Patents

Literature

48results about How to "Achieve independent rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

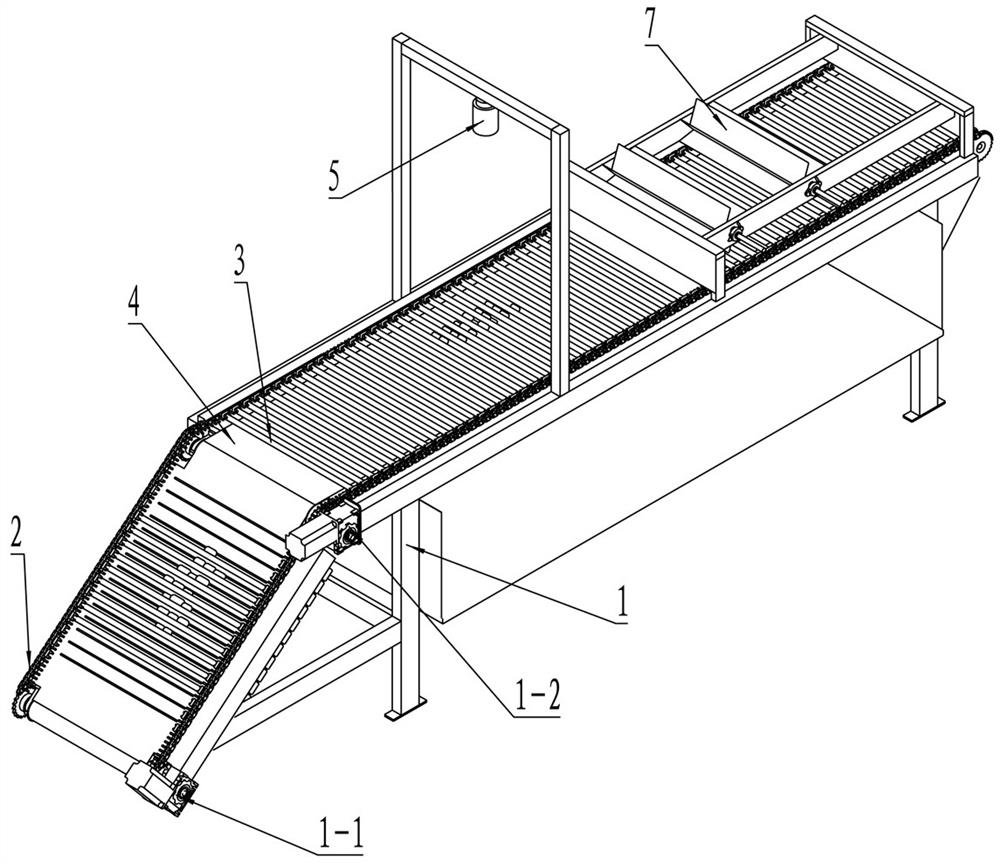

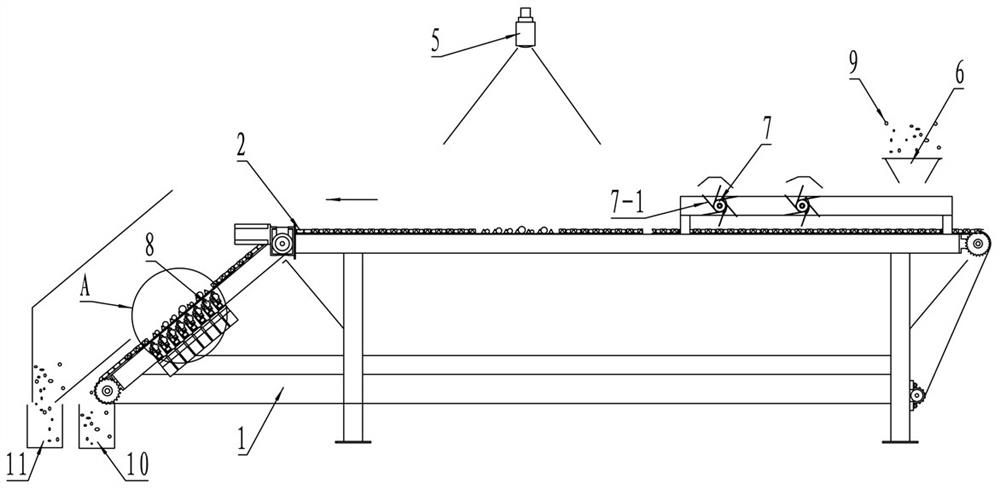

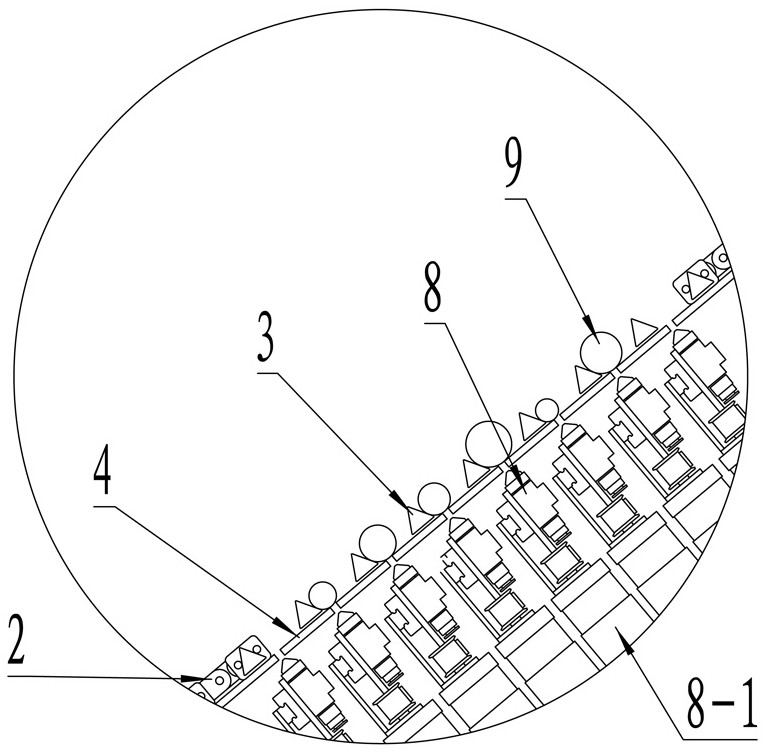

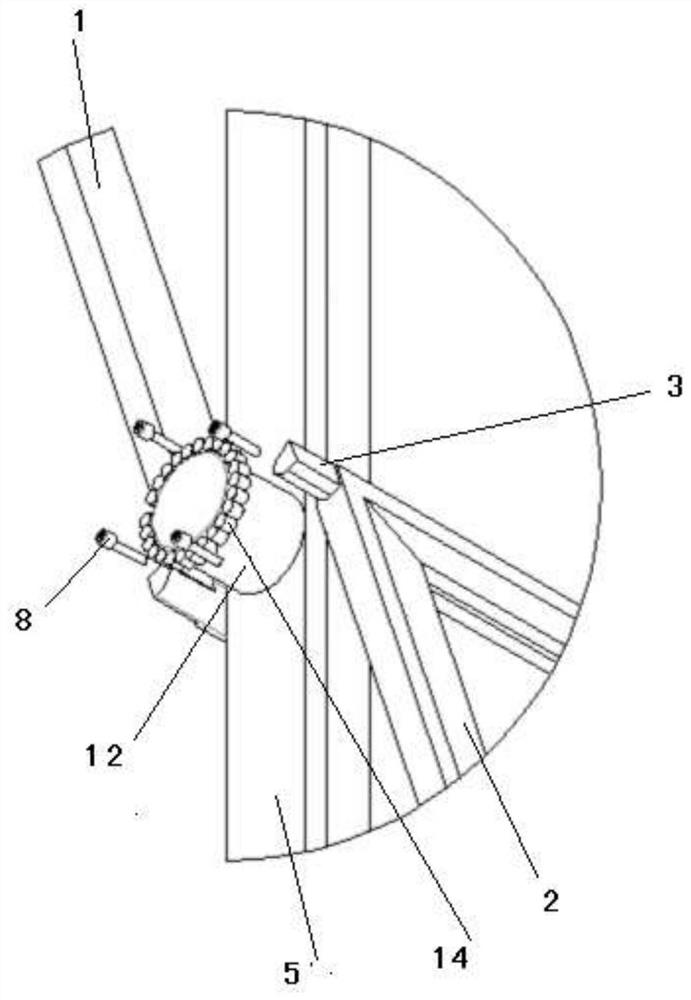

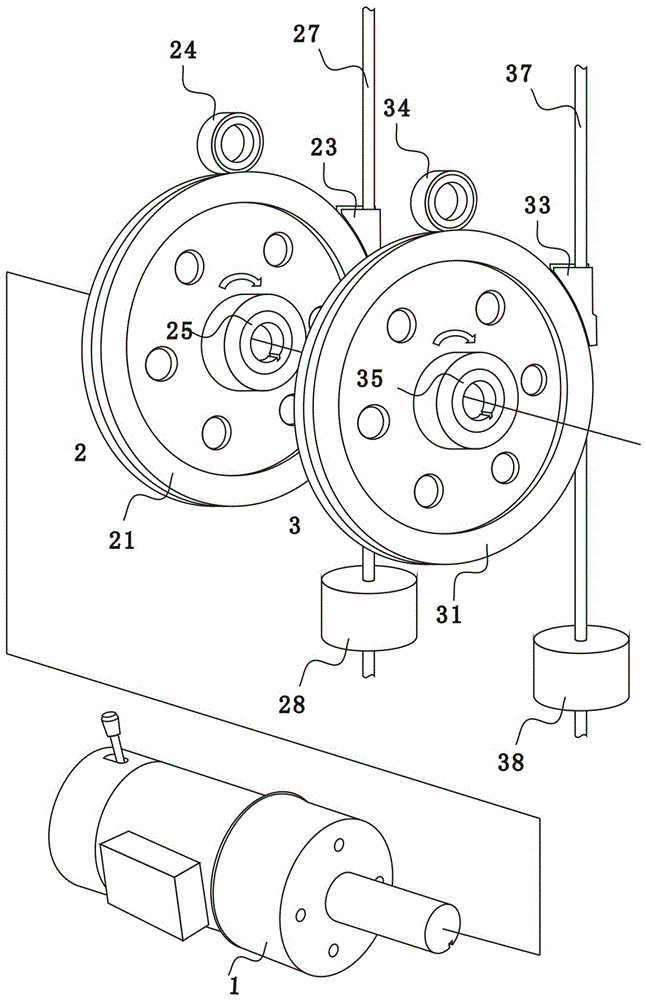

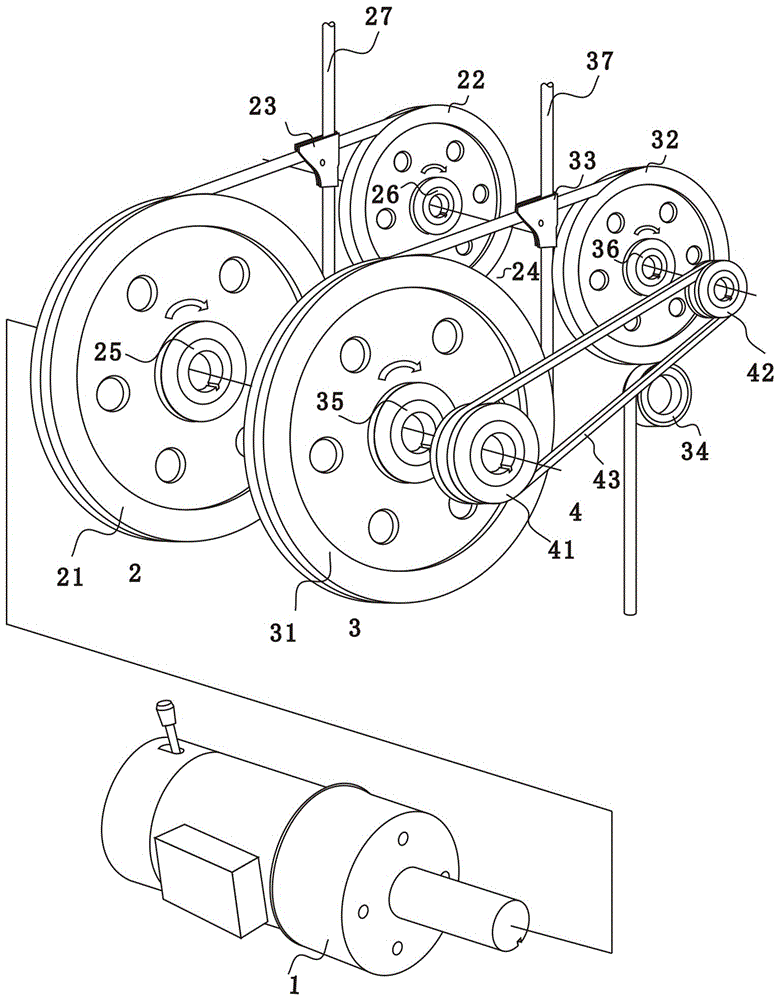

Intelligent silkworm cocoon sorting method

PendingCN113182203AImplement automatic detectionAchieve independent rotationSortingFlywheelIndustrial engineering

The invention discloses an intelligent silkworm cocoon sorting method, which comprises the step of sorting silkworm cocoons by using three intelligent silkworm cocoon sorting machines, and the sorting method comprises the following steps that firstly a batch of bonded silkworm cocoons falling from a silkworm cocoon funnel are pushed away through a rotating flywheel, and the silkworm cocoons are paved on a push rod; silkworm cocoons falling on the push rod are automatically scattered under the action of the shape of the push rod, a chain conveying chain, a belt conveying belt and flexible blades of the flywheel and rotate back and forth, and then complete information of all surfaces of each silkworm cocoon is collected and judged through a silkworm cocoon image collector; and the silkworm cocoons judged to have defects are sucked by a suction device and then placed into an unqualified product box on one side, the defective silkworm cocoons which are not sucked rapidly are blown up by a pneumatic blowing nozzle and fall into the unqualified product box far away, and the silkworm cocoons judged to have no defects obliquely and downwards move to the tail end along the conveying belt and fall into a qualified product box. According to the intelligent silkworm cocoon sorting method provided by the invention, the problems that an existing silkworm cocoon sorting machine is poor in detection reliability and silkworm cocoon sorting reliability can be solved.

