Improved 3D printing path filling method based on Hilbert curve

A 3D printing and filling method technology, applied in the field of 3D printing, can solve the problems of poor mechanical properties of molded parts, different filling rates, reduced printing efficiency, motor life, precision of molded parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

[0036] This embodiment provides an improved 3D printing path filling method based on the Hilbert curve, and its specific steps are as follows:

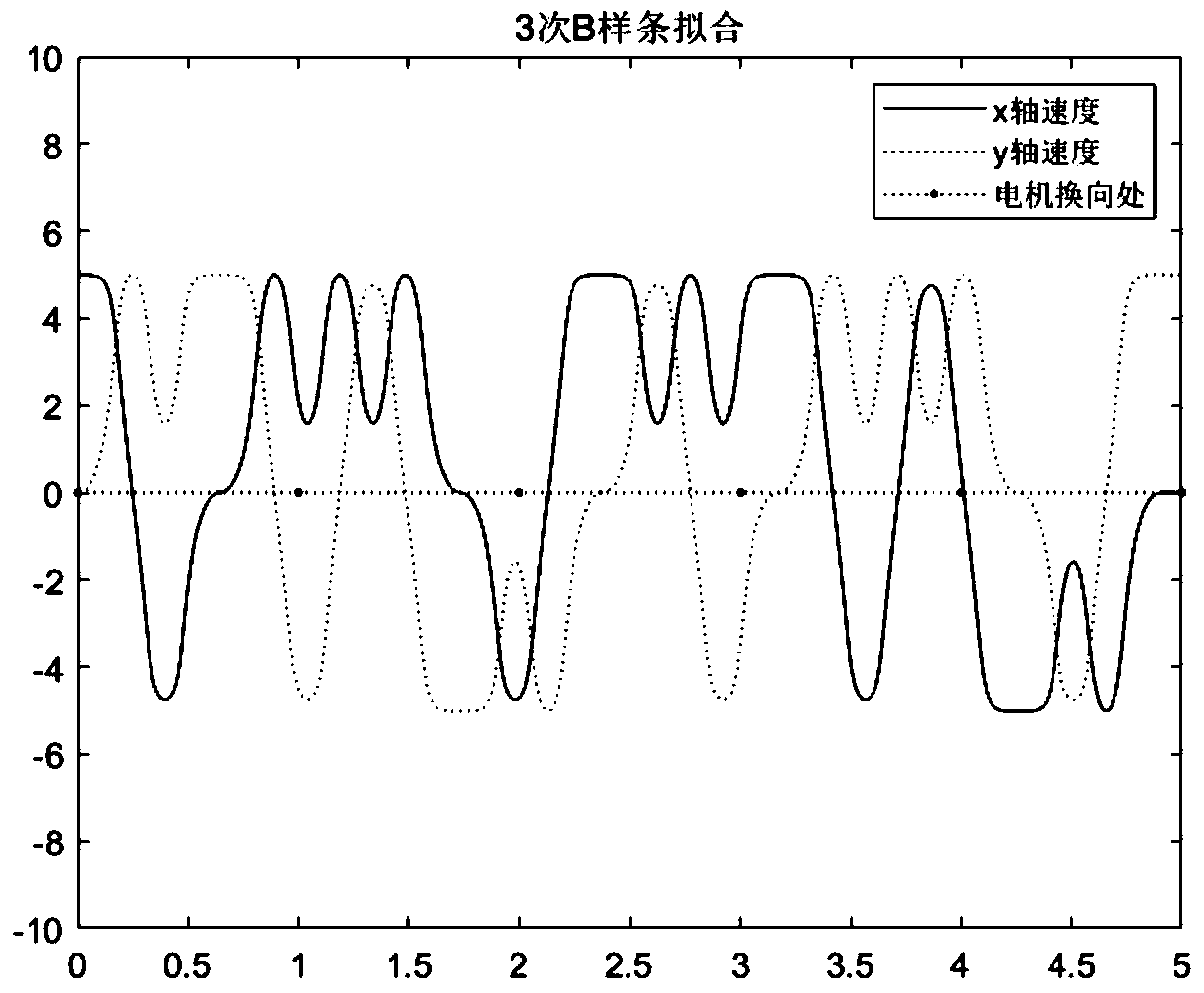

[0037] (1) Draw a Hilbert curve in MATLAB, save the coordinates of its each control point as a txt text file, and provide raw data for optimization;

