Control method of cold water unit

A control method and technology for chillers, applied in heating and ventilation control systems, heating methods, mechanical equipment, etc., can solve the problem of uneven distribution of refrigerants, achieve uniform distribution of refrigerants, solve uneven distribution, and improve unit performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

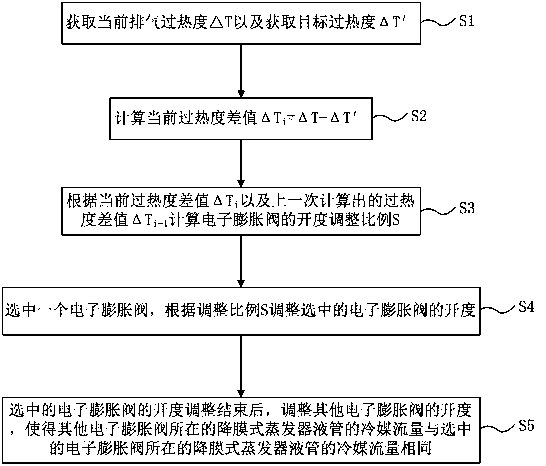

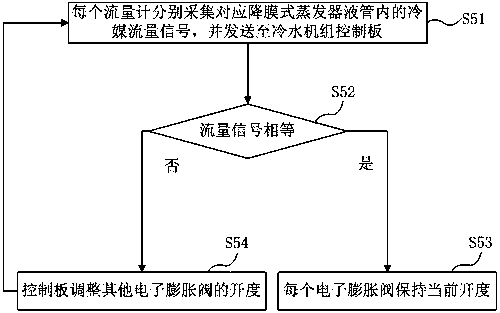

[0036] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] Aiming at the problem of uneven distribution of refrigerant in the evaporator in the prior art, this embodiment proposes a control method for the chiller unit, which solves the above technical problems. The control method for the chiller unit will be described in detail below.

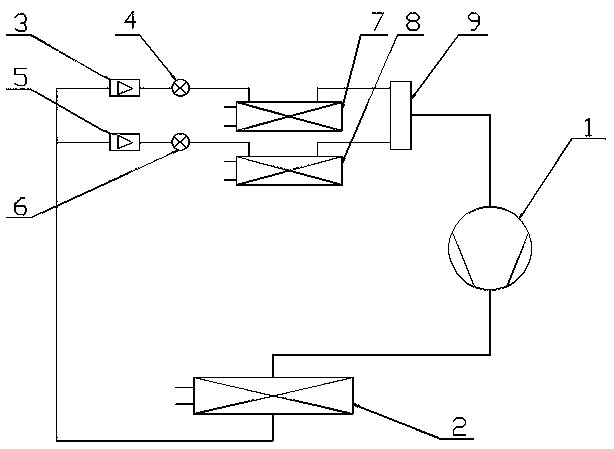

[0038] The chiller mainly includes compressor 1, condenser 2, multiple falling film evaporators, etc., see image 3 As shown; multiple falling film evaporators are connected in parallel, the liquid pipe of each falling film evaporator is connected to the liquid pipe of the condenser, and the air pipe of each falling film evaporator is respectively connected to the suction pipe of the compressor; in each A flowmeter and an electronic expansion valve are connected in series on the liquid pipe of each falling film evaporator. Each flowmeter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com