Goose egg incubation device

A technology for goose eggs and incubators, applied in poultry incubators, applications, poultry industry and other directions, can solve problems such as low work efficiency, falling, broken goose eggs, etc., to improve work efficiency, reduce hatching costs, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

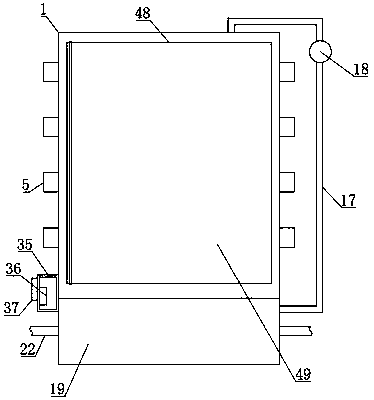

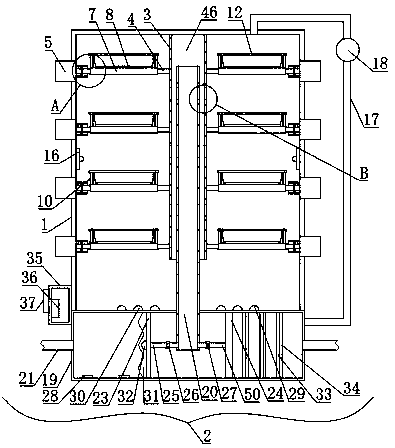

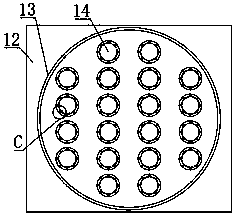

[0024] Example. A kind of goose egg hatching device, constitutes as Figures 1 to 8 As shown, an incubator 1 is included, and a temperature regulating device 2 is connected to the bottom surface of the incubator 1; a support rod 3 is arranged in the middle of the top surface of the incubator 1, and a plurality of evenly distributed rotating rods 4 are arranged on the side of the support rod 3 One end of each rotating rod 4 is connected with a rotating motor 5, and one side of each rotating motor 5 is provided with a timing device 6; each rotating rod 4 is provided with a mounting disc 7, and each mounting disc 7 The middle part of the top surface is provided with an upper hatching tray 8; the edge of each upper hatching tray 8 upper surface is provided with a number of reflectors 9 distributed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com