Non-road national IV engine TVA calibration method

A calibration method and engine technology, applied in the direction of electric controllers, mechanical parts testing, controllers with specific characteristics, etc., can solve the problems of exhaust temperature difference, DPF burning, DPF can not be regenerated, etc., to achieve the effect of smooth regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, features and effects of the present invention, the following embodiments are exemplified and described in detail with reference to the accompanying drawings.

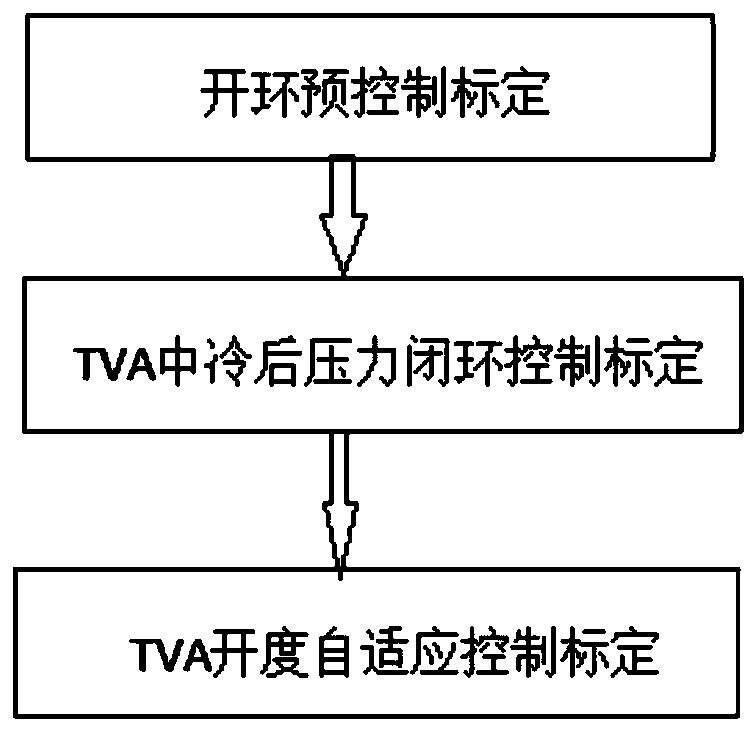

[0020] see figure 1 , a non-road national IV engine TVA calibration method:

[0021] It is mainly to improve the control and calibration method of TVA opening. The original open-loop control calibration based on the TVA target opening is changed to the closed-loop control calibration based on the pressure closed-loop after intercooling in this scheme.

[0022] The calibration method is as follows:

[0023] 1. Open-loop pre-control calibration. The open-loop control method is used to calculate the steady-state target opening of TVA. Through pre-control, the actual intake flow or pressure after intercooling can better track the target intake flow or pressure after intercooling, so as to further control TVA.

[0024] 2. Calibration of pressure closed-loop con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com