Patents

Literature

60results about How to "Fully automatic operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

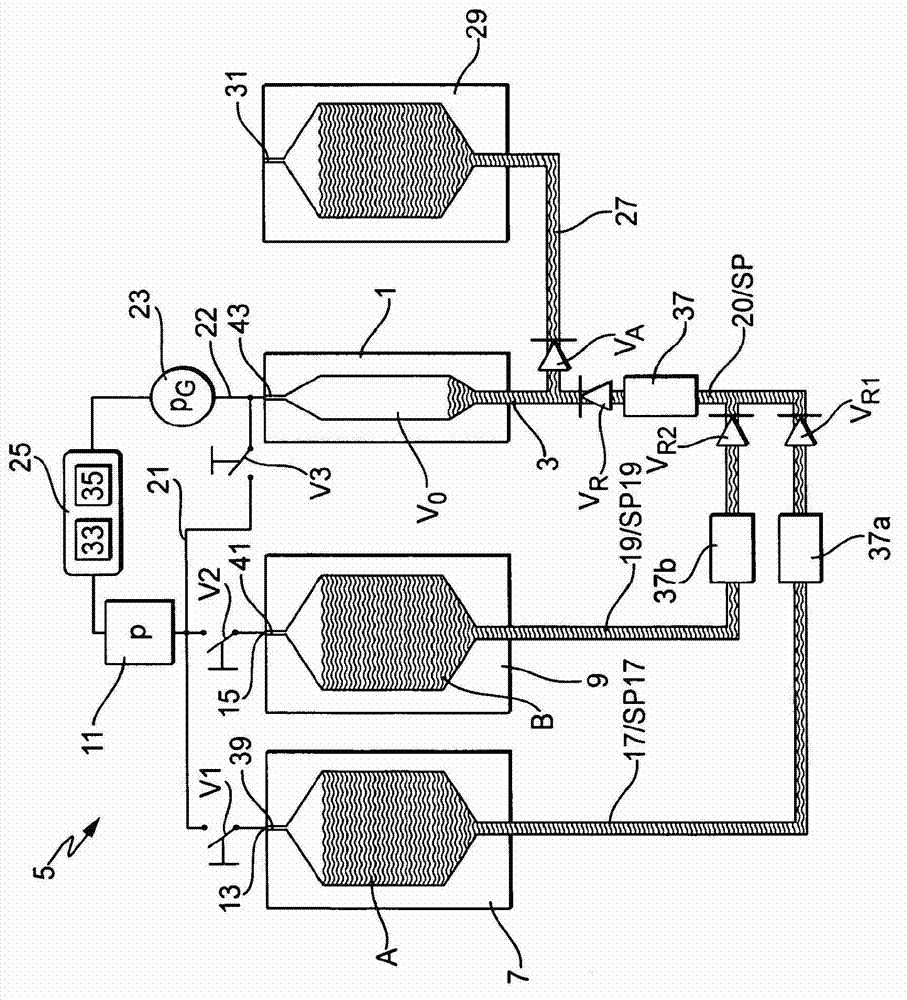

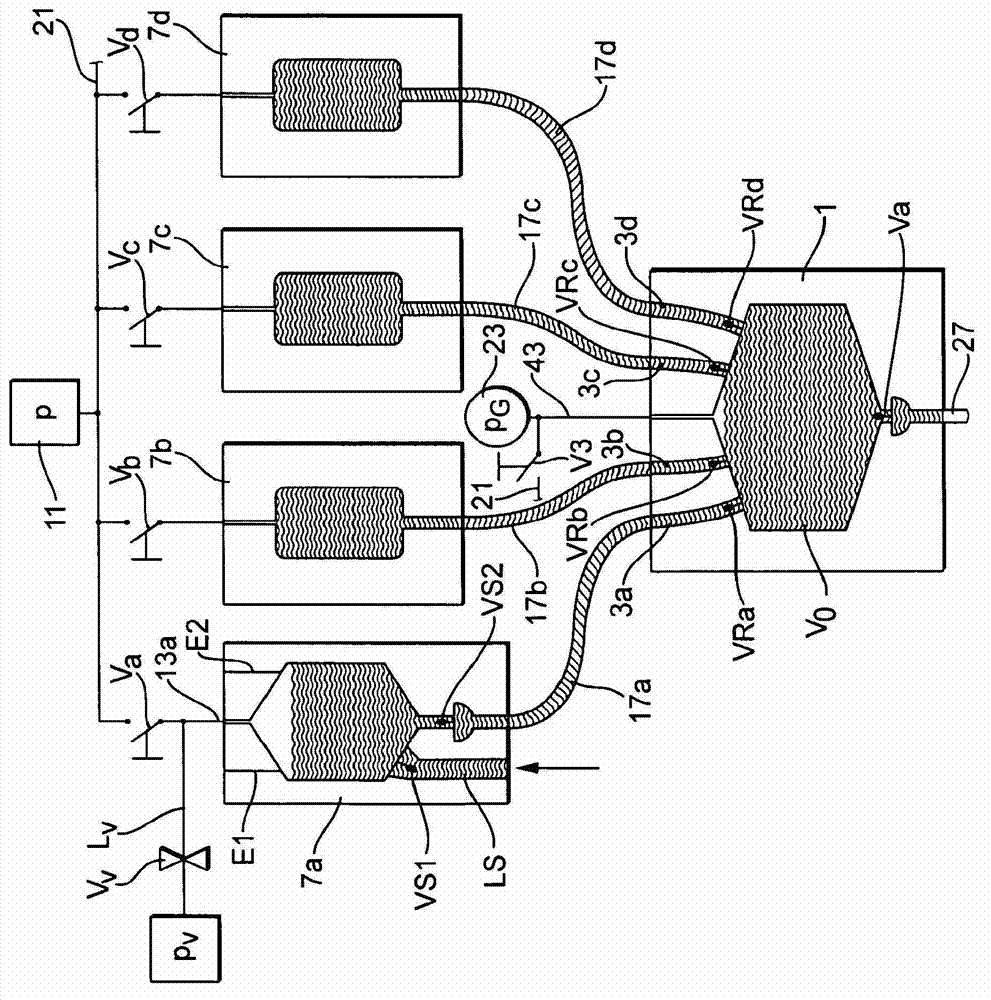

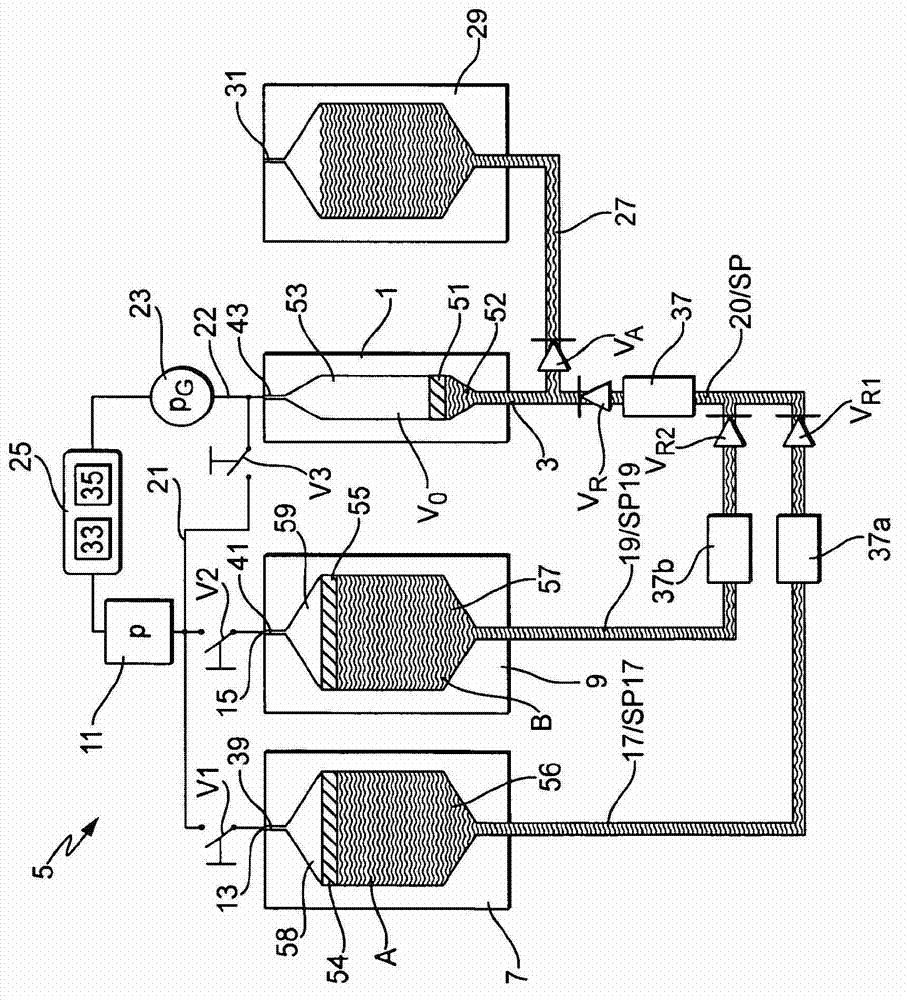

Method and device for measuring a volume flow of a liquid flowing into a container and/or a volume of the liquid having flowed into the container

ActiveCN102971610AFully automatic operationVolume measurement apparatus/methodsControlling ratio of multiple fluid flowsEngineeringStreamflow

The invention relates to a method and device for measuring a volume flow (dV(t) / dt) of a liquid (A, B) flowing into a container (1) and / or a volume (V(t)) of the liquid (A, B) having flowed into the container (1), by means of which a high degree of automation can be achieved in microfluidic systems, in particular in the field of analysis, wherein a gas is confined in the container (1) at a prescribed initial volume (V0) and at an initial pressure (p0) prior to the inflow of the fluid (A, B), the fluid (A, B) subsequently flowing into the container (1) compresses the confined gas to a gas volume that is a function of the volume (V(t)) of the liquid having flowed in and causes an increase in gas pressure (pG) of the gas in the container (1) relative to the initial pressure (PG), which is a function of the volume (V (t)) that has flowed in and the volumetric flow rate (dV(t) / dt); of the inflow, the gas pressure (pG) in the container is measured as a function of time (t), and the volume (V(t)) having flowed in up to time (t) and / or the volumetric flow rate (dV(t) / dt) of the inflow at time (t) is determined using the measured gas pressure (pG).

