Lifting device for coating device and preparation method of lifting device

A lifting device and coating equipment technology, applied in the direction of lifting device, lifting frame, spraying device, etc., can solve the problems of inconvenient use, inability to adjust the height of the spraying pipeline, and the complicated height of the spraying pipeline, so as to liberate manpower, adjust conveniently and quickly, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

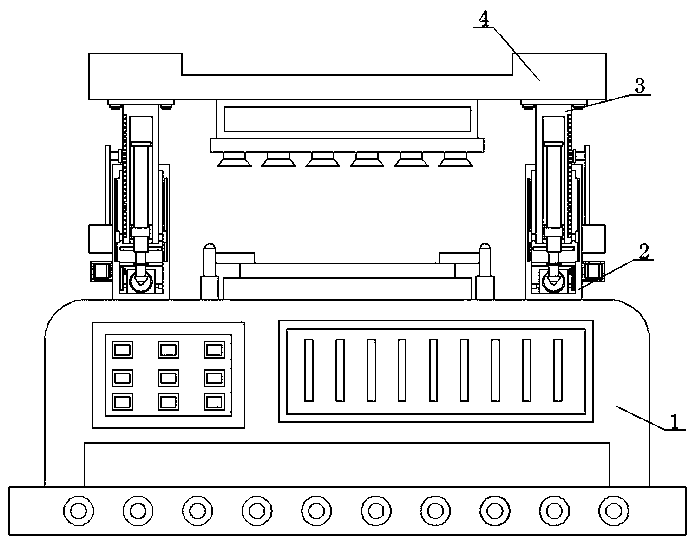

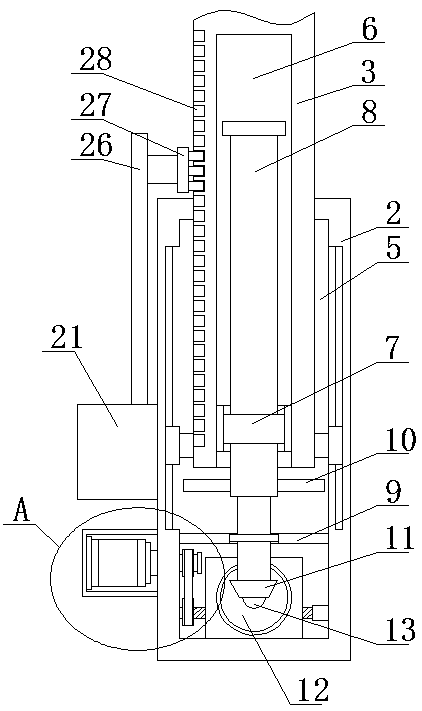

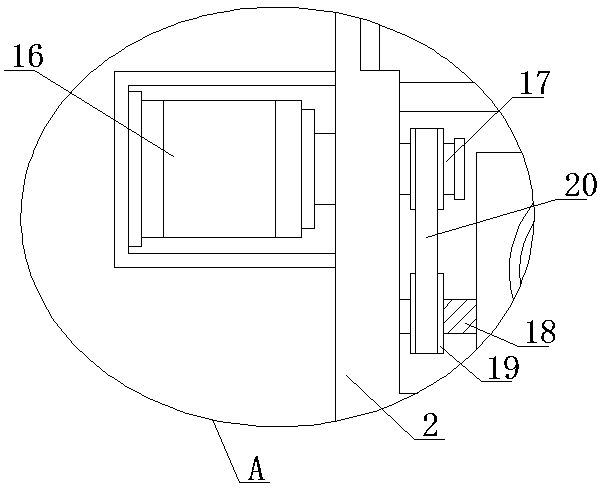

[0032] refer to Figure 1-5 In this embodiment, a lifting device for coating equipment is proposed, including a worktable 1, two symmetrically arranged lifting seats 2 are fixedly installed on the top of the working table 1, and a lifting chute 5 is provided on the top of the lifting seat 2. A support rod 3 is slidably connected in the lifting chute 5, and the tops of the two support rods 3 all extend to the top of the lifting seat 2. The tops of the two support rods 3 are fixedly mounted with the same adjustment plate 4, and the adjustment plate 4 is provided with Spraying pipe, the bottom of the support rod 3 is provided with a strip groove 6, a nut 7 is fixedly installed in the strip groove 6, a screw rod 8 is threaded on the nut 7, and a fixed plate 9 and a screw rod 8 are fixedly installed in the lifting chute 5 The bottom runs through the fixed plate 9 and is rotatably connected with the fixed plate 9. The bottom of the screw rod 8 is fixedly equipped with a first bevel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com