Tobacco leaf processing method

A processing method and blade technology, which are applied in the field of threshing and redrying production process processing, can solve the problems of low threshing intensity, reduced proportion of large pieces, and increased crushing rate, so as to reduce the threshing intensity, improve the isometric ratio, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

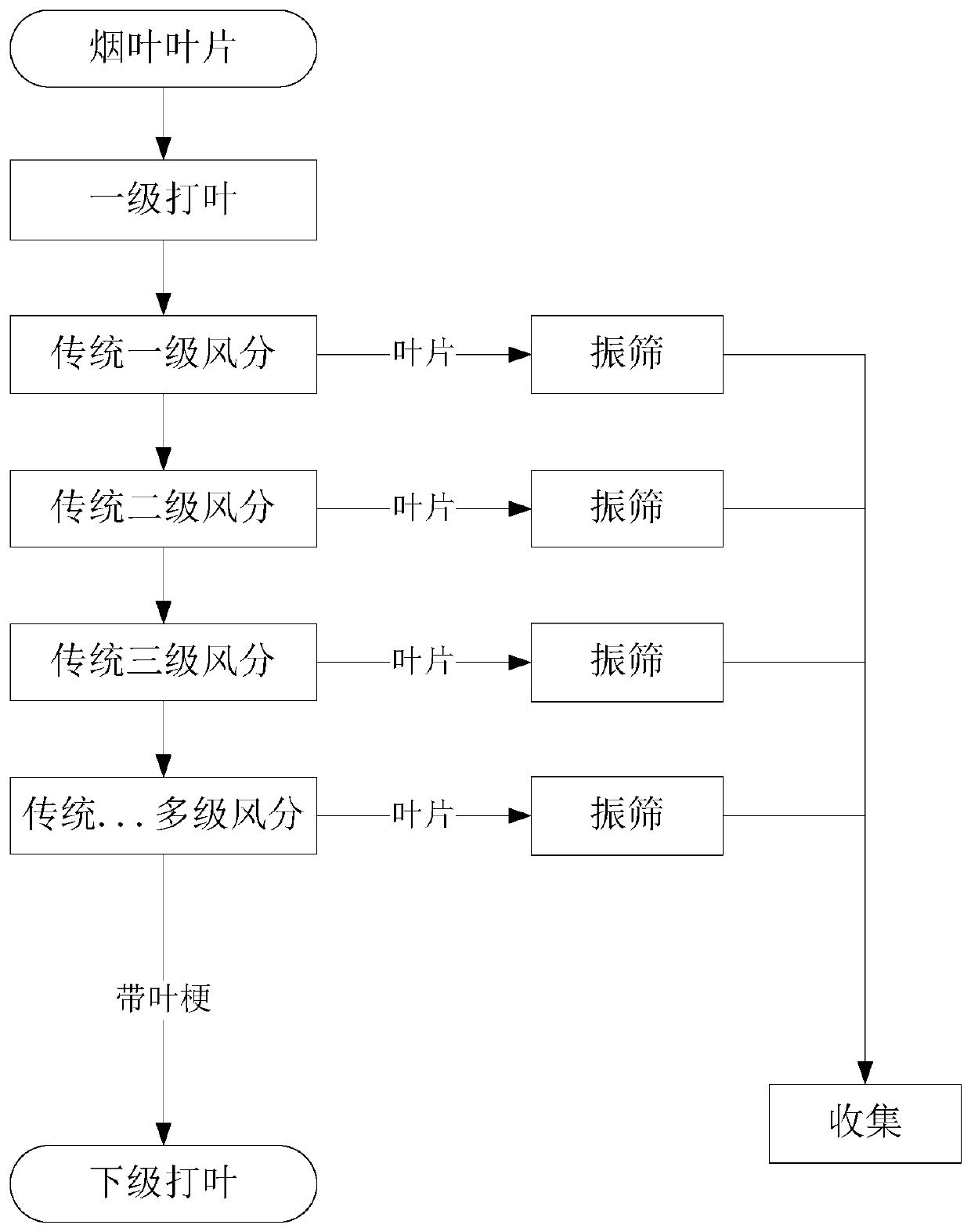

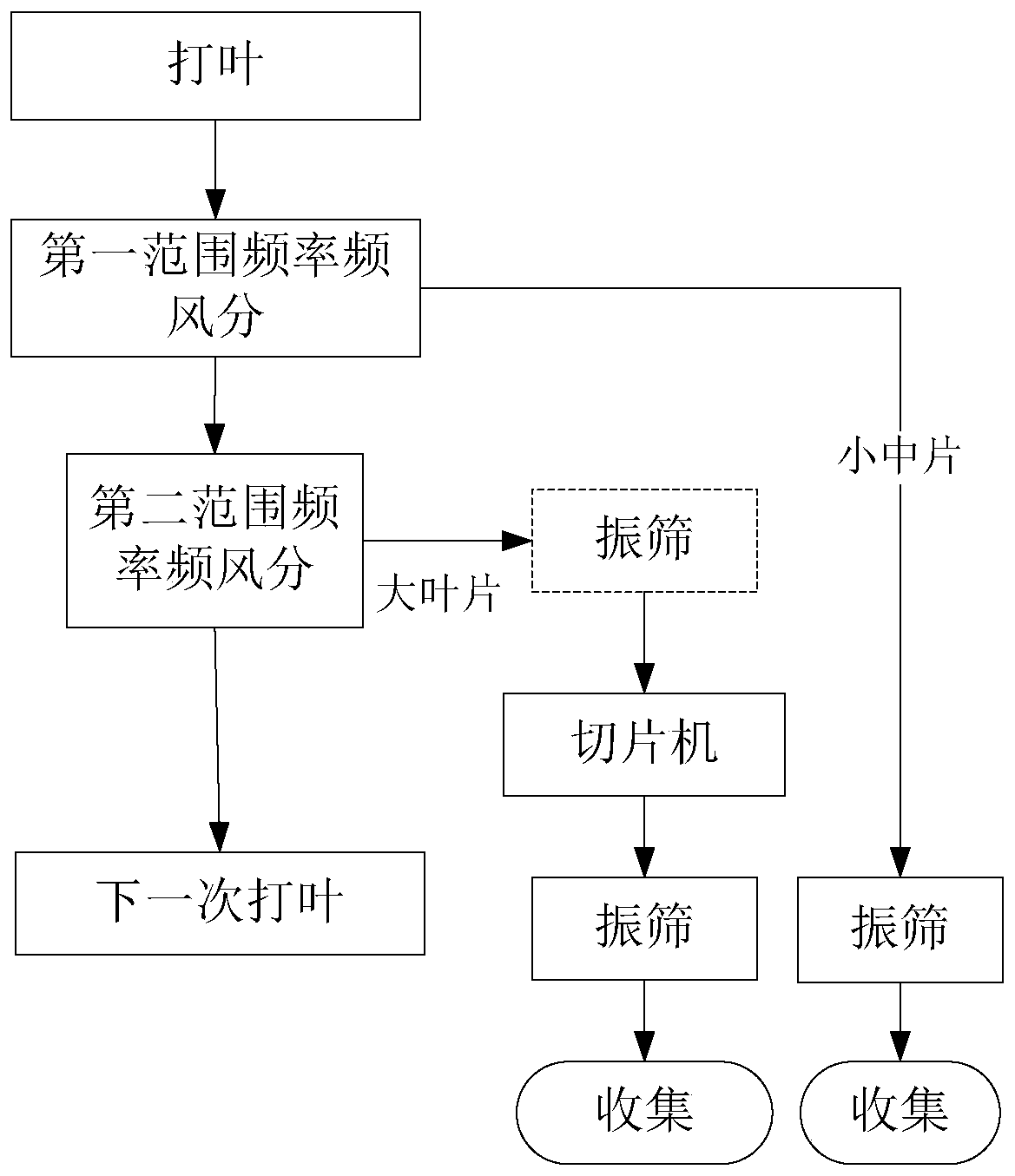