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

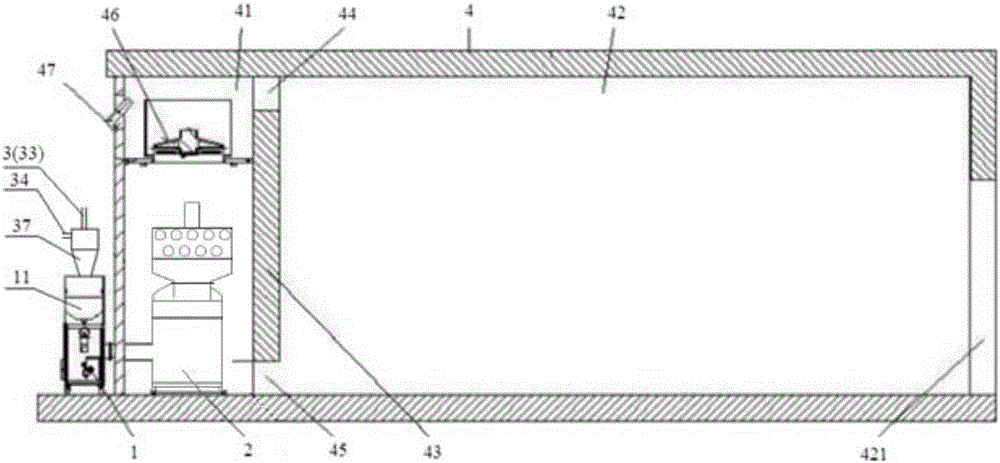

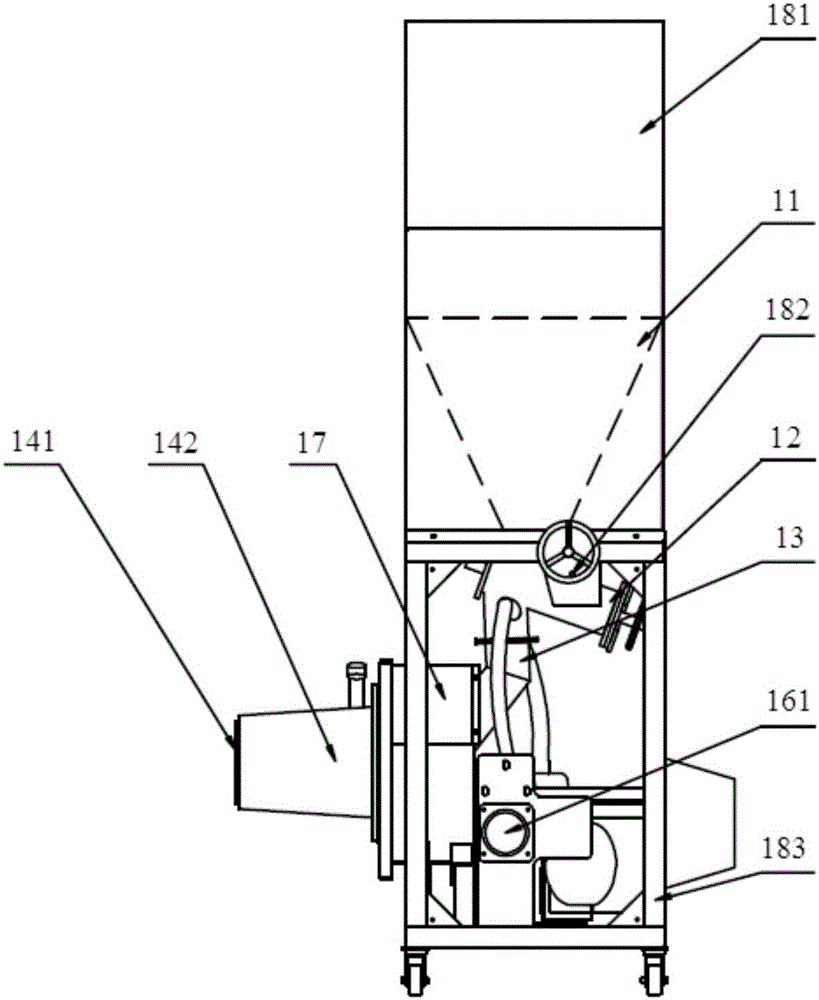

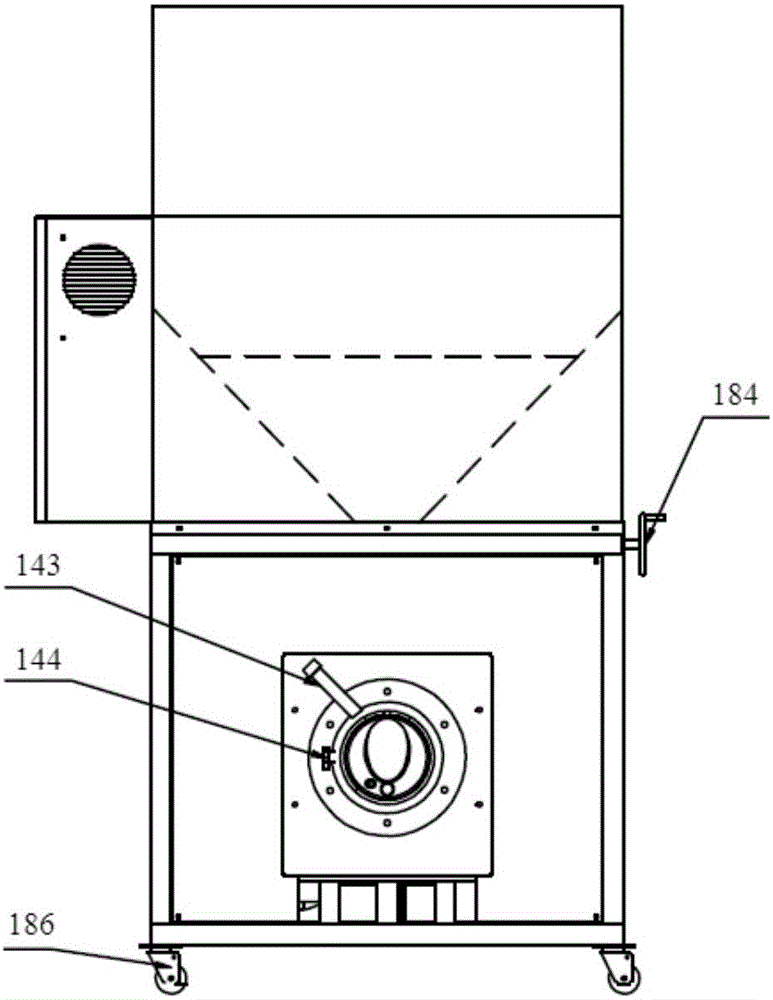

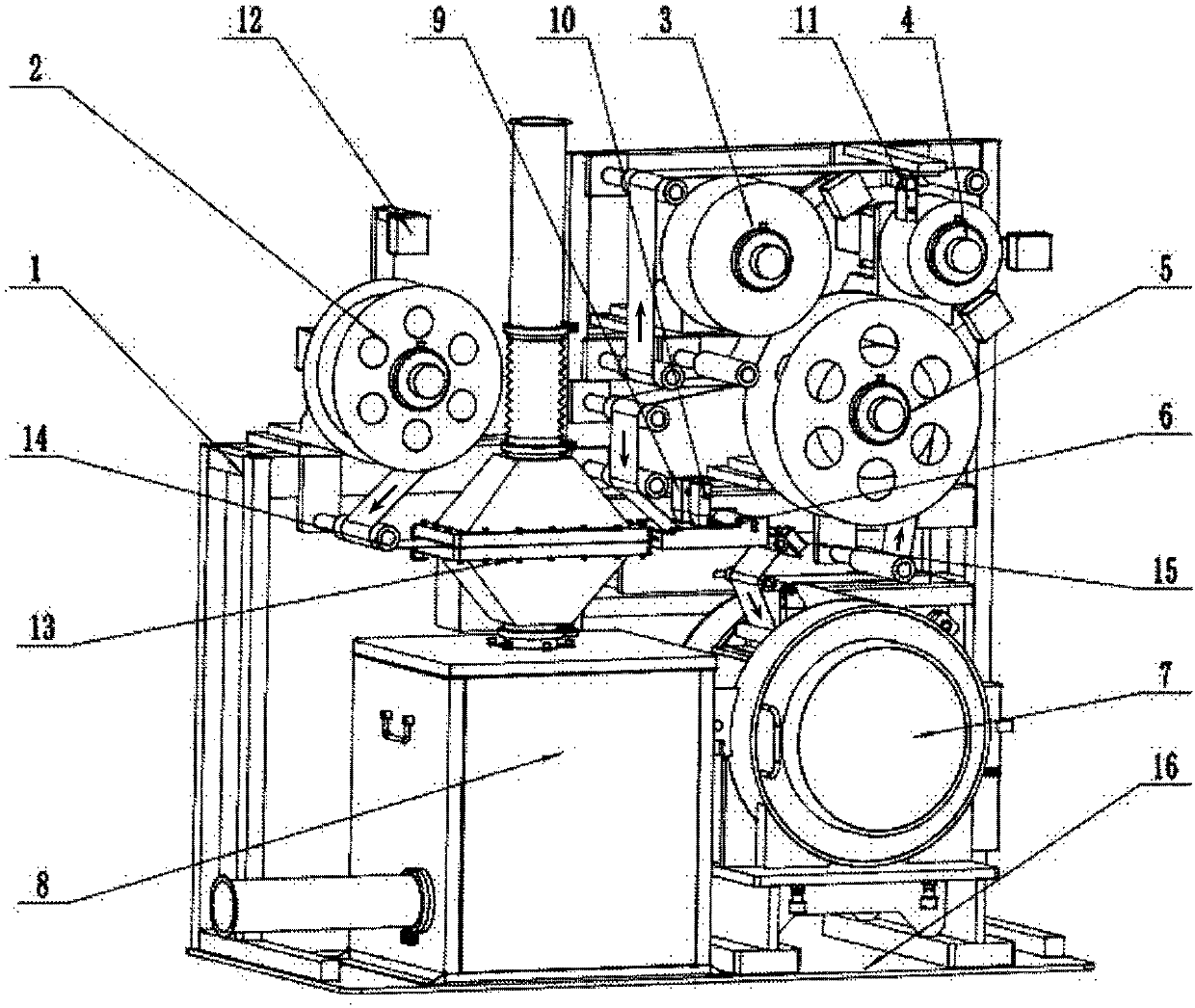

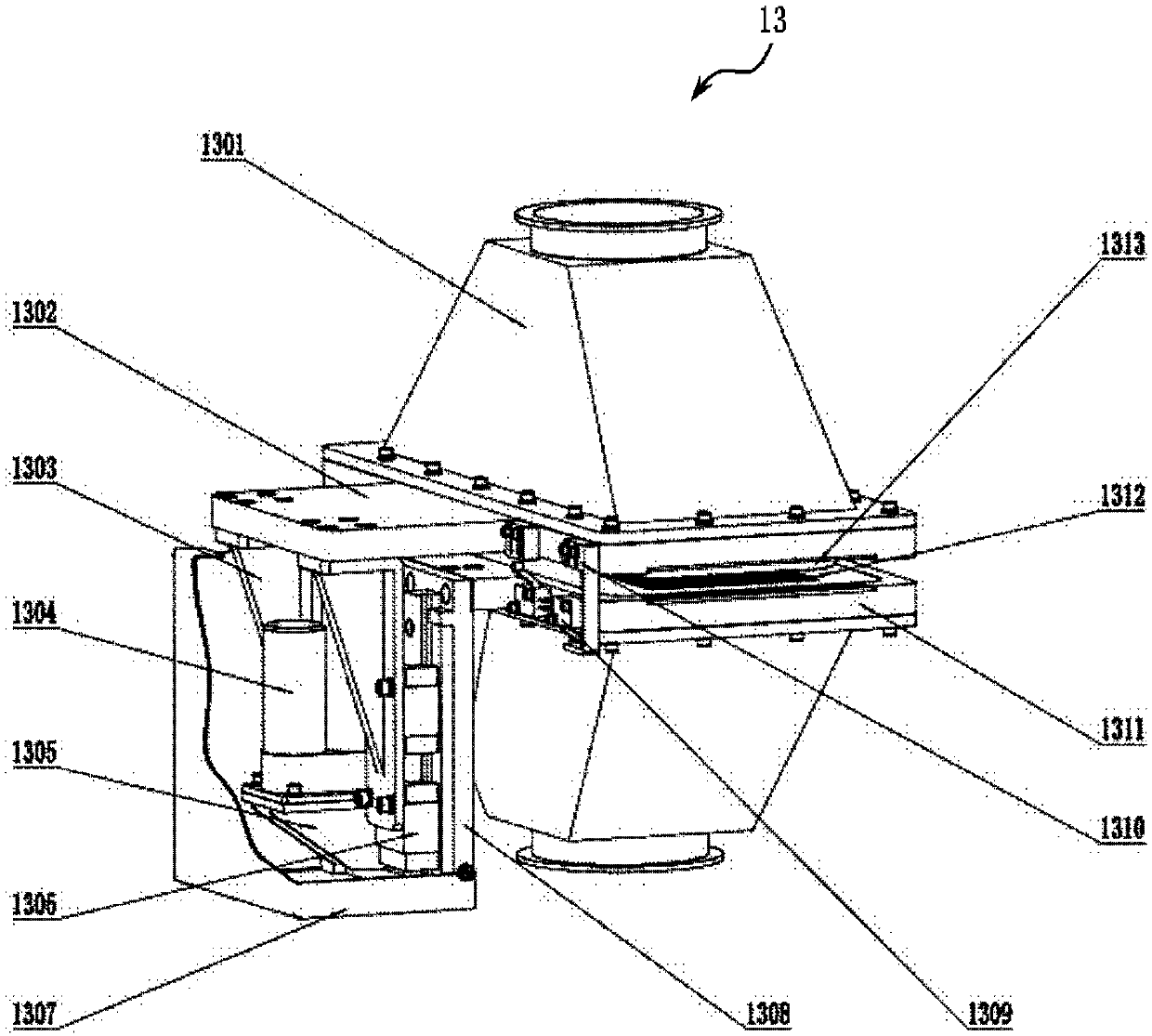

Biomass pellet fuel heating appliance

ActiveCN105942568AEnsure consistencyGuaranteed versatilityTobacco preparationDrying gas arrangementsEconomic benefitsRecuperator

The invention provides a biomass pellet fuel heating appliance, comprising a combustion furnace, a heat exchanger, a central supply system for supplying biomass pellet fuel to the combustion furnace, and a barn; the heat exchanger is used for being connected to one end of a horizontal nozzle of the combustion furnace, the barn includes a heating chamber, the heat exchanger is disposed in the heating chamber, and the combustion furnace and the central supply system are disposed outside the barn; the central supply system is used for providing biomass pellet fuel centrally for more than two combustion furnaces and comprises a suction unit with a vacuum pump, a storage barrel, more than two suction pipes, more than two feed pipes, a screw feeding mechanism, a feeding distribution connector, more than two electromagnetic valves, more than two vacuum buckets and more than two gravity valves. The heating appliance provided herein is reasonable and practical in design, safe and green, and efficient and labor-saving, reduces cost, saves resources, improves work efficiency and enterprise economic benefit, and is suitable for popularization and use.

Owner:HUNAN XINDI NEW ENERGY TECH CO LTD

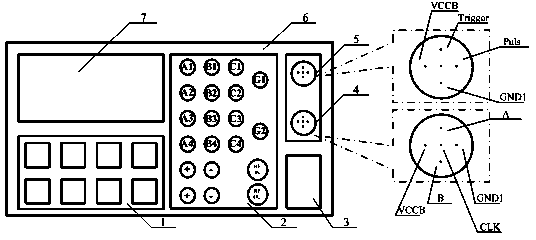

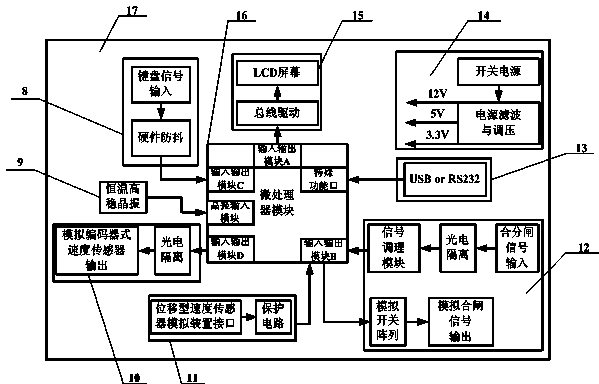

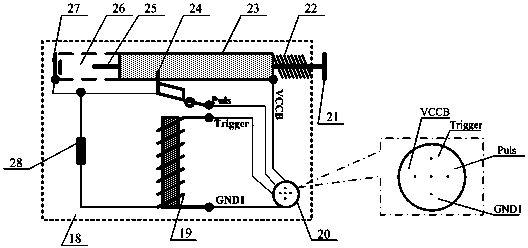

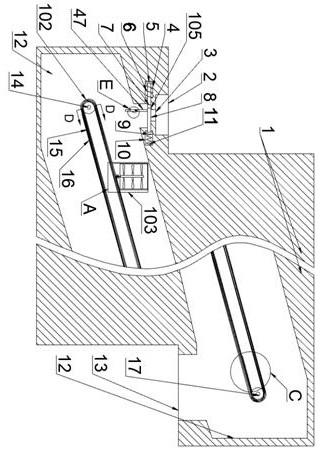

High-voltage switch mechanical feature tester verifying device

ActiveCN103487774AHighly integratedHigh measurement accuracyMachine part testingElectrical measurementsAnalog deviceTester device

The invention discloses a high-voltage switch mechanical feature tester verifying device. The problems that currently, the key parameters of a high-voltage switch mechanical feature tester are tested by setting up a temporary testing circuit, operation is complex, the number of detecting parameters is small, and data accuracy is low are solved. The high-voltage switch mechanical feature tester verifying device comprises a machine box, a main board and a displacement type speed sensor analog device. A keyboard, a power supply switch, an LCD screen, a brake opening-closing signal input-output interface, a coder type speed sensor analog output interface and a displacement type speed sensor analog device interface are arranged on a panel of the machine box. The high-voltage switch mechanical feature tester verifying device has the advantages of being high in integration level and high in testing accuracy, full-automatic operation is achieved, and complete measuring calibration and tracing on the high-voltage switch mechanical feature tester are achieved.

Owner:辽宁省检验检测认证中心

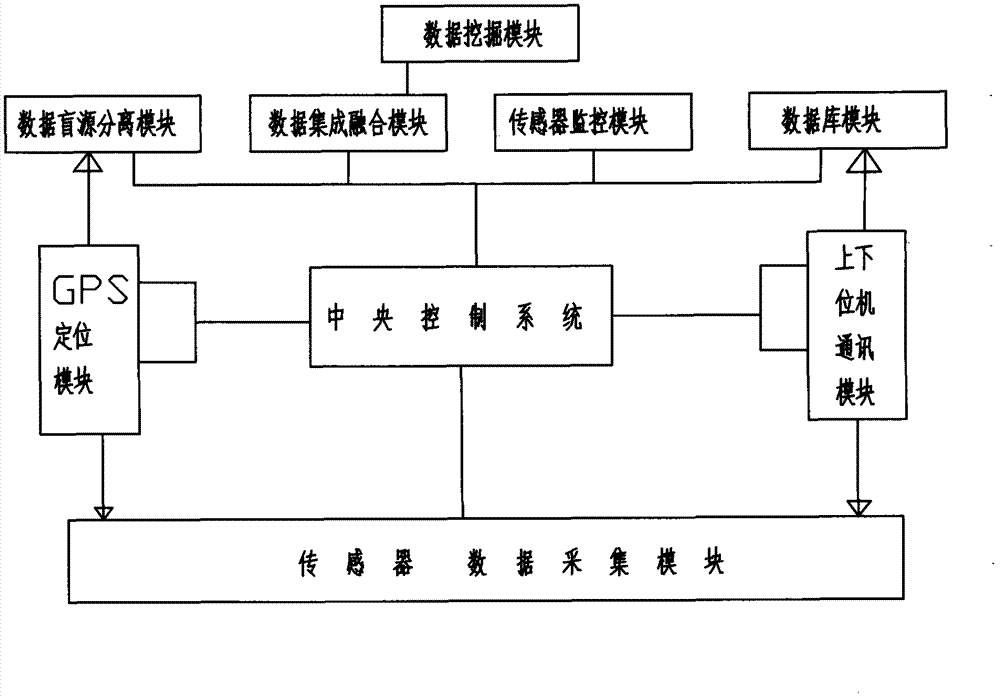

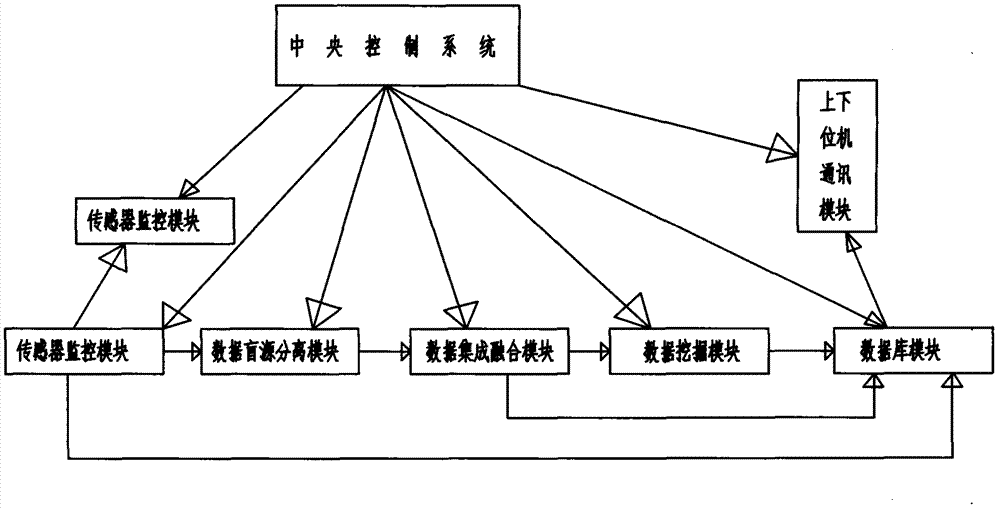

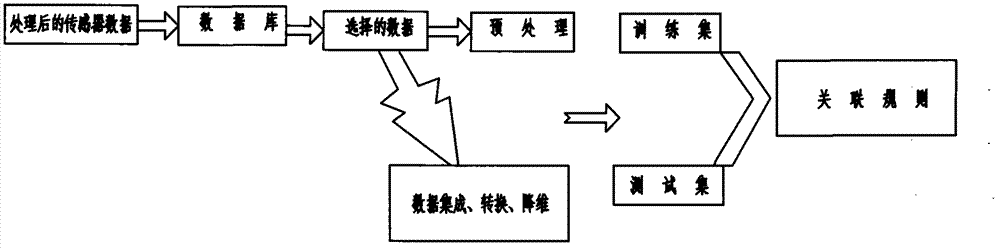

Farmland fertility data collect and analysis system based on data mining

ActiveCN103092142AFully automatic operationAchieve fully automatic intelligent precisionMeasurement devicesProgramme total factory controlData dredgingAnalysis data