Owner:LIUZHOU CHENGMING TECH CO LTD

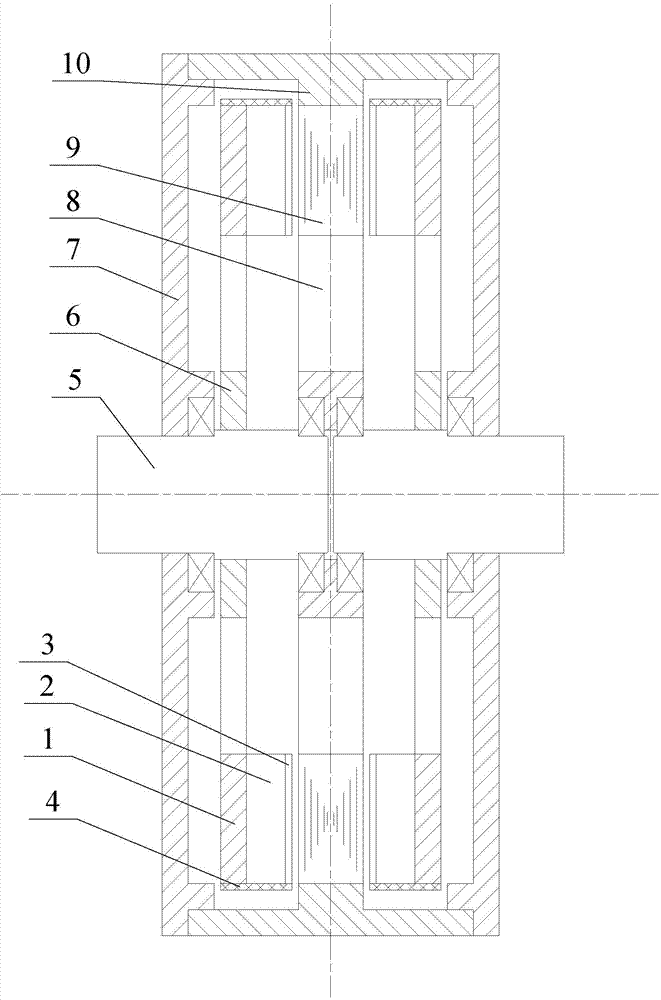

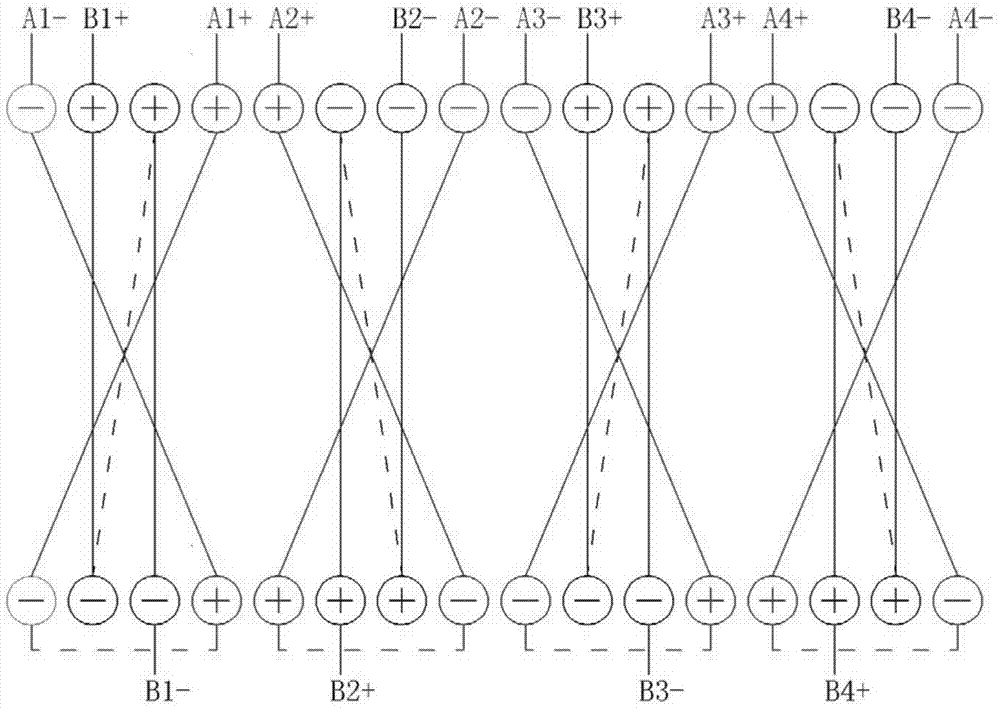

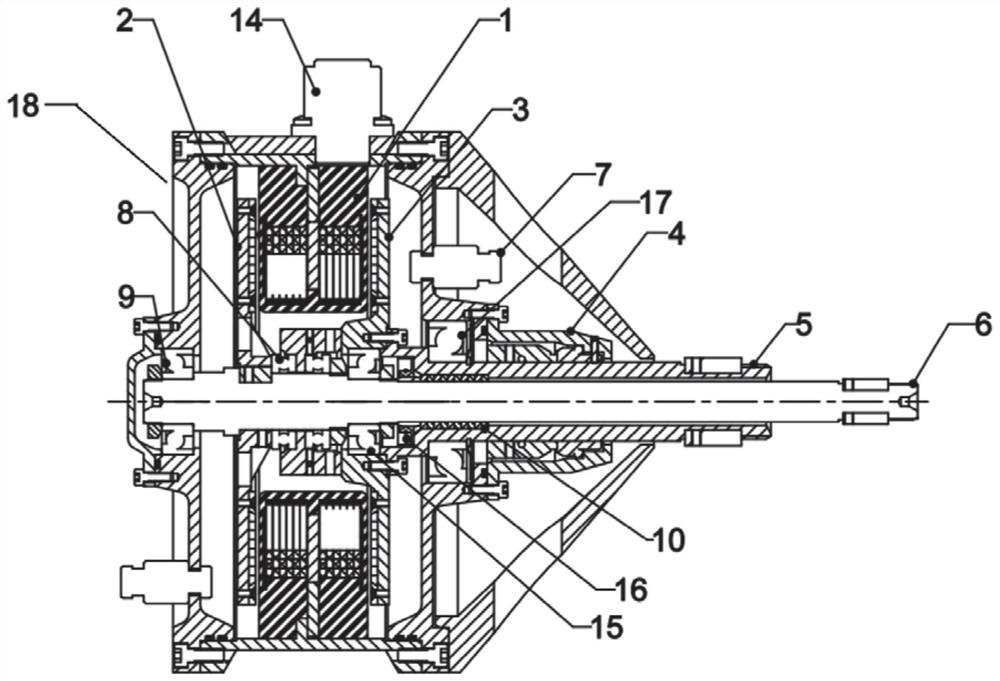

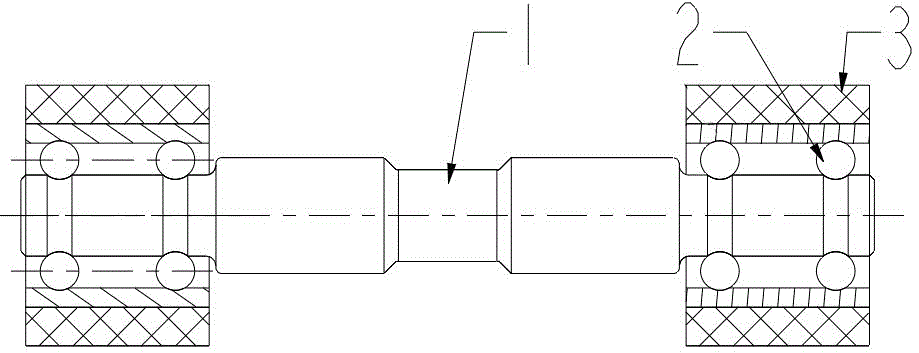

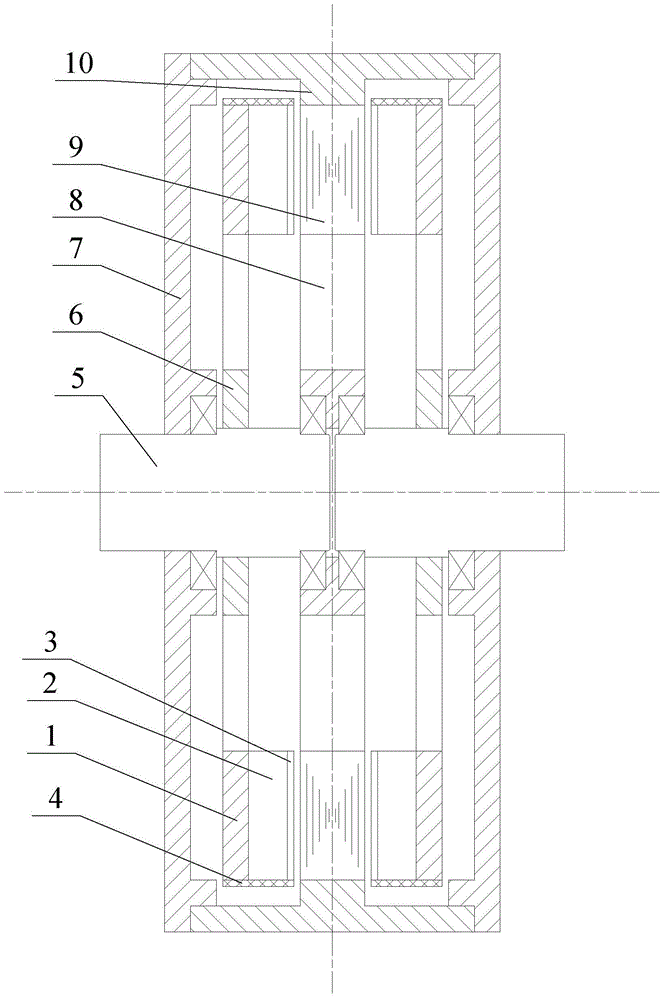

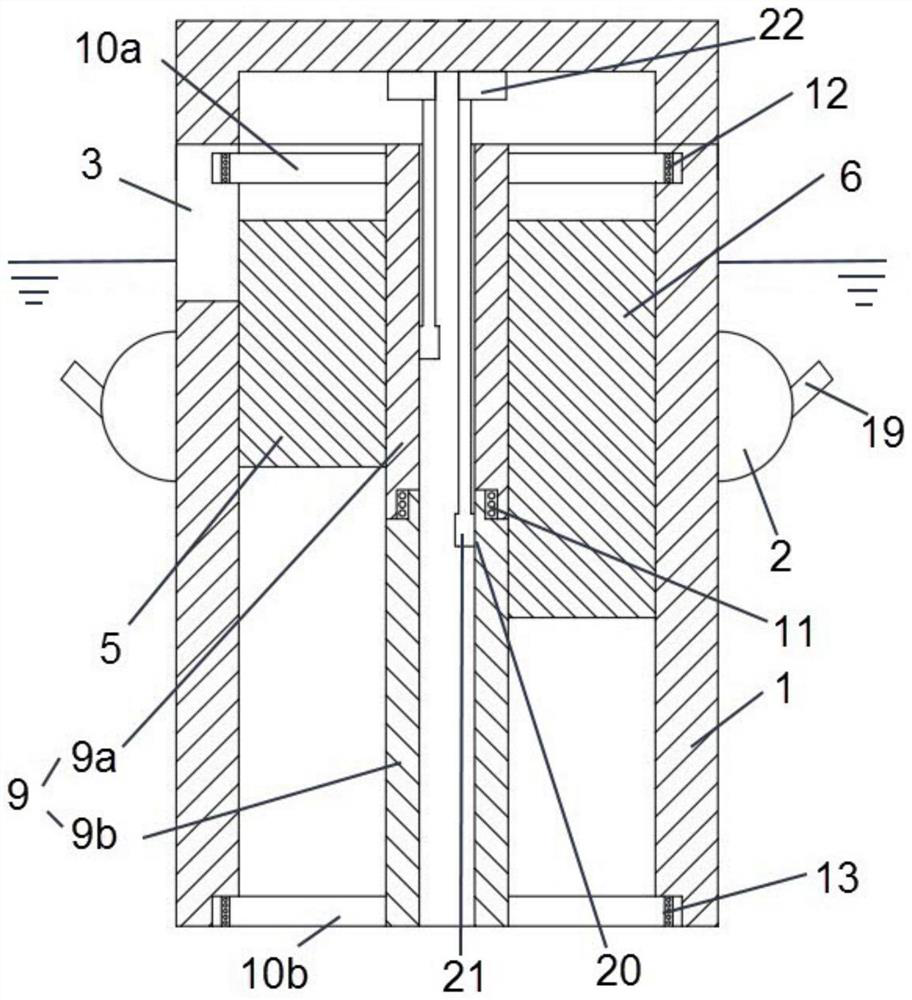

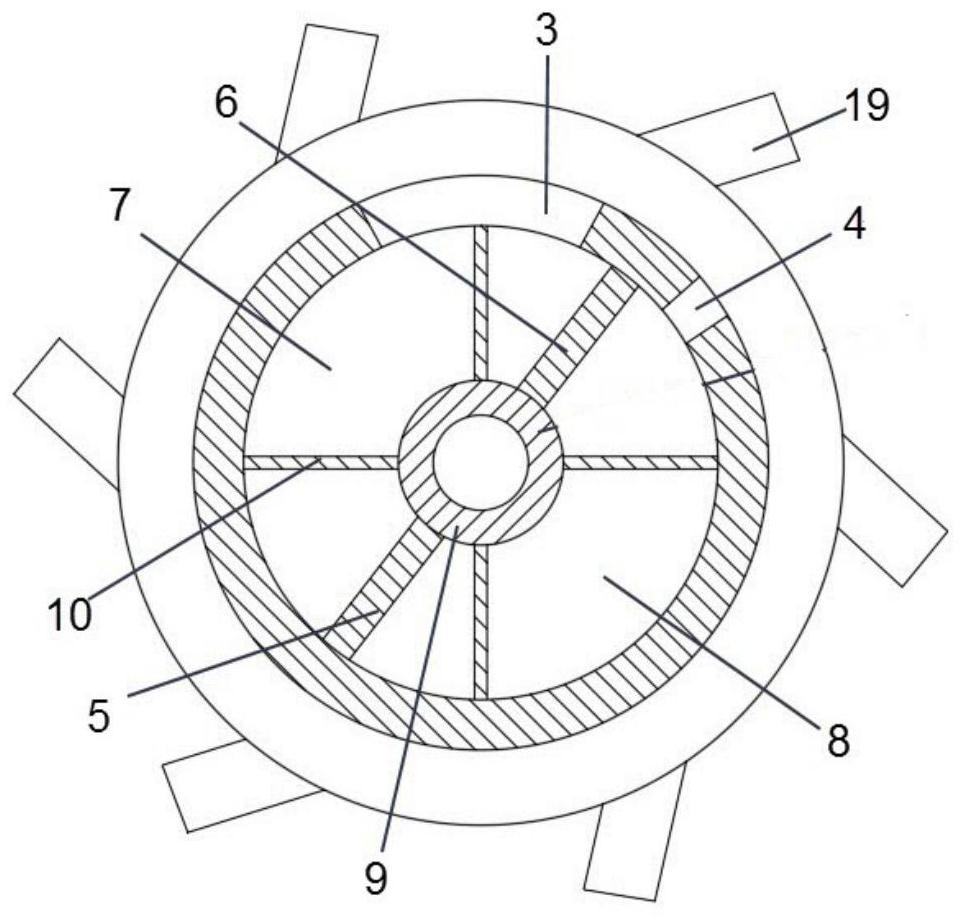

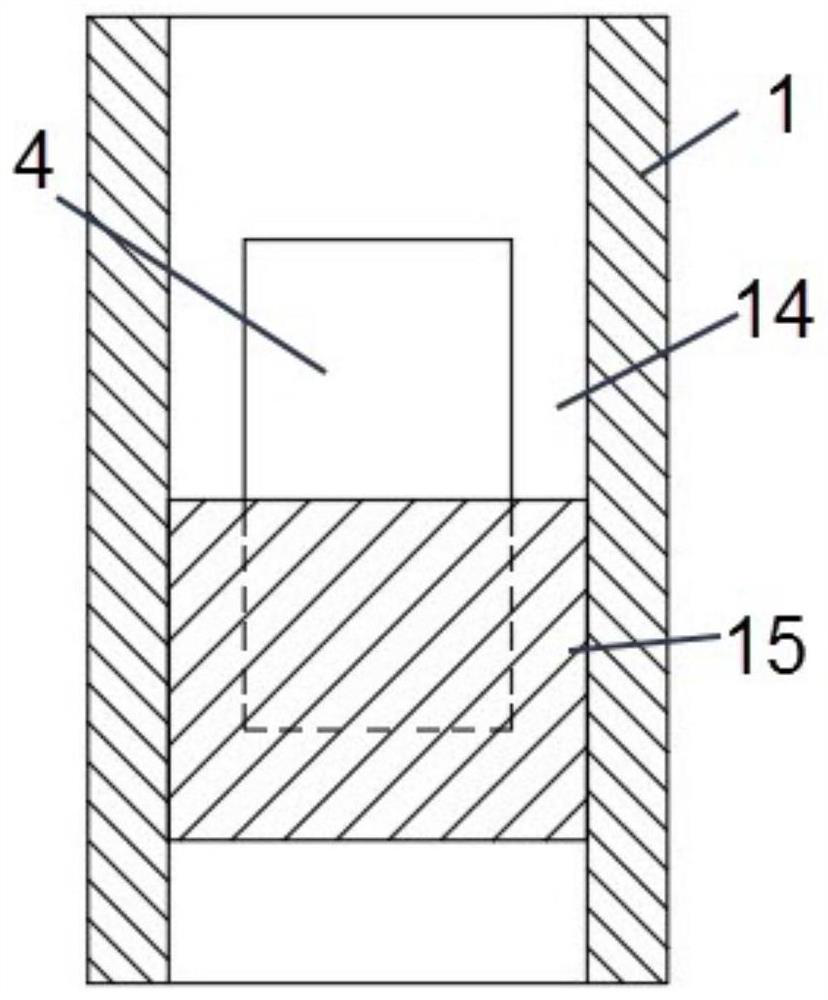

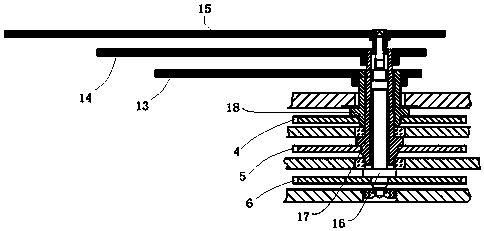

Axial-field permanent magnet compensated impulse generator with double contra-rotating rotors

ActiveCN104734438AReduce torque shockReduce system sizeDynamo-electric machinesPhysicsElectromagnetic torque

The invention relates to an axial-field permanent magnet compensated impulse generator with double contra-rotating rotors and belongs to the technical field of an impulse generator. The axial-field permanent magnet compensated impulse generator comprises a left rotor, a stator disc, a right rotor, two end caps and a shell. The left rotor, the stator disc and the right rotor are sequentially arranged in a hollow-square-shaped space formed by the two end caps and the shell along an axial direction. The left rotor along with one of the end caps and the right rotor along with the other end cap are in mirror symmetry on two sides of the stator disc. An air gap is formed between the left rotor and the stator disc, and another air gap is formed between the stator disc and the right rotor. The left rotor comprises a left rotor disc yoke, a left rotor permanent magnet, a left rotor compensation disc, a left rotor bandage, a left rotor shaft and a left rotor support. The stator disc comprises a stator support and a stator disc yoke. The double contra-rotating rotor compensated impulse generator is capable of solving the problem that the sizes of two motors are enlarged due to the fact that the two motors are arranged side by side and enabled to rotate reversely to counteract electromagnetic torque impact generated by the existing impulse generator during discharging.

Owner:HARBIN INST OF TECH

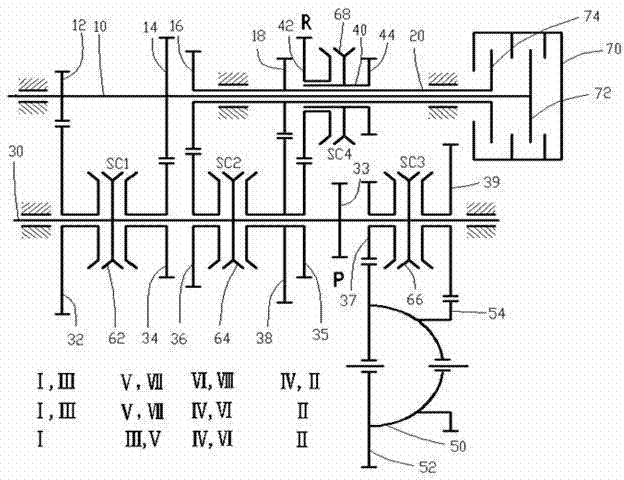

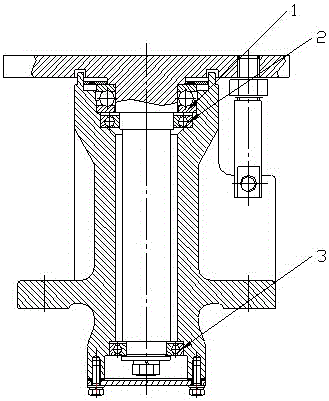

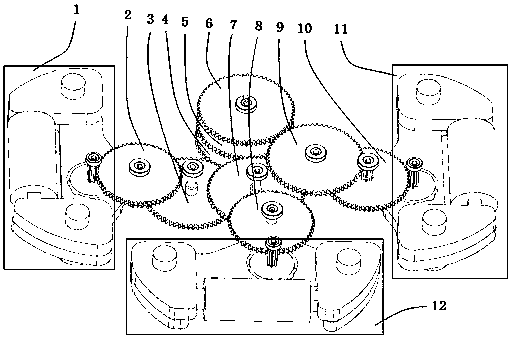

Double-clutch automatic transmission device

ActiveCN103671760AMeet the selection needsImprove comfortToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention relates to a double-clutch automatic transmission device which structurally comprises internal and external input shafts (10, 20) which are coaxially arranged, an auxiliary shaft (30) and a reverse gear shaft (40) which are parallel to the two input shafts, a double-clutch assembly (70), a differential assembly (50), multiple groups of normally engaged gear trains arranged on all the shafts as well as multiple groups of synchronizer devices (62, 64, 66 and 68) which are used for realizing selection of all gears. The double-clutch automatic transmission device can provide eight forward gears at most and a reverse gear, so that the transmission device has more excellent comfort performance and lower oil consumption. As two groups of optional reduction gear trains are adopted, each gear train can realize two different gears, so that one auxiliary shaft and assemblies thereof can be reduced, and the transmission cost is reduced. The double-clutch automatic transmission device has the characteristics of simple structure, large quantity of gears, low cost and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

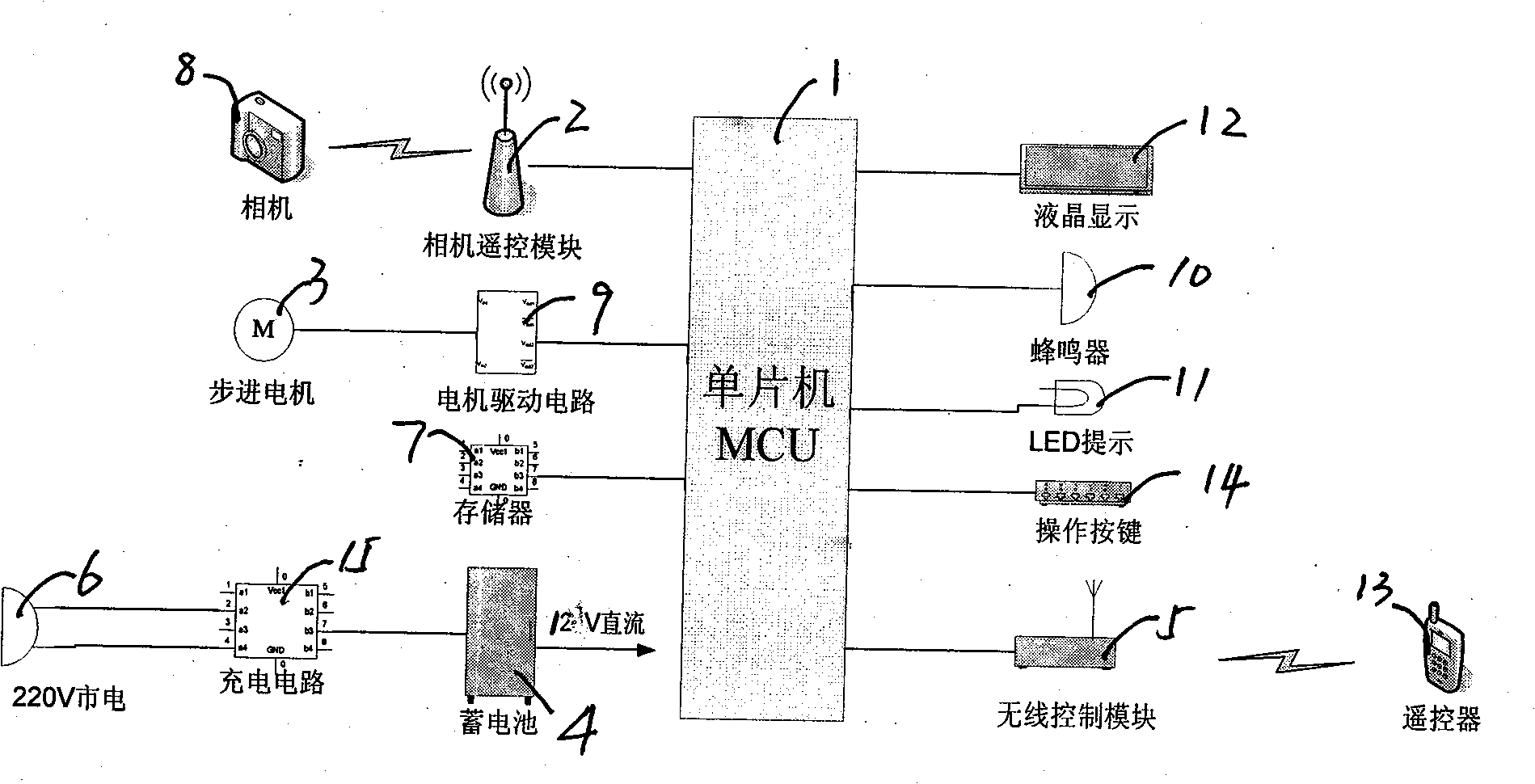

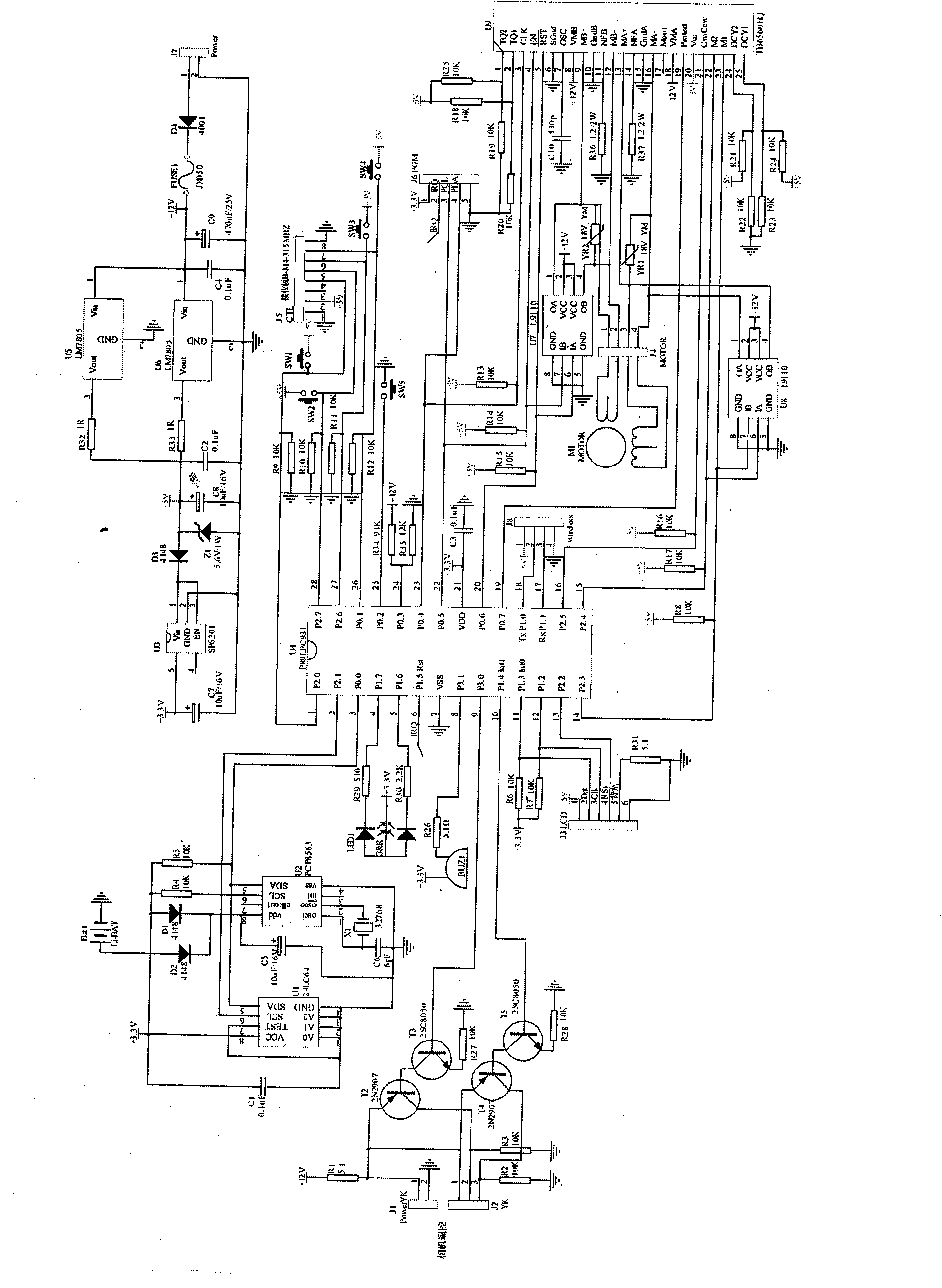

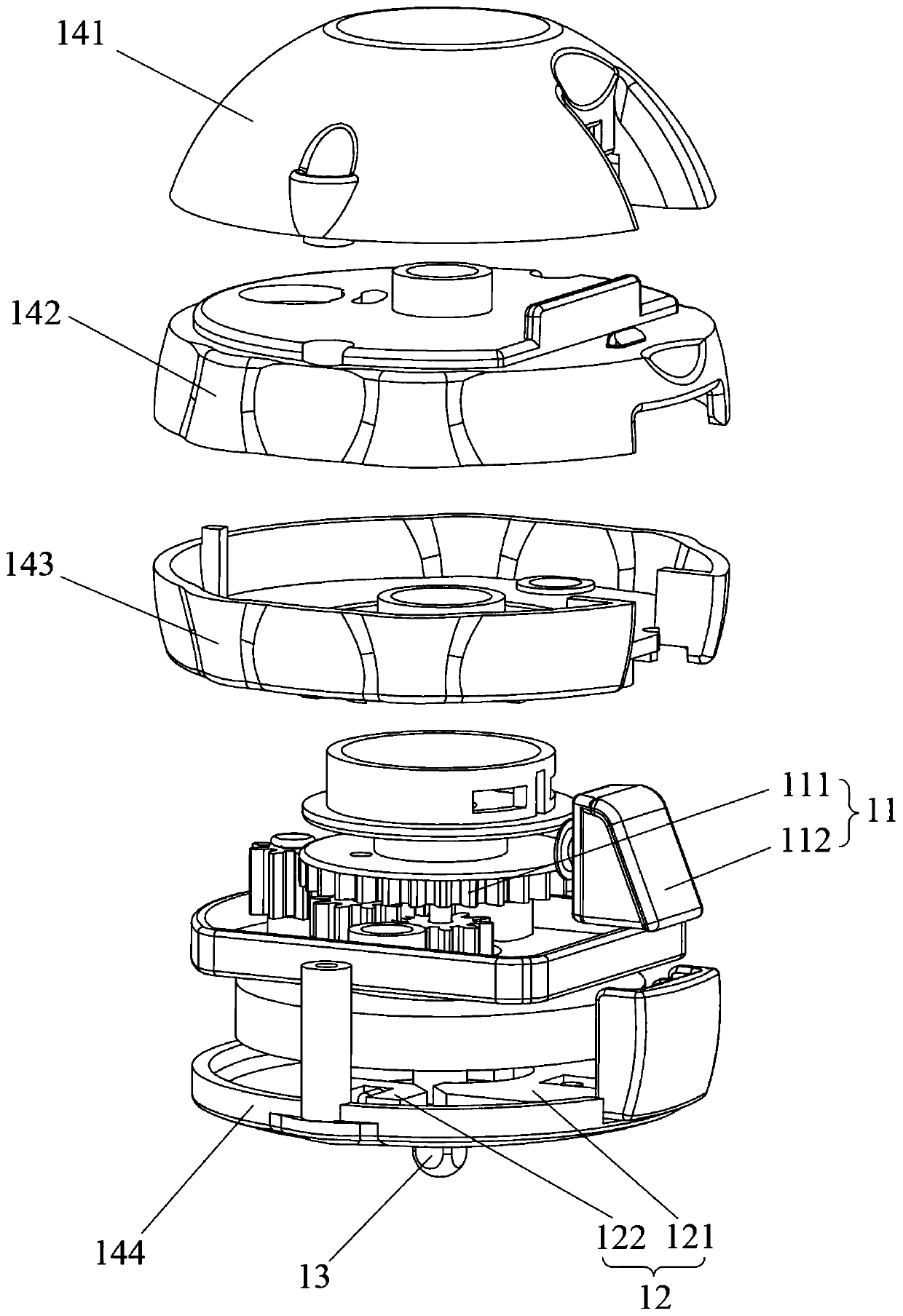

Fully automatic digital panoramic camera rotating base

InactiveCN101556423AAchieve independent rotationFully automatic operationProgramme controlTelevision system detailsDigital cameraDrive shaft

The invention discloses a fully automatic digital panoramic camera rotating base, which relates to digital camera auxiliary equipment, in particular to a camera rotating base leading a digital camera to take pictures during rotation. The fully automatic digital panoramic camera rotating base comprises a single-chip microcomputer, a camera remote control module, a stepper motor, a battery, a wireless remote control module, a camera connecting piece, operation keys and a power source; the digital camera is connected with the camera remote control module in a sensing way; the camera remote control module is connected with the single-chip microcomputer; the single-chip microcomputer is connected with a memory and the wireless remote control module; the wireless remote control module is connected with a remote controller in a sensing way; a power source charging circuit is connected with the battery; the single-chip microcomputer is supplied with power by the battery and the stepper motor is driven by a motor circuit system; the stepper motor drives a transmission shaft connected with a bearing to rotate; the transmission shaft is connected with one end of the camera connecting piece; the other end of the camera connecting piece is connected with a cradle head interface nut of the camera; and the operation keys are connecting with the single-chip microcomputer. The fully automatic digital panoramic camera rotating base has the advantages of simple and reasonable structure, and is particularly applied to fully automatic digital cameras.

