Gear ring eccentric rotation stepless speed change mechanism

A technology of infinitely variable speed change mechanism and eccentric rotation, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., and can solve problems such as large torque and small torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

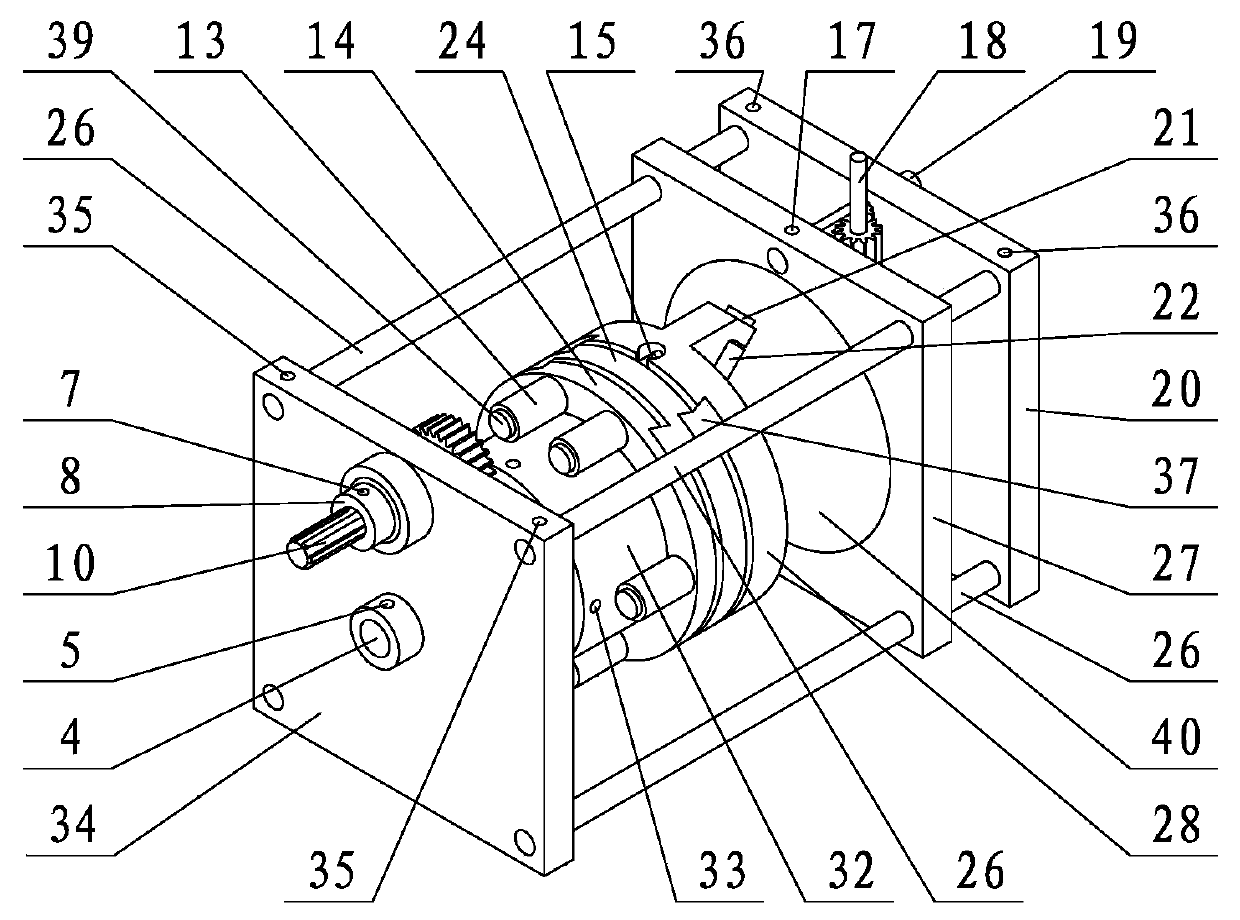

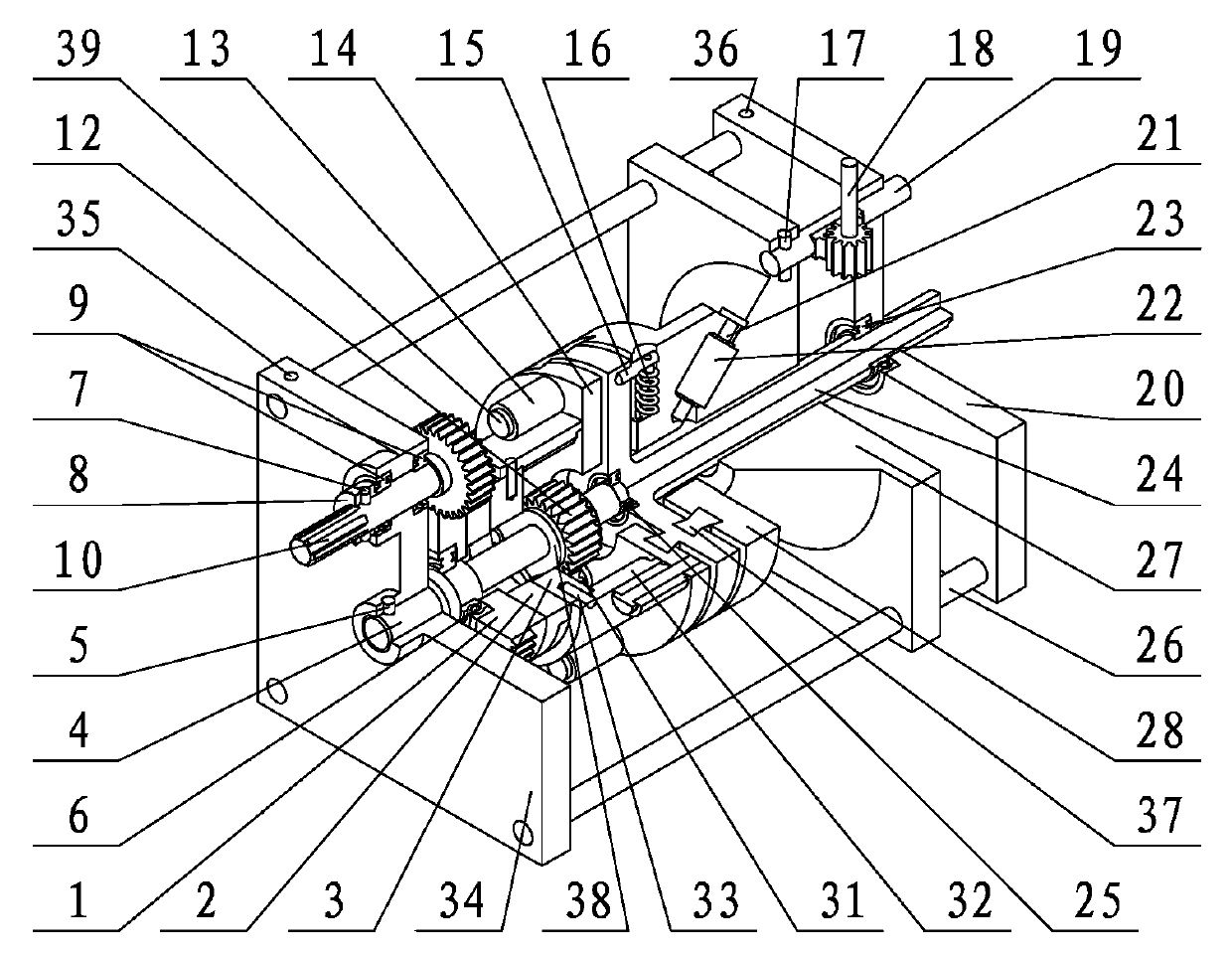

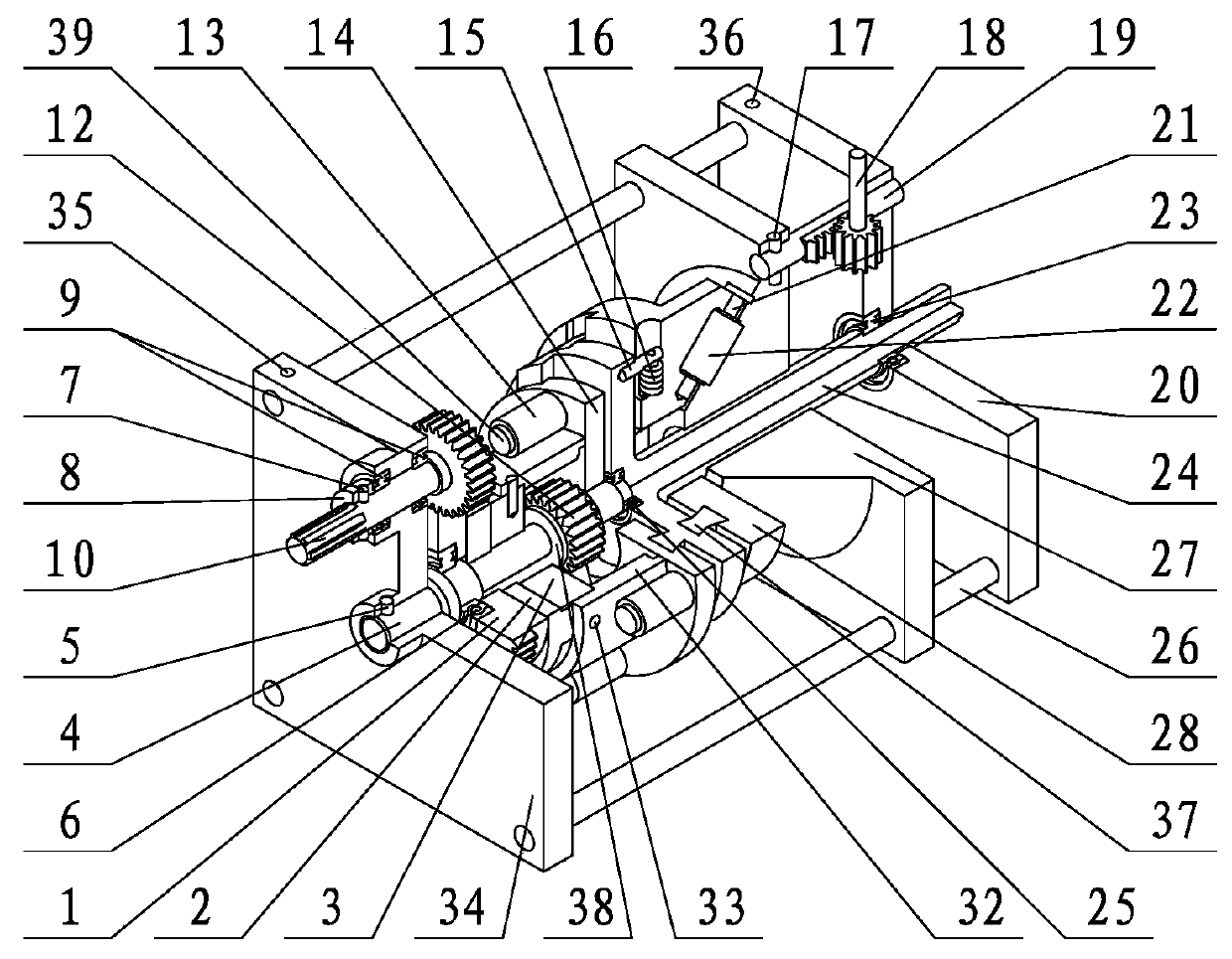

[0063] The present invention is further described below in conjunction with accompanying drawing. refer to Figure 1 to Figure 3 , Figure 27 to Figure 30, the continuously variable transmission mechanism includes a fixed plate part, a coupling part, a swinging planetary gear part, a swinging planetary support part, a slide rail support part, and a balance wheel part, and the fixed plate part includes a fixed plate one 20, a fixed plate two 34, Adjusting plate 27, guiding and fixing column 26, adjusting gear 18, adjusting rack 19, parallel output gear 10, coupling components include concentric slider 1, cross slider 2, swing slider 3, transmission pin 33, swing planetary gear Parts include swing ring gear 32, gear fixed shaft 4, sun gear 12, transition gear 67, planetary gear 31, hinge parts, hinge parts include gear connecting plate one 69, gear connecting plate two 38, gear connecting plate three 65, gear connecting plate Plate four 66, positioning shaft 68, planetary gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com