Composite corrugated paperboard

A corrugated cardboard and corrugated technology, applied in the direction of paper/cardboard layered products, layered products, chemical instruments and methods, etc., can solve the problems of corrugated cardboard inner layer not functioning, poor cardboard structural strength, damage, etc., to reduce The effect of the probability of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

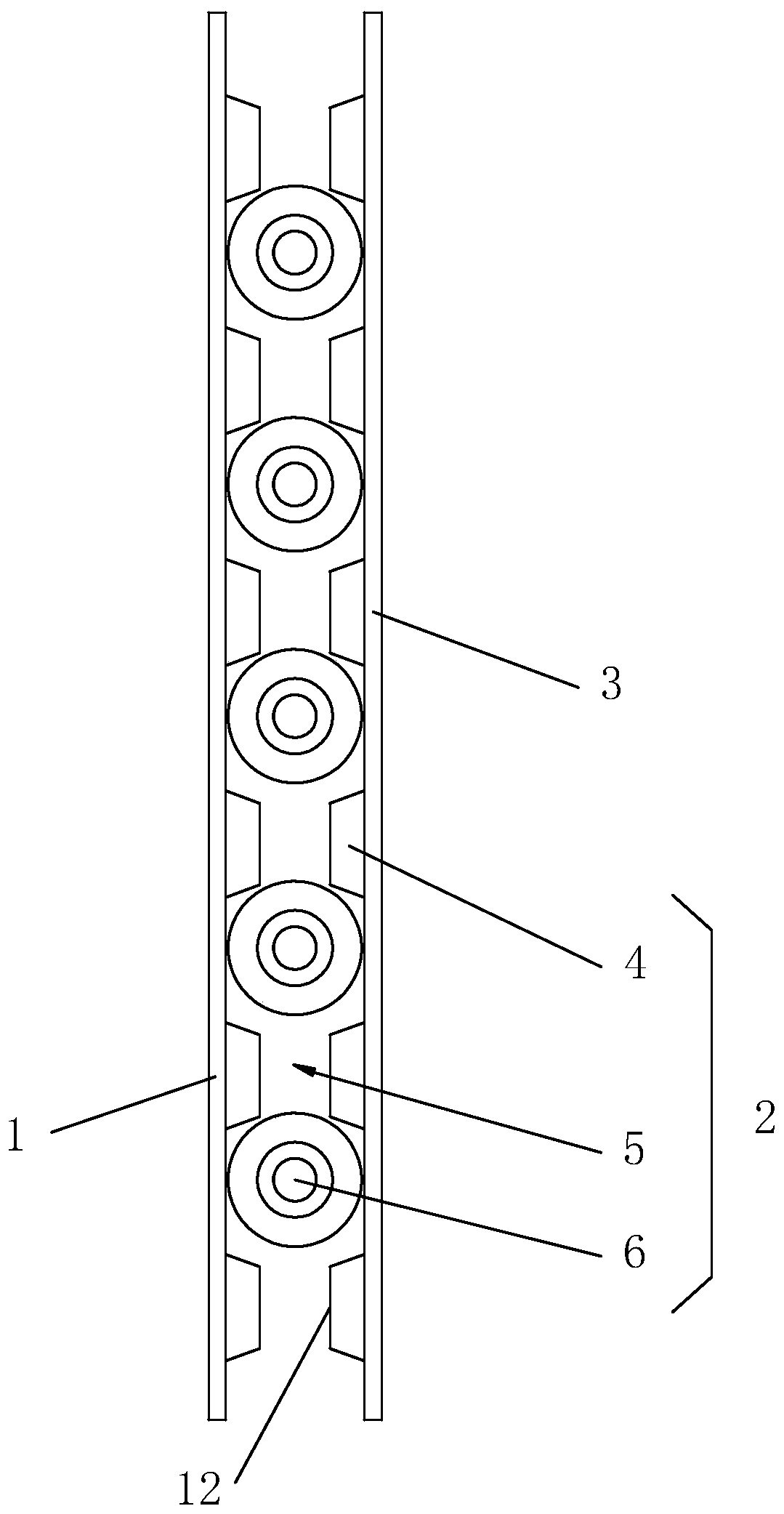

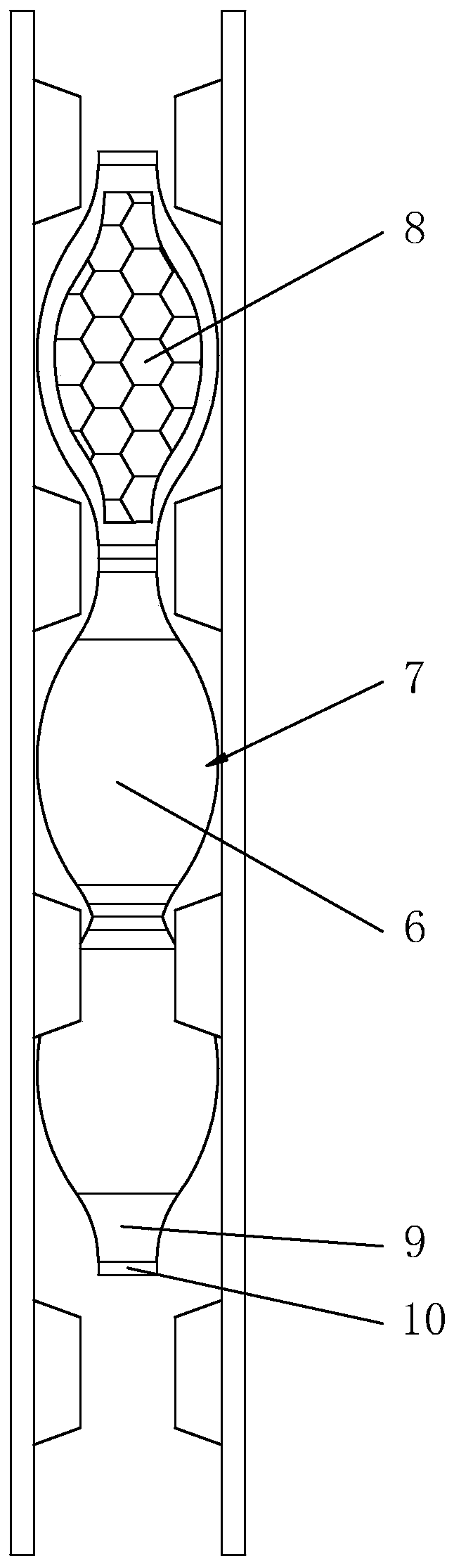

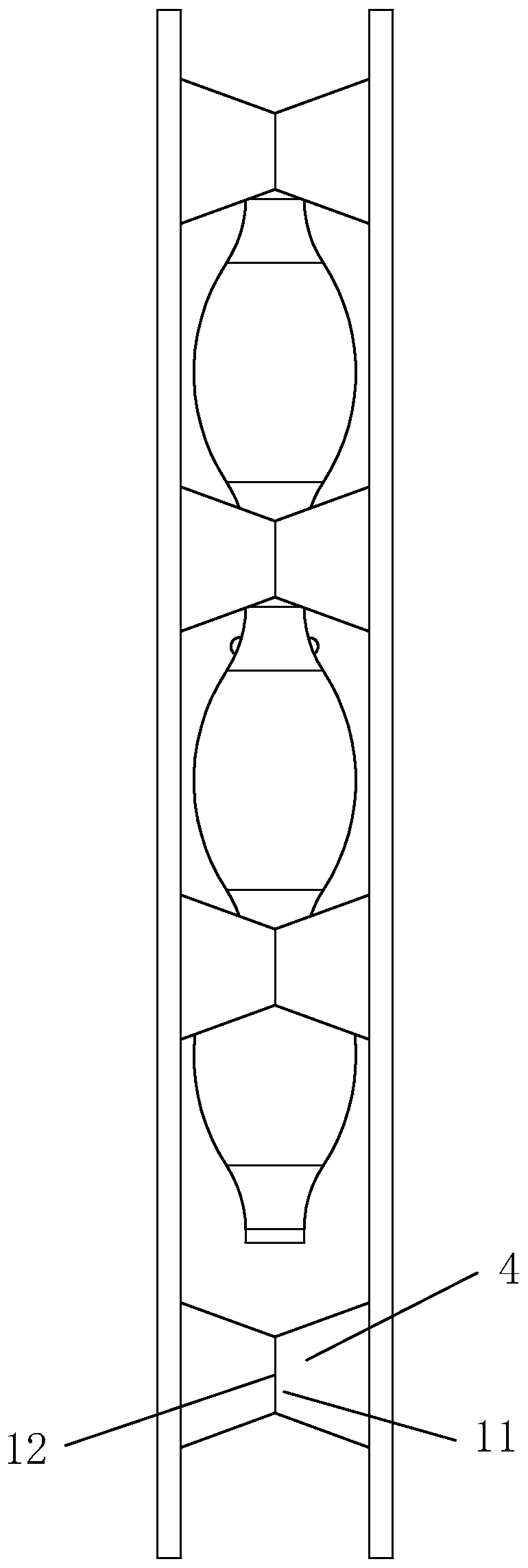

[0029] A composite corrugated cardboard, such as figure 1 and figure 2 Said comprises a face paper layer 1, a corrugated core layer 2 and an inner paper layer 3, the inner paper layer 3 is located inside the corrugated core layer 2, the face paper layer 1 is located outside the corrugated core layer 2, and the corrugated core layer 2 includes a plurality of glue The support paper block 4 glued between the inner paper layer 3 and the surface paper layer 1, the area between the support paper blocks 4 is formed with a supplementary channel 5, and the supplementary channel 5 is in the form of a net between the surface paper layer 1 and the inner paper layer 3 lattice. A slidable supplementary paper block 6 is placed in the supplementary channel 5 , and the supplementary paper block 6 fills the area between the supporting paper blocks 4 .

[0030] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com