Electric resistance welding integrated equipment for fuel tank filler

A fuel filler and resistance welding technology, which is applied in the field of resistance welding, can solve problems such as low automation, affecting product quality, and weldment deformation, and achieve the effects of improving automation, improving product quality, and increasing welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

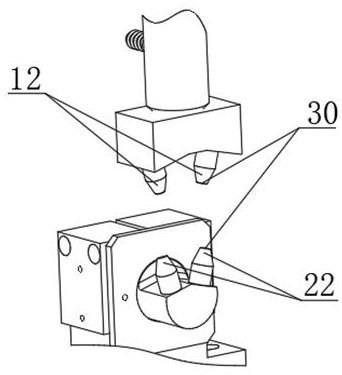

[0033] Such as figure 2 As shown, it is the second embodiment of the welding head assembly of this embodiment. The first electrode and the second electrode each include two electrode heads, which are respectively two B upper electrode heads 12 and two B lower electrode heads 22. The two B upper electrode heads 12 and the two B lower electrode heads 22 are matched respectively, and the welding process of two welding spots is completed at the same time each time.

[0034] The two B upper electrode heads 12 are spaced apart along the circumferential direction, and correspondingly, the two B lower electrode heads 22 are spaced apart along the circumferential direction. The above-mentioned interval distribution distance can be adaptively designed according to the shape of the welding surface of the position to be welded on the workpiece and the location of the welding spots to meet the maximum number of welding spot welding under the condition that the number of rotations is as sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com