Overhead line system

A technology for overhead lines and connecting devices, applied in power lines, transportation and packaging, power rails, etc., can solve the problems of spark formation, arc generation, interference with radio communication, etc., to prevent sparks and arcs, suppress vibration, and improve power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

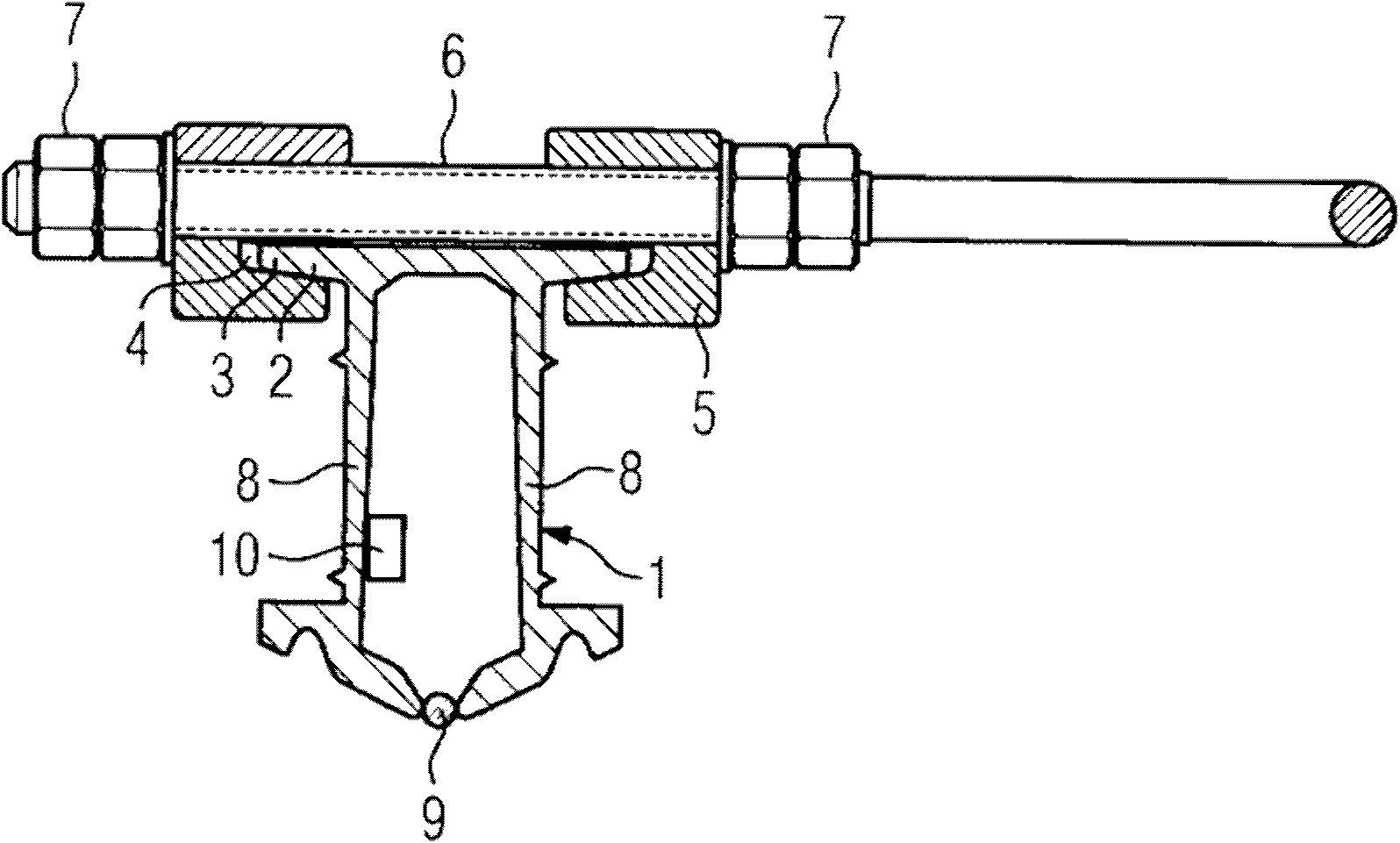

[0042] according to figure 1 , the suspension busbar 1 is fastened particularly stably, so that good power transmission is possible without sparks forming at the same time. For this purpose, the suspension contact rail 1 has a cross member 2 which has conically narrowed shaped sections 3 which can be inserted into corresponding grooves 4 of clamping fittings 5 . The clamping fitting 5 is fastened to the fastening device 6 with screws 7 . This achieves a particularly stable fixation of the suspension rail 1 . Protruding from the cross member 2 are two clamping arms 8 for securing conductors 9 . An electrical connector 10 is fixed inside the suspension contact rail 1 for connecting the suspension contact rail 1 and the chain device.

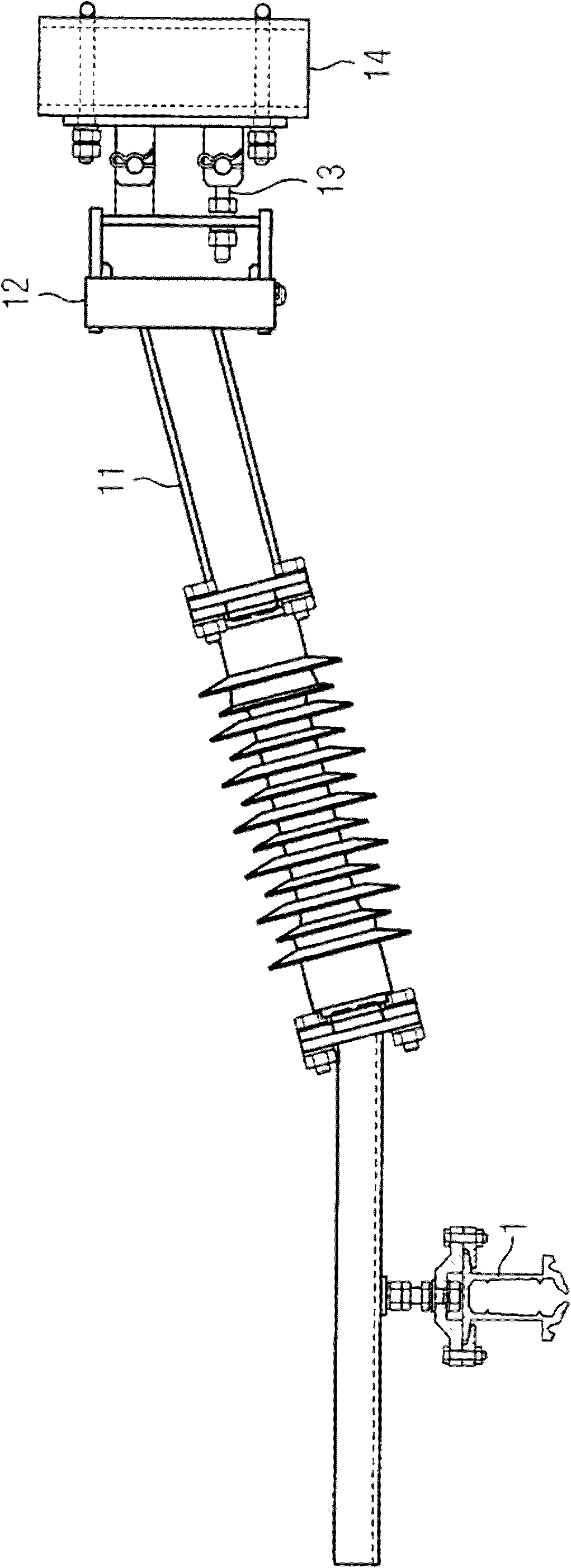

[0043] figure 2 It shows how the suspension conductor rail 1 connects the pivot pin 12 and the adjusting device 13 via the support arm 11 to the building 14 , for example to a tunnel wall, or to a supporting structure. By means of the adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com