Online sampling device for high-temperature smoke dust

A sampling device and smoke dust technology, which is applied in the direction of sampling device, test sample preparation, etc., can solve the problems of large sampling location setting limitations, low capture efficiency, and unsuitable for containing water-soluble component smoke dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

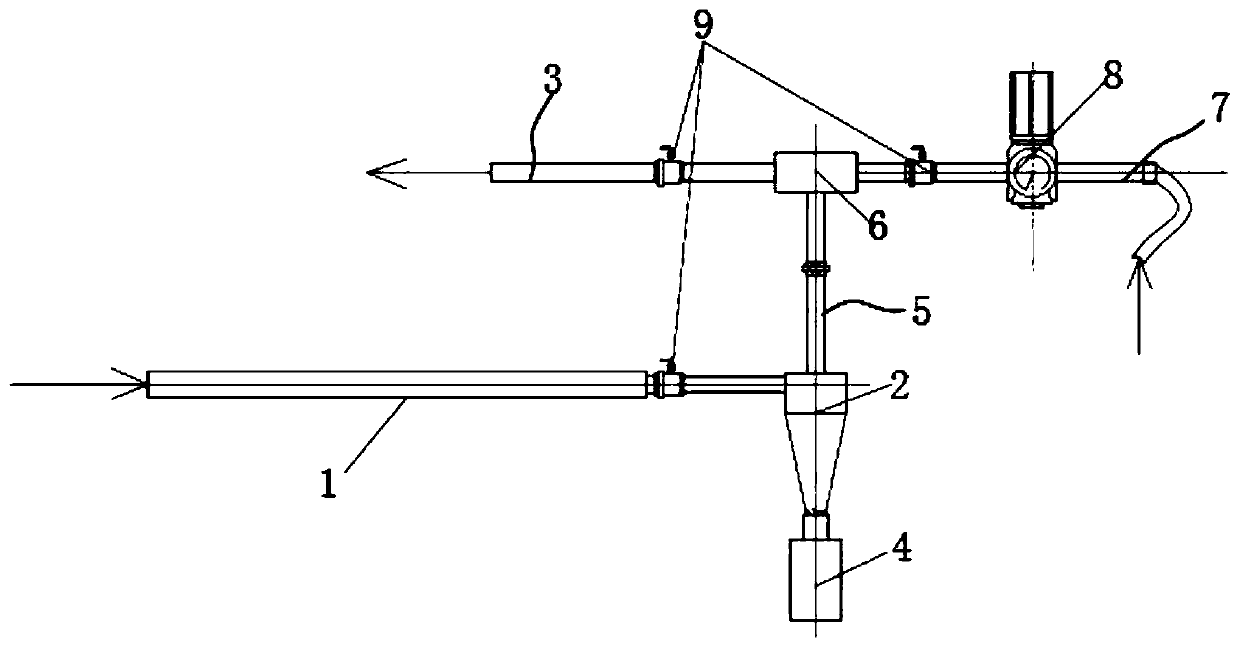

[0008] Such as figure 1 As shown, a high-temperature smoke and dust online sampling device includes a sampling tube 1, one end of the sampling tube 1 is connected to the air inlet of the cyclone 2, the gas outlet of the cyclone 2 is connected to an outlet pipe 3, and the gas outlet of the cyclone 2 is connected to the air outlet of the cyclone 2. The bottom is threadedly connected with a collection tank 4 , the furnace gas enters the cyclone 2 from the sampling pipe 1 , the smoke and dust separated by the cyclone 2 falls into the collection tank 4 , and the flue gas is discharged through the outlet pipe 3 . Furnace gas enters through the sampling pipe 1 from one side of the cyclone 2 along the tangential direction. Under the strong swirl force, the soot particles in the flue gas are collected and enter the soot collection tank 4, while the flue gas flows from the outlet The air pipe 3 is discharged, and the dust collection speed is fast and the efficiency is high; in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com