Owner:陈祜

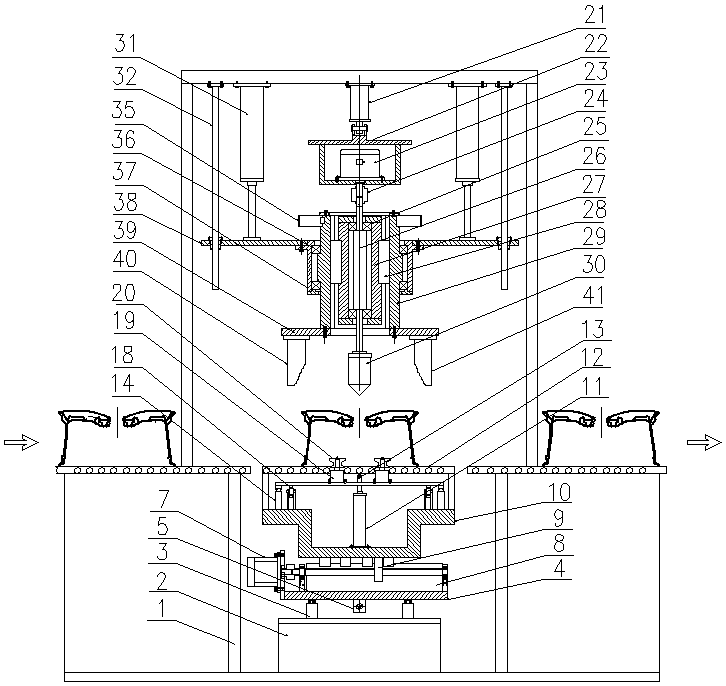

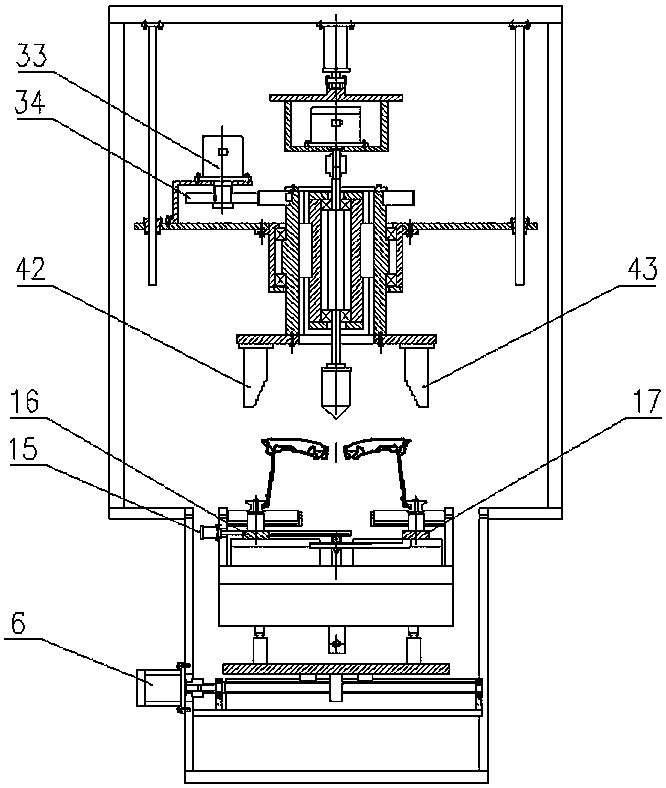

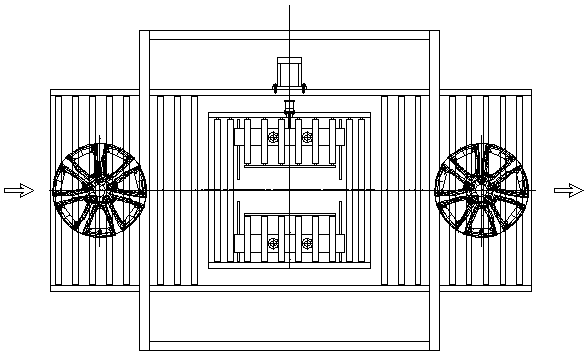

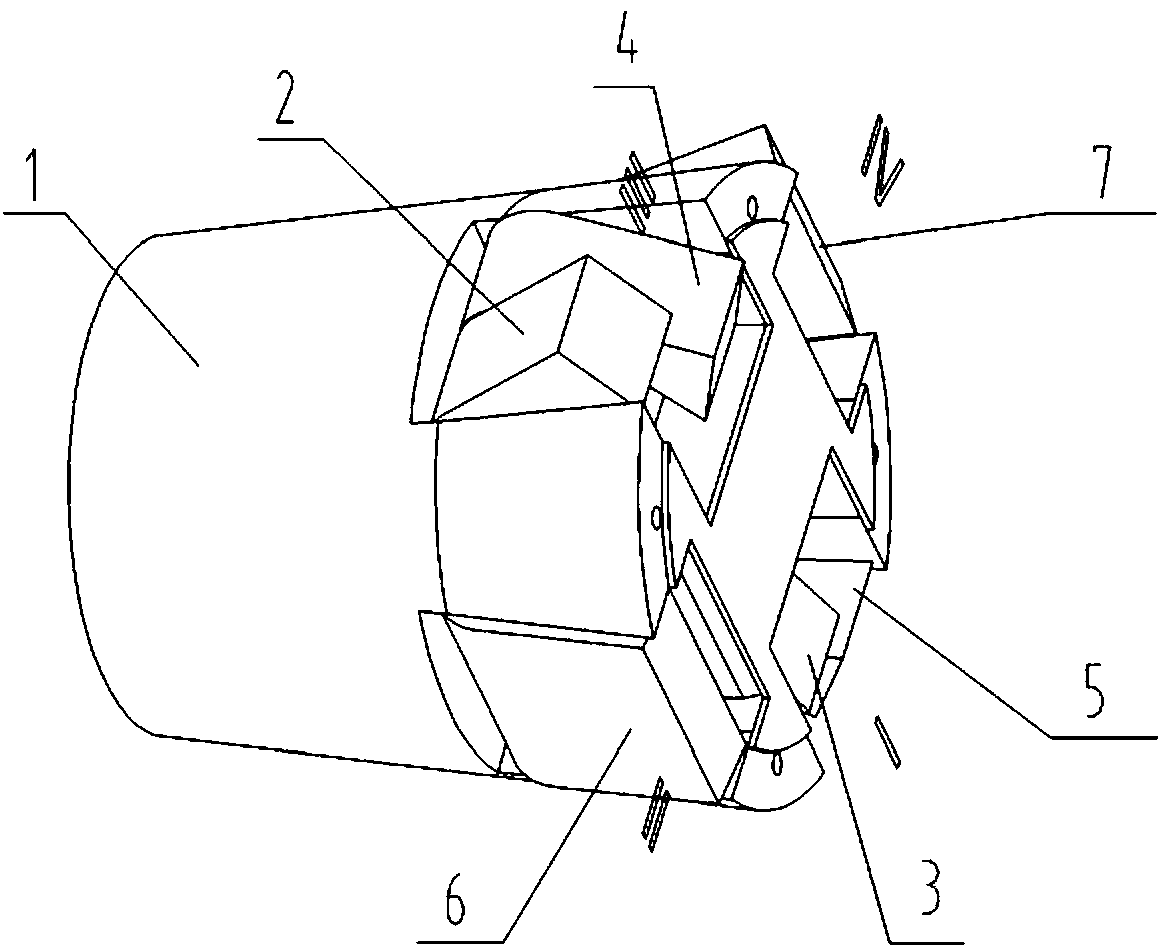

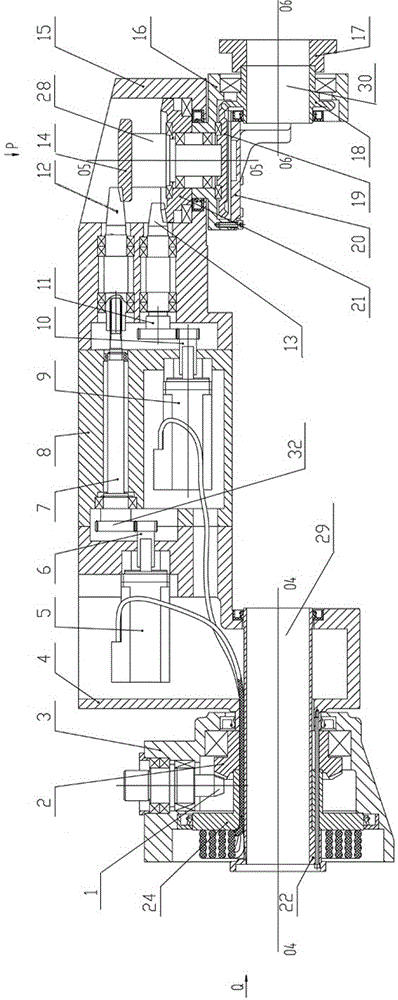

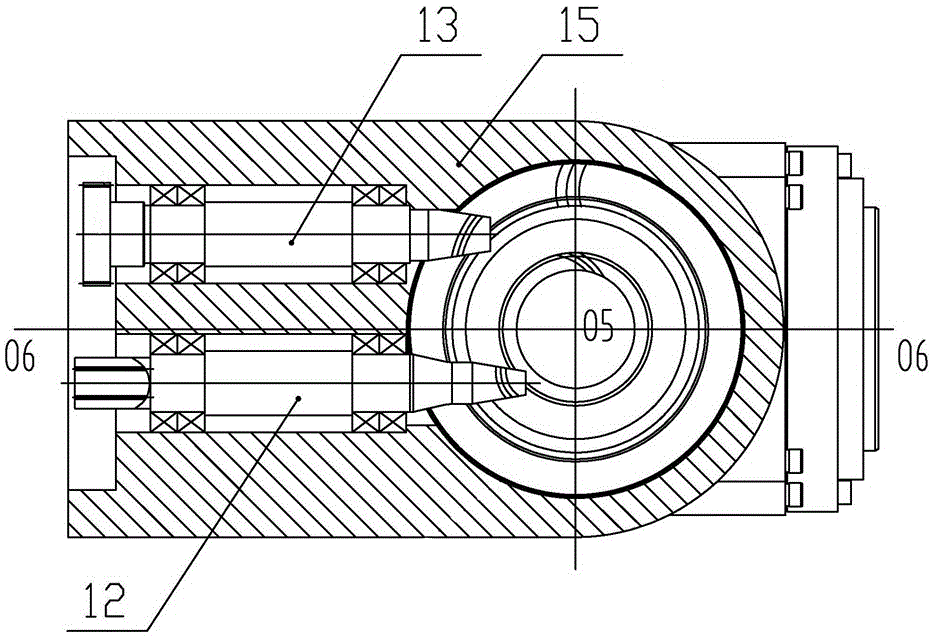

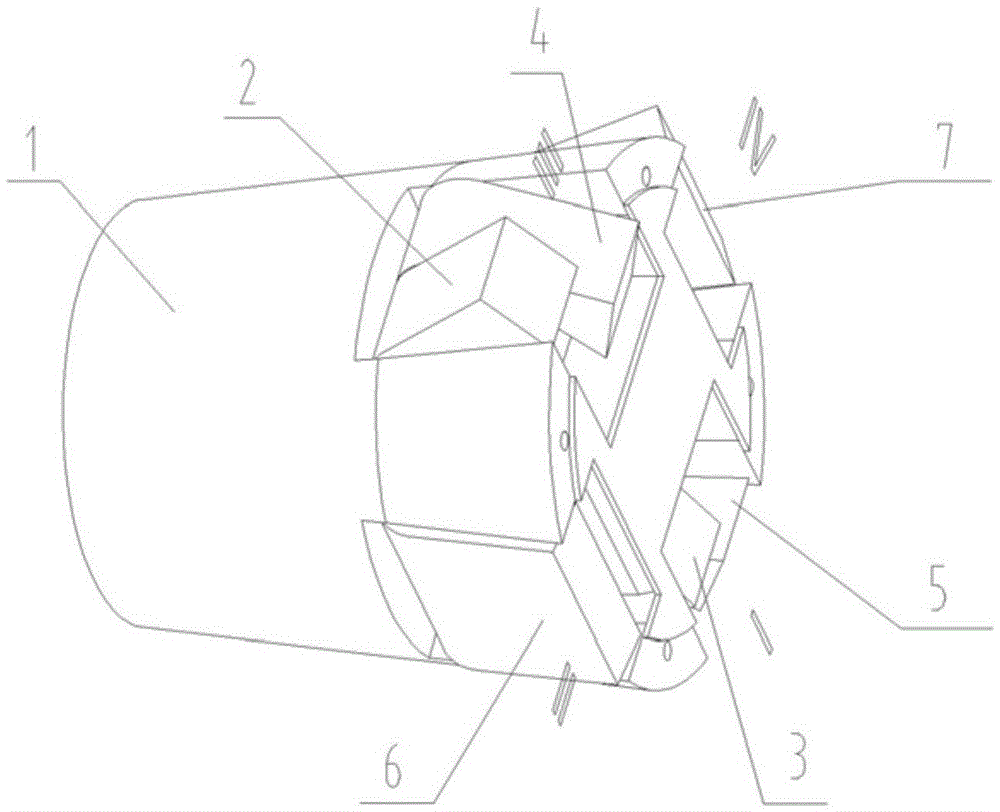

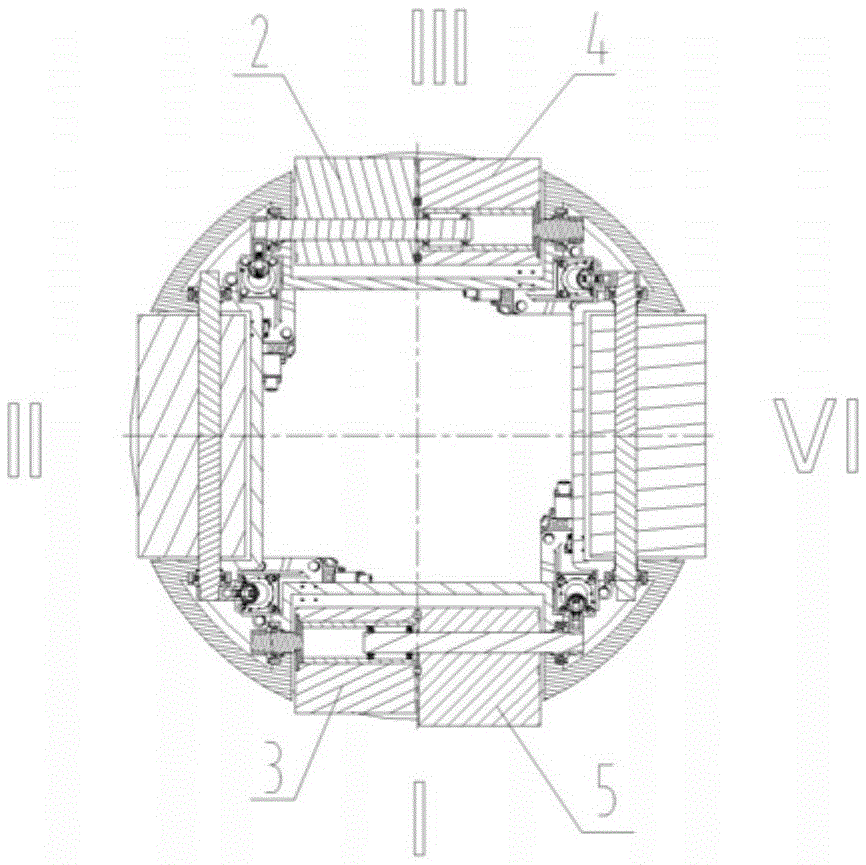

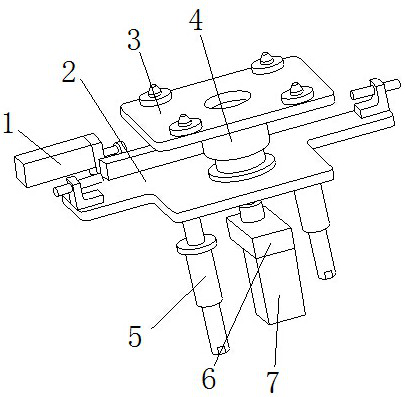

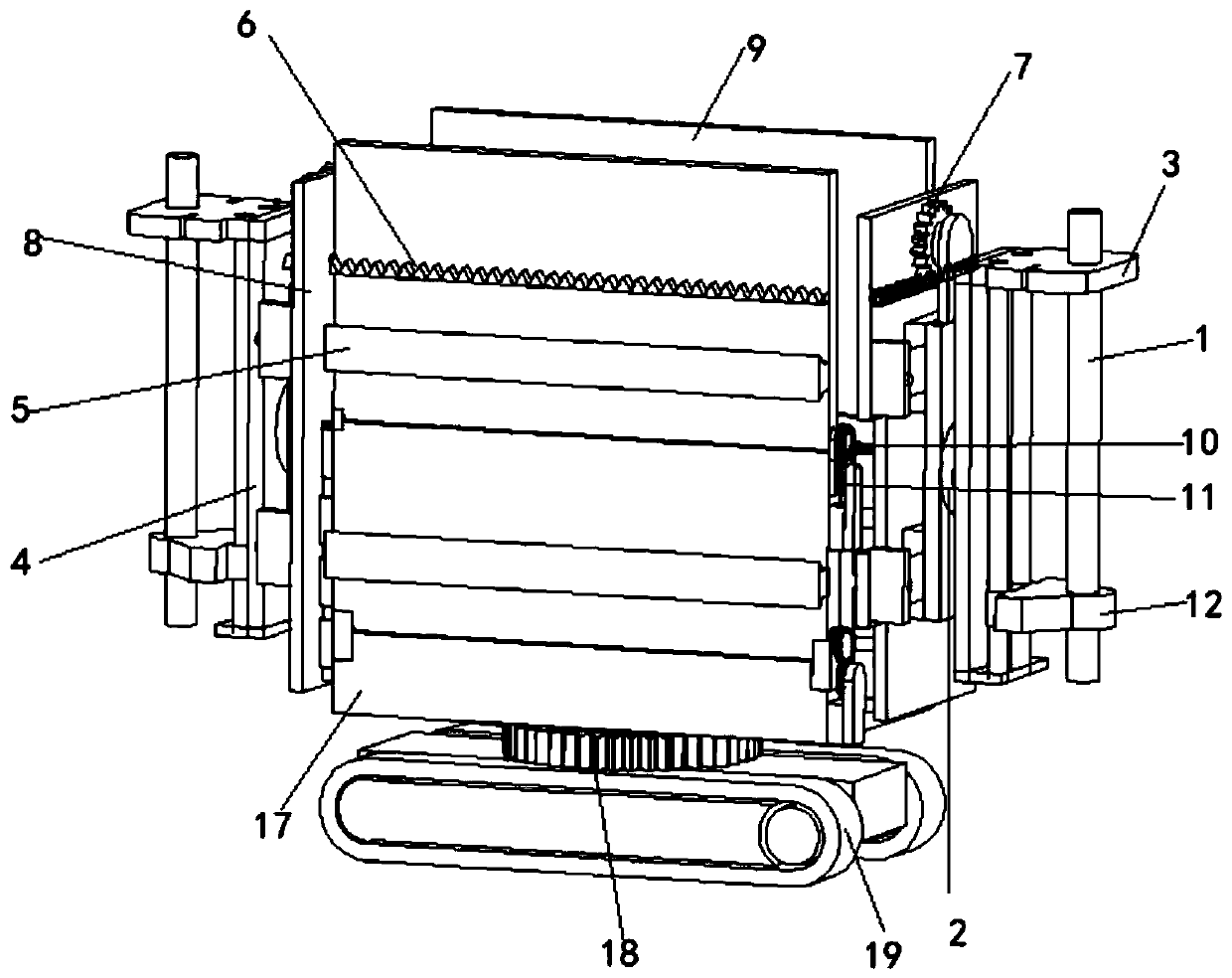

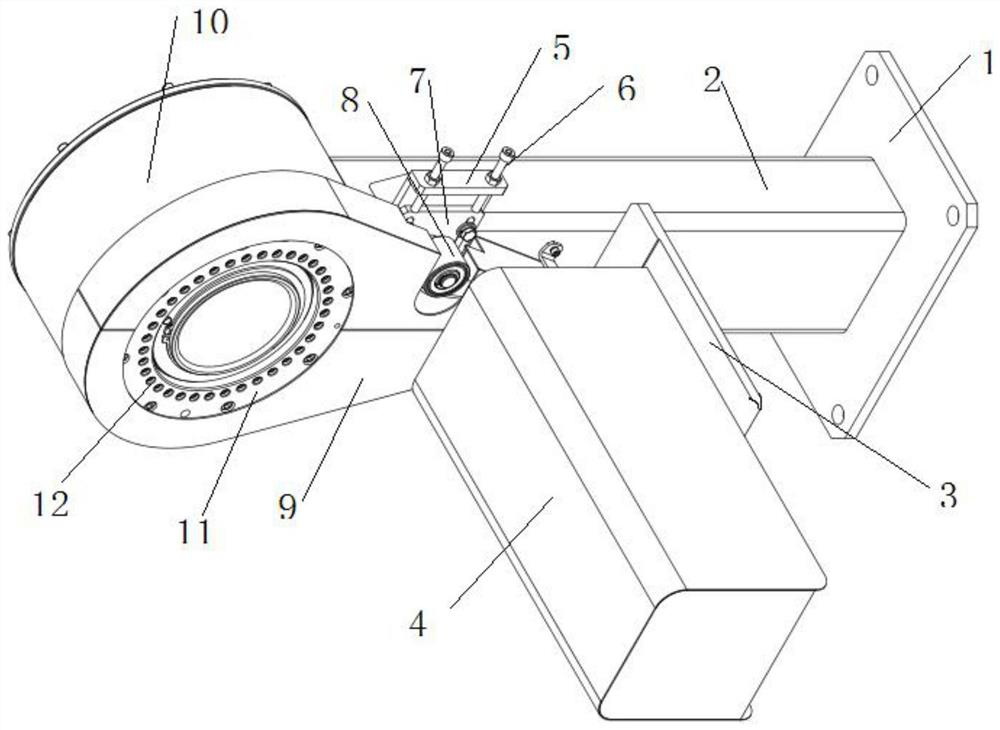

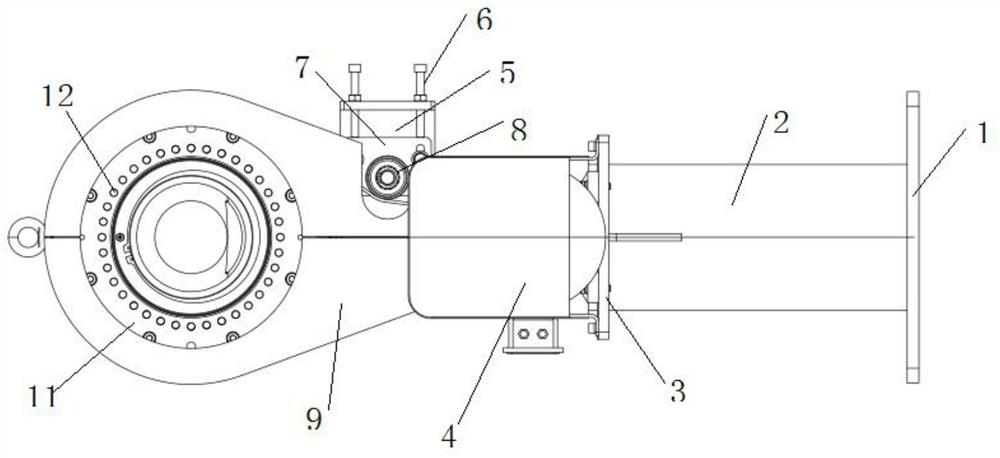

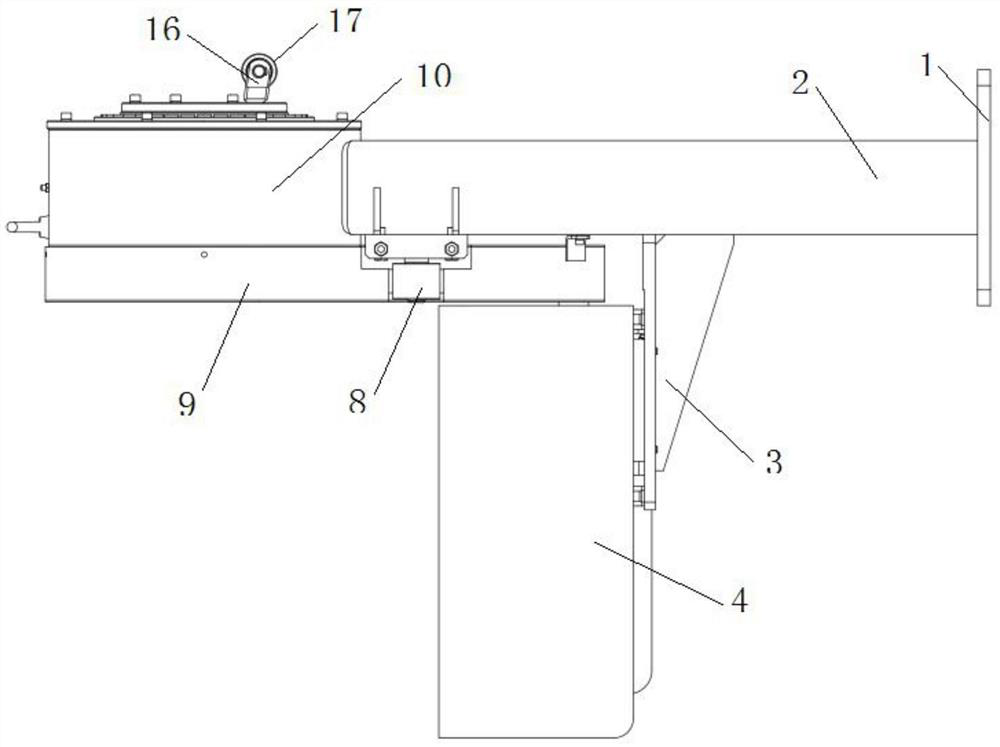

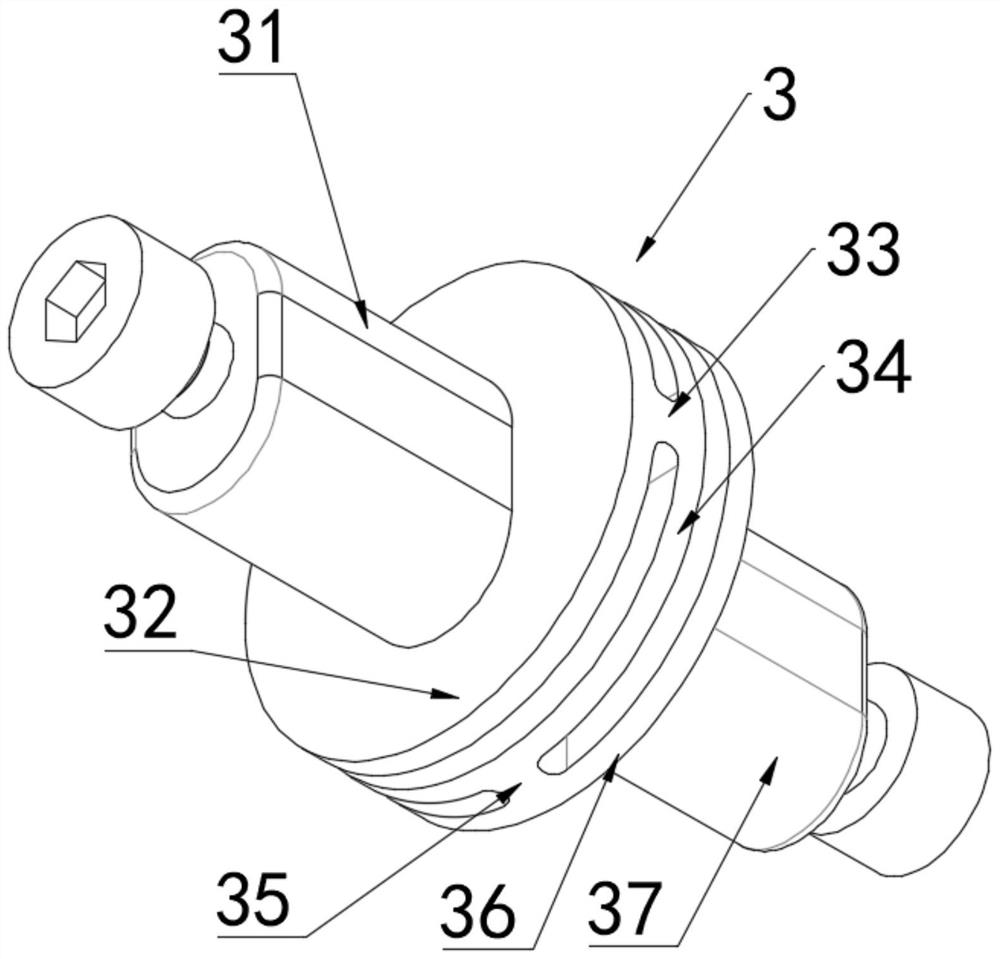

Device for removing wheel tool receiving ridge burrs

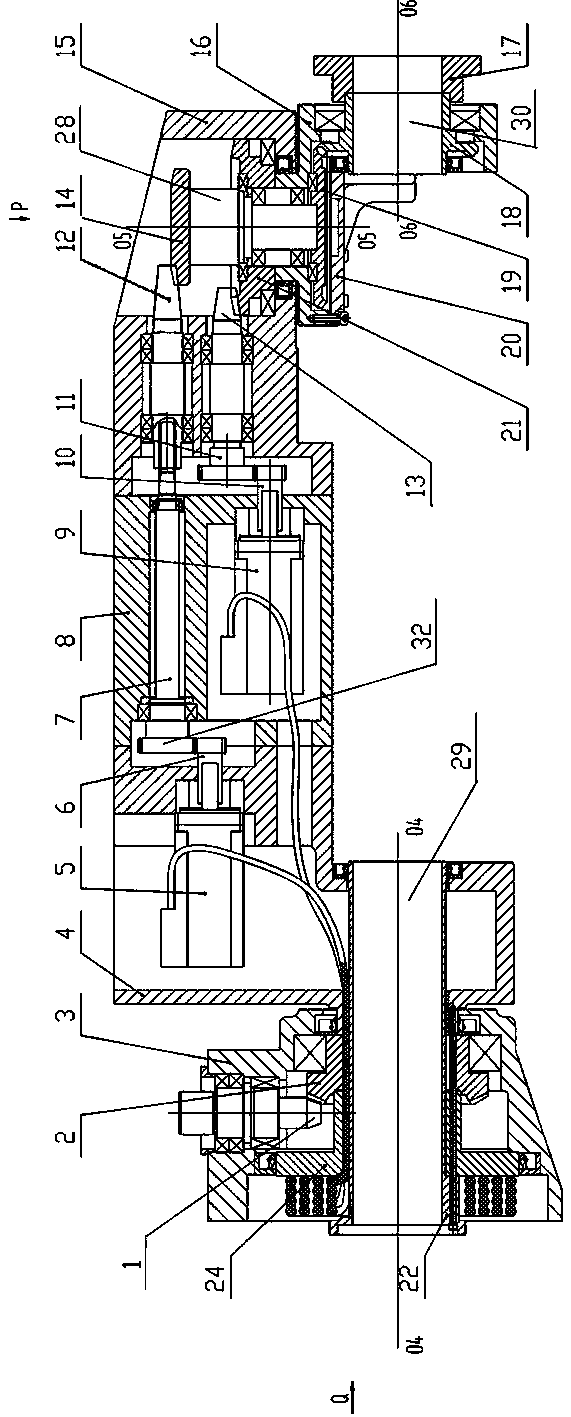

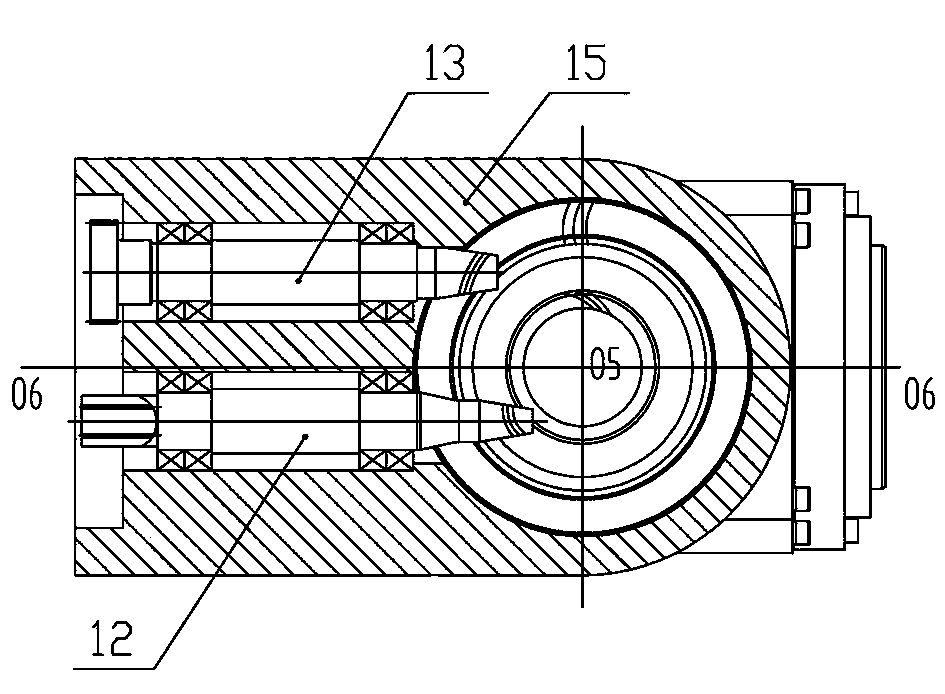

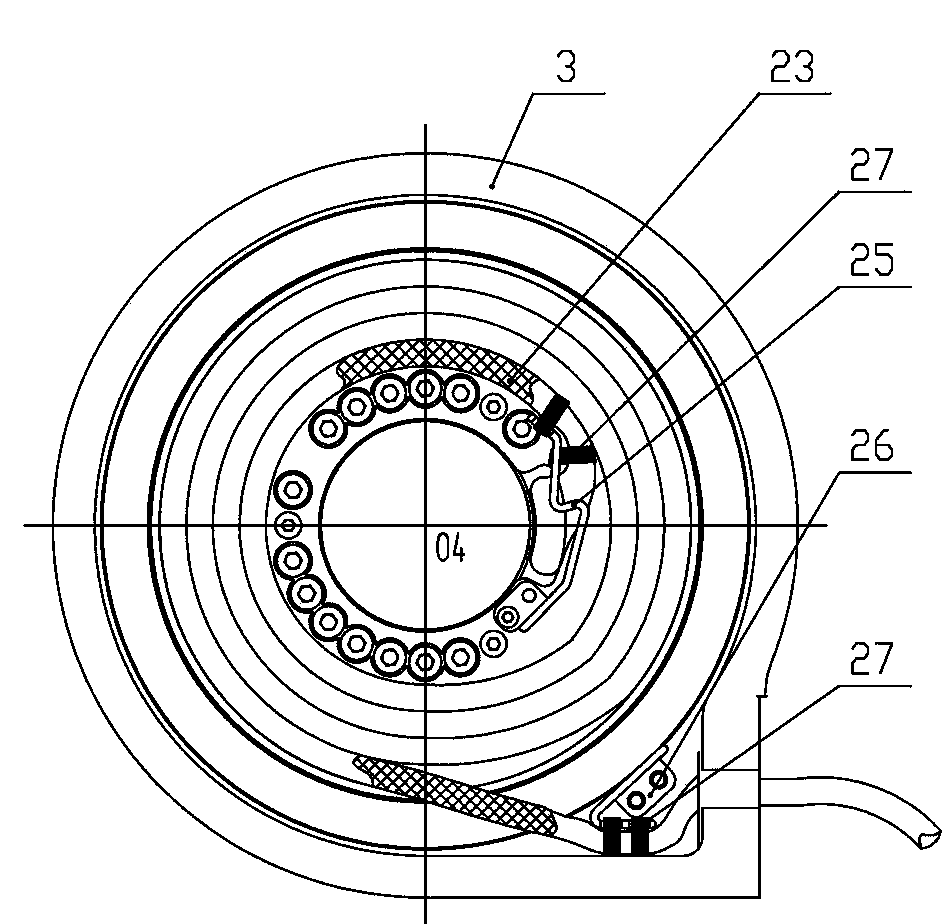

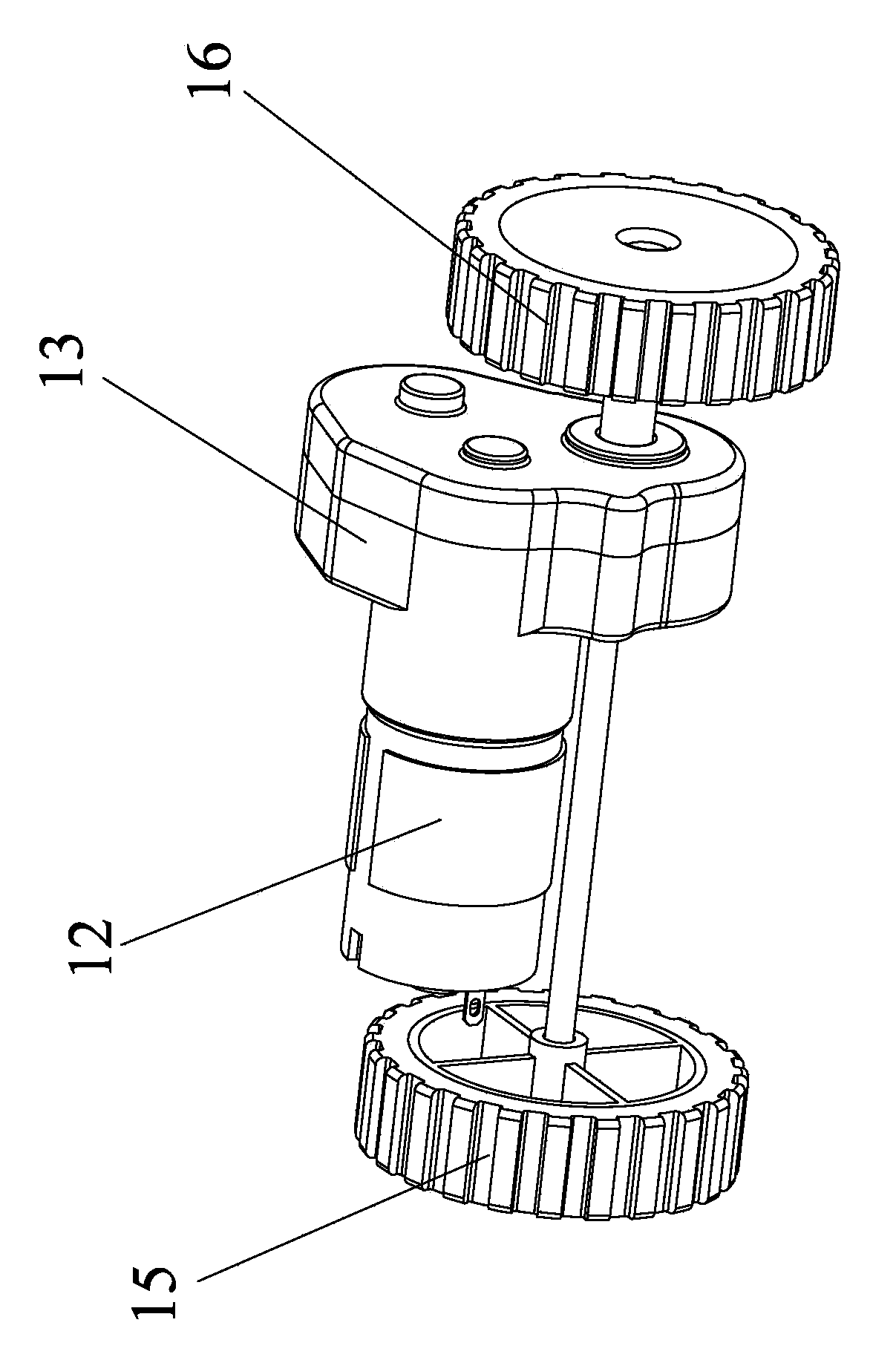

PendingCN108057931AWide versatilityImprove coaxialityEdge grinding machinesAutomatic control devicesBall screwElectric machinery

A device for removing wheel tool receiving ridge burrs is composed of a rack (1), a base (2), a guide rail I (3), a movable plate I (4), a ball screw I (5), a longitudinal motor (6), a transverse motor (7), a guide rail II (8), a ball screw II (9), a movable plate II (10), an electric cylinder (11), a moving roller bed (12), a circle center measuring sensor (13), an inner bearing (25), a shaft (26), a sleeve (27), a guiding key (28), a hollow shaft (29), a ridge cone tool (30), an outer air cylinder (31), a left blade (40), a right blade (41) and the like. By means of the device, outer side wheel edge and cap groove edge tool receiving ridge burrs can be removed at the same time, through inner side and outer side deburring tool integration, the space is saved, inner side and outer side independent feeding and independent rotating are achieved, tools on the inner side and the outer side have higher coaxiality, and the deburring effect is better.

Owner:CITIC DICASTAL

Hollow forearm and wrist structure for low-load industrial robot

The invention discloses a hollow forearm and wrist structure for a low-load industrial robot. The hollow forearm and wrist structure comprises a shaft J4 arranged on an arm base, a second large-speed-ratio hypoid gear shaft arranged in a wrist base, and a shaft J5 motor base. The top and the bottom of the second-large-speed ratio hypoid gear shaft are respectively provided with a second large-speed-ratio hypoid gear and a first bevel gear respectively, and the middle is provided with a fourth large-speed-ratio hypoid gear and a shaft J6 support in a rotating mode. The shaft J6 is arranged in the shaft J6 support in a rotating mode. A second bevel gear is arranged on the shaft J6. The first bevel gear and the second bevel gear are meshed. The shaft J5 motor base is connected with the shaft J6 motor base and the wrist base. A shaft J5 motor and a shaft J6 motor shaft are arranged in the shaft J5 motor base. One end of the shaft J6 motor shaft is connected with the shaft J6 motor, and the other end is provided with a first large-speed-ratio hypoid gear. The first large-speed-ratio hypoid gear and the second large-speed-ratio hypoid gear are meshed. The output shaft of the shaft J5 motor is provided with a third large-speed-ratio hypoid gear. The hollow forearm and wrist structure solves the problem that a transmission line is not distinct in the prior art.

