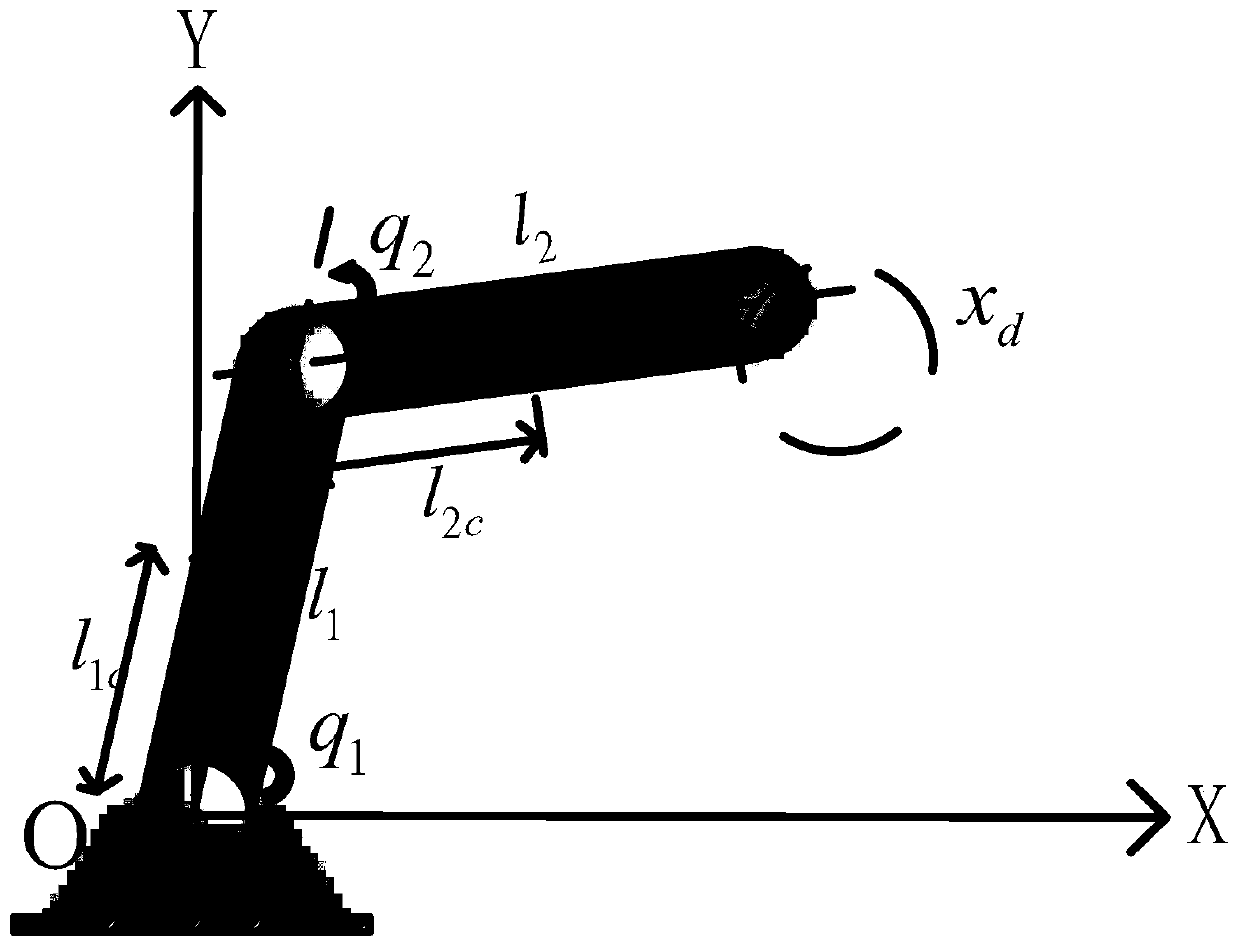

Impedance control method for multi-joint mechanical arm based on finite time command filter

A multi-joint robotic arm, limited-time technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., and can solve problems such as linearity and computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

