Online embossing equipment device and online operation method

A technology of embossing and equipment, applied in the field of automation, can solve the problems of long stop time and low efficiency of sheet embossing, and achieve the effect of improving embossing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

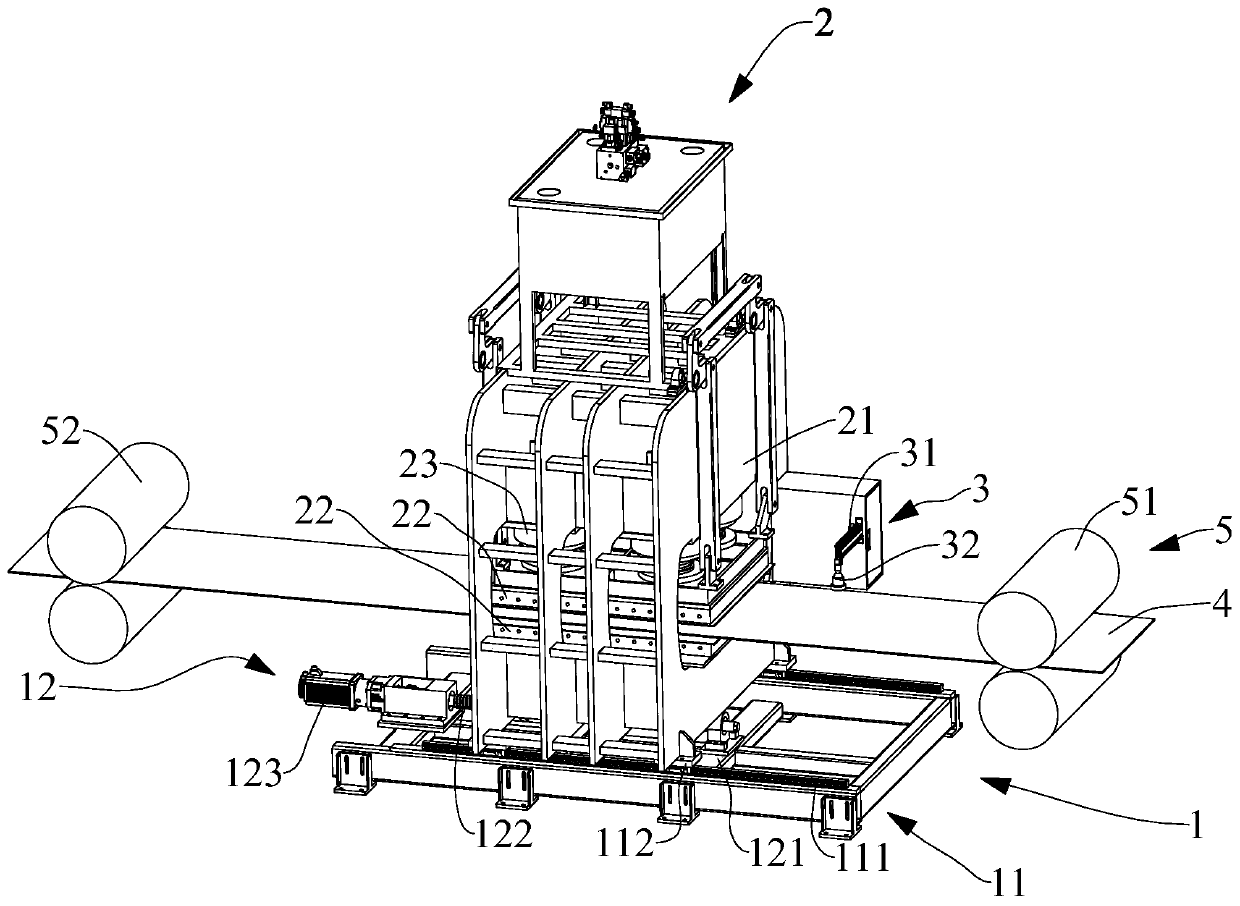

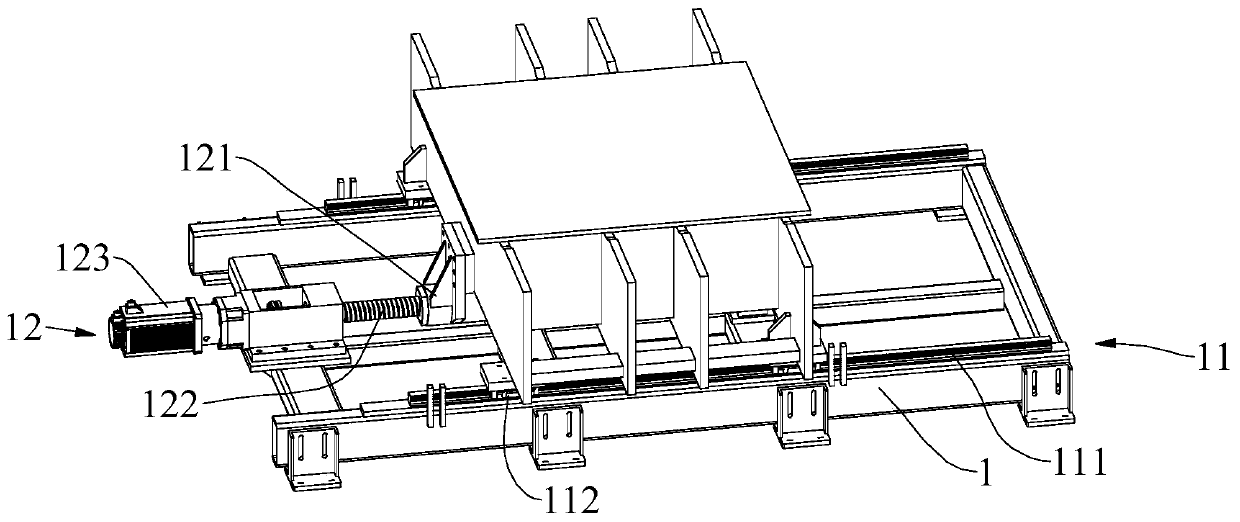

[0049] figure 1 It is a perspective view of a preferred embodiment of the visual recognition mechanism of the online embossing equipment of the present invention.

