Line finishing device for electrical equipment

A technology for electrical equipment and arranging devices, applied in the field of electrical equipment auxiliary appliances, can solve the problems of inconvenient operation of the wire arranging device, and achieve the effects of simple structure, small footprint and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

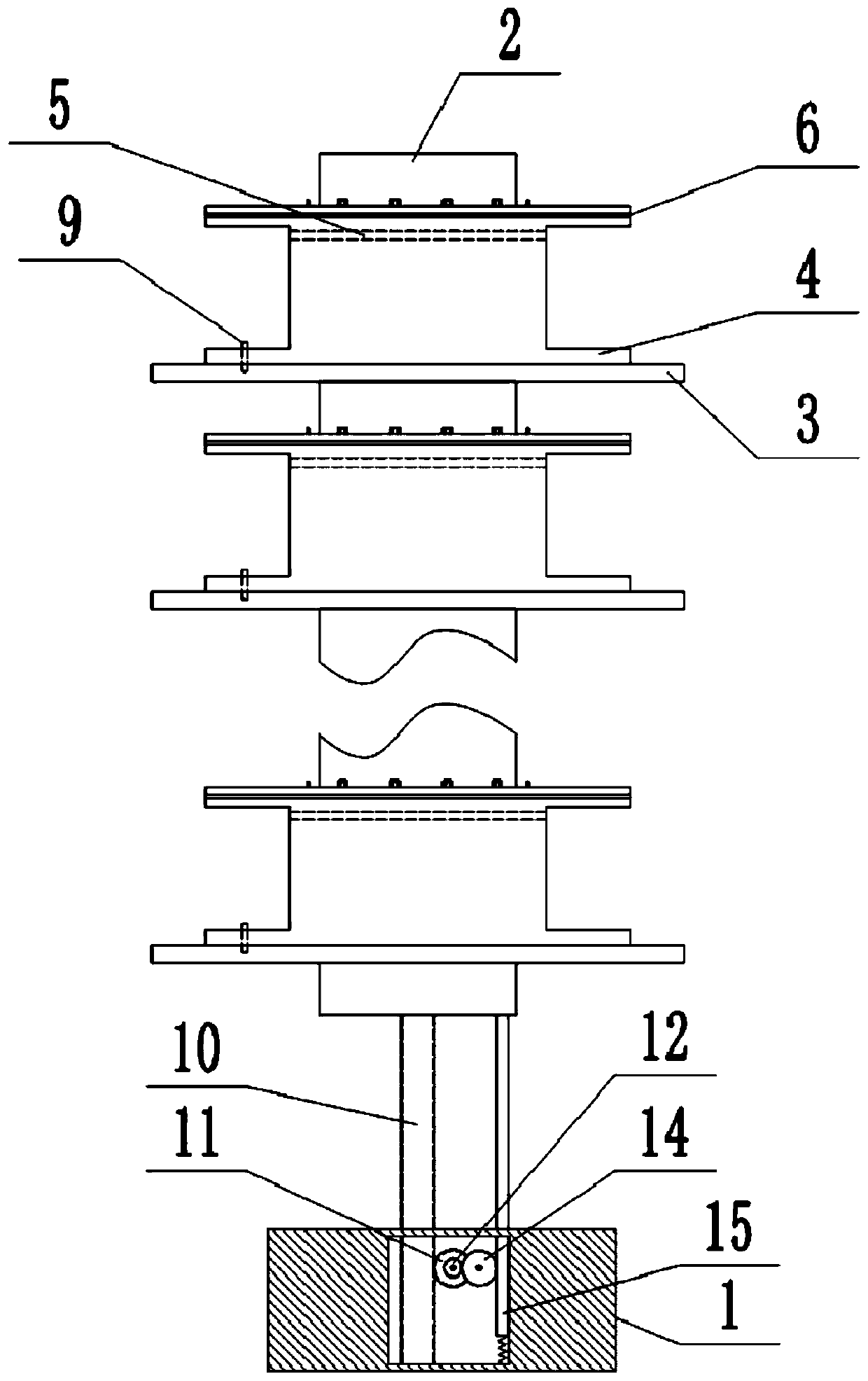

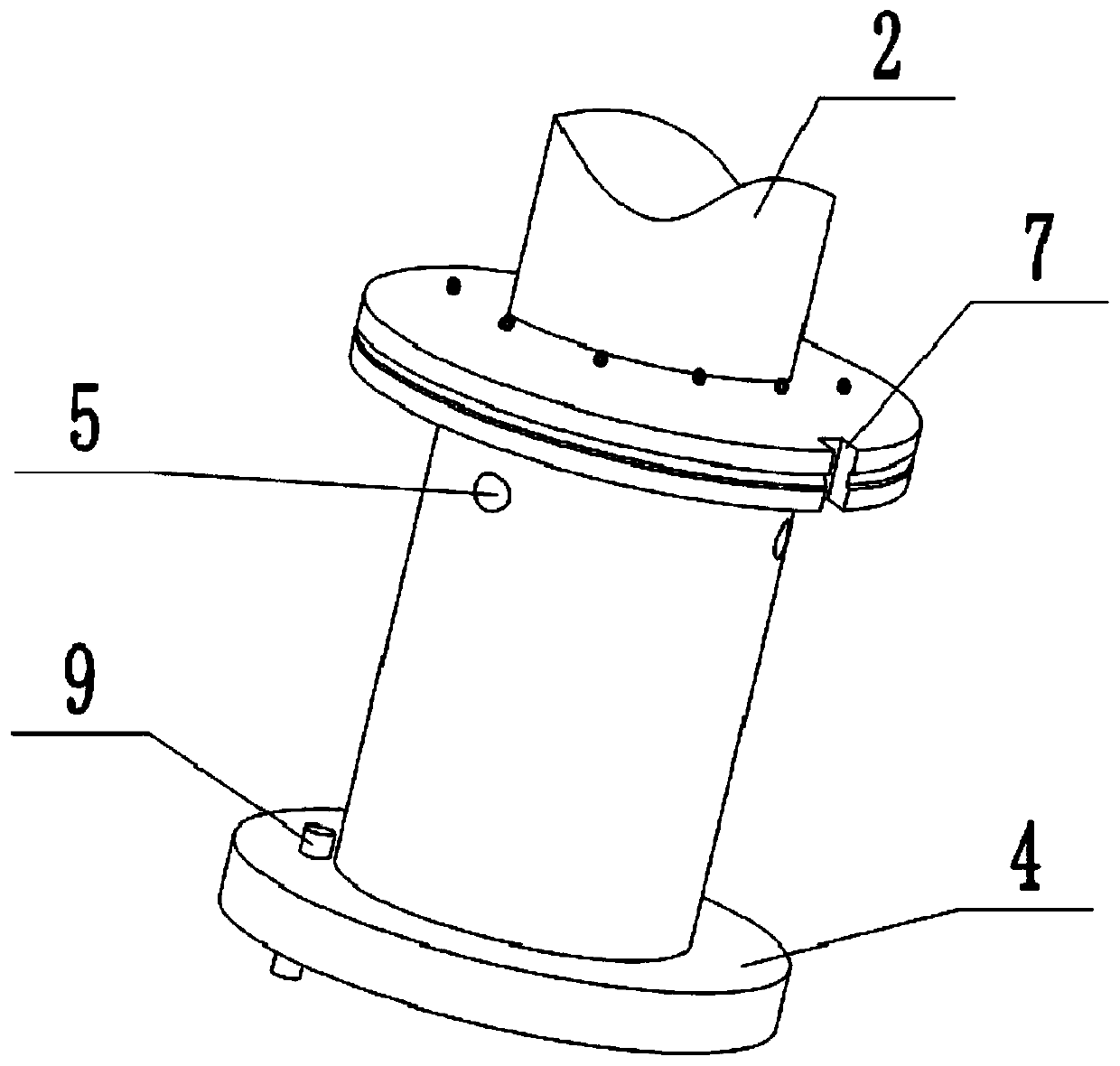

[0035] Line finishing device for electrical equipment, combined with attached figure 1 And attached figure 2 As shown, it mainly consists of a base 1, a rotating rod 2, several wire management and winding mechanisms, a driving mechanism, and a fastening mechanism. The base 1 is fixed in the housing 22 of the electrical equipment by means of screws or bonding. A cavity is provided in the base 1, and a driving mechanism for driving the rotating rod 2 to rotate is arranged in the cavity. The driving mechanism mainly consists of a worm screw 10, a second A rotating shaft, a worm wheel 11, and a push-up unit are formed, and the top of the worm 10 is connected with the bottom of the rotating rod 2 in a splined manner. The first rotating shaft is rotatably connected in the cavity, and one end of the first rotating shaft passes through the base 1 and is connected with a handle 13 . A worm wheel 11 is installed on the first rotating shaft, and the worm wheel 11 cooperates with the w...