Owner:NANJING ESTUN ROBOTICS CO LTD

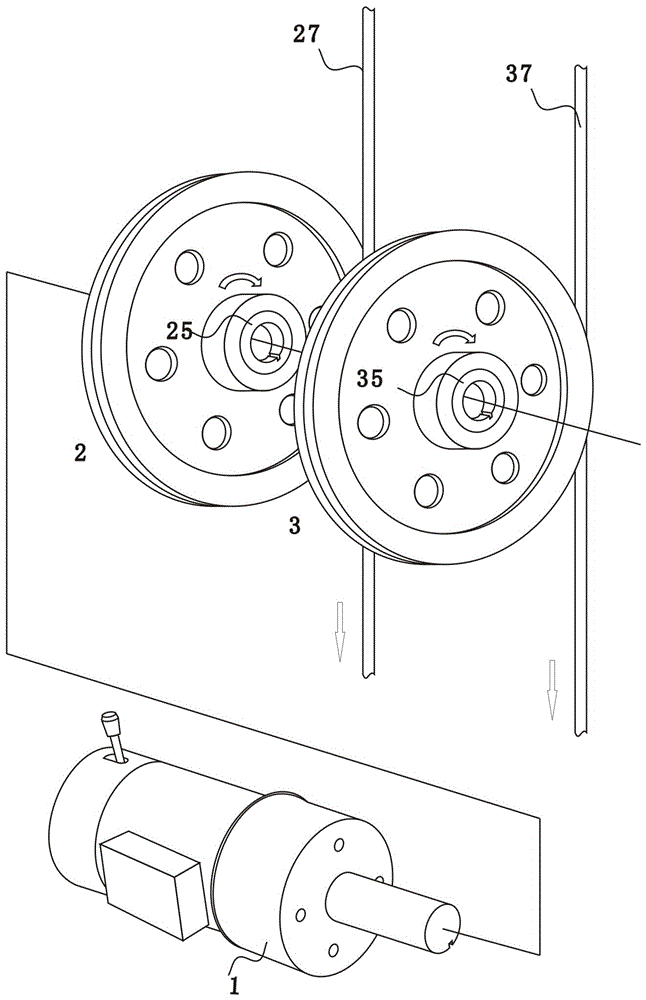

Robot cleaner driving wheel mechanism

InactiveCN103654640ASimple structureStable structureSuction cleanersMachine detailsDrive wheelFree state

The invention discloses a robot cleaner driving wheel mechanism which comprises a motor, a left driving wheel, a right driving wheel and a gear case connected with the motor. A first one-way bearing and a second one-way bearing are arranged in the gear case, and the first one-way bearing and the second one-way bearing both can work in a self-locking state and a free state. Through forward and backward rotation of the motor and control of the first one-way bearing and the second one-way bearing, the left driving wheel and the right driving wheel can rotate in different rotation directions. The robot cleaner driving wheel mechanism is simple in structure, reliable, low in cost, economical and practical. Due to the fact that the two driving wheels can rotate and turn at the same time, the rotation radius is small, resistance is low, and turning is easier. The driving wheel mechanism can be applied to various robot sweepers or dust collectors or similar cleaning machines.

Owner:光荣电业(东莞)有限公司

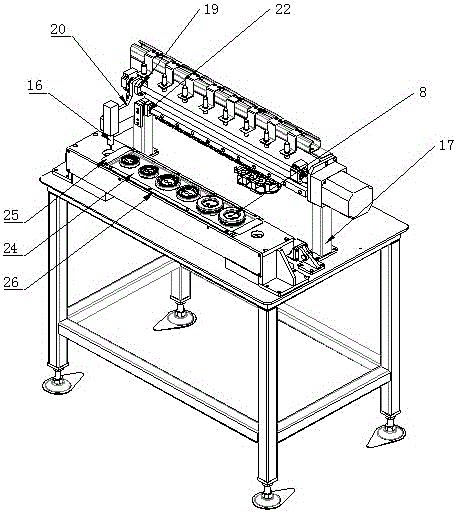

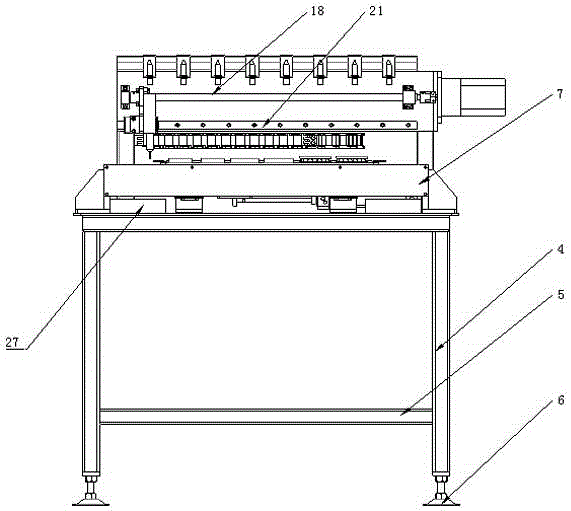

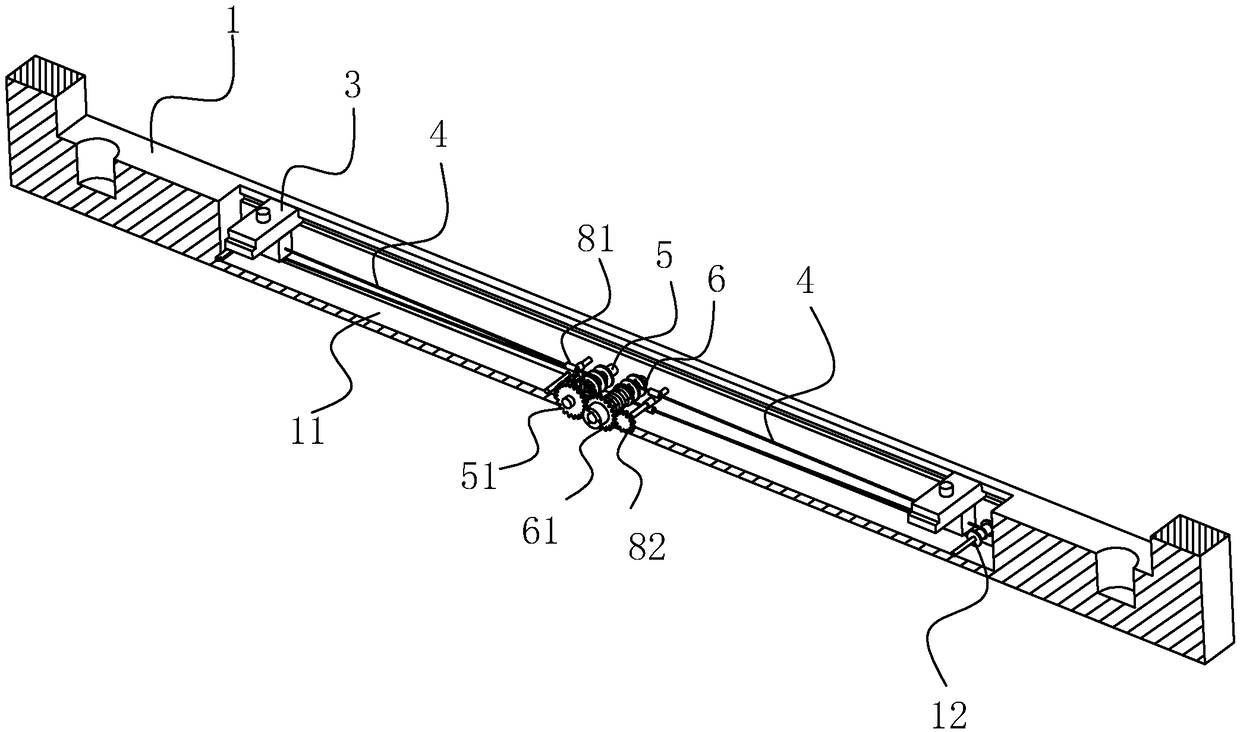

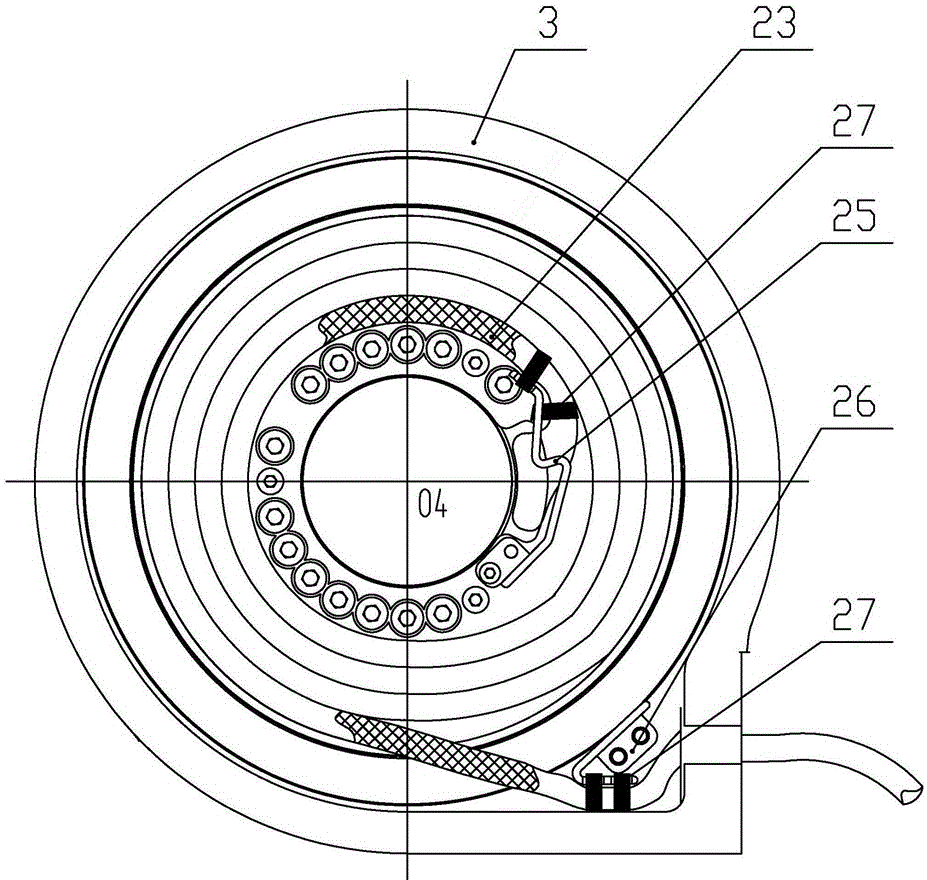

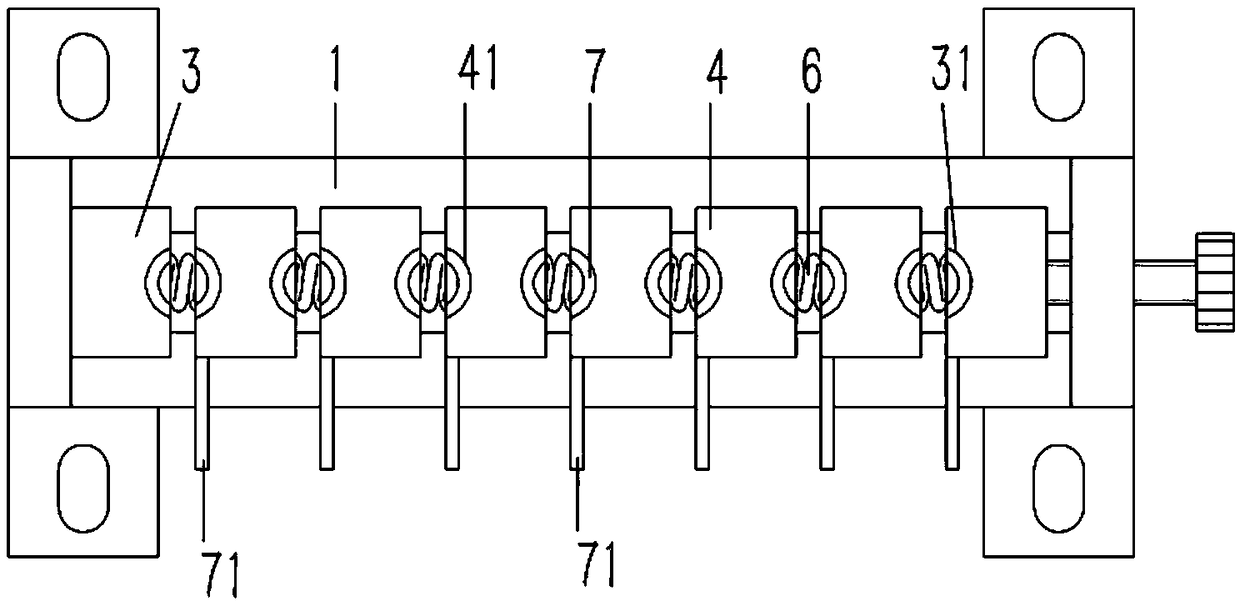

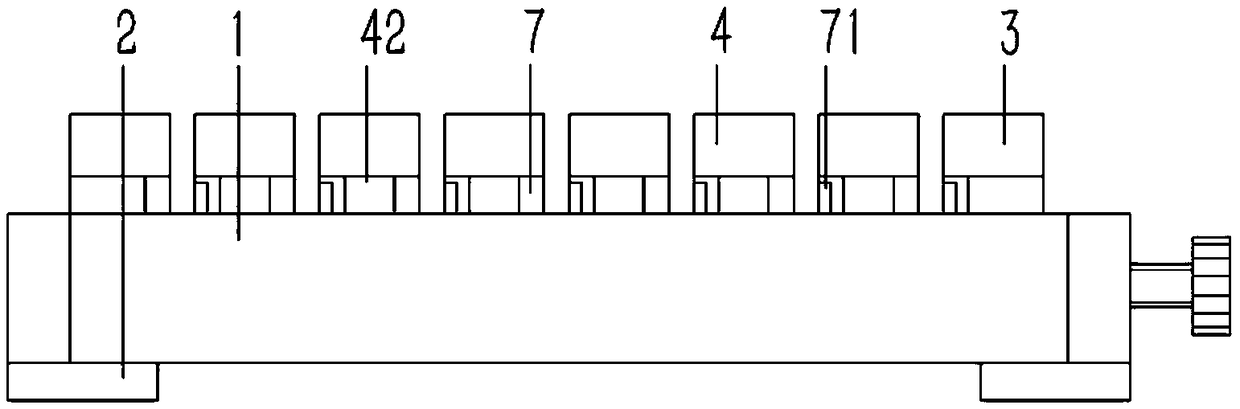

Bearing oiling system for disconnector bearing seats

The invention relates to a bearing oiling system for disconnector bearing seats. The bearing oiling system for the disconnector bearing seats comprises a rack. An oiling platform is mounted at the upper end of the rack. A plurality of bearing mounting bases which are distributed in parallel and used for mounting of bearings are arranged on the oiling platform, and the bearing mounting bases can be driven by an independent rotating mechanism or a linkage rotating mechanism. An automatic oiling mechanism is further arranged above the oiling platform. The bearing oiling system for the disconnector bearing seats has the advantages that when the bearing oiling system is used for coating the bearings with lubricating grease, the bearings to be machined are arranged on the bearing mounting bases in a sleeving mode, the bearing mounting bases rotate to drive the bearings to rotate, and thus the rotting state of the bearings during work can be simulated; meanwhile, balls of the bearings are evenly coated with the lubricating grease through the automatic oiling mechanism in the rotating process, the lubricating grease can be smeared onto the portions, needing the lubricating grease, of the balls, and waste of the lubricating grease is effectively reduced; and furthermore, manual oiling is not needed in the whole process, and manual work is reduced.