[0050] Such as figure 1 As shown, the online embossing equipment of this embodiment includes: a main control module, a sliding guide mechanism 1 electrically connected to the main control module, an embossing mechanism 2 and a visual recognition mechanism 3; wherein the visual recognition mechanism 3 recognizes After the sheet to be embossed 4 advances to the embossing position, the embossing mechanism 2 is driven by the sliding guide mechanism 1 to move synchronously with the sheet to be embossed 4, and aligns with the embossing position and presses down to form, thereby improving the embossing efficiency.

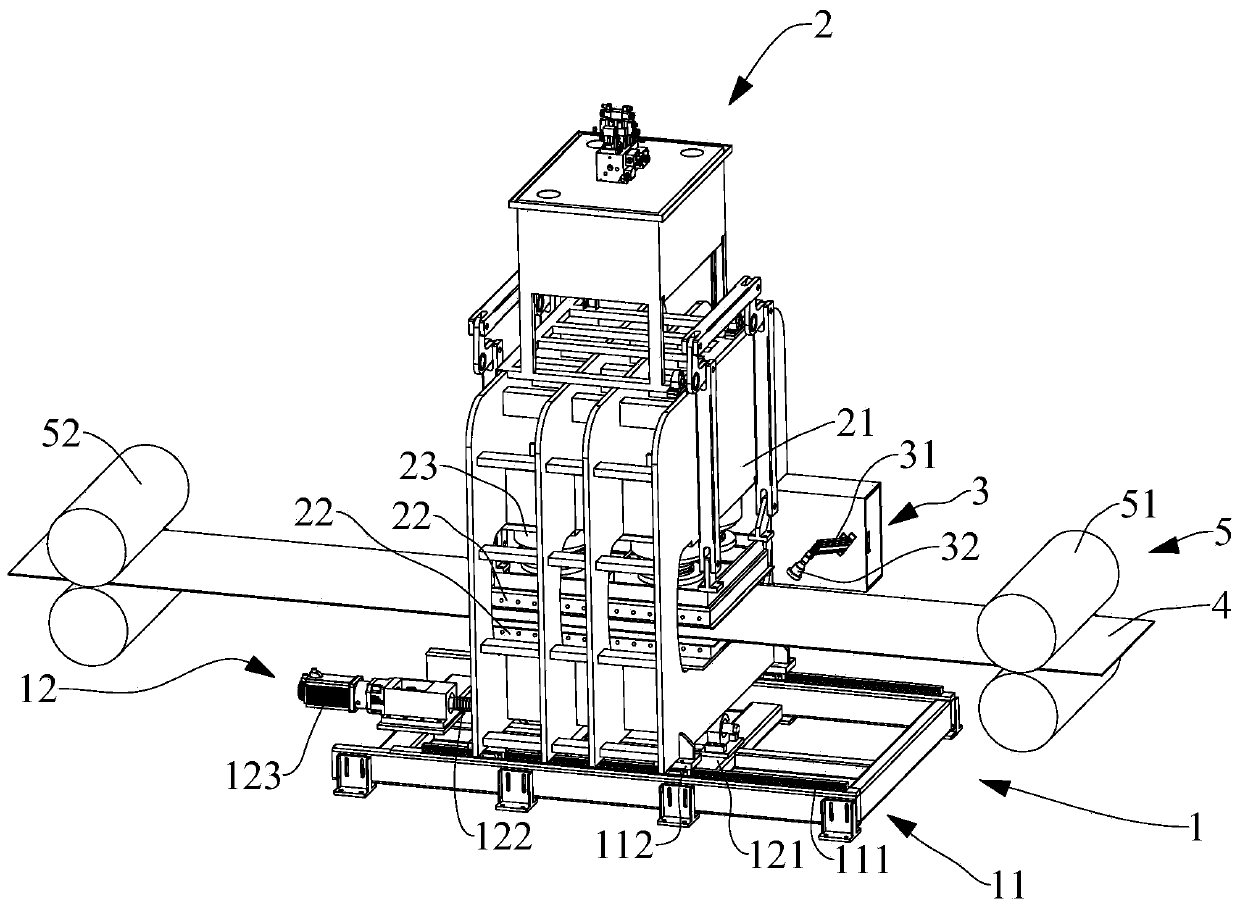

[0051] image 3 It is a perspective view of a preferred embodiment of a side shot of the visual recognition mechanism of the online embossing equipment of the present invention.

[0052] Such as figure 1 ...

Embodiment 2

[0062] On the basis of Embodiment 1, this Embodiment 2 also provides an online operation method, including: capturing the movement track of the target implement when the target implement is moving; controlling the actuator to move synchronously with the target implement according to the movement track , and execute job operations to improve job efficiency.

[0063] Optionally, the target implementation object is the blank 4 to be embossed; the movement track of the target implementation object is captured by the visual recognition mechanism 3, that is, it is determined that the blank 4 to be embossed travels to the embossing position; the actuator includes: The main control module electrically connected with the visual recognition mechanism 3, and the main control module controls the embossing mechanism 2 and the sliding guide mechanism 1; according to the motion track, the actuator is controlled to move synchronously with the target implement, and perform the operation, that i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap