Pipeline carrying and clamping device and method capable of achieving multi-degree-of-freedom adjustment

A technology of clamping device and degree of freedom, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of slow construction process, waste of manpower, and high labor intensity, so as to reduce clamping stress concentration and increase stress distribution point, to meet the effect of precise alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments.

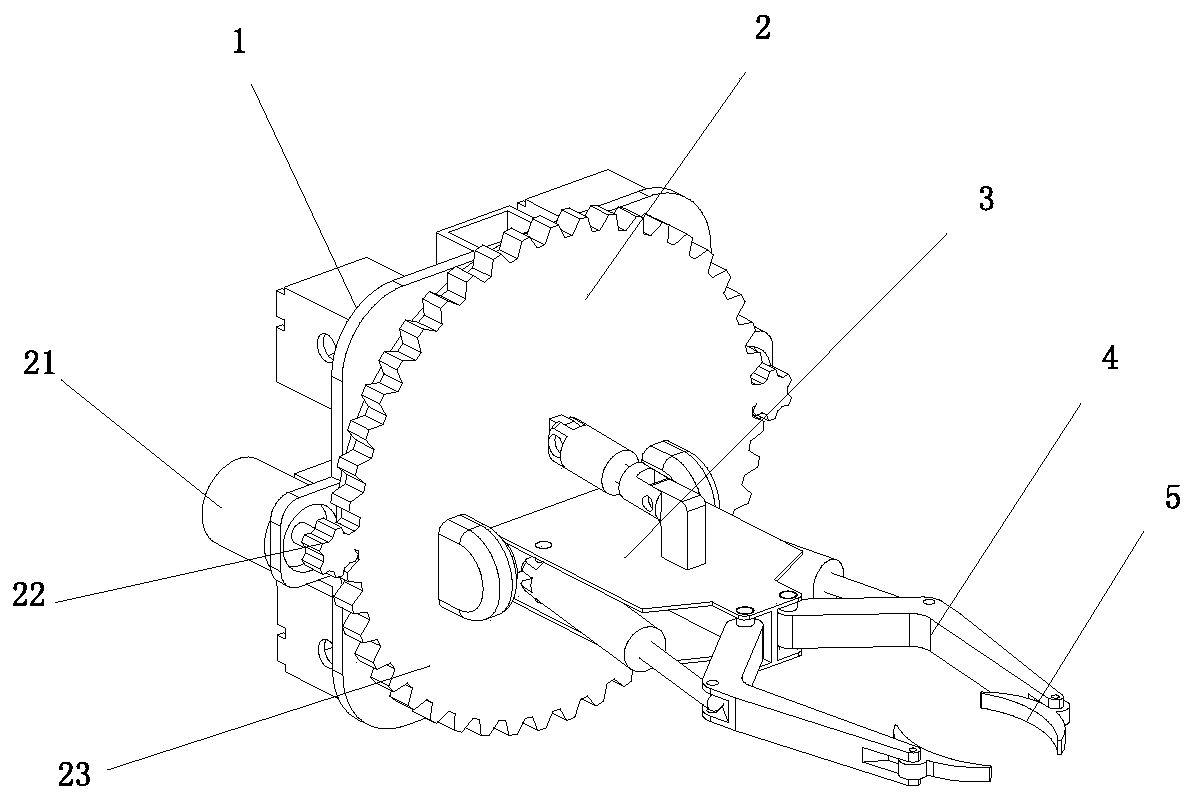

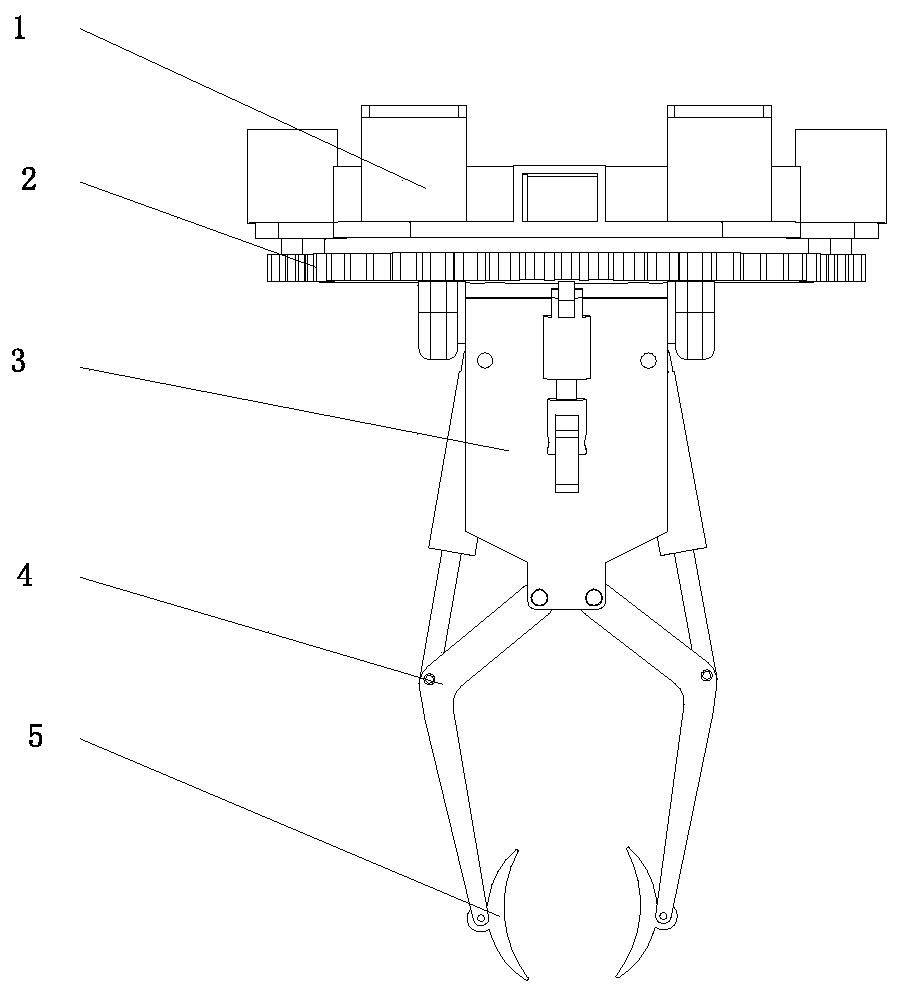

[0024] The multi-degree-of-freedom-adjusted pipe handling and clamping device of the present invention uses the opening degree of the circumferential rotation assembly 2, the pitch angle adjustment