Owner:JIANGSU RUGAO HIGH VOLTAGE ELECTRIC APP

Pseudo-cLassic architecture window

ActiveCN108868466ASimple structureEasy to operateWing fastenersWing arrangementsEngineeringComfort levels

Owner:桐乡市乌镇内利仿古园林建设有限公司

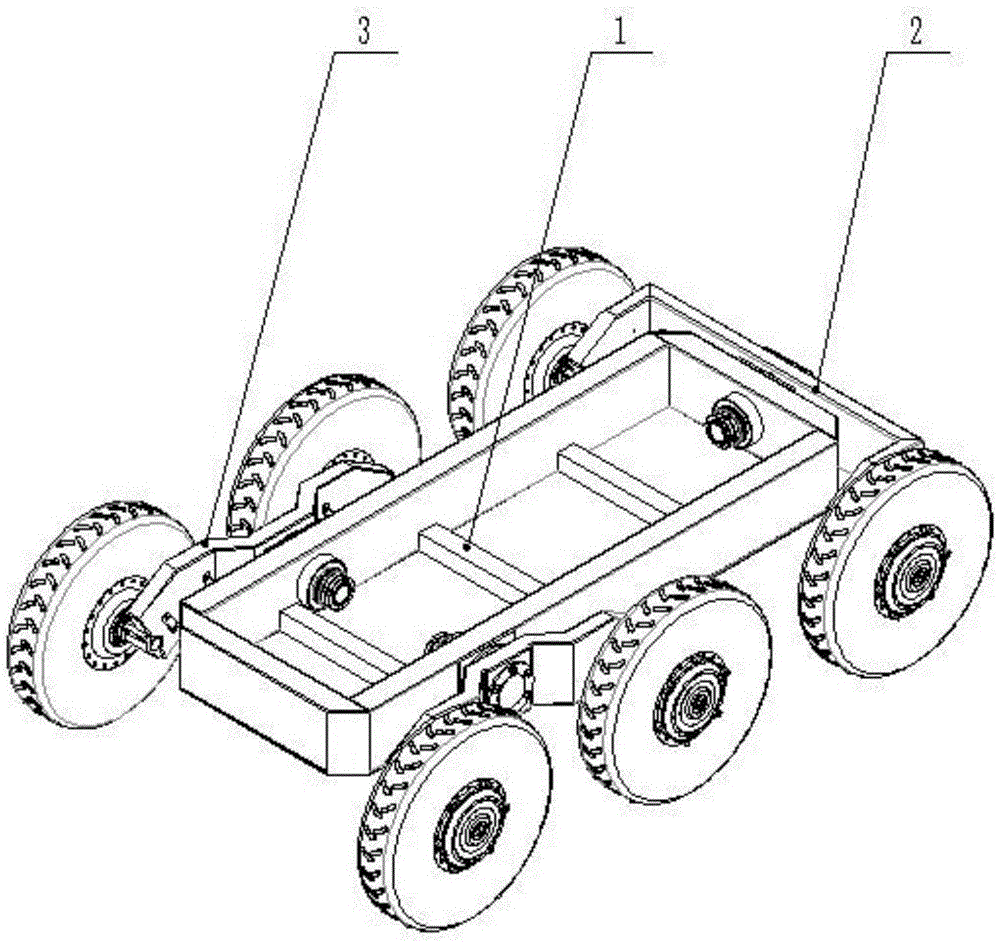

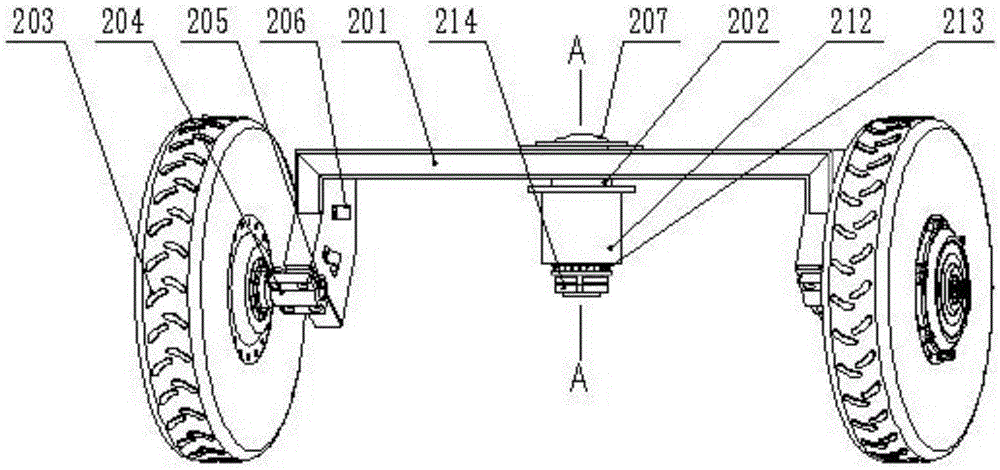

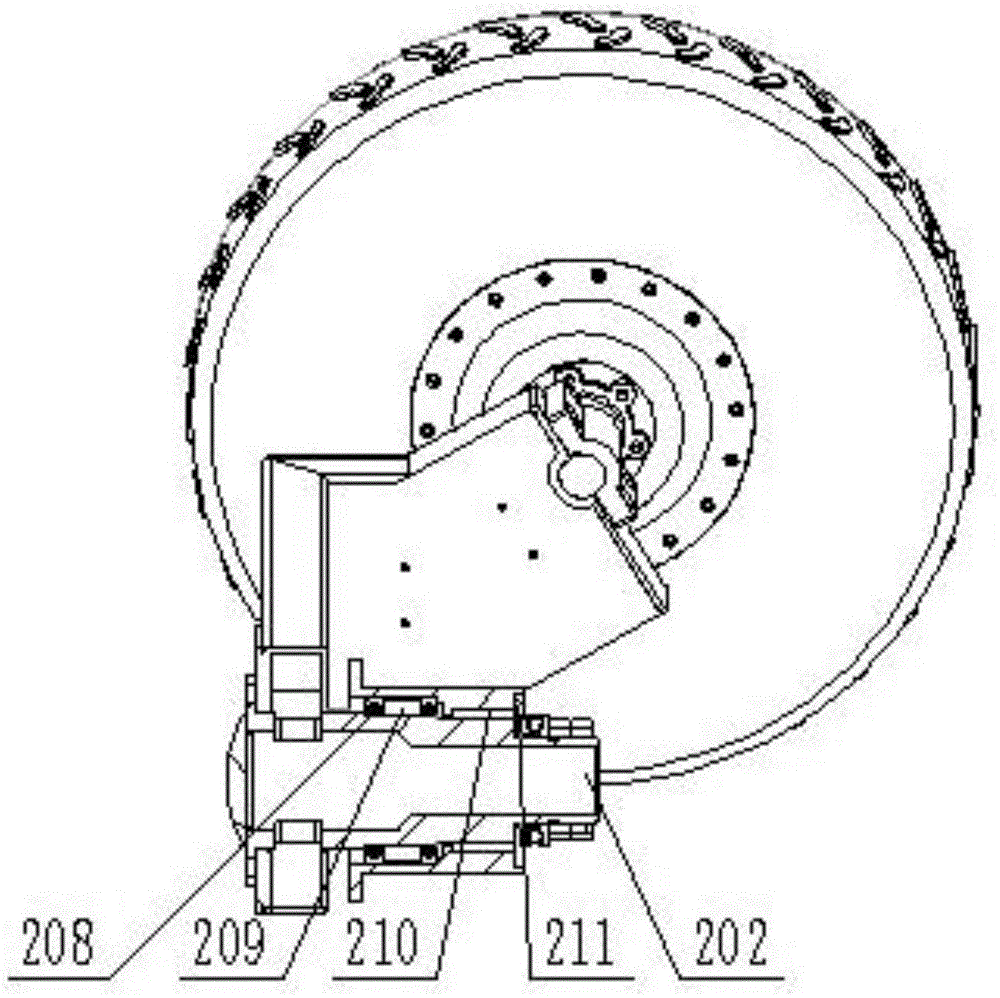

Vehicle frame chassis for radiation source detecting and processing robot, robot and application

The invention relates to a vehicle frame chassis a radiation source detecting and processing robot, the robot and application. The vehicle frame chassis part mainly comprises a vehicle frame, wherein the front end of the vehicle frame is connected with a front rotating arm in a rotating manner through a front rotating shaft; front wheels and an advancing power source for driving the front wheels are respectively mounted at the left end and the right end of the front rotating arm; the left side and the right side of the rear part of the vehicle frame are a left side rotating arm and a right side rotating arm in a rotating manner through side part rotating shafts; middle wheels, rear wheels and an advancing power source for driving the corresponding wheels are respectively mounted at the left ends and the right ends of the left side rotating arm and the right side rotating arm; the ground clearance of the vehicle frame is changed through self rotation of the front rotating arm and / or the side rotating arms, so that the robot can span a barrier. According to the vehicle frame chassis disclosed by the invention, a bran-new structure is designed, so that the barrier spanning capacity is high, and requirements in an adverse road condition are met.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

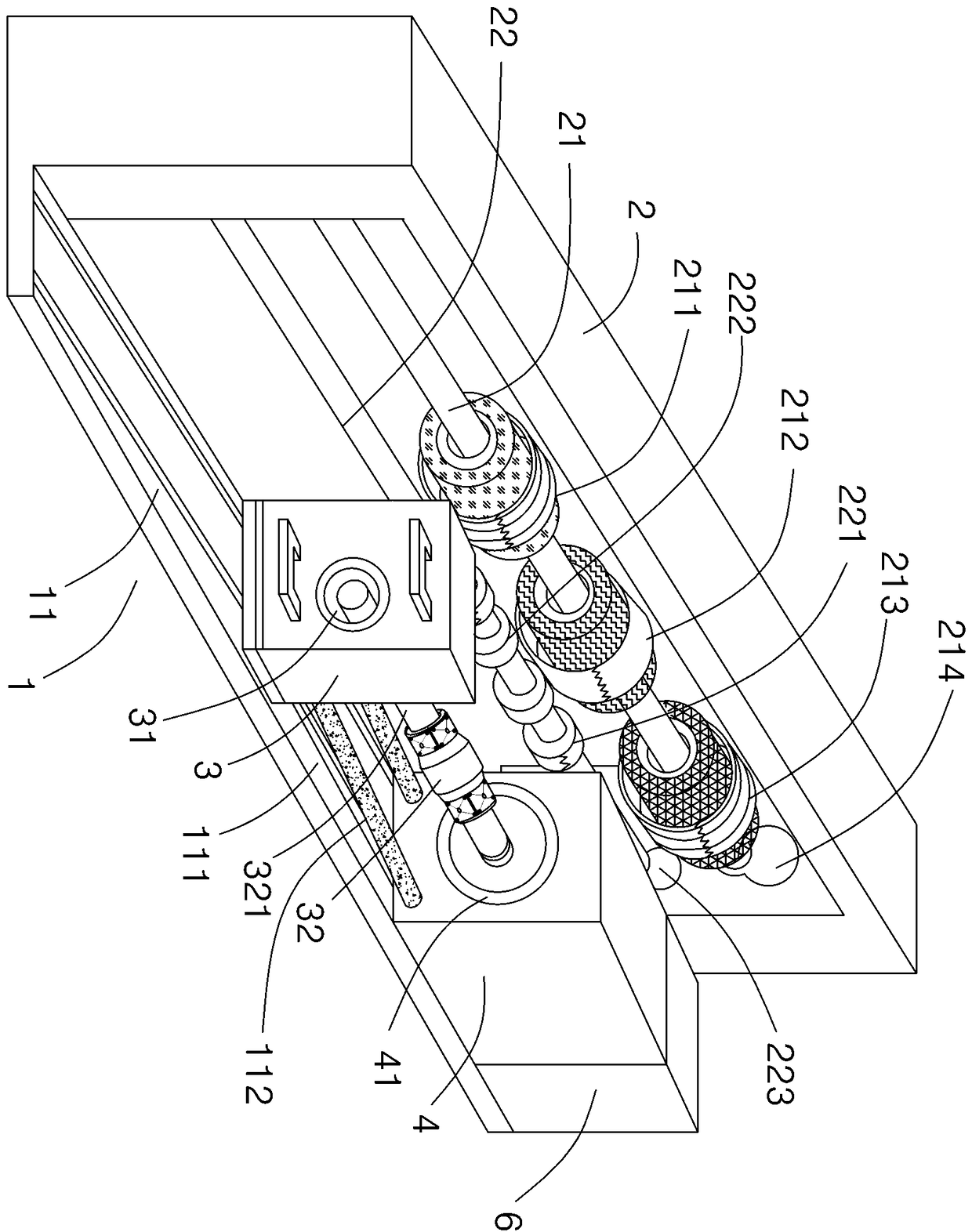

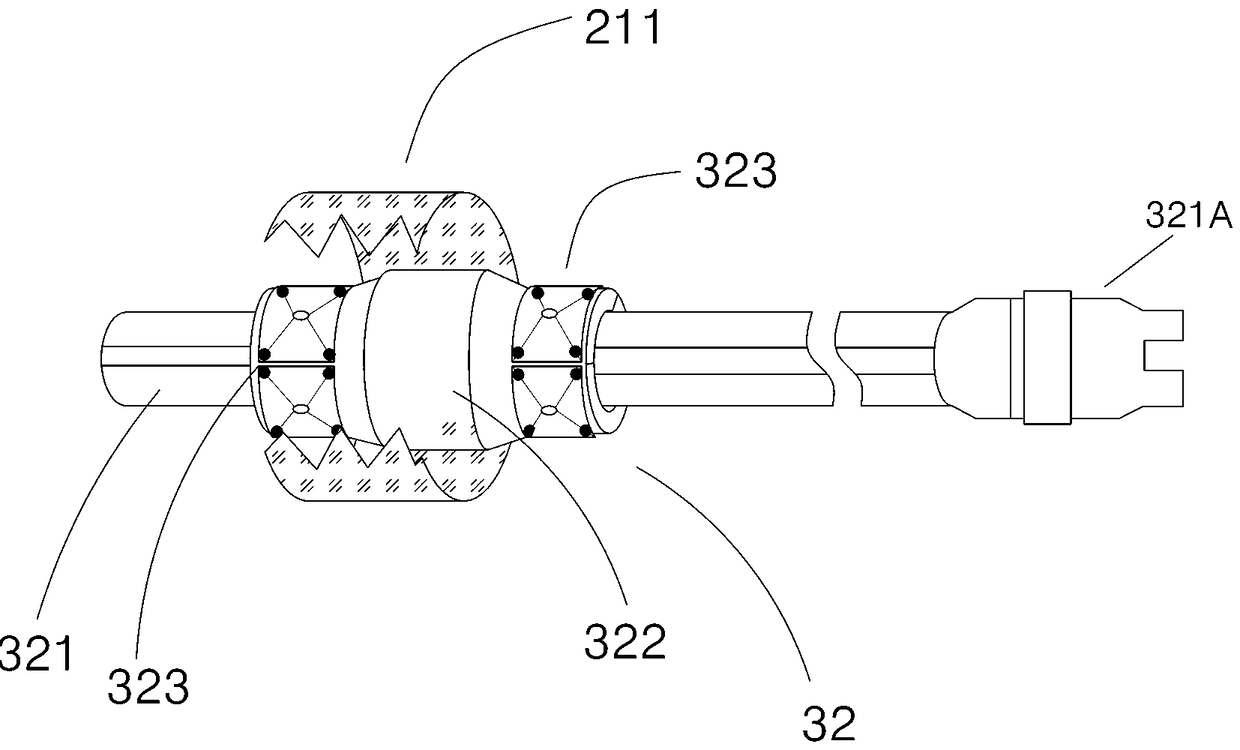

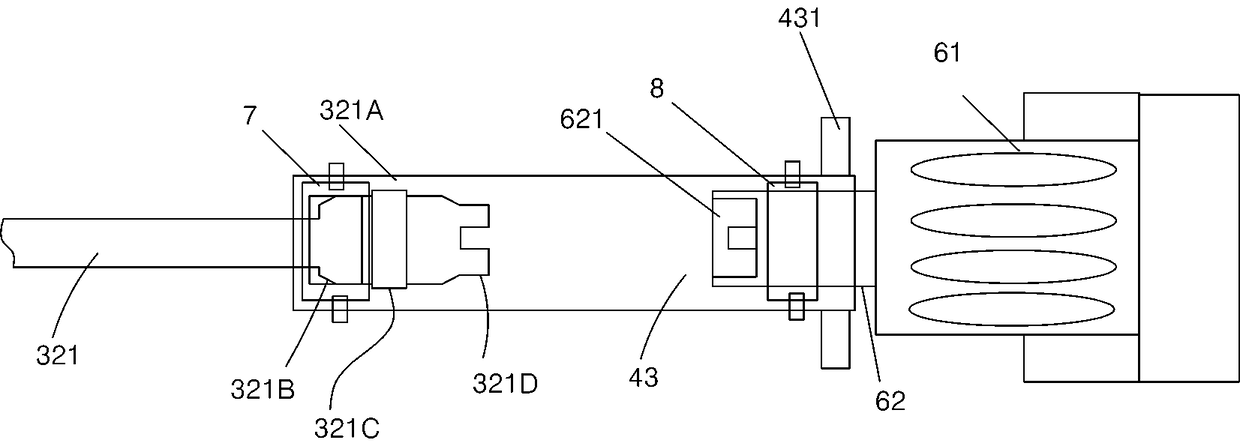

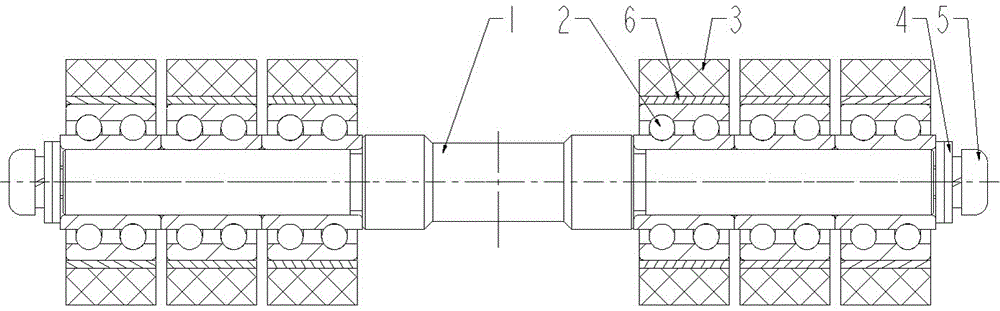

Tyre building machine

ActiveCN109291483AConvenient pre-pressing treatmentEnables embedded pivot connectionsTyresElectric machineryWork in process

The invention relates to a tyre building machine which comprises an operating floor, a feed table and a drive control bin. A first feed roller and a second feed roller are arranged on the feed table;a sliding support frame and a multilayer pre-laminating device are arranged on the operating floor; a tyre building drum is arranged between the sliding support frame and the multilayer pre-laminatingdevice; a rotary shaft is arranged in the tyre building drum in a penetrating way; one end of the rotary shaft is connected with a support frame pivot hole on the sliding support frame in an embedding way; the other end of the rotary shaft is connected with a roller joining pipe arranged in the multilayer pre-laminating device in an embedding way; a pre-laminating motor is arranged in the drive control bin; a cylindrical through hole is formed in the roller joining pipe; a first bearing and a second bearing are arranged at two ends of the through hole; the first bearing enables a connector ofthe rotary shaft to be locked into the through hole; and the second bearing in the through hole enables a motor rotary shaft to be locked and pivotly connected into the roller joining pipe. The invention provides the tyre building machine capable of folding and pressing multiple layers of sheets into a tyre semi-finished product and capable of realizing convenient pre-laminating treatment on thetyre semi-finished product.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

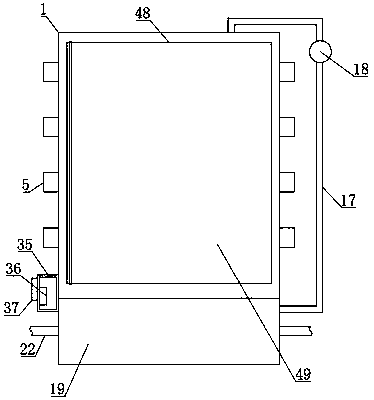

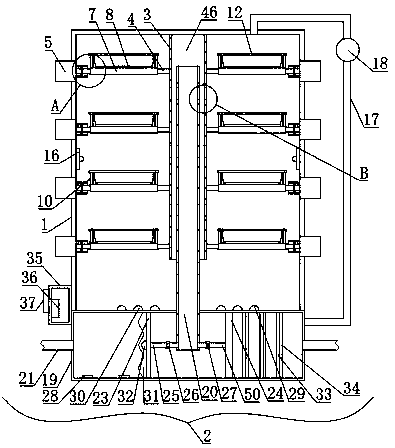

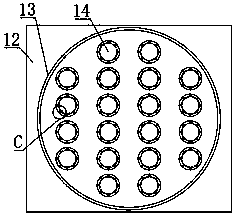

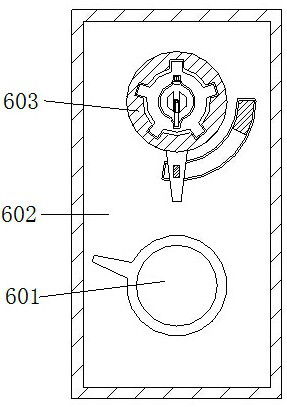

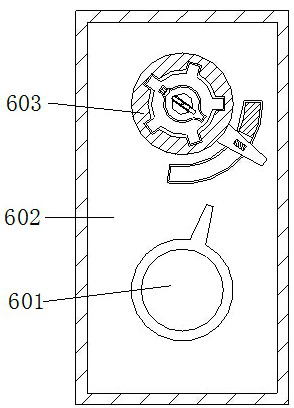

Goose egg incubation device

InactiveCN111011258ARealize independent egg turning operationAchieve independent rotationPoultry incubationFisheryEngineering

The invention discloses a goose egg incubation device. The goose egg incubation device comprises an incubation box, wherein a temperature adjusting device is connected with the incubation box; supporting rods are arranged in the incubation box, and multiple rotating rods are arranged on each supporting rod; each rotating rod is connected with a rotating motor, a timing device and an installation disk, and an upper incubation disk, a plurality of reflectors, fixing rods, pushing air cylinders, a lower incubation disk and illuminating light bars are arranged on each installation disk; the lowerincubation disks and the upper incubation disks are each provided with multiple incubation grooves which are evenly distributed, and fixing devices are arranged in each incubation groove; humidification pipes are arranged on both inner side surfaces of the incubation box, and an atomizer is arranged on each humidification pipe; and a ventilation pipe is arranged on the top surface of the incubation box, and a suction pump is arranged on the ventilation pipe. The goose egg incubation device not only can improve the safety of egg turning, but also has the advantages that the stability of goose egg placement is good, the working efficiency is high, use is convenient, an application range is wide, the incubation efficiency of goose eggs is high, the adjustment rate is high, and the heating rate is high.

Owner:贵州锦屏生态鹅业发展有限公司

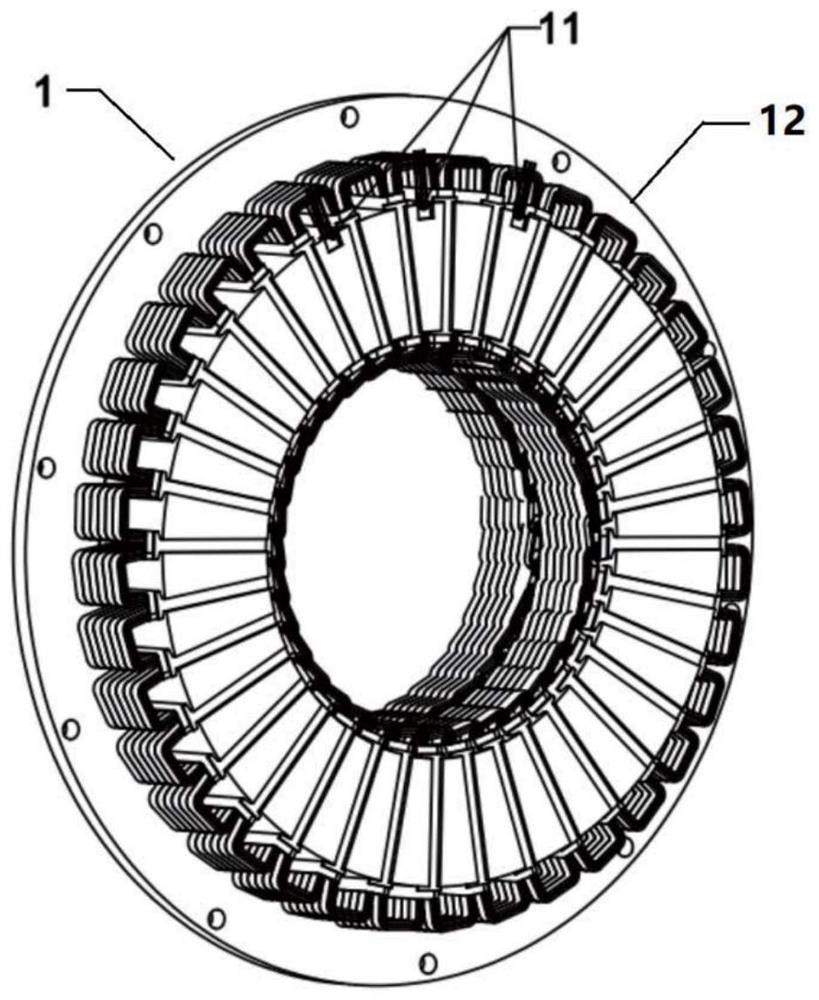

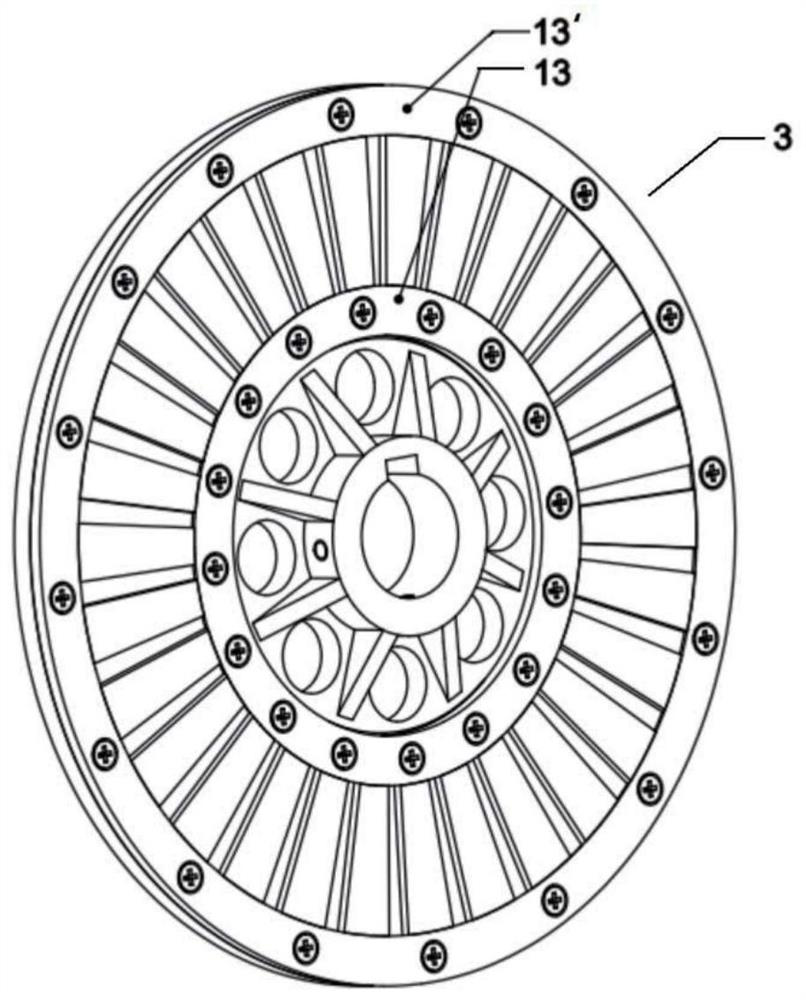

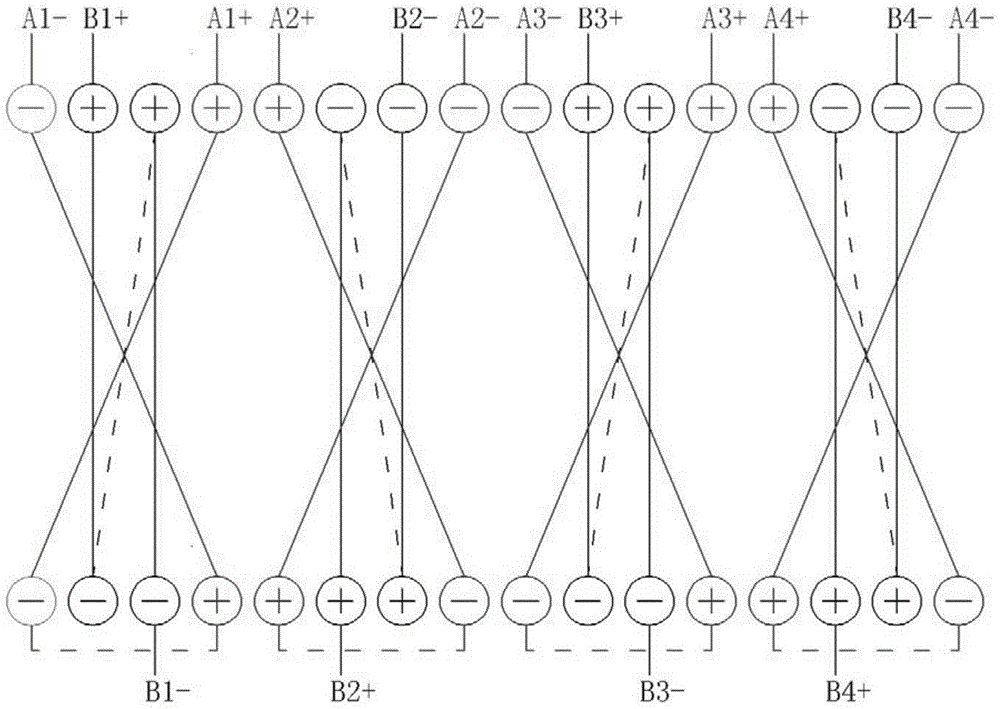

Disk-type double-rotor counter-rotating motor and aircraft

ActiveCN112737255BImprove power densitySimple assembly structureMagnetic circuit stationary partsStructural associationElectric machineEngineering

