Clogged container dredging tool for cleaning

A container and tooling technology, which is applied in the field of dredging the blockage of complexed iron desulfurization containers, to achieve the effects of ensuring sealing, saving costs, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

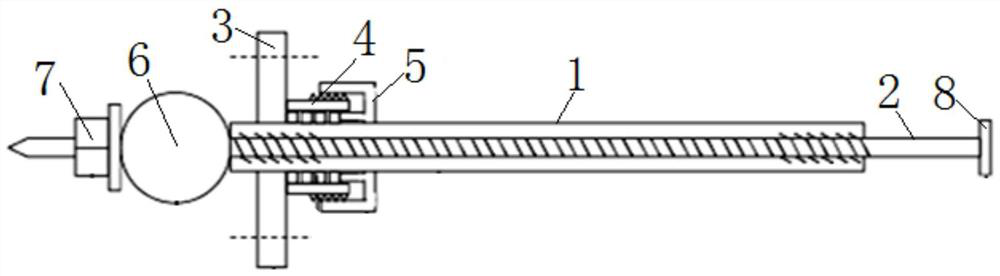

[0026] see figure 1 As shown, the present invention includes a sleeve 1 and a rod 2 .

[0027]The outer diameter of the sleeve 1 is smaller than the inner diameter of the clogging part of the clogging container to be cleaned (because the clogging part of the clogging container is usually a circular pipe structure or a through-hole structure, for the convenience of description, hereinafter referred to as the clogging pipe). The outer circumference of the sleeve 1 is sheathed with a flange 3 in a movable assembly structure, which can ensure that the sleeve 1 can achieve axial displacement or circumferential rotation in the flange 3; the flange 3 is matched to the method of blocking the end of the pipe. Flange structure, the flange 3 on the sleeve 1 can be connected to the flange structure at the end of the blocking pipe through a plurality of locking bolts. A dynamic sealing structure is arranged between the flange plate 3 and the sleeve 1, and the dynamic sealing structure is ...

Embodiment 2

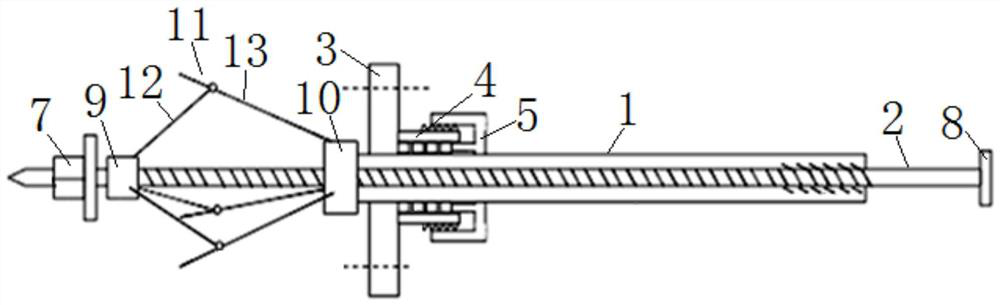

[0036] see figure 2 As shown, the present invention includes a sleeve 1 and a rod 2 .

[0037] The outer diameter of the sleeve 1 is smaller than the inner diameter of the clogging part of the clogging container to be cleaned (because the clogging part of the clogging container is usually a circular pipe structure or a through-hole structure, for the convenience of description, hereinafter referred to as the clogging pipe). The outer circumference of the sleeve 1 is sheathed with a flange 3 in a movable assembly structure, which can ensure that the sleeve 1 can achieve axial displacement or circumferential rotation in the flange 3; the flange 3 is matched to the method of blocking the end of the pipe. Flange structure, the flange 3 on the sleeve 1 can be connected to the flange structure at the end of the blocking pipe through a plurality of locking bolts. A dynamic sealing structure is arranged between the flange plate 3 and the sleeve 1, and the dynamic sealing structure i...

Embodiment 3

[0046] The present invention includes a sleeve and a rod.

[0047] The outer diameter of the sleeve is smaller than the inner diameter of the clogging part of the clogging container to be cleaned (because the clogging part of the clogging container is usually a circular pipe structure or a through-hole structure, for the convenience of description, hereinafter referred to as the clogging pipe). The outer circumference of the sleeve is sleeved with a flange plate in a movable assembly structure, which can ensure that the sleeve can realize axial displacement or circumferential rotation in the flange plate; the flange plate is matched with the flange structure blocking the end of the pipe, and the sleeve The upper flange can be butted with the flange structure at the end of the blocking pipe through a plurality of locking bolts. A dynamic sealing structure is arranged between the flange plate and the sleeve, and the dynamic sealing structure is located on the rear side of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com