Apparatus for mechanical testing of materials and method of use thereof

A test device and material mechanics technology, applied in measurement devices, analytical materials, scientific instruments, etc., can solve the problems of occupying human activity space, students' personal operation, short course time, etc., to achieve simple structure, improve safety, and improve accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

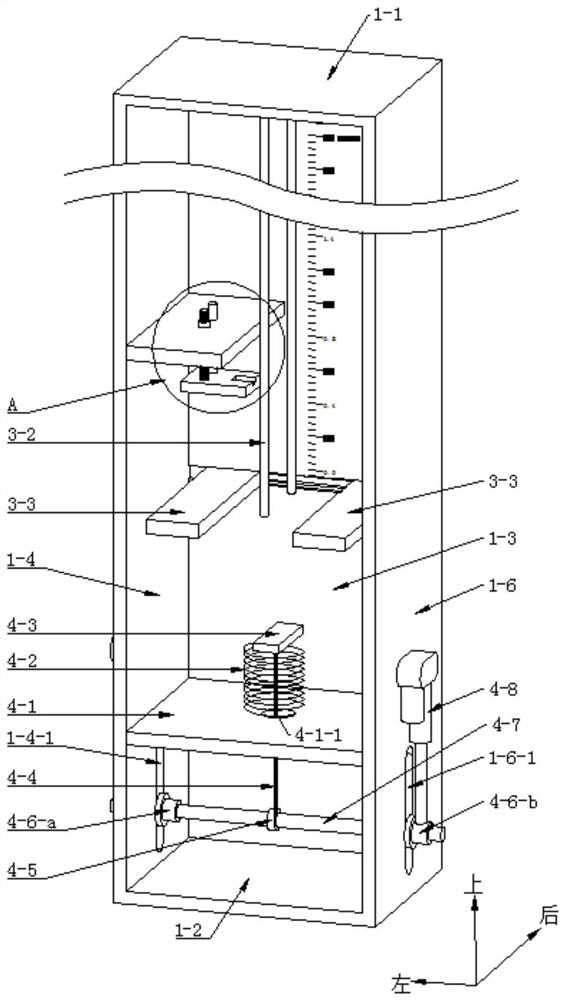

[0085] A material mechanics test device includes a casing, a sample placing mechanism, a hammer body placing mechanism, and a hammer body launching mechanism. The sample placement mechanism, the hammer body placement mechanism, and the hammer body launch mechanism are sequentially arranged in the casing from top to bottom.

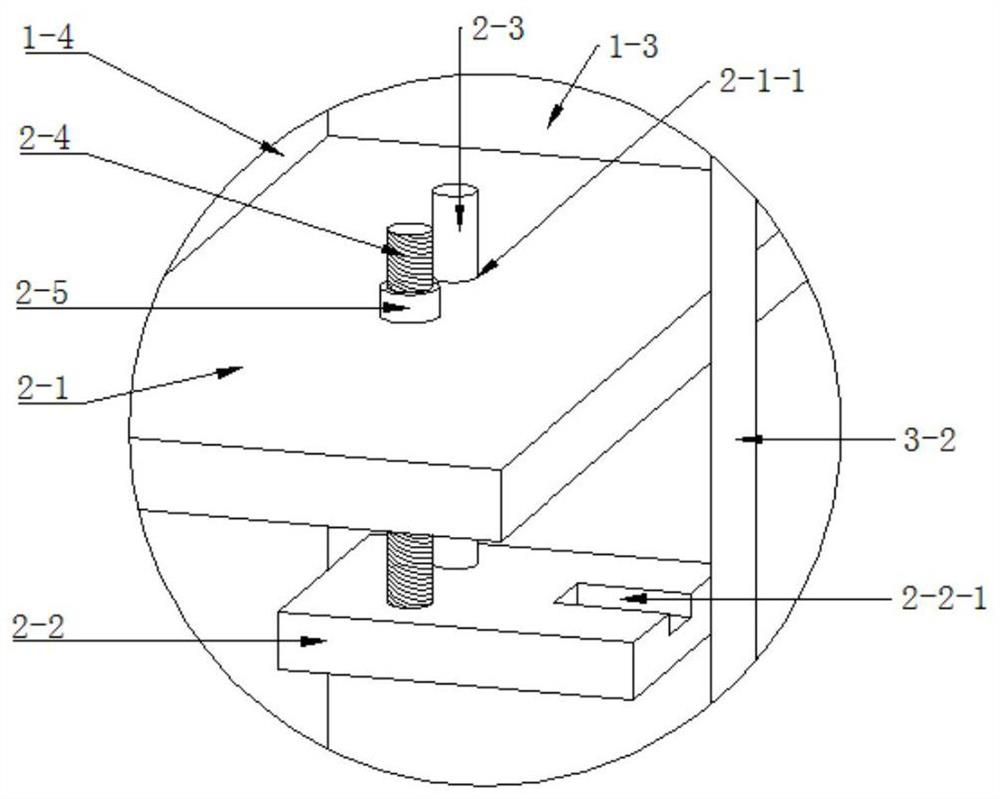

[0086] Such as figure 2 As shown, the casing includes a top plate 1-1, a side plate, and a bottom plate 1-2. The side plates include a first side plate 1-3, a second side plate 1-4, a third side plate 1-5, and a fourth side plate 1-6 which are welded and fixed in sequence. The upper end of the first side plate 1-3, the upper end of the second side plate 1-4 and the upper end of the fourth side plate 1-6 are welded and fixed with the top plate 1-1, and the lower end of the first side plate 1-3 reaches the fourth side plate. The lower ends of the side plates 1-6 are welded and fixed to the bottom plate 1-2. In order to improve the stability of the casing...

Embodiment 2

[0136] This embodiment 2 is the same as embodiment 1, the difference is that, as Figure 18-20 As shown, in a kind of material mechanics test device of the present embodiment 2. In order to prevent the hammer body 3-1 from being damaged when the hammer body 3-1 falls, a buffer mechanism is also provided between the sample placement mechanism and the hammer body placement mechanism.

[0137] The buffer mechanism includes a third guide rod 5-1, a first buffer pad 5-2, a second buffer pad 5-3, an iron core 5-5, an armature 5-6, a switch, and a power supply.

[0138] The third guide rod 5-1 is provided with two side by side, and the two second guide rods 3-2 are located between the two third guide rods 5-1, and the hammer body 3-1 can move between the two third guide rods 5-1. Swipe up and down between -1. One end of the third guide rod 5-1 is welded and fixed to the second side plate 1-4, and one end of the third guide rod 5-1 away from the second side plate 1-4 is welded and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com