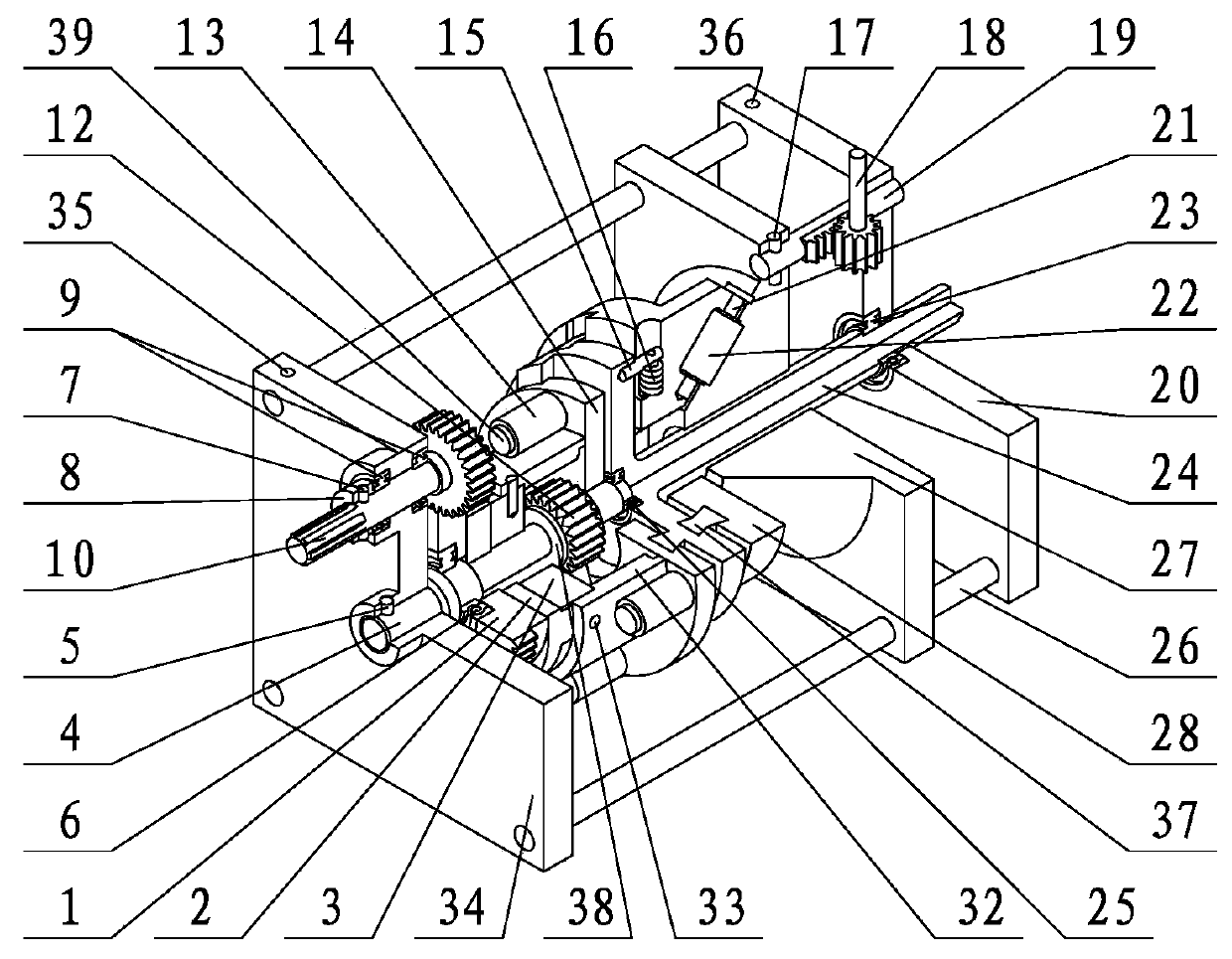

[0086] The present invention is further described below in conjunction with accompanying drawing. refer to Figure 31 to Figure 33 , Figure 1 to Figure 4 , Figure 27 to Figure 30 , the continuously variable transmission system includes an internal combustion engine 201, a clutch one 202, a connecting gear part two 203, a connecting gear part one 206, an adjusting mechanism power device one 207, a continuously variable transmission one 208, an adjusting mechanism power device two 209, a stepless Transmission two 210, speed measuring device 211, final drive 213, clutch two 214. The input shaft of the clutch one 202 is connected with the output shaft of the internal combustion engine 201, the connecting gear part one 206 and the connecting gear part two 203 respectively adopt two conical gears or two cylindrical gears, and the connecting gear part one 206 connects the clutch The output shaft of one 202 is connected together with the input shaft of CVT one 208, and the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com