Double rope climbing hoist

A hoist and climbing technology, which is applied in the field of hoisting equipment, can solve the problems of impact, regret, and safety device damage, and achieve the effect of simplifying the structure of the carrier and improving the safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

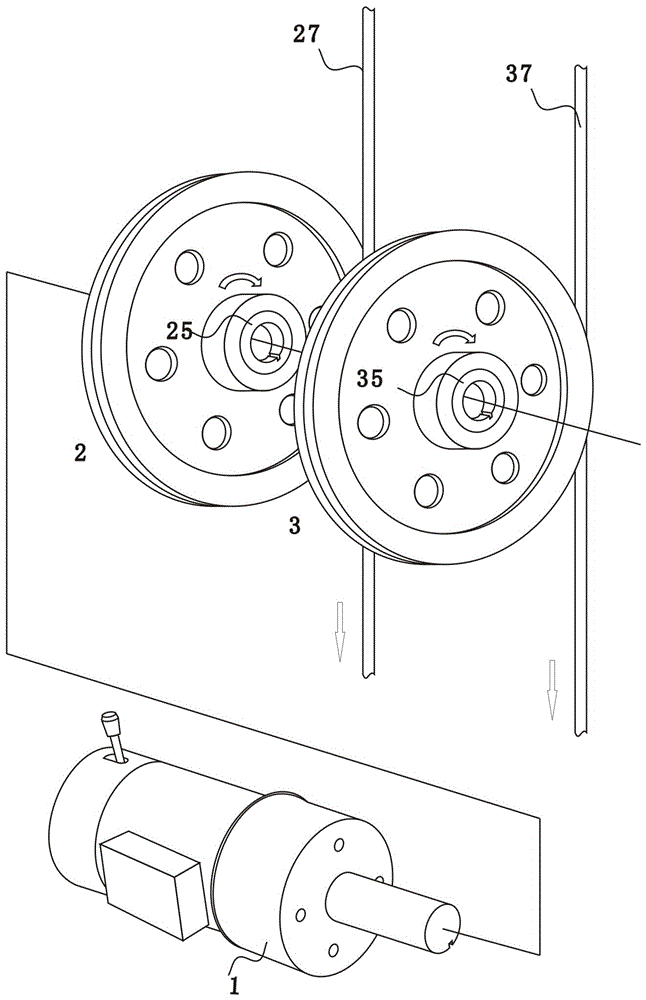

Embodiment 1

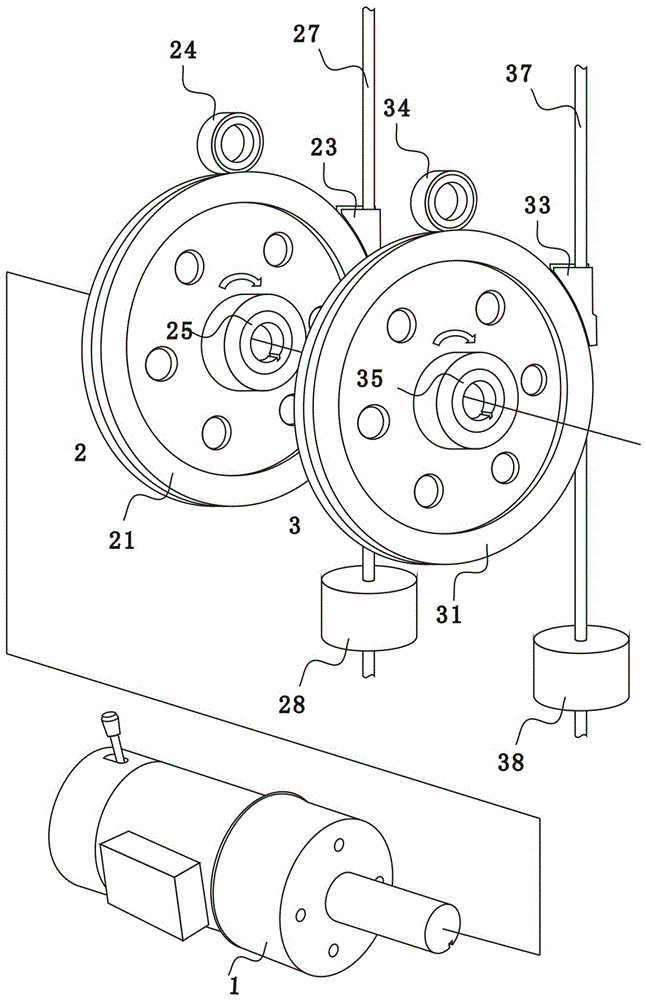

[0044] Embodiment 1 is a type winding rope, gravity pulling structure, as figure 2 Shown: among the figures, the first rope winding mechanism (2) includes the first sheave (21), the first rope divider (23) and the first rope pressing device (24), and the first rope (27) is in the first The winding rope mode on the sheave (21) is a shape, and the first rope divider (23) is installed at the rope intersection, and the first rope pressing device (24) is installed on the top of the rope divider, and the first rope (27) The first weight (28) is suspended from the bottom of the suspension, and the first sheave (21) is coupled with the driving mechanism (1) through the first overrunning clutch (25).

[0045] The second rope winding mechanism (3) of the double-rope hoisting system has the same structure as the first rope winding mechanism (2), and the corresponding shaft-mounted components in the two mechanisms are coaxially installed, and will not be repeated here.

[0046] The work...

Embodiment 2

[0047] Embodiment 2 is a type winding rope, traction pulling structure, as image 3 Shown: in the figure, the first rope winding mechanism (2) includes the first sheave (21), the first rope divider (23) and the first rope pressing device (24), and also includes the first Additional sheave (22) and transmission mechanism, the winding rope mode of the first rope (27) on the first sheave (21) is a type shape, and the first rope divider (23) is installed in the rope intersection, at the The first rope pressing device (24) is installed on an additional sheave (22), the first sheave (21) is connected with the drive mechanism (1) through the first overrunning clutch (25), and the first sheave (22) passes through The first additional overrunning clutch (26) and the transmission mechanism are connected with the drive mechanism (1).

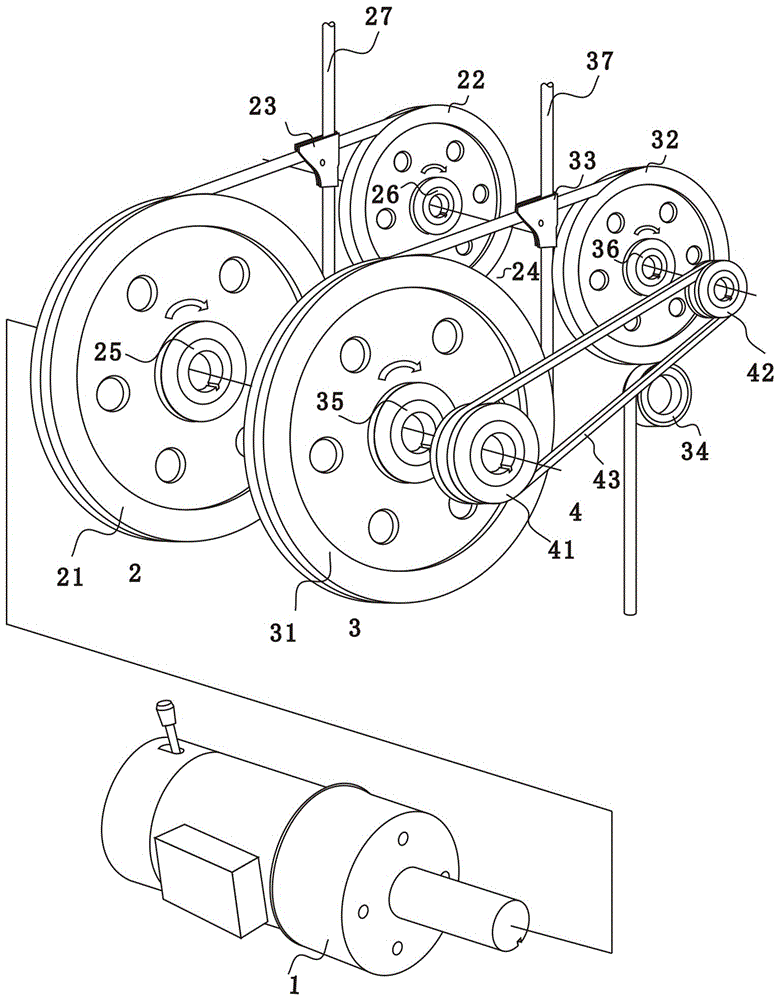

[0048] As a preferred solution, the transmission mechanism adopts a belt transmission mechanism (4), which includes a driving pulley (41), a driven pulle...

Embodiment 3

[0051] Embodiment 3 is a type coiling rope, rope-retracting type traction pulling structure, such as Figure 4 Shown: the difference between this embodiment and embodiment 2 is that the first additional sheave (22) adopts a drum structure as a rope take-up wheel, and it winds up the first rope (27) below the first sheave (21) Wherein; described transmission mechanism comprises belt transmission mechanism (4), and it comprises driving pulley (41), driven pulley (42) and transmission belt (43), and its transmission ratio is to make the first additional sheave (22) The rotary linear speed is greater than the first sheave (21); the transmission mechanism also includes a first additional overrunning clutch (26), whose direction is combined when the hoist rises, and the drive mechanism (1) drives the first additional sheave (22 ) turns in the direction of the arrow in the figure; the hoist is separated when it descends, and the driving mechanism (1) and the first additional sheave (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com