Disk-type double-rotor counter-rotating motor and aircraft

A double-rotor, rotary motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems affecting the power density and performance of the motor, the low output efficiency of the outer rotor, and the easy loss of control of the motor, so as to ensure compactness and good performance. Application prospect, effect of increasing power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

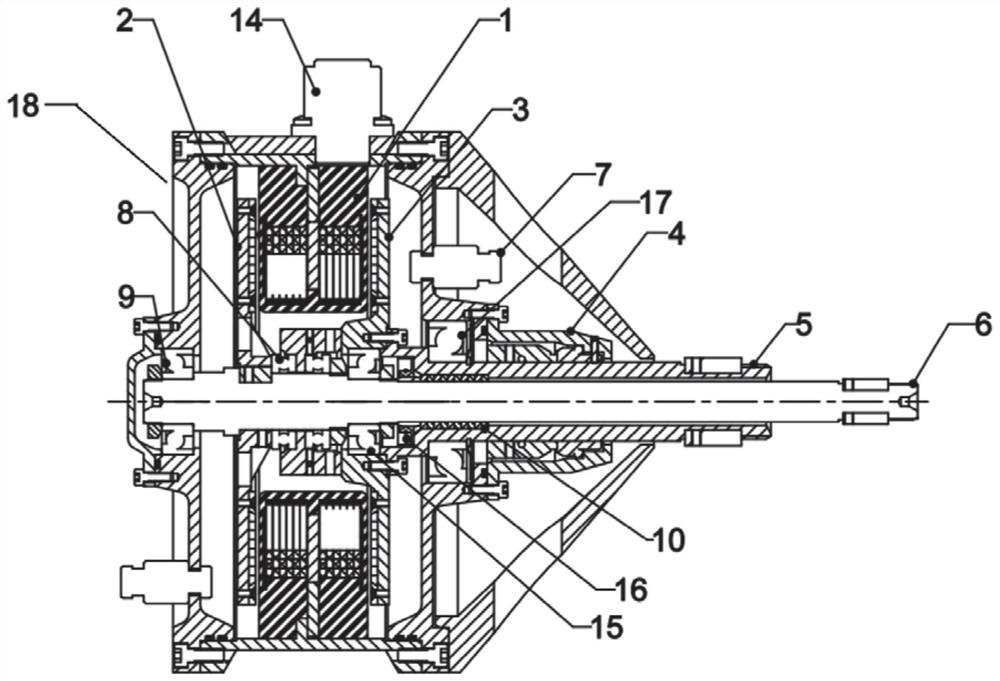

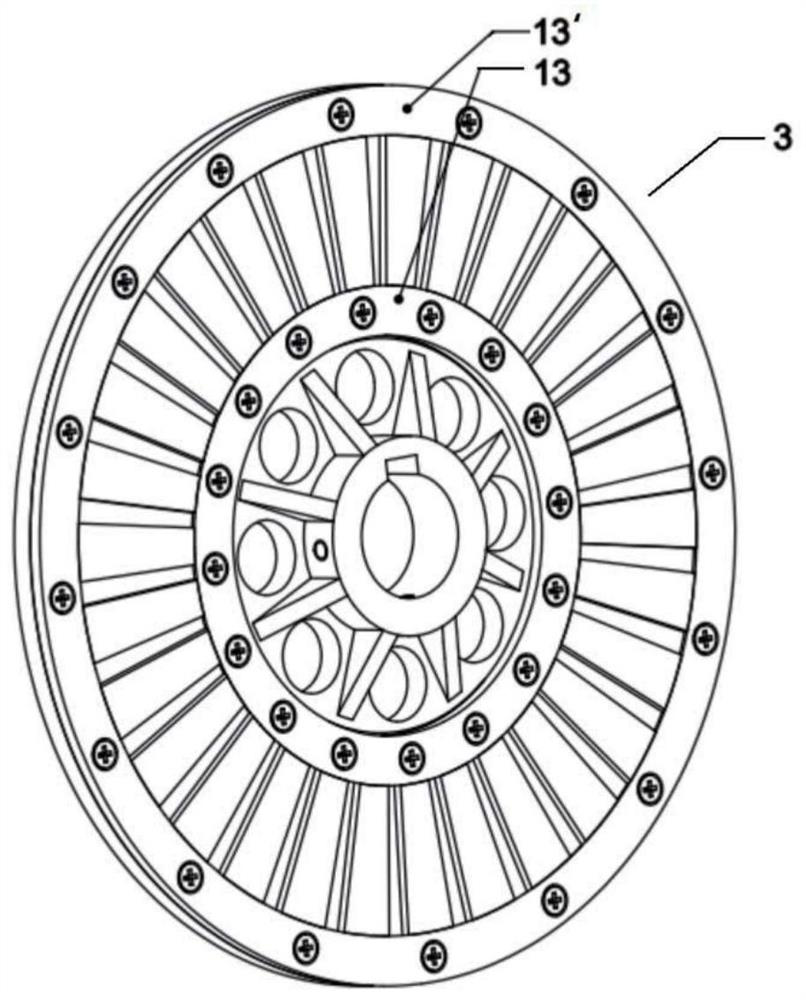

[0067] Example 1: See figure 1 , a disc-type double-rotor counter-rotating motor provided in this embodiment includes a stator assembly 1, a first rotor assembly 2 and a first rotor assembly 3, the first rotor assembly 2 and the second rotor assembly 3 are identical and symmetrical Distributed on both sides of the stator assembly 1.