The invention discloses a disc-type double-rotor counter-rotating motor and an aircraft. The disc-type double-rotor counter-rotating motor includes a stator assembly and two identical rotor assemblies, and the two rotor assemblies are symmetrically arranged on both sides of the stator assembly. The stator assembly includes two stator windings, the two stator windings are symmetrically distributed on both sides of the stator assembly, and the phase arrangement of the two stator windings is opposite, when the two stator windings are energized, the corresponding two gas The armature magnetomotive force generated in the gap has the same rotation speed and opposite direction, so as to drive the two rotor assemblies to rotate in opposite directions at the same speed, and sensors are installed on the stator teeth on both sides of the stator assembly. The disc-type double-rotor counter-rotating motor provided by the invention has the advantages of light weight and high power density, can output two torques with opposite directions and equal amplitudes, and is easy to install, high in stability, and easy to control. It has good application prospects in the fields of robot propulsion and other fields.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

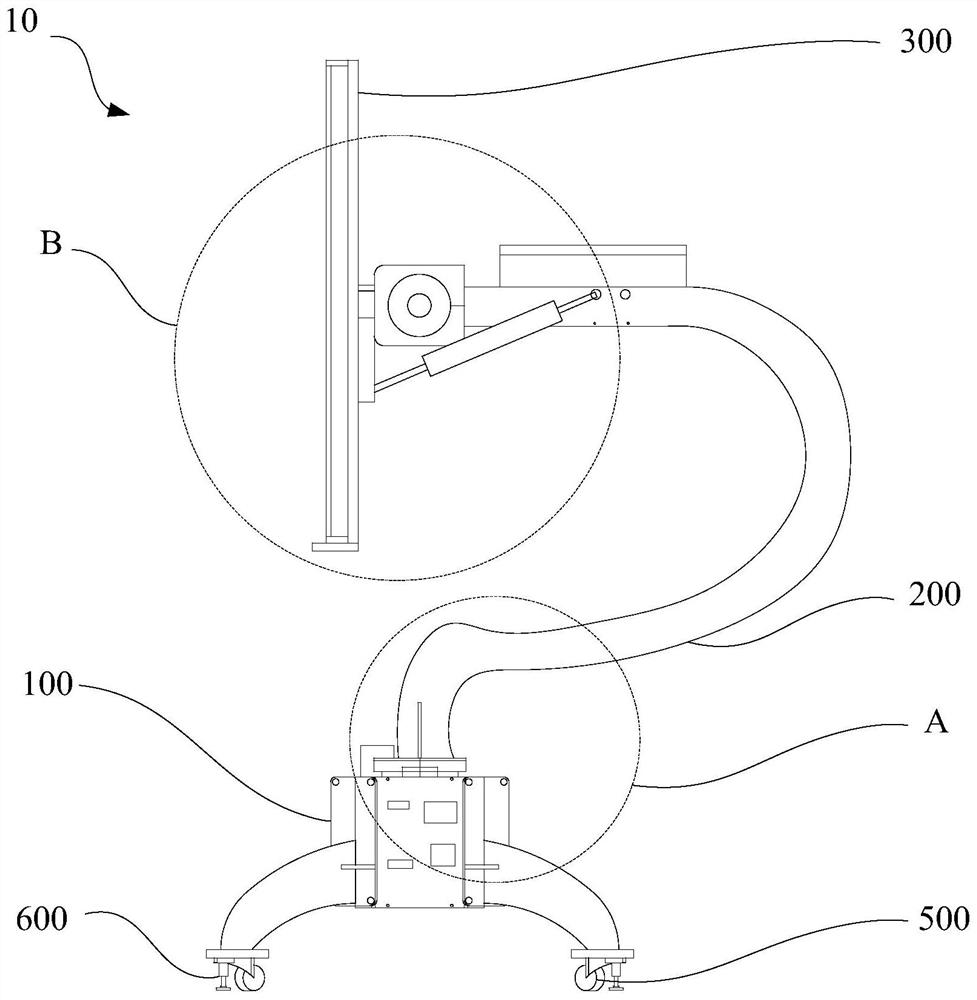

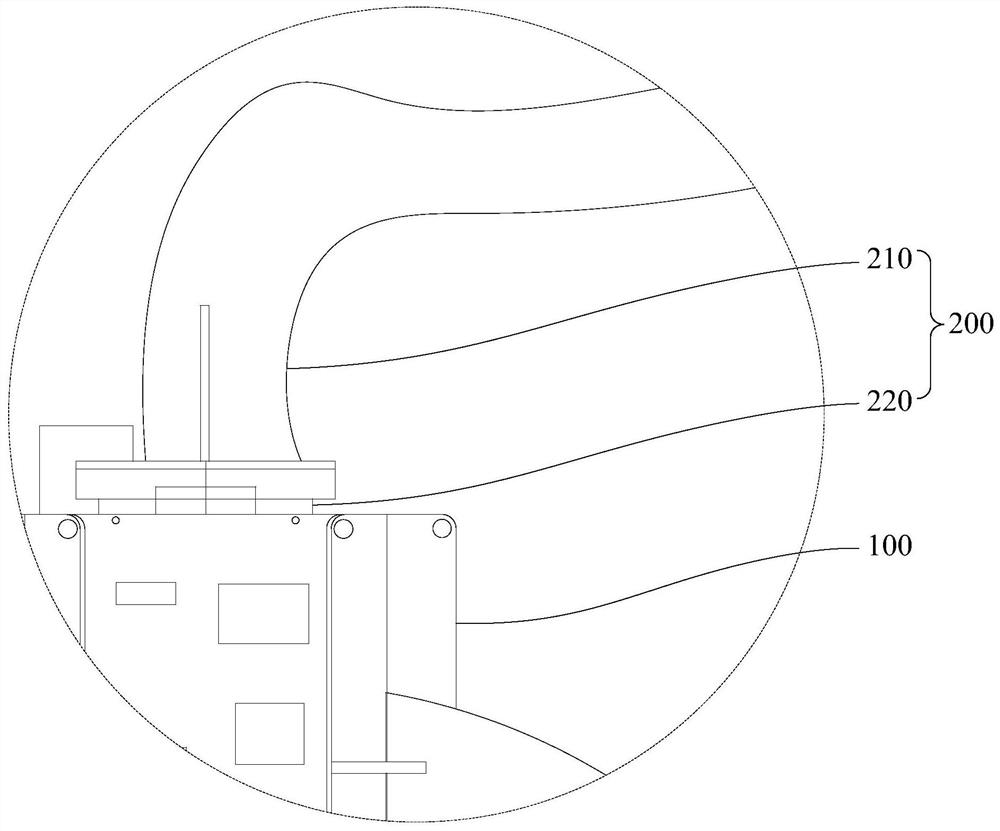

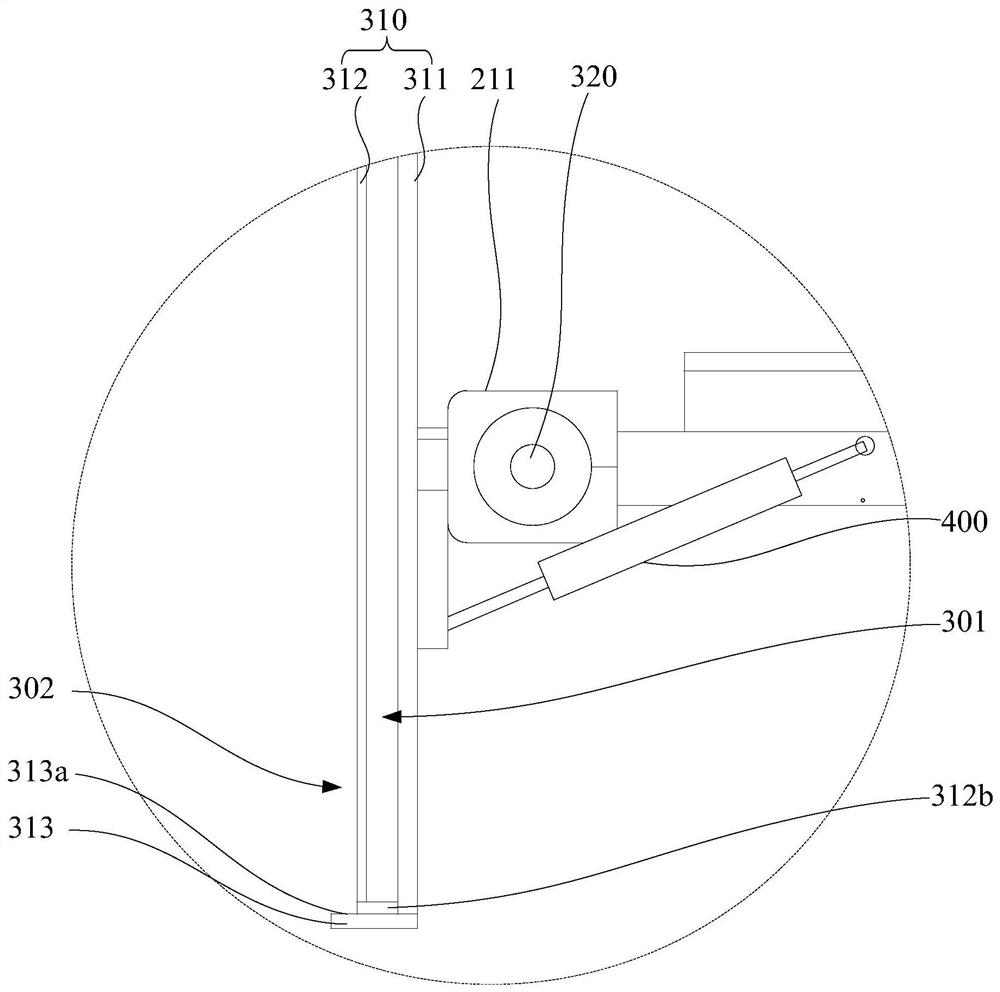

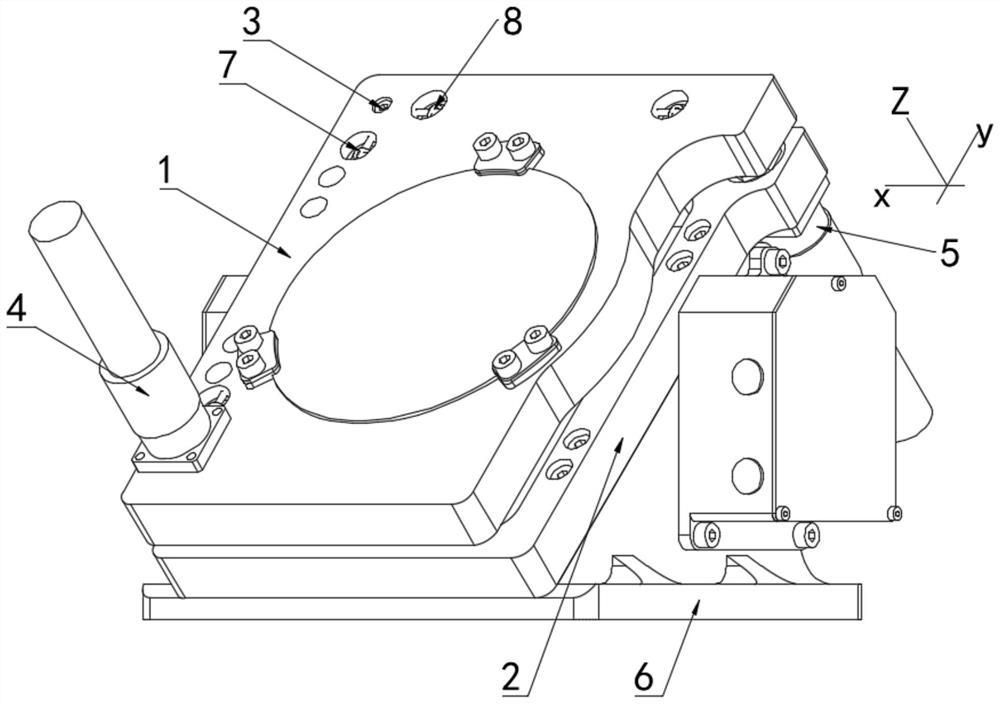

Angle testing device and display screen system

ActiveCN111735612AHigh precisionAchieve independent rotationTesting optical propertiesPhotovoltaic energy generationEngineeringMechanical engineering

The invention relates to an angle testing device. The angle testing device comprises a base, a connecting arm assembly and a mounting frame assembly. The connecting arm assembly comprises a connectingarm and a first rotating shaft which are connected with each other, and the first rotating shaft is rotationally arranged on the base. The mounting frame assembly comprises a mounting frame and a second rotating shaft, the second rotating shaft is rotationally connected with the connecting arm, and an included angle is formed between the second rotating shaft and the first rotating shaft. The mounting frame comprises a frame body and a plurality of mounting plates, the second rotating shaft is connected with the frame body, each mounting plate is provided with a mounting surface deviating from the frame body, the mounting plates are slidably connected with the frame body, and gaps are formed between the surfaces, deviating from the mounting surfaces, of the mounting plates and the frame body. According to the angle testing device and the display screen system, the left-right visual angle and the up-down visual angle of the display screen can be respectively tested, the angle testing precision of the display screen is improved, the visual angles of the display screens with different thicknesses and different lengths can be conveniently and stably tested, and the angle testing precision of the display screen is further improved.

Owner:LEDMAN OPTOELECTRONIC HZ CO LTD +1

Novel differential FLAP rudder control cabinet structure

InactiveCN104386242ASolve the problem of poor installationAchieve independent rotationWithout power ampliicationEngineeringBall bearing

The invention discloses a novel differential FLAP rudder control cabinet structure. The tail of a control cabinet body is provided with two FLAP rudders, being marked as a rudder II and a rudder IV, in quadrant II and quadrant IV of a yaw channel; two coaxial FLAP rudders are arranged in quadrant I, and marked as a rudder I1 and a rudder I2, and two coaxial FLAP rudders are arranged in quadrant III, and marked as a rudder III1 and a rudder III2; a bearing box is arranged at the end, connected with the rudder III1 or the rudder I2, of a revolving shaft I, two angular contact ball bearings are arranged at the other end of the revolving shaft I back to back, the angular contact ball bearings are arranged at one end of a shaft sleeve fixedly connected with the rudder III2 or the rudder I1, and the other end of the shaft sleeve is connected with a connecting shaft on which a bearing box is arranged; the rudder I1 and the rudder III1 are driven to realize synchronous rotation in a manner that a crank-link mechanism is driven by an actuator installed in the control cabinet; the rudder I2 and the rudder III2 are driven to realize synchronous rotation in a manner that a crank-link mechanism is driven by an actuator installed in the control cabinet; the rudder II and the rudder IV are driven by respective actuators installed in the control cabinet.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

A low-load industrial robot hollow forearm and wrist structure

The invention discloses a hollow forearm and wrist structure for a low-load industrial robot. The hollow forearm and wrist structure comprises a shaft J4 arranged on an arm base, a second large-speed-ratio hypoid gear shaft arranged in a wrist base, and a shaft J5 motor base. The top and the bottom of the second-large-speed ratio hypoid gear shaft are respectively provided with a second large-speed-ratio hypoid gear and a first bevel gear respectively, and the middle is provided with a fourth large-speed-ratio hypoid gear and a shaft J6 support in a rotating mode. The shaft J6 is arranged in the shaft J6 support in a rotating mode. A second bevel gear is arranged on the shaft J6. The first bevel gear and the second bevel gear are meshed. The shaft J5 motor base is connected with the shaft J6 motor base and the wrist base. A shaft J5 motor and a shaft J6 motor shaft are arranged in the shaft J5 motor base. One end of the shaft J6 motor shaft is connected with the shaft J6 motor, and the other end is provided with a first large-speed-ratio hypoid gear. The first large-speed-ratio hypoid gear and the second large-speed-ratio hypoid gear are meshed. The output shaft of the shaft J5 motor is provided with a third large-speed-ratio hypoid gear. The hollow forearm and wrist structure solves the problem that a transmission line is not distinct in the prior art.

Owner:NANJING ESTUN ROBOTICS CO LTD

Rough yarn feeding type rear top roller rubber roller device and ring spinning frame with same

PendingCN105463638ACompact structureGood processing performanceDrafting machinesContinuous wound-up machinesAluminiumYarn

The invention relates to a rough yarn feeding type rear top roller rubber roller device which comprises a rear top roller mandrel, special bearings, aluminum bushings and rubber rollers. At least two spindle positions are arranged on the rear top roller mandrel, each spindle position is provided with the corresponding multiple special bearings, the inner rings of the special bearings are completely attached to the rear top roller mandrel, gaps are formed between the adjacent special bearings to ensure that the outer rings of all the special bearings can rotate freely, the aluminum bushings are installed on the outer rings of the special bearings, and the outer surfaces of the aluminum bushings are wrapped with the rubber rollers. The special bearings are adopted, the outer rings of the special bearings and the rubber rollers can independently rotate, and thus the purpose that different coarse yarns on all the spindle positions are fed in and discharged out at different speeds is achieved. Meanwhile, the rough yarn feeding type rear top roller rubber roller device is compact in structure, convenient to disassemble and replace and beneficial to maintenance and preserving, and the special bearings have good bearing capability and meet the heavy and pressed spinning technology.

Owner:JINGWEI TEXTILE MASCH CO LTD

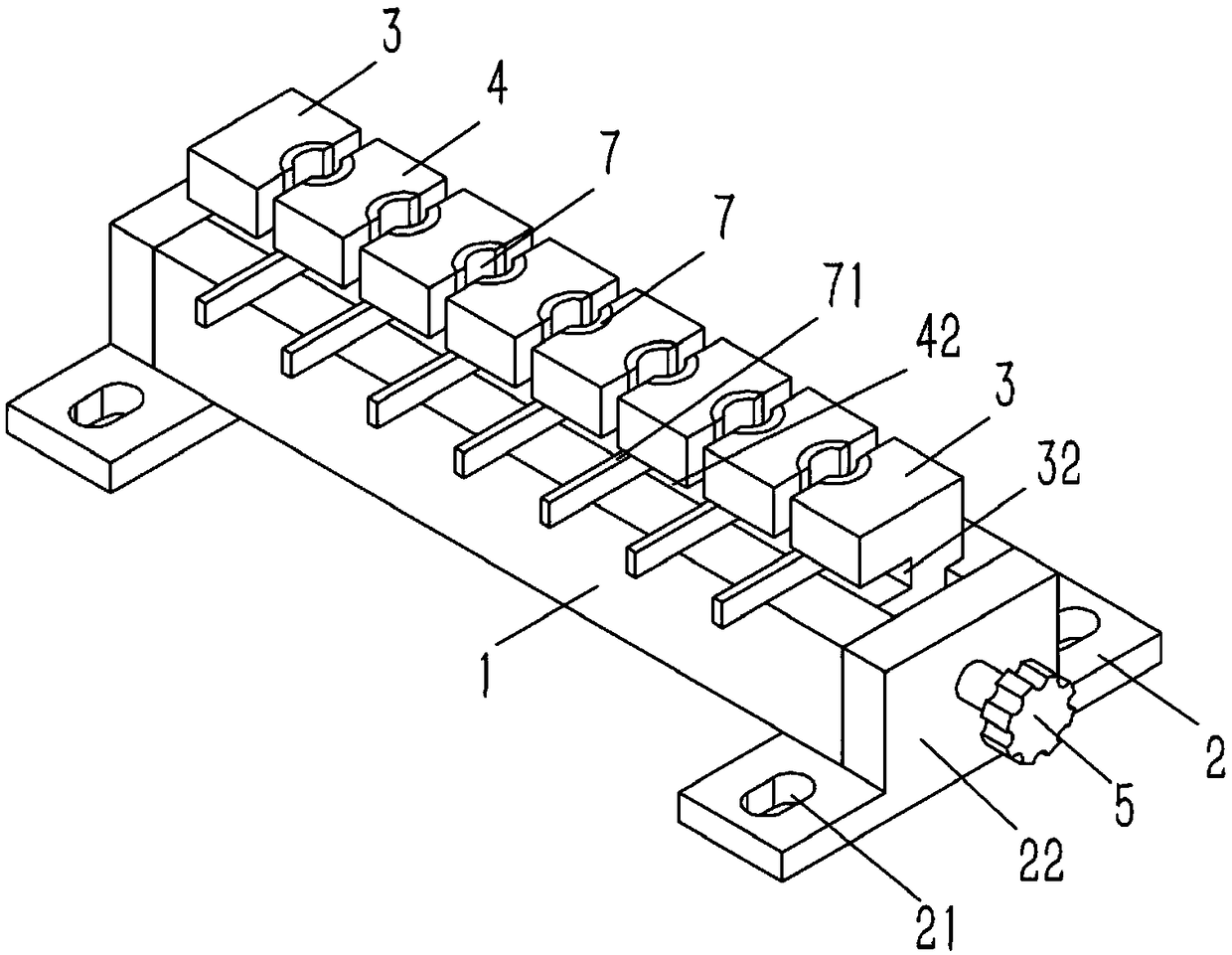

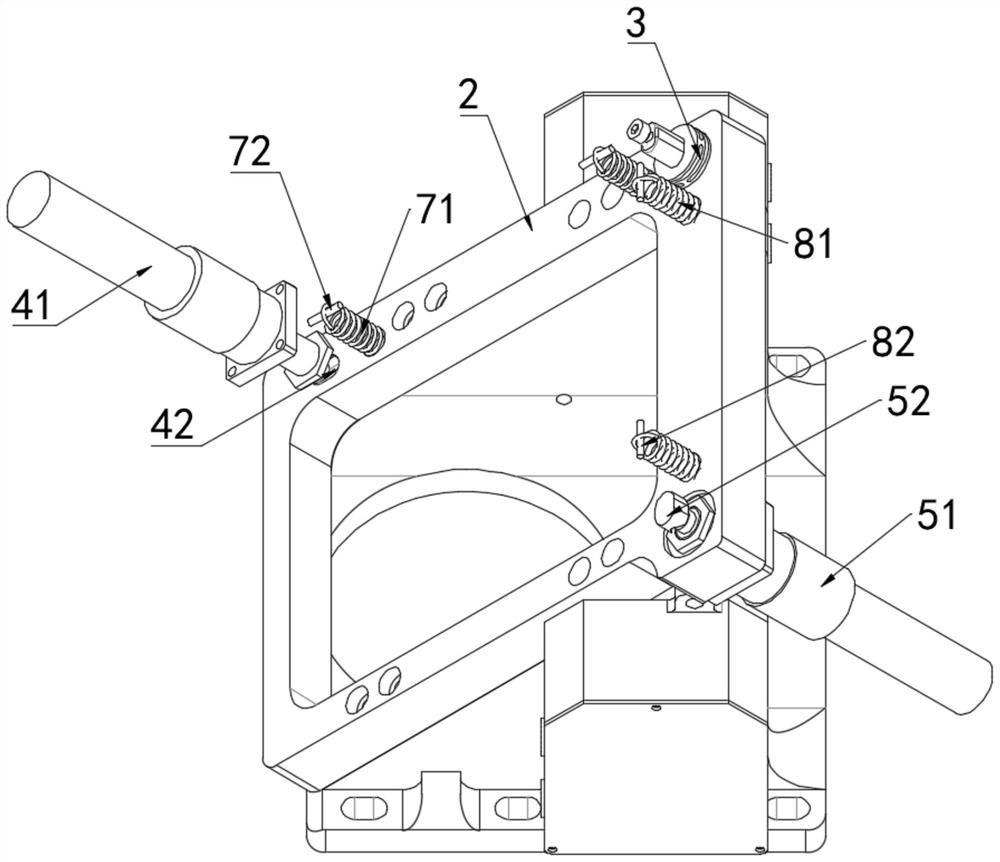

Clamping device for spraying automobile air conditioner blades

InactiveCN108970855AAchieve independent rotationEasy to spraySpraying apparatusAutomobile air conditioningEngineering

The invention discloses a clamping device for spraying automobile air conditioner blades. The clamping device comprises C-shaped channel steel, wherein two opposite I-shaped check blocks are insertedinto the C-shaped channel steel, and a plurality of I-shaped clamping blocks are inserted into the C-shaped channel steel between the stop blocks; strip-shaped mounting plates are fixed on the lower end surfaces of the two ends of the C-shaped channel steel, vertical end plates are formed on the mounting plates, and the end plates are fixed on the two end faces of the C-shaped channel steel; and two I-shaped check blocks are inserted into the C-shaped channel steel, the plurality of I-shaped clamping blocks are inserted into the C-shaped channel steel between the stop blocks, counter holes areformed in the end faces, close to the clamping blocks, of the stop blocks and the two end faces of the clamping blocks, pressure springs are inserted into the counter bores of the clamp blocks and the stop blocks in an inserted mode, the two ends of the pressure spring are pressed against the adjacent clamping blocks or the clamping blocks and the stop blocks correspondingly, and the pressure springs are inserted into the C-shaped channel steel. According to the clamping device, the plurality of blades can be clamped, independent rotation of each blade can be realized, the spraying operationof the blades is facilitated, and the spraying efficiency of the automobile air conditioning blades is effectively improved.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Axial magnetic field permanent magnet counter-rotating dual-rotor compensation pulse generator

ActiveCN104734438BReduce torque shockSimple control systemDynamo-electric machinesElectromagnetic torqueSquare Shape

The invention relates to an axial-field permanent magnet compensated impulse generator with double contra-rotating rotors and belongs to the technical field of an impulse generator. The axial-field permanent magnet compensated impulse generator comprises a left rotor, a stator disc, a right rotor, two end caps and a shell. The left rotor, the stator disc and the right rotor are sequentially arranged in a hollow-square-shaped space formed by the two end caps and the shell along an axial direction. The left rotor along with one of the end caps and the right rotor along with the other end cap are in mirror symmetry on two sides of the stator disc. An air gap is formed between the left rotor and the stator disc, and another air gap is formed between the stator disc and the right rotor. The left rotor comprises a left rotor disc yoke, a left rotor permanent magnet, a left rotor compensation disc, a left rotor bandage, a left rotor shaft and a left rotor support. The stator disc comprises a stator support and a stator disc yoke. The double contra-rotating rotor compensated impulse generator is capable of solving the problem that the sizes of two motors are enlarged due to the fact that the two motors are arranged side by side and enabled to rotate reversely to counteract electromagnetic torque impact generated by the existing impulse generator during discharging.