assembly 3, and the clamping assembly 4 to adjust multiple degrees of freedom for the workpiece clamped by the movable chuck 5, To achieve precise alignment of the clamped workpiece during handling and installation.

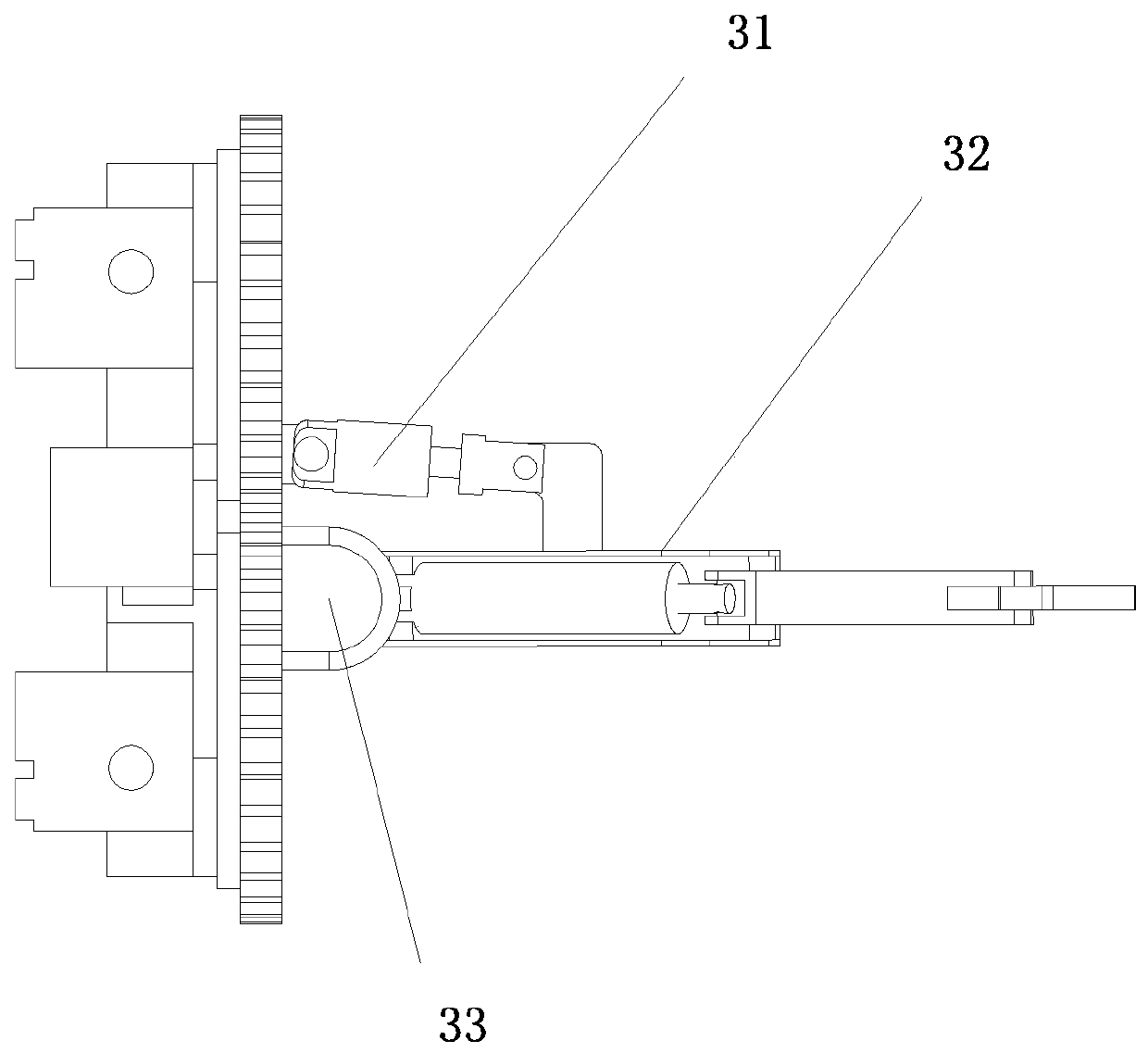

[0025] like figure 1 , 2 As shown, the multi-degree-of-freedom adjustment pipe handling and clamping device of this embodiment includes a base 1, a circumferential rotation assembly 2, a pitch angle adjustment assembly 3, a clamping assembly 4, and a movable chuck 5, wherein the circumferential rotation assembly 2 Set on the base 1, the circumferential rotation assembly 2 includes a rotating toothed disc 23, a transmission gear set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com