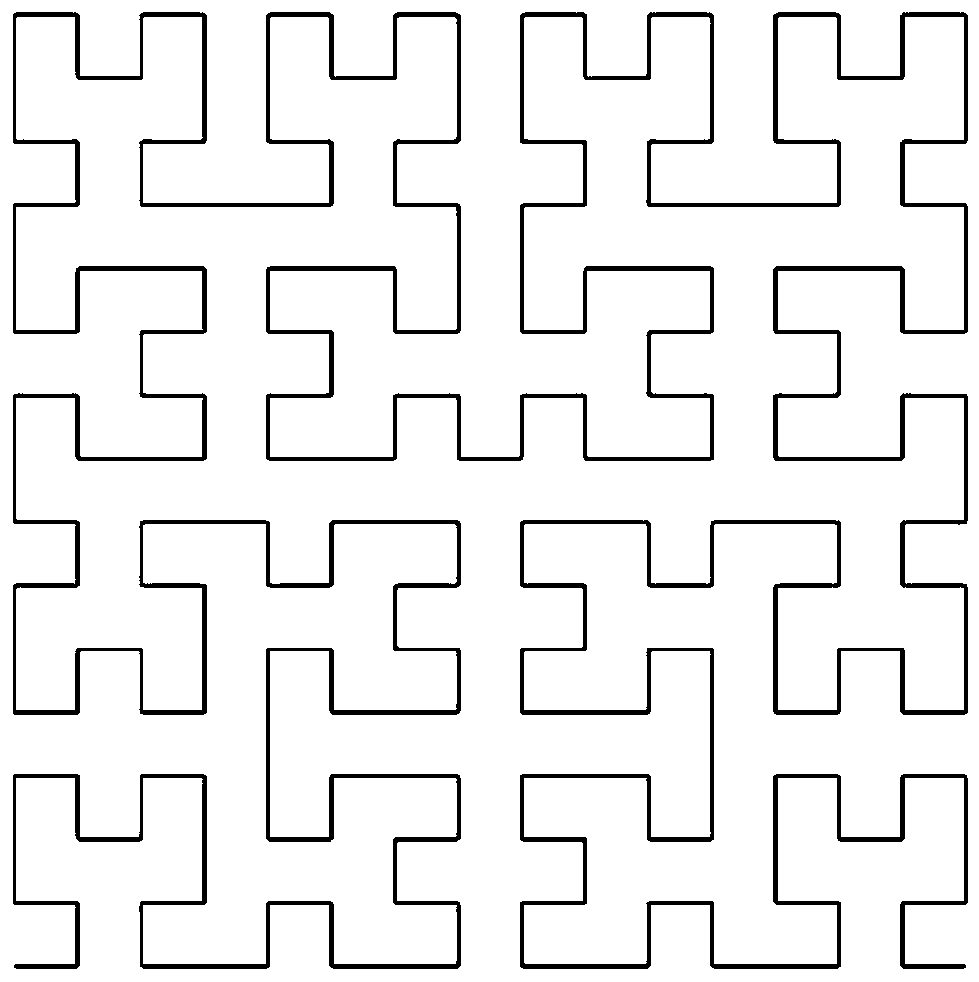

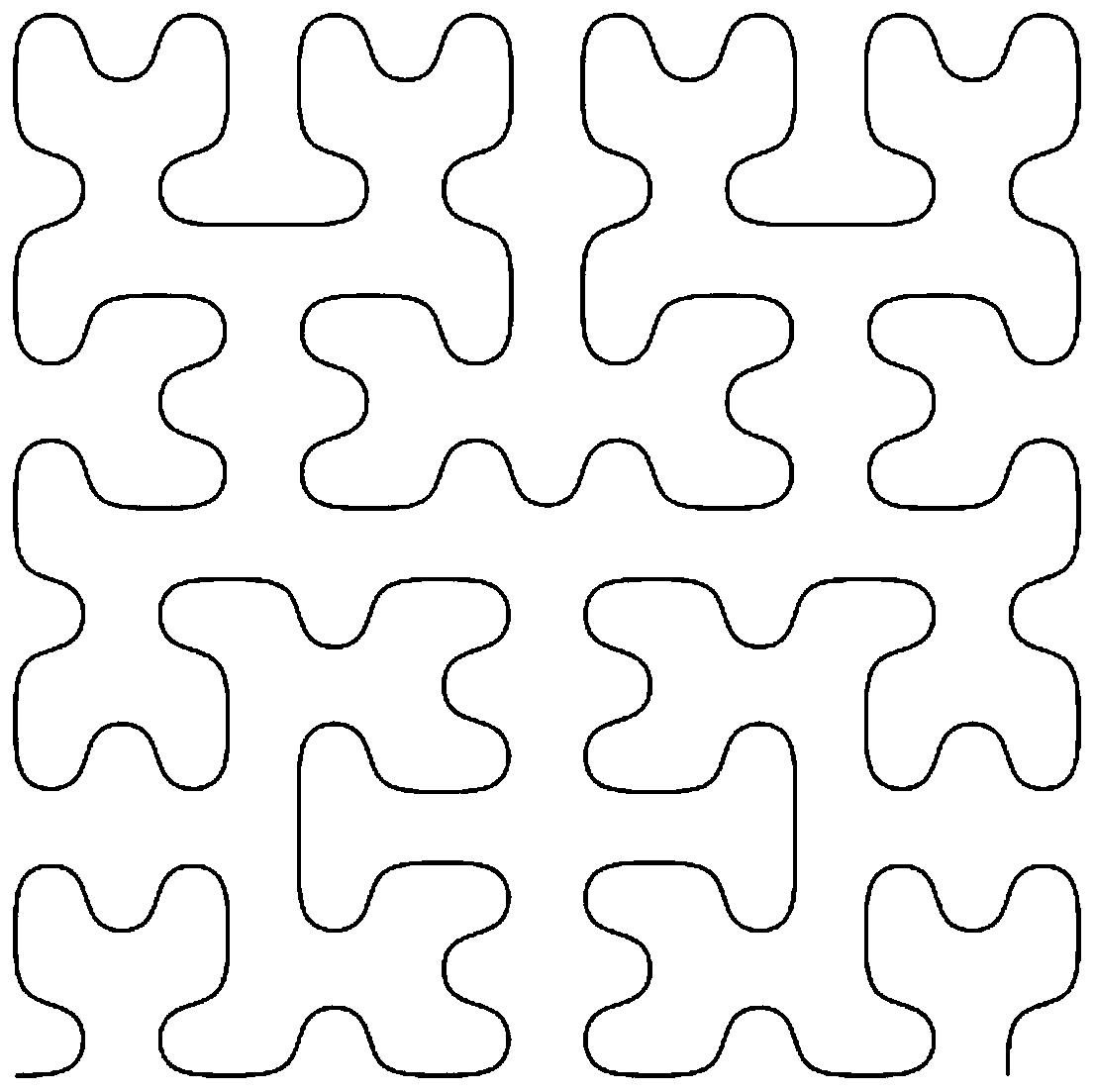

[0038] The Hilbert curve is a space-filling curve, which is formed by dividing the known area into 2 exponential square areas, and then connecting their center points according to certain rules. Now set the order of the curve to 4 and draw it in MATLAB, the result is as follows figure 1 shown. Save the coordinates of its control points to "p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com