Plastic particle screening device

A screening device and plastic granule technology, applied in the field of plastic processing, can solve the problems of single screening device, single direction of reciprocating motion, low efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

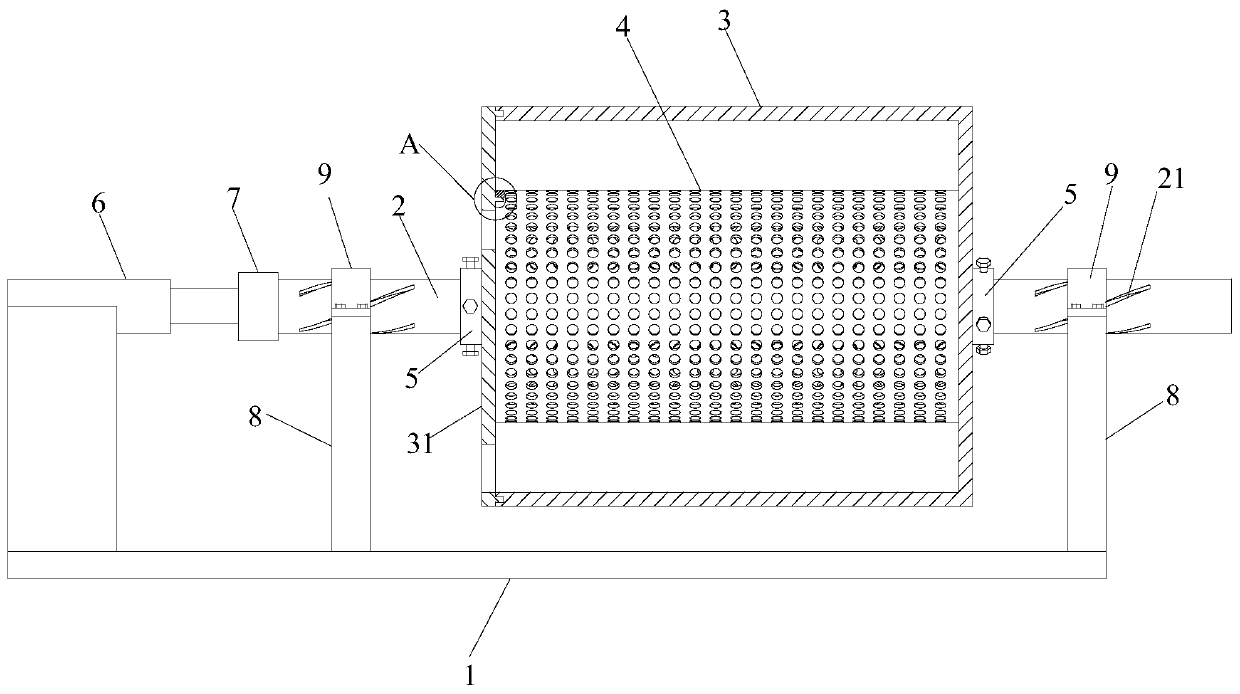

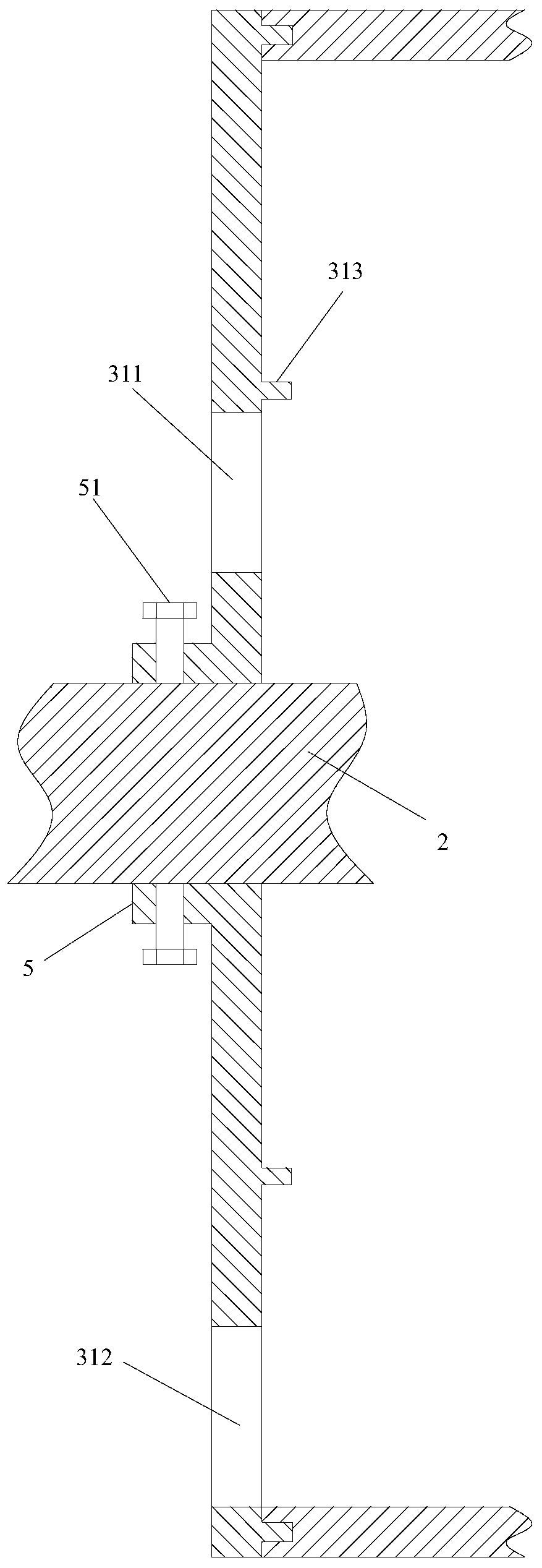

[0024] Such as Figure 1 to Figure 3 As shown, the present invention provides a plastic particle screening device, comprising a base 1, two support columns 8 are symmetrically arranged on the base 1, and a movable main shaft 2 is arranged on the support column 8, and the main shaft 2 A screening unit is fixed on it;