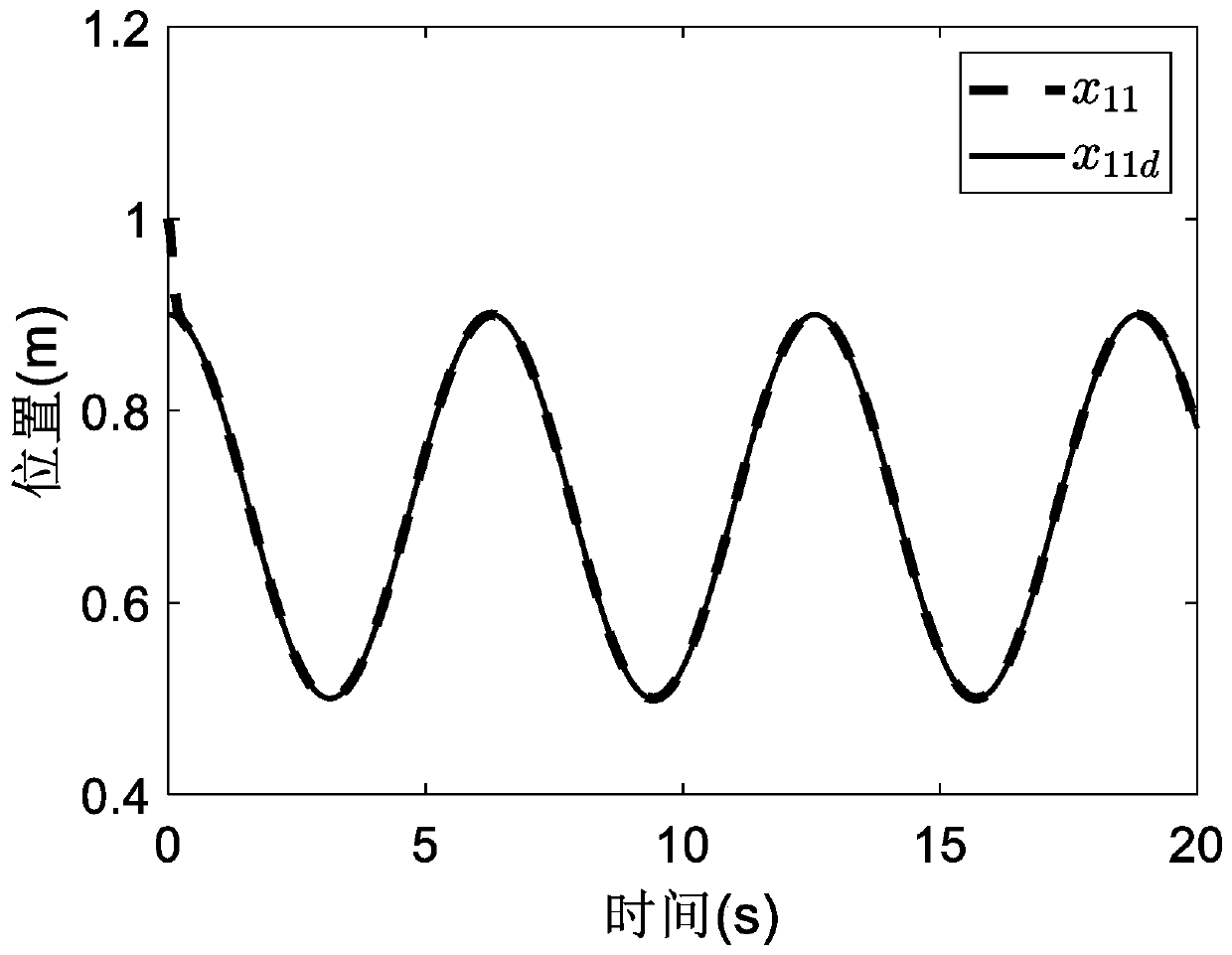

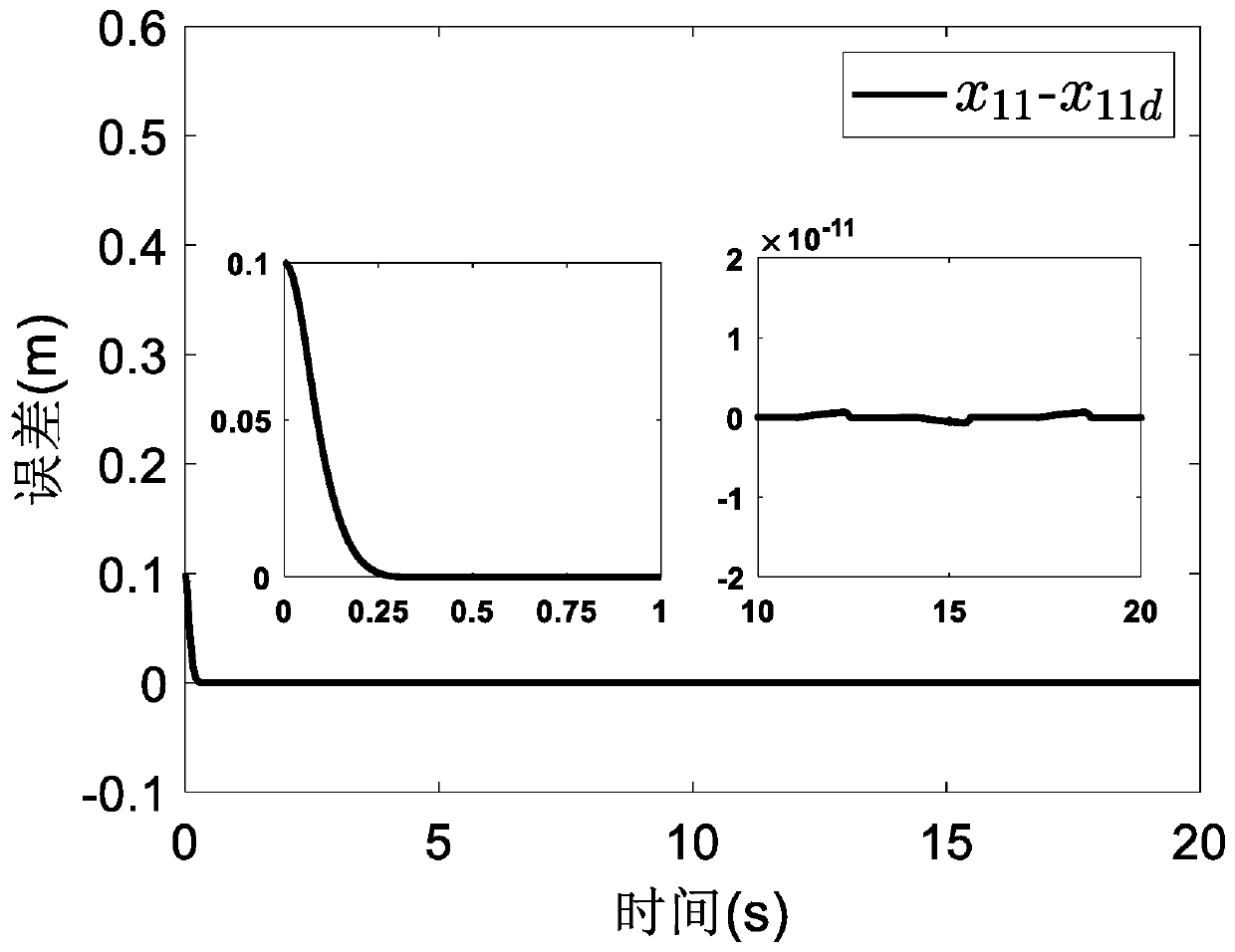

[0115]The basic idea of the present invention is: based on the Lyapunov function, use the backstepping method to construct the intermediate virtual control signal, and obtain the control law step by step, so as to control the end effector of the multi-joint robot arm; For the unknown friction in the joint manipulator system, the command filtering technology is used to solve the problem of repeated derivation of the virtual control law in the design of the backstepping method. This technology solves the problem of filtering error through the error compensation signal, and simplifies the finite time command filter impedance. The structure of the controller and the finite time control are used to make the force / position tracking signal of the manipulator converge in a finite time.

[0116] The above inventive concept ensures that the multi-joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com