Owner:HARBIN INST OF TECH

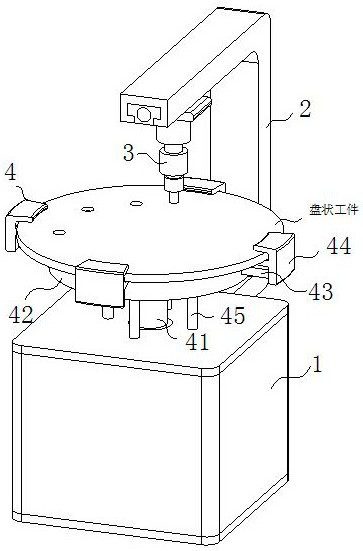

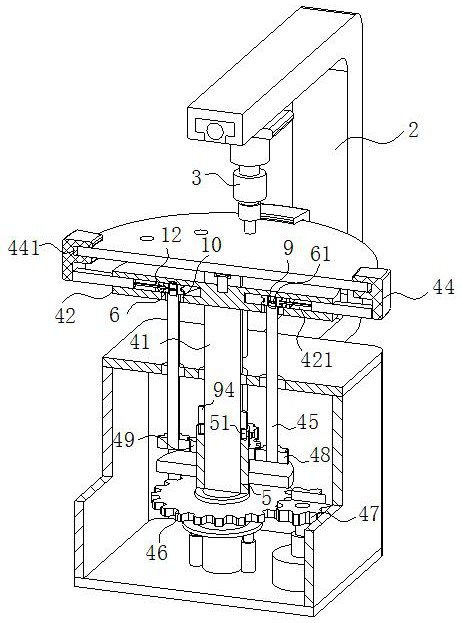

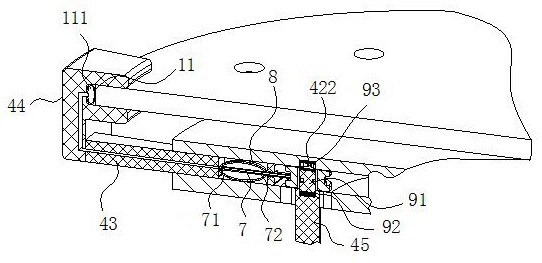

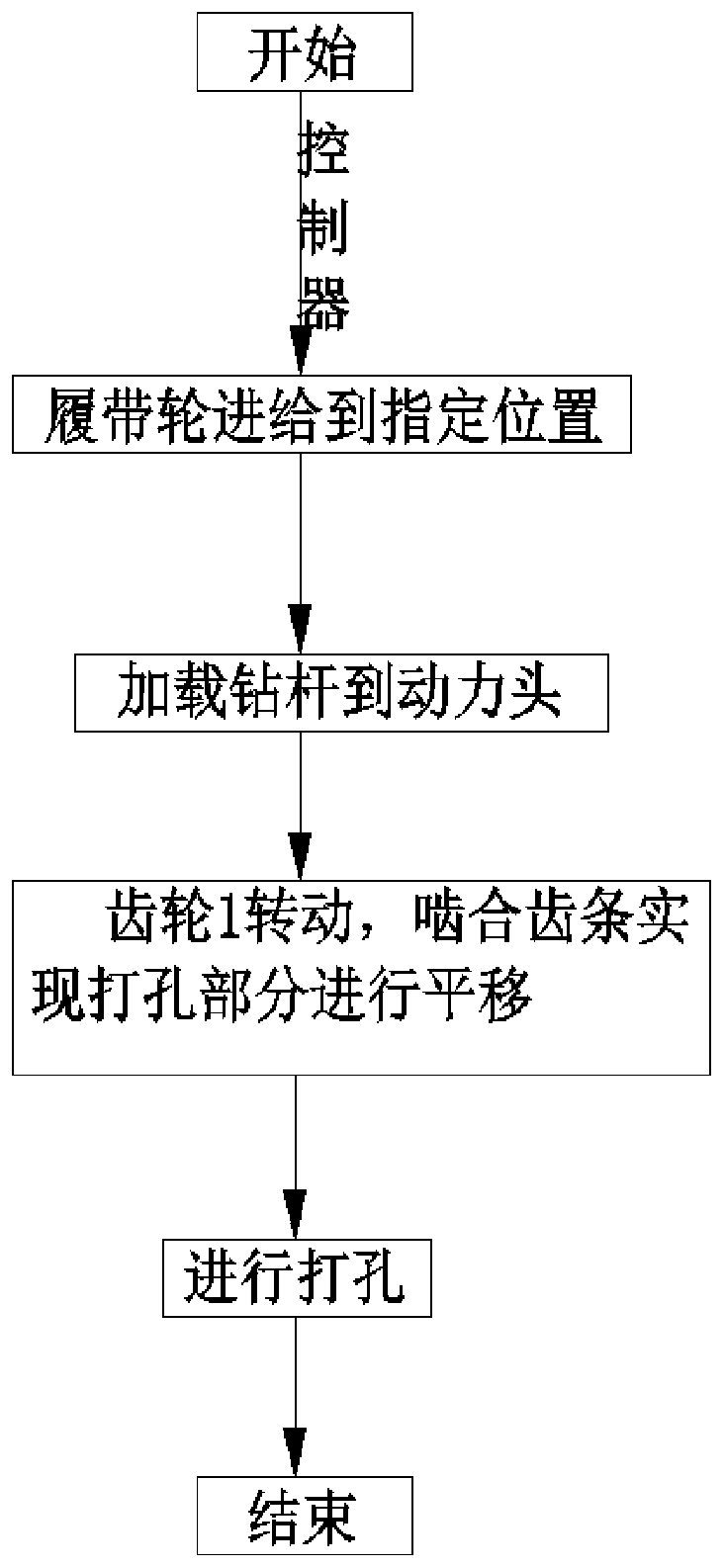

Hole punching machine for automotive parts processing using gears for precise positioning

ActiveCN111822584BHigh precisionIncrease the rangeMetal-working feeding devicesPositioning devicesPhysicsEngineering

The invention belongs to the technical field of auto parts processing, and specifically relates to a punching machine for processing auto parts by using gears for precise positioning; it includes a chassis, a beam and a driving punching mechanism; the beam is provided with a driving punching mechanism; the main shaft is supported It is installed on the chassis through bearing rotation, and a fixed plate is installed on the top of the supporting spindle; a sliding cavity is opened inside the fixed plate, and a plurality of sliding rods are slidingly arranged in the sliding cavity; the outer ends of the multiple sliding rods are connected with snap-fit block; a plurality of rotating rods are arranged in the circumferential direction of the outer ring of the supporting spindle; a driven gear is fixed on the outer wall of the rotating cylinder, and an engaging toothed disc is fixed on the upper end of the rotating cylinder; the engaging toothed disc is located above the driven gear; multiple rotating rods Planetary gears are fixed at the bottom of the bottom, and multiple planetary gears are meshed with the meshing toothed disc; multiple engaging blocks can simultaneously perform clamping and positioning operations on the disc-shaped workpiece, thereby improving the clamping of the disc-shaped workpiece on the punching machine. Tight positioning accuracy.

Owner:芜湖市夯福机械模具有限公司

A differential flap rudder control cabin structure

InactiveCN104386242BAchieve independent rotationRealize the form of differential motionWithout power ampliicationBall bearingCrank

The invention discloses a novel differential FLAP rudder control cabinet structure. The tail of a control cabinet body is provided with two FLAP rudders, being marked as a rudder II and a rudder IV, in quadrant II and quadrant IV of a yaw channel; two coaxial FLAP rudders are arranged in quadrant I, and marked as a rudder I1 and a rudder I2, and two coaxial FLAP rudders are arranged in quadrant III, and marked as a rudder III1 and a rudder III2; a bearing box is arranged at the end, connected with the rudder III1 or the rudder I2, of a revolving shaft I, two angular contact ball bearings are arranged at the other end of the revolving shaft I back to back, the angular contact ball bearings are arranged at one end of a shaft sleeve fixedly connected with the rudder III2 or the rudder I1, and the other end of the shaft sleeve is connected with a connecting shaft on which a bearing box is arranged; the rudder I1 and the rudder III1 are driven to realize synchronous rotation in a manner that a crank-link mechanism is driven by an actuator installed in the control cabinet; the rudder I2 and the rudder III2 are driven to realize synchronous rotation in a manner that a crank-link mechanism is driven by an actuator installed in the control cabinet; the rudder II and the rudder IV are driven by respective actuators installed in the control cabinet.

Owner:BEIJING AEROSPACE INST OF THE LONG MARCH VEHICLE +1

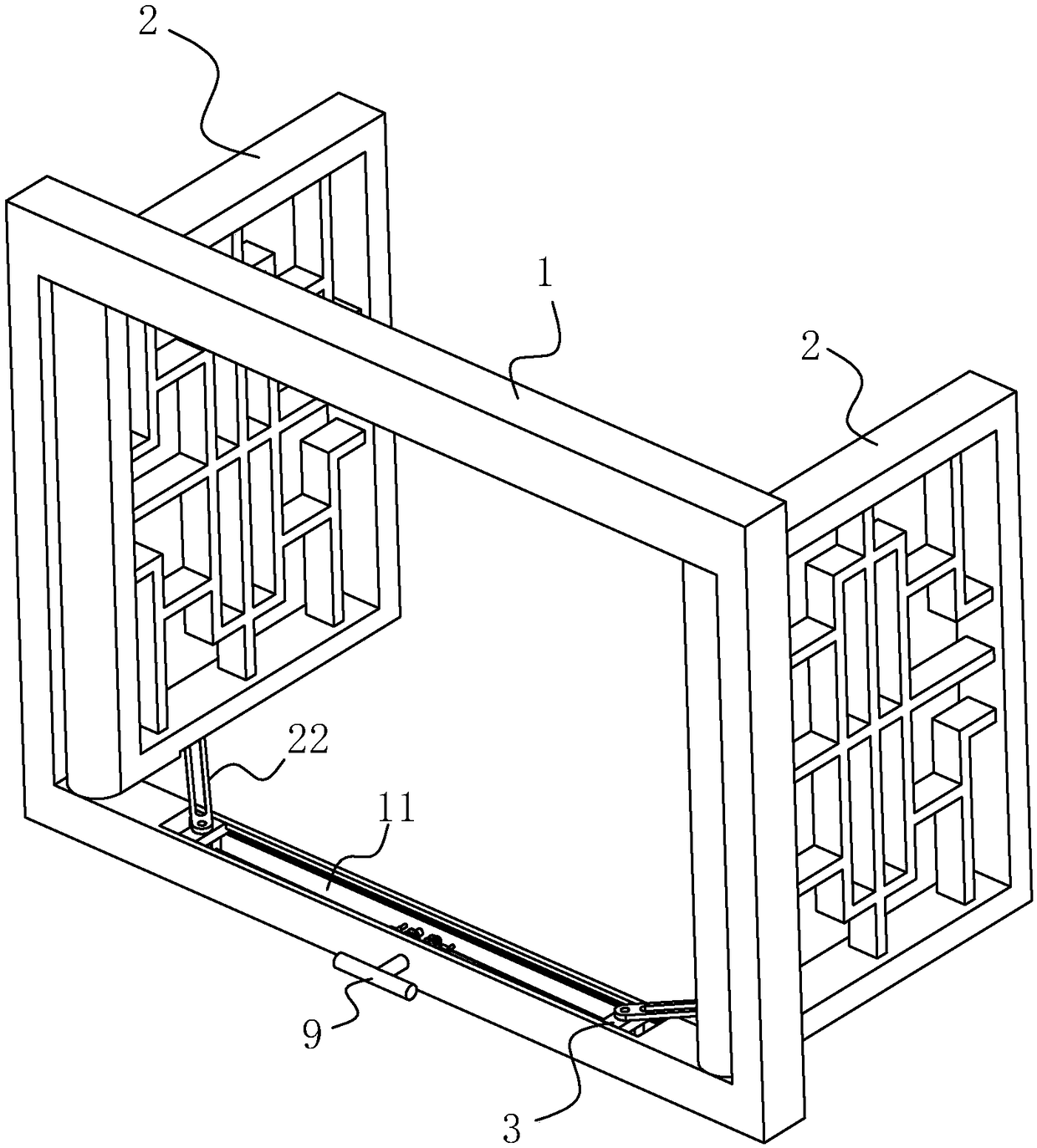

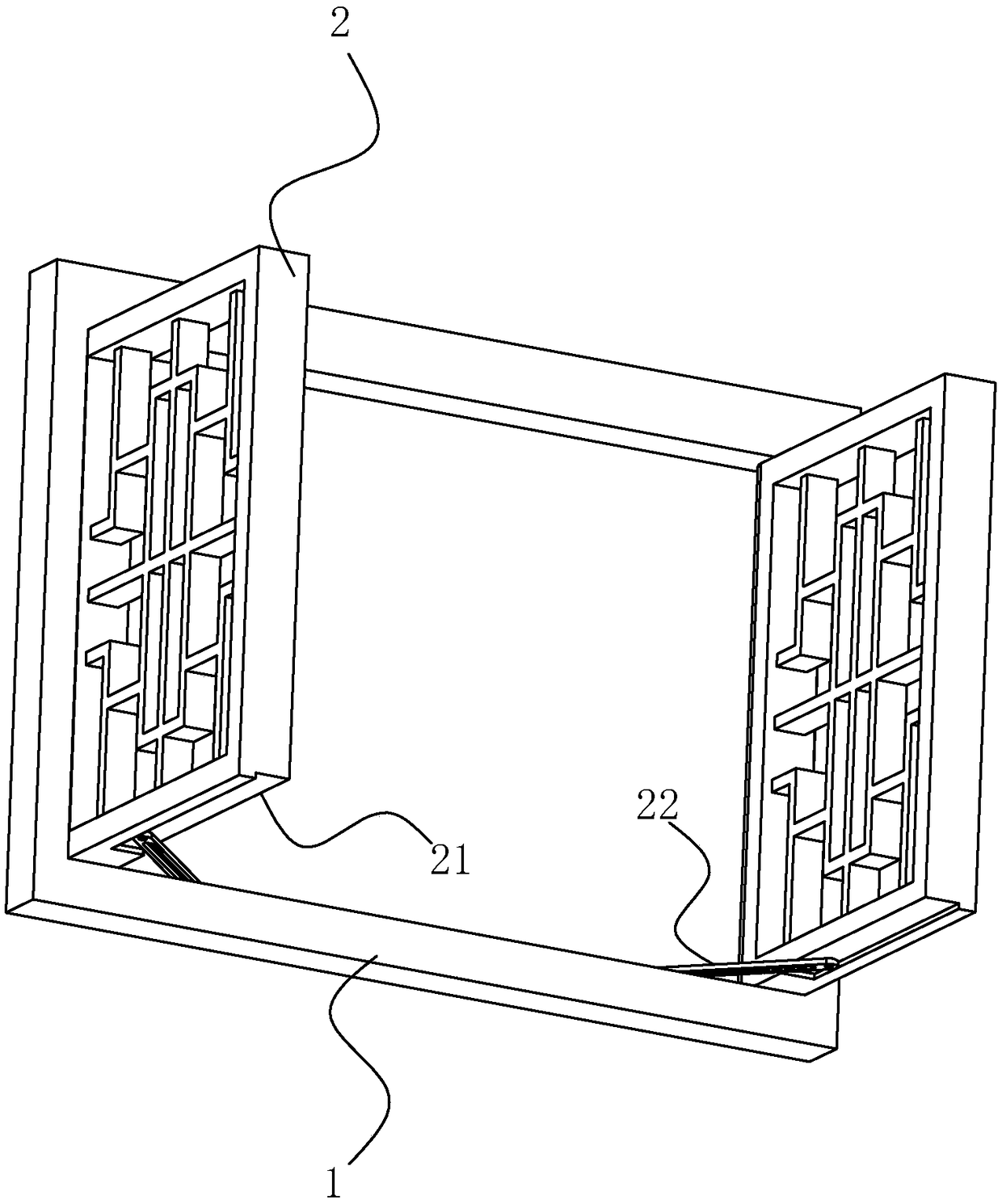

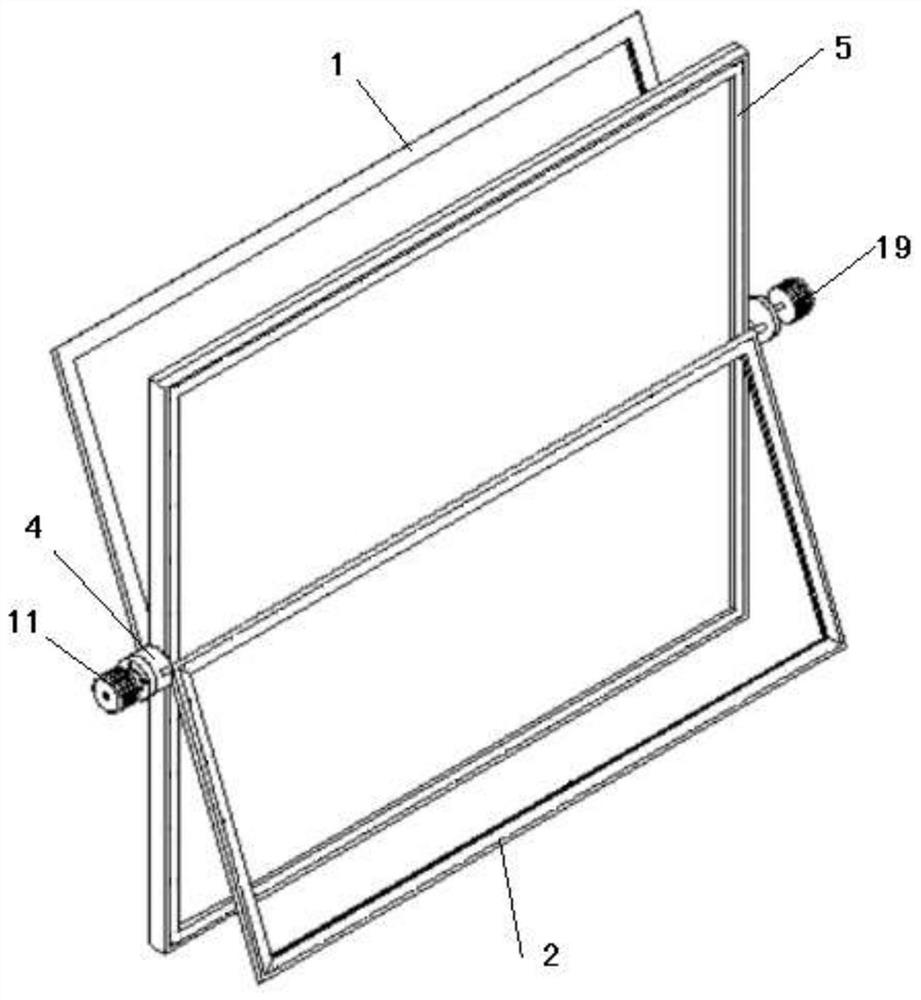

A shaft nested automatic switch window

ActiveCN110805375BRealize automatic switchingAchieve independent rotationInsect protectionPower-operated mechanismStructural engineeringWindow screen

The invention discloses a rotating shaft nested type automatic switch window, which comprises a glass frame, a first glass rotating shaft and a second glass rotating shaft are respectively fixed symmetrically in the middle of the left and right sides of the glass frame, and the first glass rotating shaft and the second glass rotating shaft are respectively fixed. The window screen rotating shaft is sleeved, and the left and right two screen rotating shafts are fixed on one end surface far away from the glass frame. The first end cover and the second end cover are respectively fixed. An upper window screen frame and a lower window screen frame are also connected together, the upper window screen frame and the lower window screen frame are located on both sides of the glass frame, and the end of the second glass rotating shaft away from the glass frame is connected with a second rotating device, the first glass rotating shaft and the second glass rotating shaft Shaft axes coincide. A rotating shaft nested automatic opening and closing window of the present invention solves the problems in the prior art that the transmission reliability and stability are poor and the window screen cannot be opened and closed automatically.

Owner:YANAN UNIV

A dual-motor direct-drive positioning and rotating mechanism

ActiveCN110640421BAchieve independent rotationGuaranteed matchAssembly machinesMetal working apparatusEngineeringControl theory

The invention discloses a dual-motor direct-drive positioning and rotating mechanism, the structure of which comprises a No. 1 motor, a fixed plate, a connecting plate, a main connecting shaft, a support rod, a transfer device, a No. 2 motor, and the No. 1 motor is connected to the fixed plate. , the fixed plate is provided with a connecting plate, and the connecting plate and the fixed plate are parallel to each other. The beneficial effect of the present invention is that the rotating rod rotates to push the movable rod to rotate accordingly, and the traction solid turntable rotates in the same direction, so that the activities in the first cavity The push rod rotates under the drive of the No. 1 cavity, and when the movable push rod slides on the fixed groove, it is separated from the slot on the inner wall of the No. 1 cavity for a small part of the time, so that the disc body can rotate independently and drive the main connecting shaft to rotate at a corresponding angle , and use the elastic layer to push the movable push rod into the inner wall of the No. 1 cavity again, so that the disk body stops rotating. When the rotating rod collides with the movable rod again, the rotating part of the disk body rotates intermittently through an angle. The purpose of controlling the small adjustment of the rotating mechanism is achieved.

Owner:重庆高新技术产业研究院有限责任公司

Energy-saving marine oil pollution cleaner

ActiveCN112064606BAchieve independent rotationImprove cleaning efficiencyWater cleaningGeneral water supply conservationEnvironmental engineeringPetroleum engineering

The invention discloses an energy-saving marine oil pollution cleaner, which at least includes a cleaning body and a floating body, the floating body is arranged on the cleaning body so that the cleaning body can float on the sea surface, and the cleaning body is provided with a The independently rotatable first oil discharge push plate and the second oil discharge push plate separate the inner cavity of the cleaning body into a first area and a second area, and the cleaning body is provided with a first The oil inlet and the first oil discharge port communicated with the second area, the first oil discharge push plate and the second oil discharge push plate are arranged in an alternate rotation mode to continuously push the oil in the second area into the first oil discharge port. In a row of oil ports. After the oil on the sea surface enters the cleaning body from the first oil inlet, the cleaning body can block the waves on the sea surface. At this time, the oil that enters the cleaning body will not be shot into the seabed by the waves, and then enters the oil in the cleaning body Can be completely drained to improve oil cleaning efficiency.

Owner:ZHEJIANG OCEAN UNIV

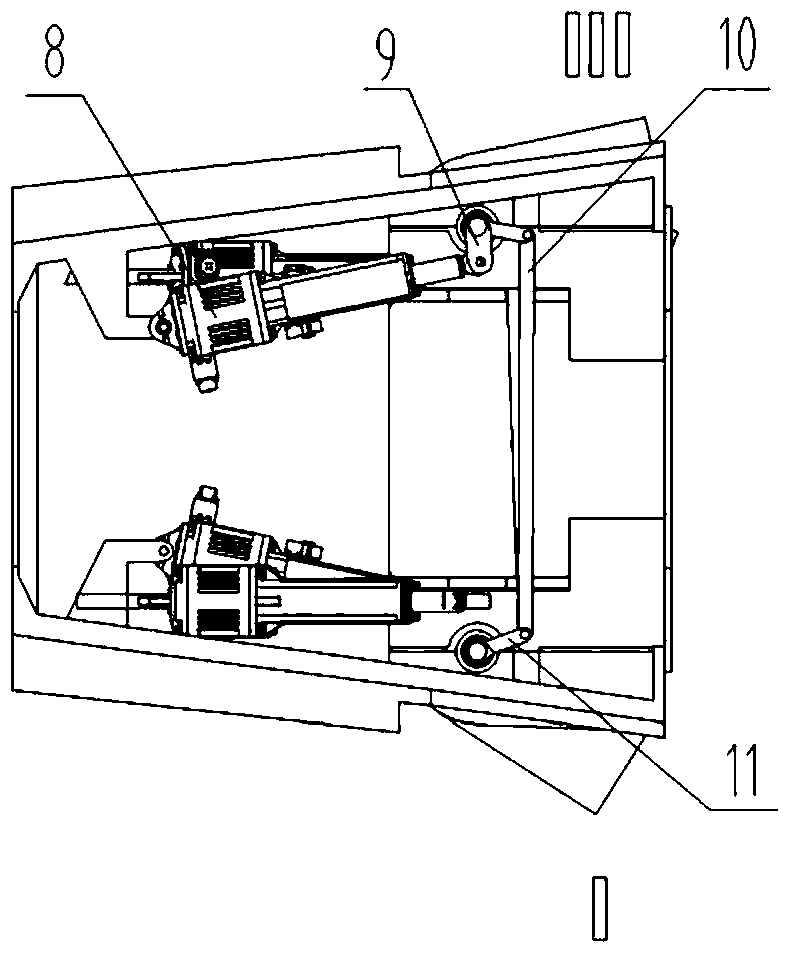

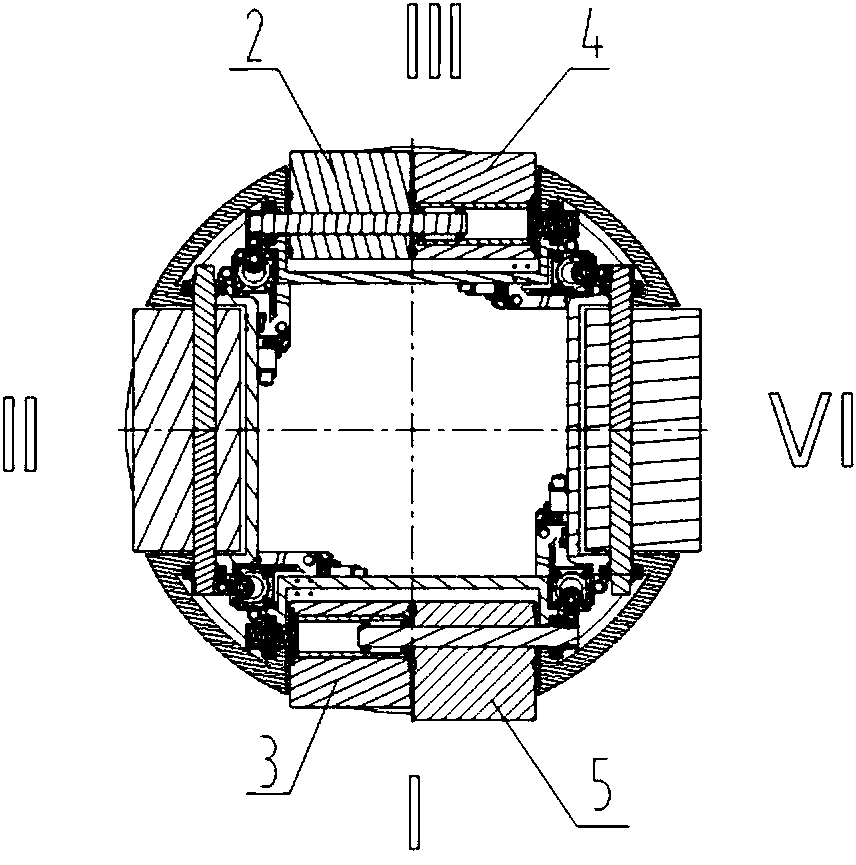

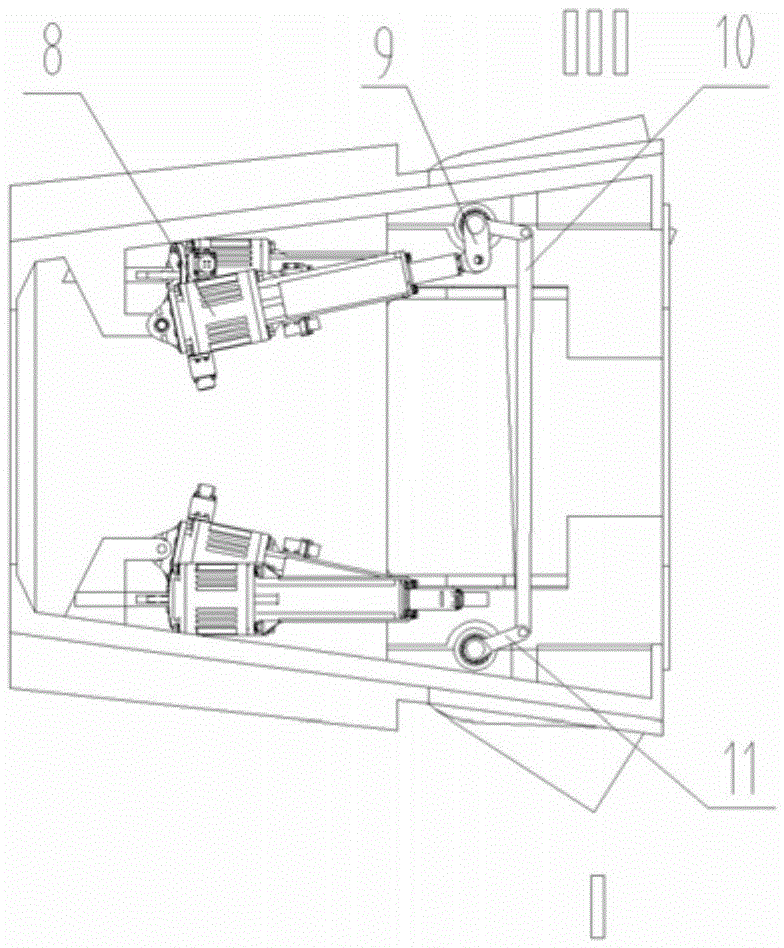

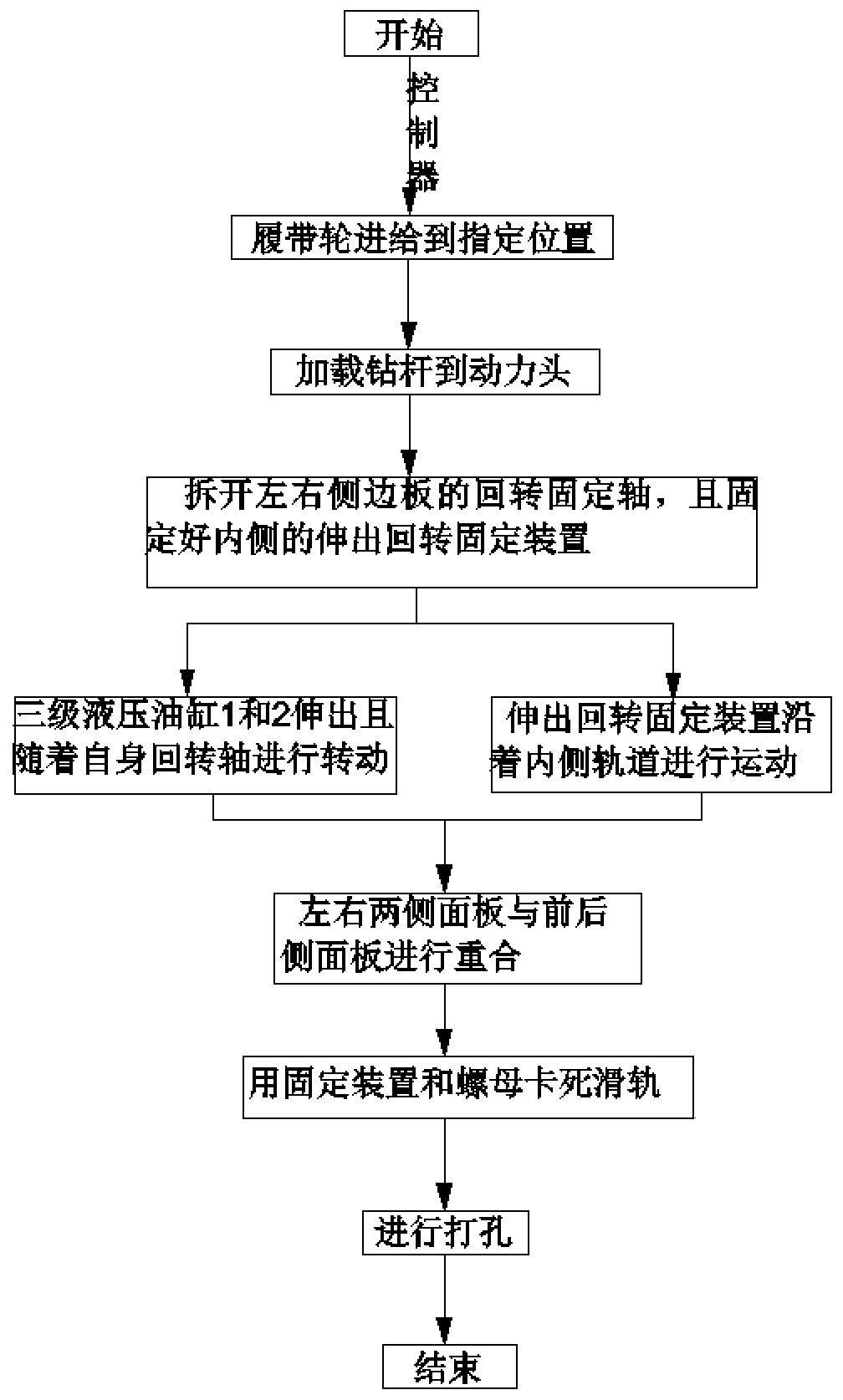

Folding roof bolter capable of carrying out circumferential rotation for multi-hole construction

