Rough yarn feeding type rear top roller rubber roller device and ring spinning frame with same

A feed-in, roving technology used in spinning machines, continuous-winding spinning machines, textiles and papermaking, etc., to achieve the effect of facilitating maintenance and maintenance, good processing performance, and good bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be further described in detail below with reference to the drawings and embodiments.

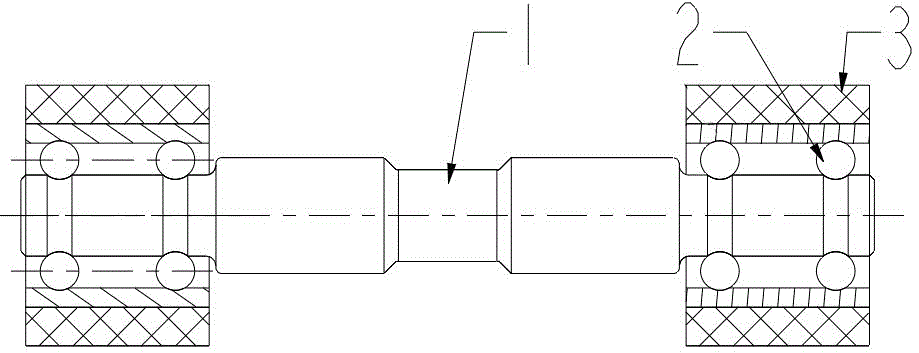

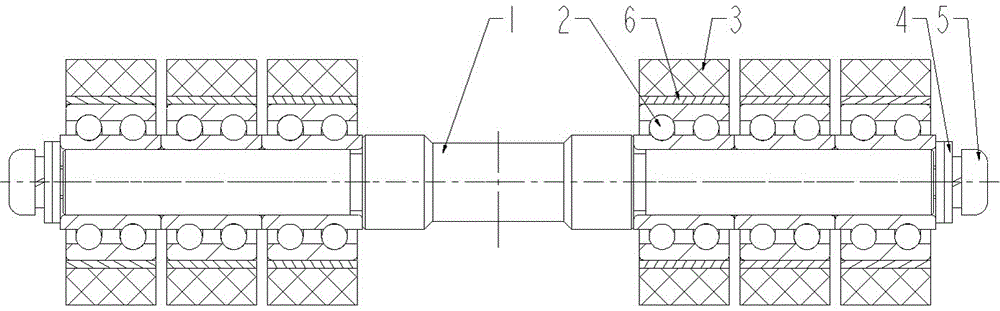

[0015] Such as figure 2 As shown, a roving feeding type rear top roller top roller device includes: rear top roller mandrel 1, special bearing 2, rubber roller 3, washer 4, screw 5 and aluminum bushing 6, and rear top roller mandrel 1 There are 2 spindles on the upper, and each spindle is equipped with a number of special bearings 2. The special bearing 2 is a double-row ball bearing whose inner ring width is greater than that of the outer ring. Oil ring, the width of the inner ring of the special bearing 2 is 6-15mm, and the diameter of the outer ring is Φ15-Φ20mm. The inner ring of the special bearing 2 is completely attached to the rear top roller mandrel 1, and the adjacent special bearing 2 is set between There is a gap to ensure that the outer ring of each special bearing 2 can rotate freely. The outer ring of the special bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com