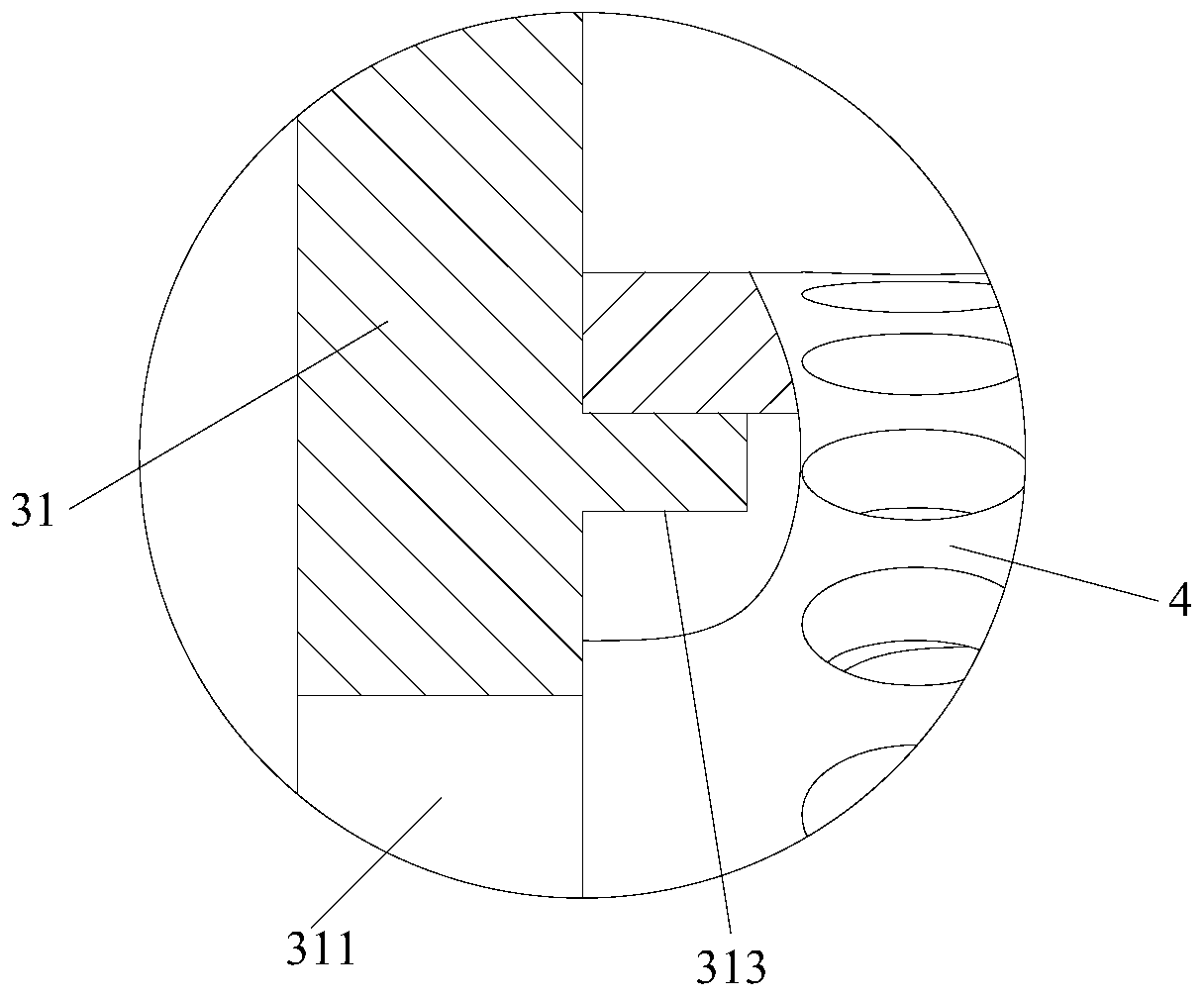

[0025] The screening unit includes an outer cylinder 3 fixedly arranged on the main shaft 2 and a screen cylinder 4 detachably arranged in the outer cylinder 3, the outer cylinder 3 is a cylindrical cylinder with one end open , the sieve cylinder 4 is a cylindrical cylinder with openings at both ends, and the outer peripheral wall of the sieve cylinder 4 is provided with several evenly distributed sieve holes;

[0026] Both the outer cylinder 3 and the screen drum 4 are coaxial with the main shaft 2;

[0027] The main shaft 2 is also provided with an end cap 31, the end cap 31 is attached to the opening of the outer cylinder 3, and the two ends of the screen cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com