PendingCN110905405AAchieving moment balanceImprove positioning accuracyDrilling rodsDerricks/mastsDrill holeRock bolt

The invention provides a folding roof bolter capable of carrying out circumferential rotation for multi-hole construction. The folding roof bolter comprises a base part, circumferential holing parts and two-stage folding parts. The circumferential holing parts are located on two sides of the base part. The two-stage folding parts are located on the other two sides of the base part. Each circumferential holing part is provided with a holing part and an axial rotation mechanism, wherein the axial rotation mechanism is used for making the circumferential holing part to axially rotate to be at thesame horizontal plane as the two-stage folding parts, and the holing part is used for smooth feeding drilling in the horizontal plane or a horizontal plane where the circumferential holing part is located on before or after axial rotation. The two-stage folding part is used for implementing inclined drilling. With the folding roof bolter capable of carrying out circumferential rotation for multi-hole construction, it is solved that a drilling equipment in the prior art cannot make anchor holes be in the same straight line, and cannot meet the requirements of construction for large, medium, small and narrow roadways either.

Owner:CHANGAN UNIV

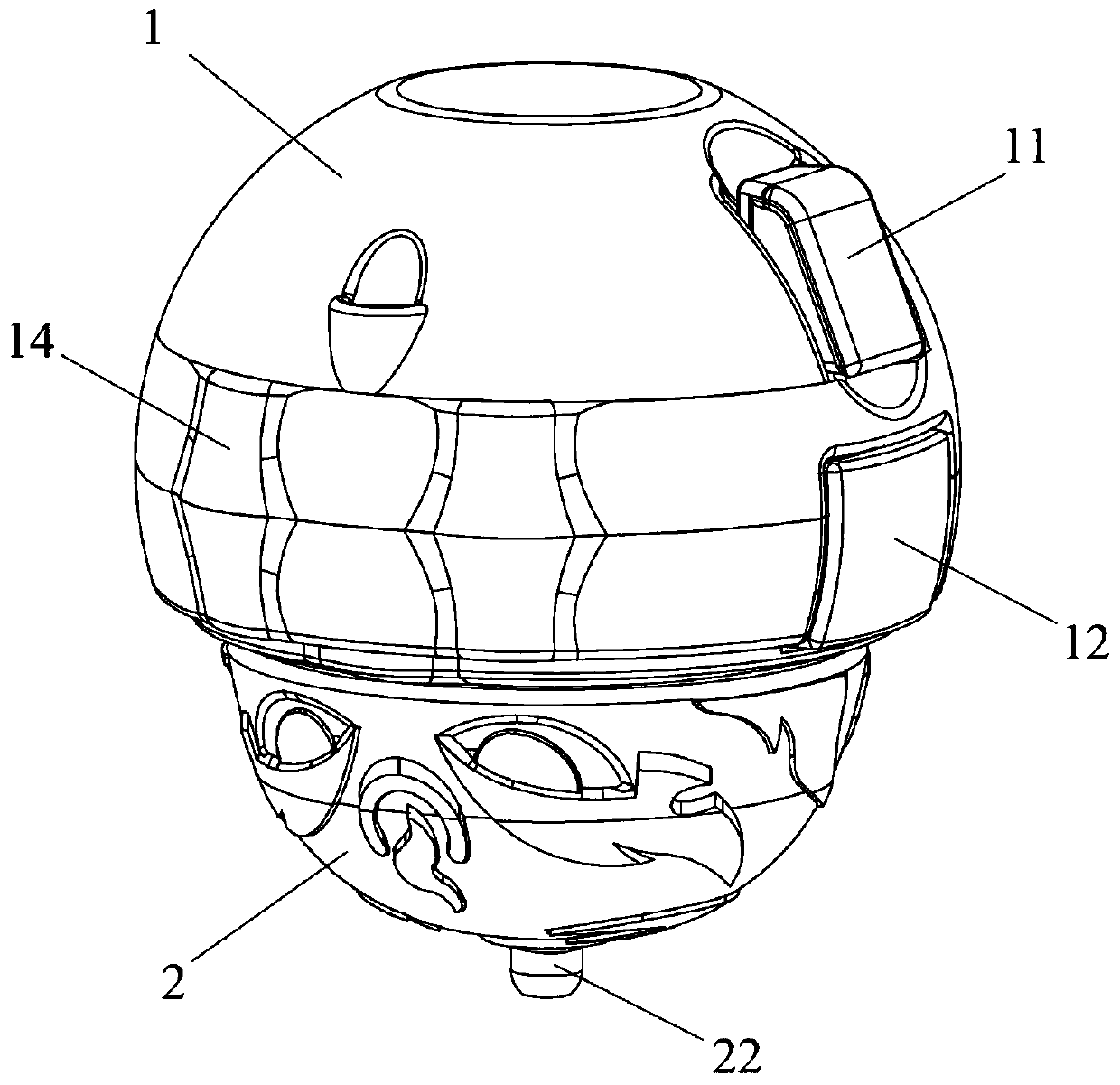

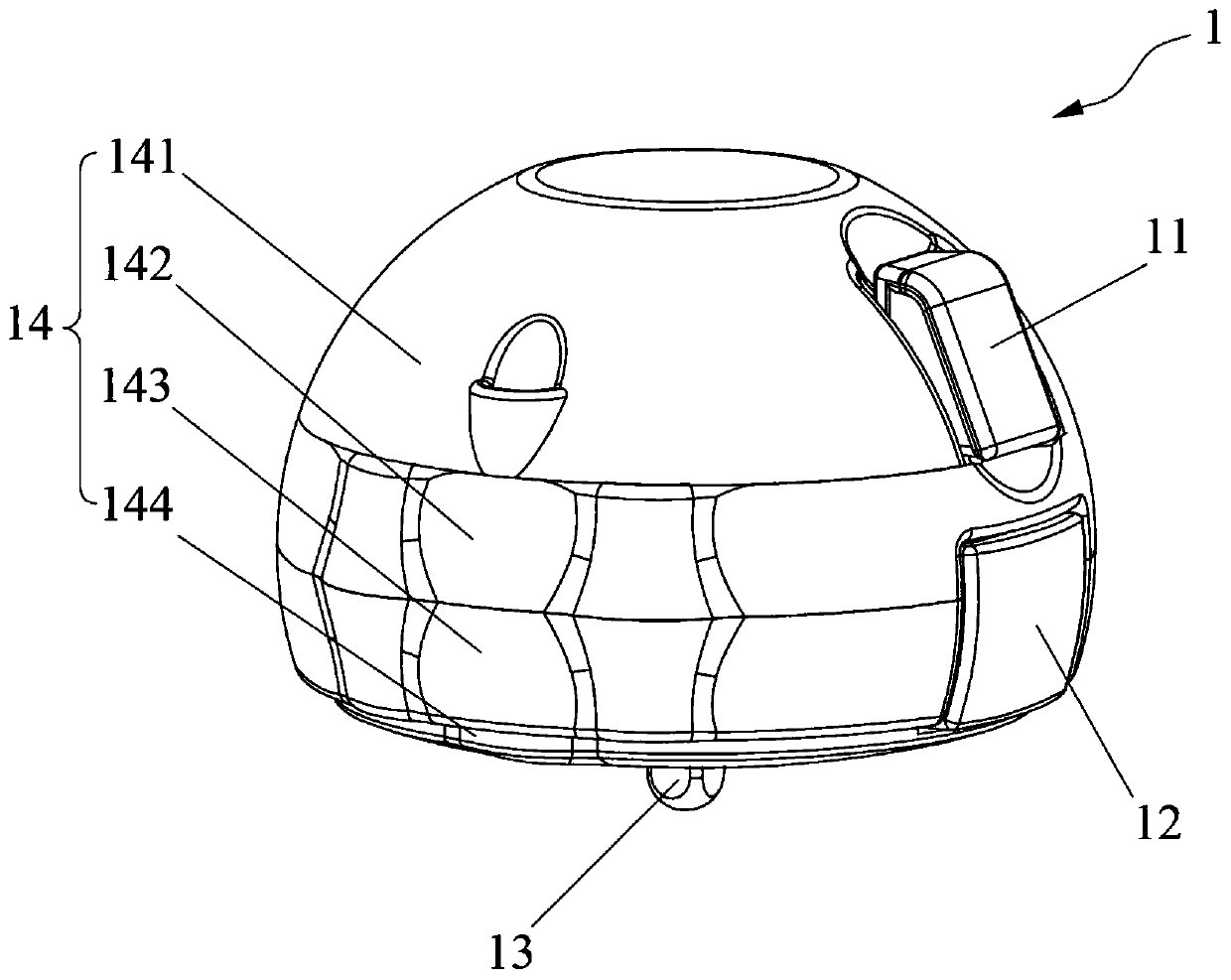

Gyro toy

PendingCN111450542AVarious combinationsNovel structureTopsSport apparatusCompetitive gameEngineering

The invention relates to the field of toys, and discloses a gyro toy. The gyro toy is formed by combining a first gyro and a second gyro which can rotate independently. An energy storage accelerationassembly and a separation assembly are arranged in the first gyro; the energy storage acceleration assembly can perform energy storage acceleration on the first gyro and the second gyro, and the firstgyro and the second gyro subjected to energy storage acceleration can be used as a combination to rotate together, or the first gyro and the second gyro subjected to energy storage acceleration can be separated from each other through the separation assembly and then rotate respectively. The gyro toy provided by the invention is novel in structure and various in playing methods, the interestingness and playability of the gyro toy are enhanced, richer competitive game experience is brought to players, and the participation interestingness of the players is improved.

Owner:GUANGZHOU SUNBOY ANIMATION & TOYS CO LTD

Synchronous twisting support device for cable production

ActiveCN113223780BPlay a protective effectImprove driving effectCable/conductor manufactureElectric machineryDrive motor

The invention discloses a synchronous twisting support device for cable production. The support is fixedly installed at the center of the base, and mounting holes are provided at the four corners of the base. A twisted outer disc is fixedly installed at the end of the support away from the base. The motor base is horizontally and fixedly installed in the middle of the support, and a drive motor is fixedly installed on the motor base, and a driving pulley is fixedly installed on the output shaft of the drive motor, and the twisted middle disc is connected with the twisted outer disc through the first bearing, The inner ring of the first bearing is fixedly connected to the outer circumference of the twisting middle disc, the outer ring of the first bearing is fixedly connected to the inner circumference of the outer twisting disc, and a driven pulley is fixedly installed on the end of the twisting middle disc close to the driving motor. The disc is rotatably connected to the twisted outer disc through the first bearing, and the twisted middle disc is rotatably connected to the twisted inner disc through the second bearing to realize the independent rotation of the twisted disc, and the supporting rollers set on the twisted outer disc twist the cables Machining acts as a synchronous support.

Owner:HEFEI SMARTER TECH GROUP CORP

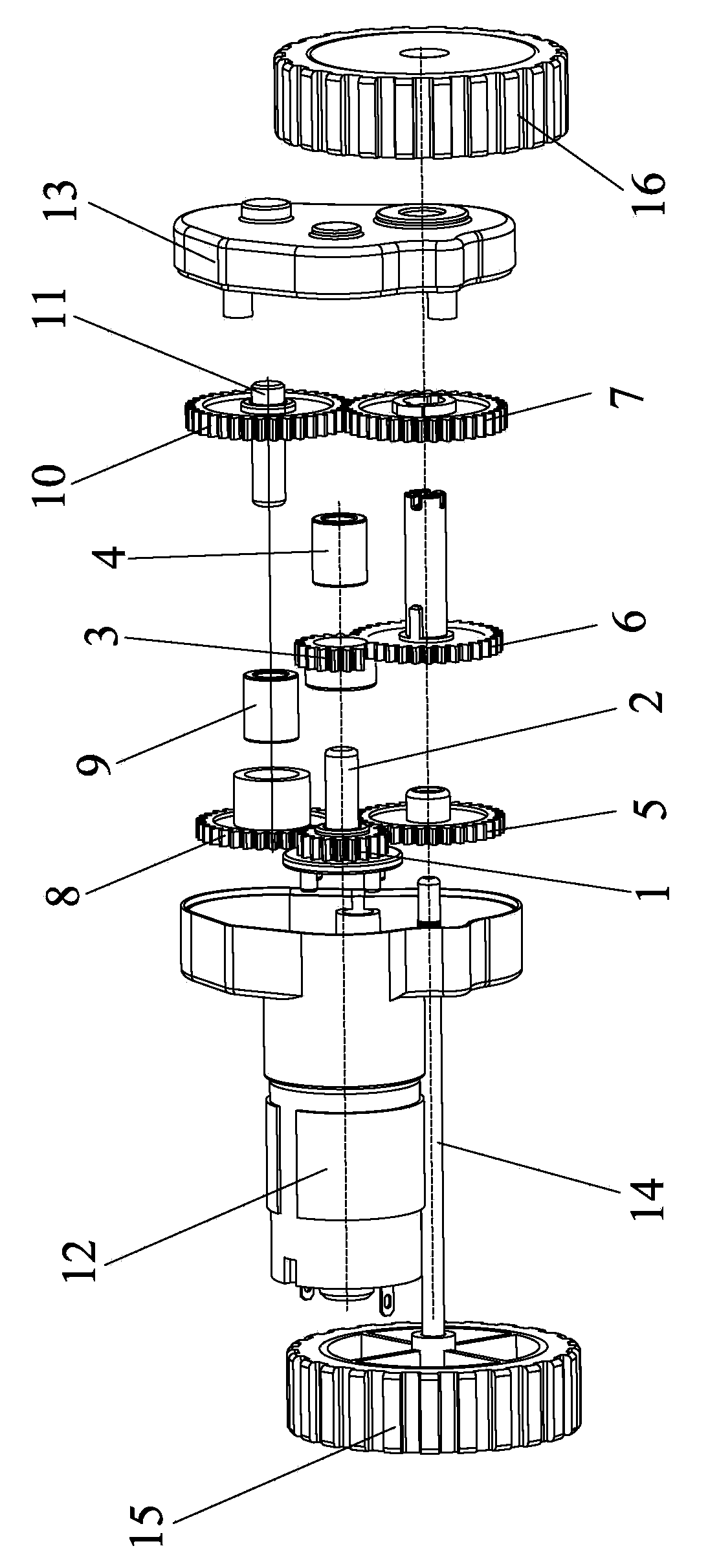

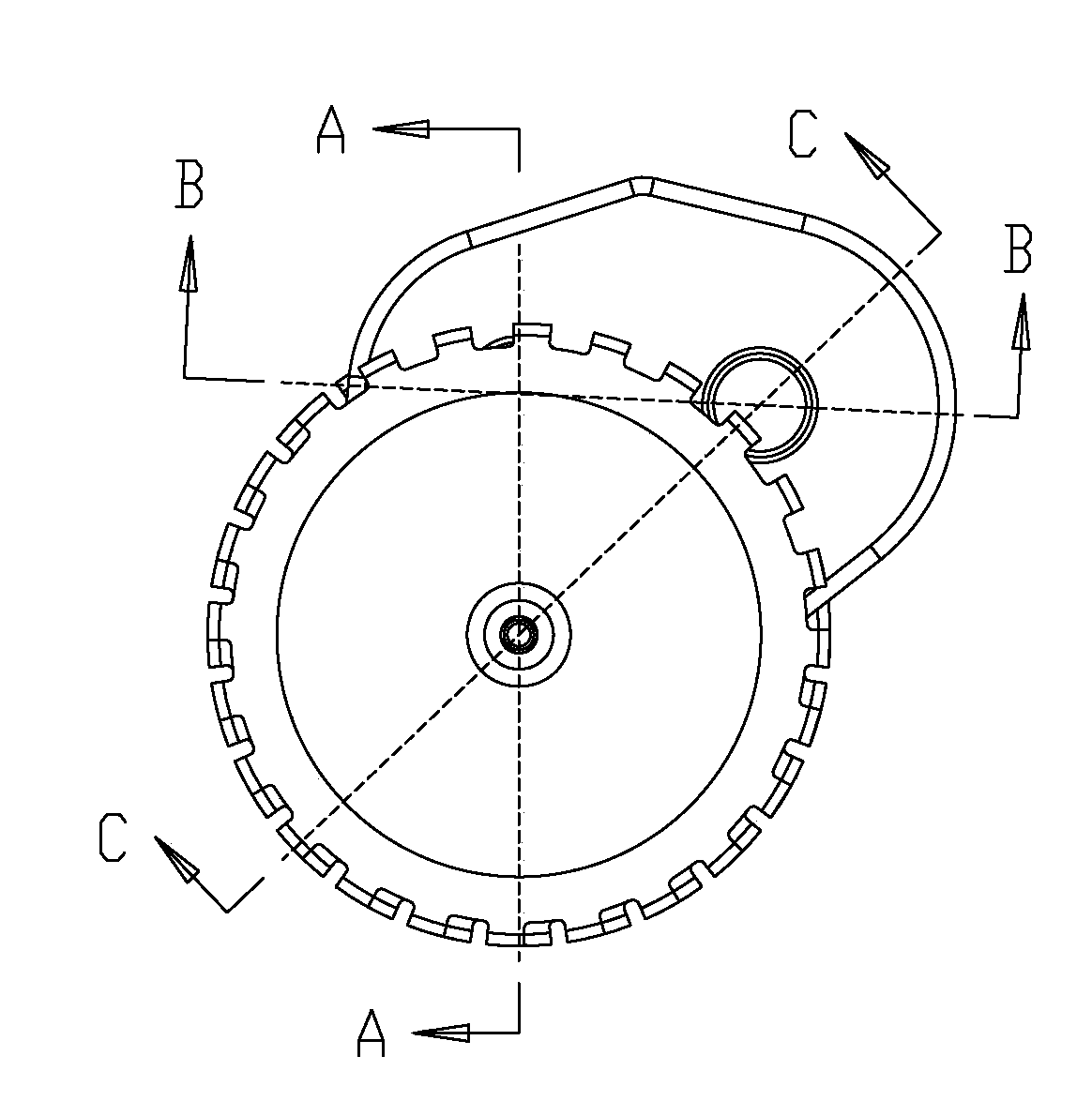

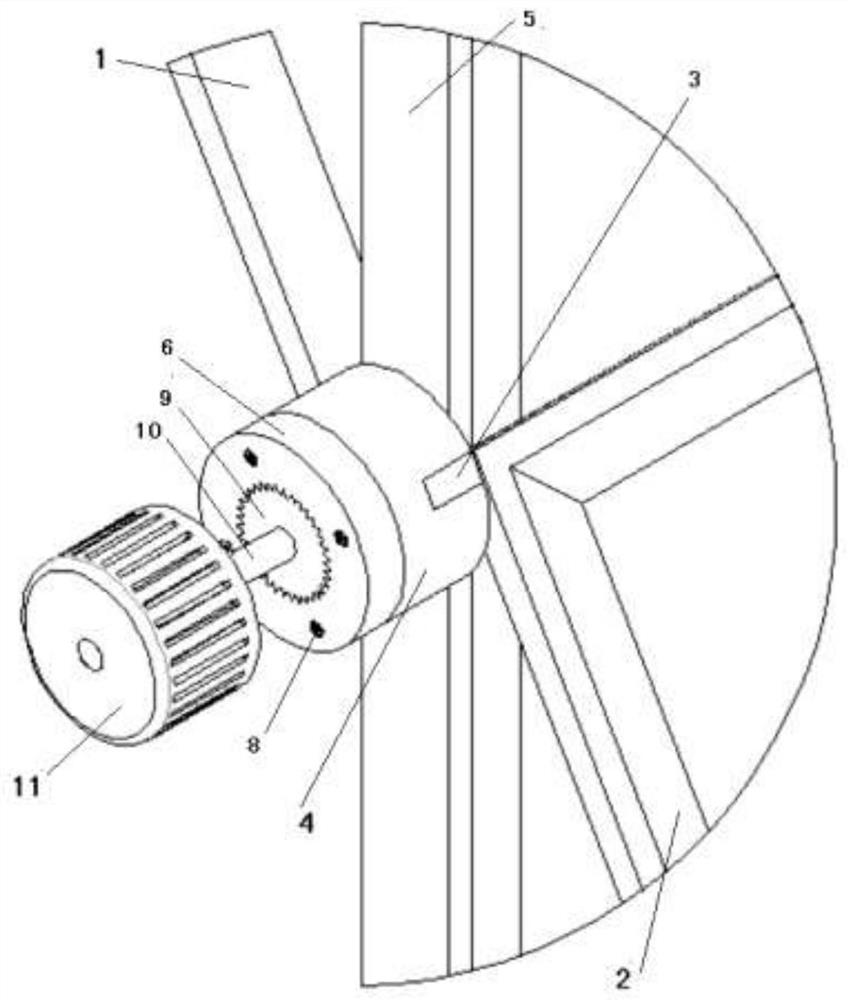

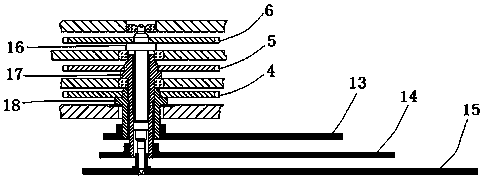

An analog watch movement with multiple hands that rotate independently about the same axis

ActiveCN105045078BAchieve independent rotationVersatileGearworksElectric windingEngineeringDrive motor

The invention discloses a pointer watch movement with a plurality of pointers independently rotating around the same axis. It includes a plurality of pointers, a gear transmission mechanism that drives each pointer to rotate, and a corresponding drive motor; wherein, one of the gears in each gear transmission mechanism is set on the central axis from bottom to top at the same time, and passes through the respective The pointer shafts of the pointers are connected with the corresponding pointers to drive the corresponding pointers to rotate, the drive motors are controlled by different driving signals, and the axis of the multiple pointer shafts is the axis of the central axis. Each pointer of the present invention adopts an independent set of drive motor and gear transmission mechanism, which realizes the independent rotation of different pointers, and the rotation of each pointer is independent of each other, which solves the problem that the existing pointers cannot display azimuth, altitude, air pressure, and incoming calls through pointers. , text messages, emails and other information problems, the functions are more complete, and the purpose of intelligence is truly achieved. The structure design is ingenious, which is very suitable for large-scale promotion and use.

Owner:CHENGDUSCEON ELECTRONICS

Double rope climbing hoist

ActiveCN104692270BImprove securityAchieve independent rotationWinding mechanismsEngineeringHanging basket

The invention discloses a climbing elevator. The climbing elevator is characterized in that ropes are respectively wound on two rope winding mechanisms, the two rope winding mechanisms are connected with a driving mechanism by overrunning clutches, are pulled by the ropes along climbing directions and can rotate beyond the driving mechanism, the ropes can be wound in type-a rope winding modes and type-s rope winding modes, and the rope winding mechanisms can be pulled by gravity pulling and traction pulling structures. The climbing elevator has the advantages that asynchronous elastic extension of the double ropes of the elevator with double rope systems capable of independently rotating can be automatically adjusted, and loads can be reasonably shared by the double ropes during work; equipment defects can be timely found out during running; the climbing elevator has double protection functions, accordingly, external safety devices can be completely replaced, and carrier structures can be simplified; the optional system still can continue working when the other system fails, and accordingly the safety performance of the climbing elevator can be obviously improved; the climbing elevator can be widely applied to the fields of high-place operation hanging baskets, window cleaning machines, rescue lifters of high-rise buildings and the like.

Owner:温建

Electrically-adjustable optical spectacle frame

PendingCN114114584AGood overall stiffnessAvoid interferenceMountingsOptical instrumentationEngineering

The invention relates to the technical field of optical instruments, and particularly discloses an electrically tunable optical mirror bracket which comprises a mirror frame, a fixing plate hinged to the mirror frame, an X-axis driving mechanism installed on the mirror frame and used for controlling the mirror frame to rotate in the X-axis direction, and a Y-axis driving mechanism installed on the fixing plate and used for controlling the mirror frame to rotate in the Y-axis direction. According to the invention, the problems of inconvenience in driving inclined lenses, large size and poor rigidity in the rolling direction of the mirror surface of the existing electrically tunable mirror bracket can be effectively solved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com