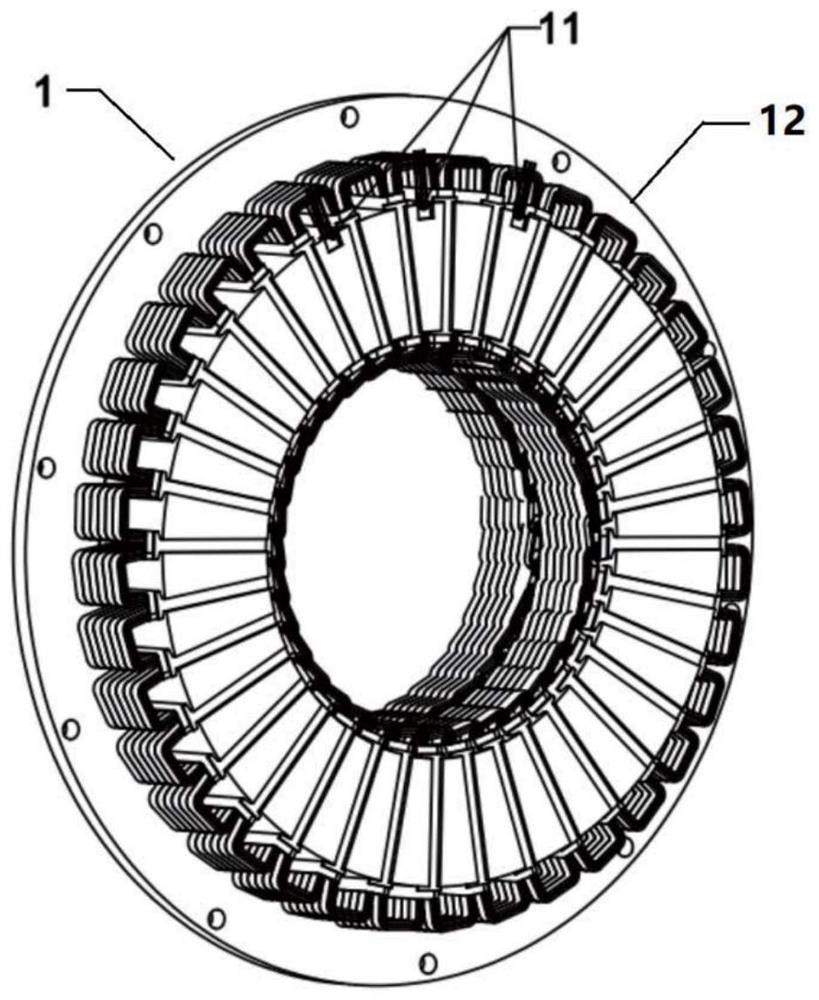

[0068] Further, the stator assembly 1 may include a stator core, two stator windings wound on the core, a stator housing, a fixed installation plate 12 and the like. Among them, the stator slots opened on both sides of the stator core are arranged symmetrically, and the two corresponding stator windings are symmetrically distributed on both sides of the stator core. Specifically, the two stator windings are respectively wound on the stator teeth on both sides of the stator assembly, and the arrangement of the ends is as follows: figure 2 As shown, and the phase sequence arrangement of the two stator windings is reversed, it is used to generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com