Embodiment 2

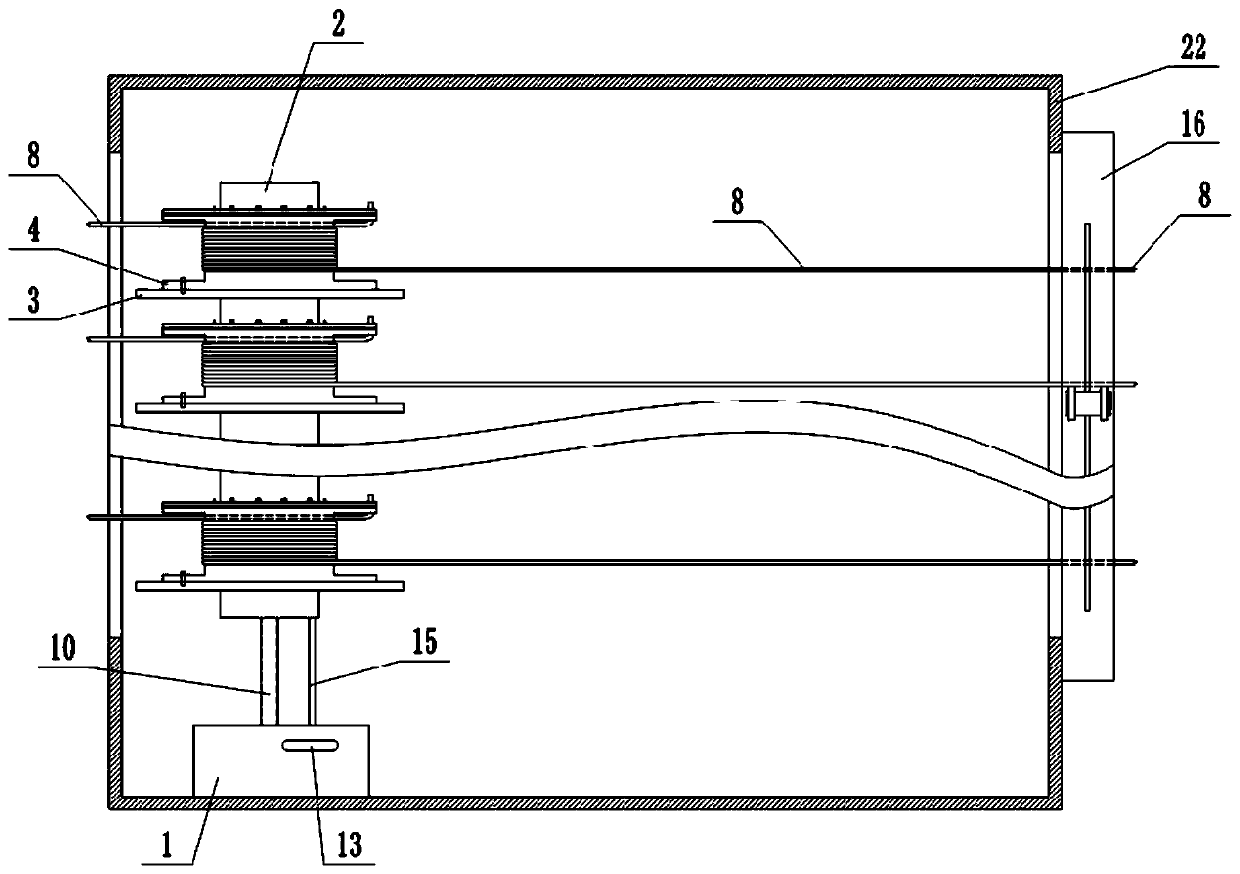

[0046] The difference between this embodiment and embodiment 1 is that: image 3 And attached Figure 4 As shown, this embodiment also includes a fastening mechanism for fixing the drawn-out electric wires 8, and the fastening mechanism is arranged outside the electrical equipment casing 22 and near the wire outlet. The fastening mechanism is mainly composed of a column 16, a plurality of second through holes 17, and a tightening unit. The column 16 is fixed outside the housing 22 of the electrical equipment by means of screws or bonding, and the plurality of second through holes 17 are vertically uniform. Cloth on the column 16.

[0047] The jacking unit is used to fasten the electric wire 8. The jacking unit is mainly composed of several chutes, several jacking rods 18, a connecting rod 19 and a jacking assembly. Several chutes are set on the column 16. And each chute is correspondingly connected to a second through hole 17, and several ejector rods 18 are slidably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com