Discharge friction generator

A technology of friction generator and friction layer, applied in the direction of friction generator, etc., can solve the problem of lack of output capacity of friction generator, and achieve the effect of simple and controllable material system, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

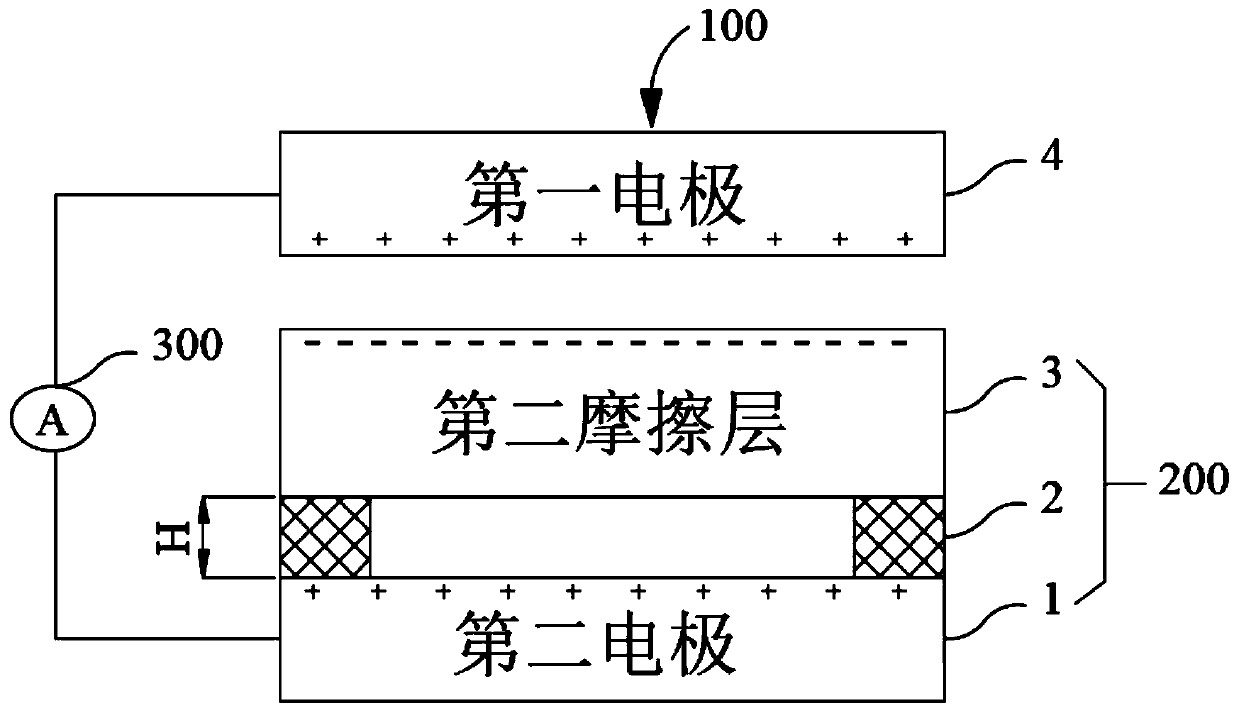

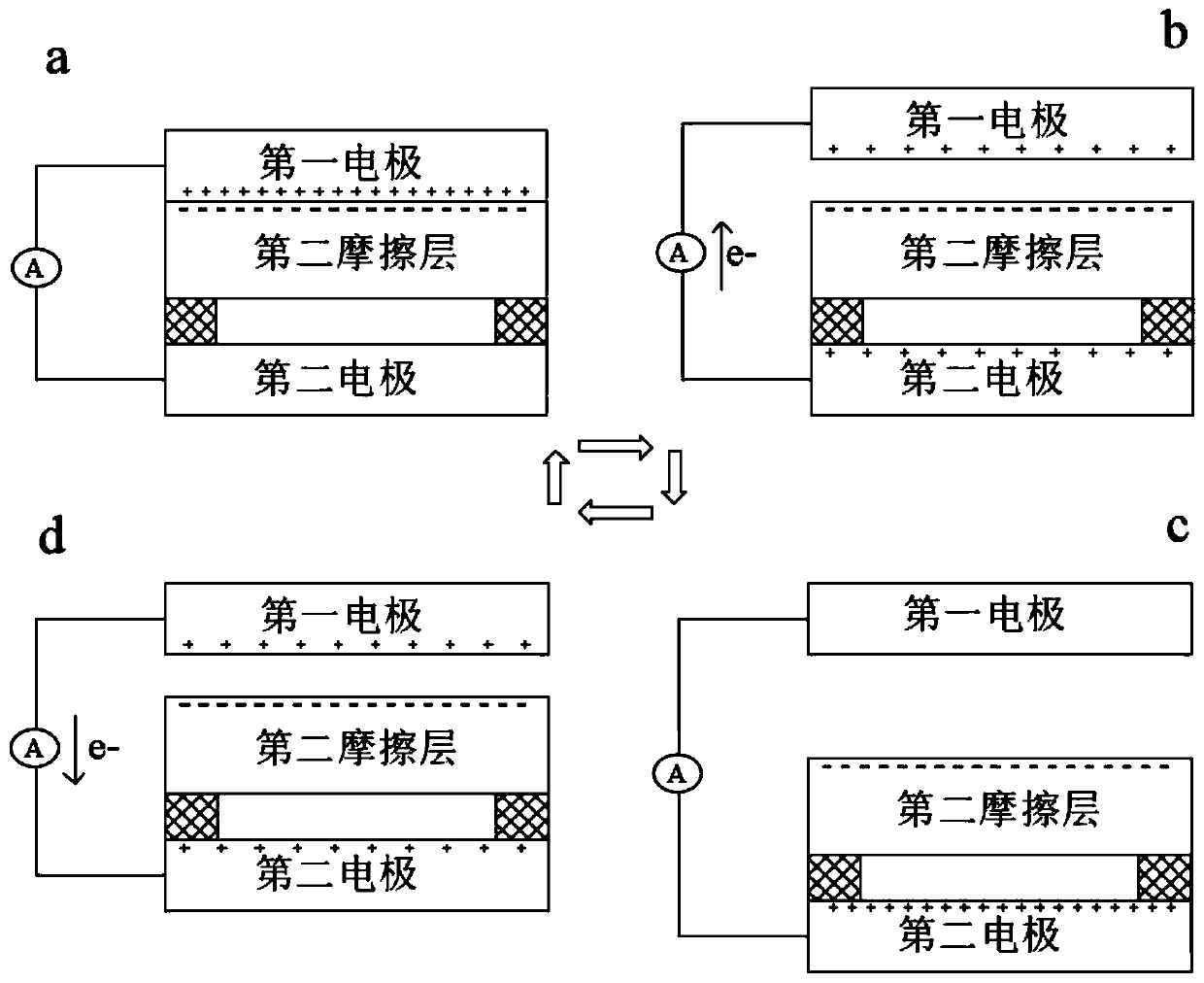

[0035] figure 1 shows a schematic structural diagram of a discharge friction generator of the present invention, please refer to figure 1 , the discharge friction generator includes a first friction unit 100, including a first electrode 4; a second friction unit 200, including a second friction layer 3 and a second electrode 1, and the second electrode 1 is arranged on the second The surface of the friction layer 3 away from the first friction unit 100; wherein, a first preset interval H is reserved between the second electrode 1 and the second friction layer 3, and the second friction layer 3 and the first electrode 4 are respectively located in different positions of the electrostatic sequence.

[0036] It should be noted, figure 1 The shown discharge friction generator works in vertical contact-separation mode, but it should be understood that the technical solution of this embodiment is also applicable to discharge friction generators in other working modes such as slidi...

Embodiment 2

[0058] Image 6 A schematic structural diagram of the second discharge friction generator of the present invention is shown. see Image 6 , the discharge triboelectric generator includes: a first friction unit 100', including a first electrode 4' and a first friction layer 6', and the first electrode 4' is disposed far below the first friction layer 6' The surface of the second friction unit 200' to be introduced; the second friction unit 200' includes a second friction layer 3' and a second electrode 1', and the second electrode 1' is arranged on the second friction layer 3' The surface away from the first friction unit 100'; wherein, a first preset interval H1 is reserved between the first electrode 4' and the first friction layer 6', and the second friction layer 3 ' and the first electrode 4' are respectively located in different positions of the electrostatic sequence.

[0059] It should be noted, Image 6 The shown discharge friction generator works in vertical conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com