Refrigerator door foaming outer clamp

A technology for refrigerator doors and fixtures, which is applied to home appliances, other home appliances, and household components. It can solve problems such as unstable clamping, damaged interfaces, and inability to connect molding molds to production lines, so as to improve production efficiency. Good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

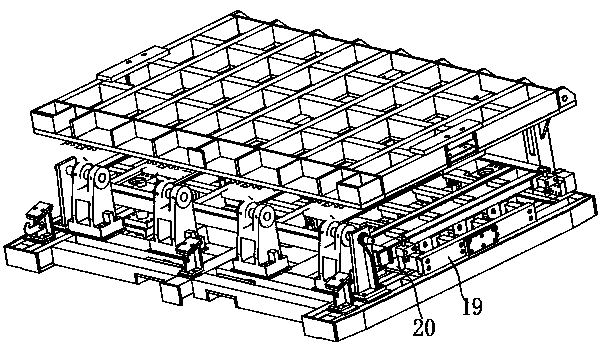

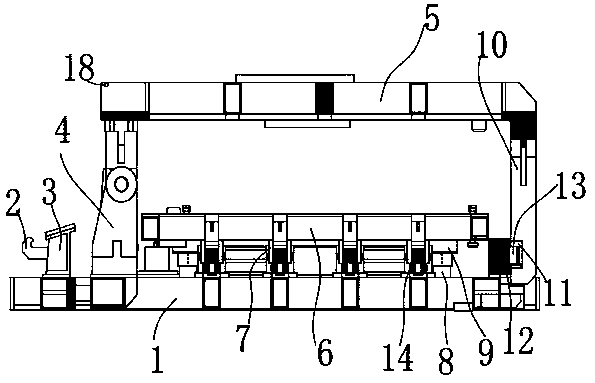

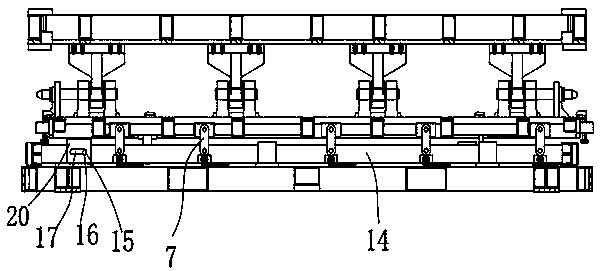

[0021] Embodiment: A foaming outer fixture for a refrigerator door body, comprising a bottom plate 1, an upper splint 5 hinged to the rear side of the bottom plate 1, a lower splint 6 arranged on the top of the bottom plate 1 and connected to the bottom plate 1 up and down, The front side of the upper splint 5 is provided with a front lock frame 10 extending downward, the bottom of the rear side of the front lock is provided with a locking gap 11 opening backward, and the front side of the bottom plate 1 is horizontally sliding connected with a front lock Bar 12, the front side of the front locking bar 12 is provided with a front locking block 13, in the mold closing state, the locking notch 11 is located on the stroke path of the front locking block 13, and the top of the bottom plate 1 is provided with a left and right horizontal sliding A power rod 14, a hinged rod 7 is connected between the power rod 14 and the lower splint 6, the top of the hinged rod 7 is hinged with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com