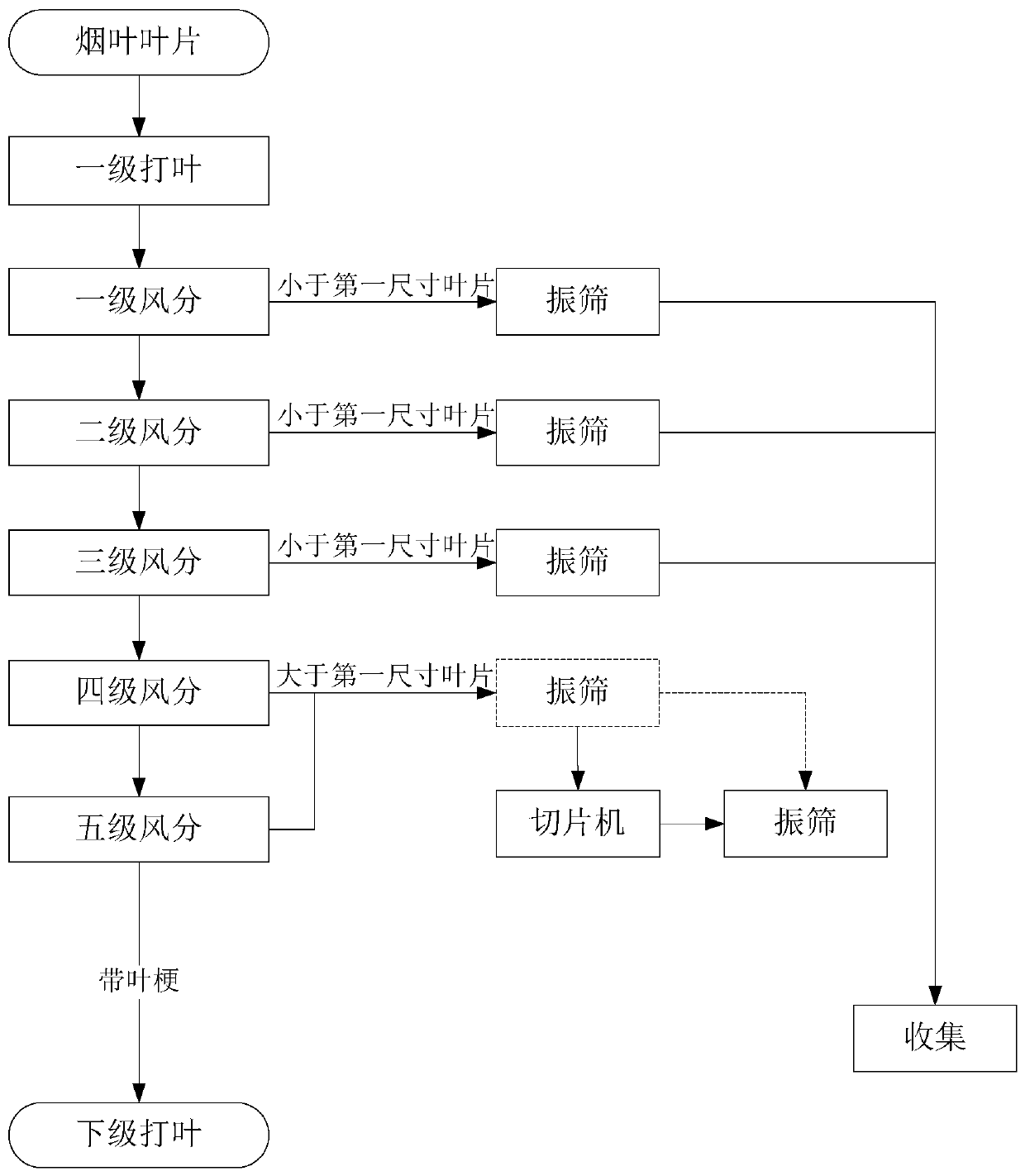

[0041] figure 2 It is a flowchart of the tobacco leaf processing method of the embodiment of the present invention; image 3 It is a detailed flow chart of the middle process of the first-level defoliation and the second-level defoliation in the embodiment of the present invention, as figure 2 and image 3 Shown:

[0042] The invention provides a tobacco leaf processing method, comprising the following steps:

[0043] S1: Treating the threshed tobacco leaves with at least one level of wind in the frequency range of the first range.

[0044] Preferably, the wind fractions within the first frequency range include first-order wind fractions, second-order wind fractions, and third-order wind fractions, and their frequencies increase sequentially.

[0045] In this embodiment, the air classification within the first frequency range adopts thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com