The invention discloses a farmland fertility data collect and analysis system based on data mining and relates to the technical field of farmland accurate variable rate fertilization operation. The farmland fertility data collect and analysis system based on the data mining comprises a sensor data collect module, a global positioning system (GPS) positioning module, a data blind source separation module, a multi-data integration fusion module, a data mining module, a database module, a sensor supervisory module and an upper and lower computer communicating module. Due to the fact that the data mining module and the upper and lower computer communicating module are added to a sensor data collect and analysis system, the farmland fertility data collect and analysis system can effectively analyze analytical data of various sensors. By means of the data mining module, the farmland fertility data collect and analysis system analyzes real-time data collected by the various sensors, obtains certain regularity, generates content asocciation rules of soil matters such as moisture, carbon, phosphorus, potassium and heavy metal about different land parcels, and transmits the association rules to the upper and lower computer communicating module, the upper and lower computer communicating module sends a control order to a central control system, and therefore different accurate operation models can be carried out to the land parcels of different space and different time. Therefore, a purpose of accurate fertilization and irrigation can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

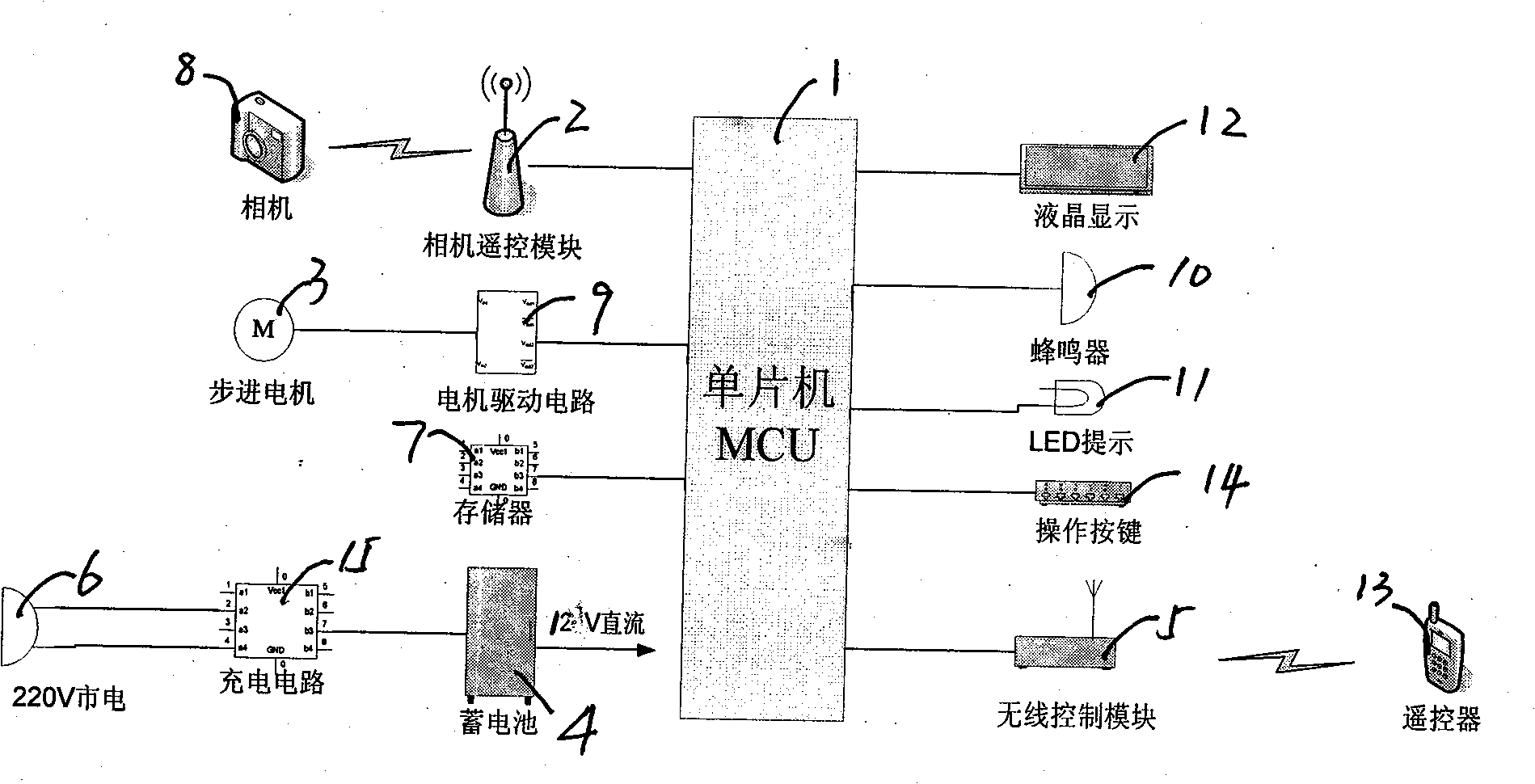

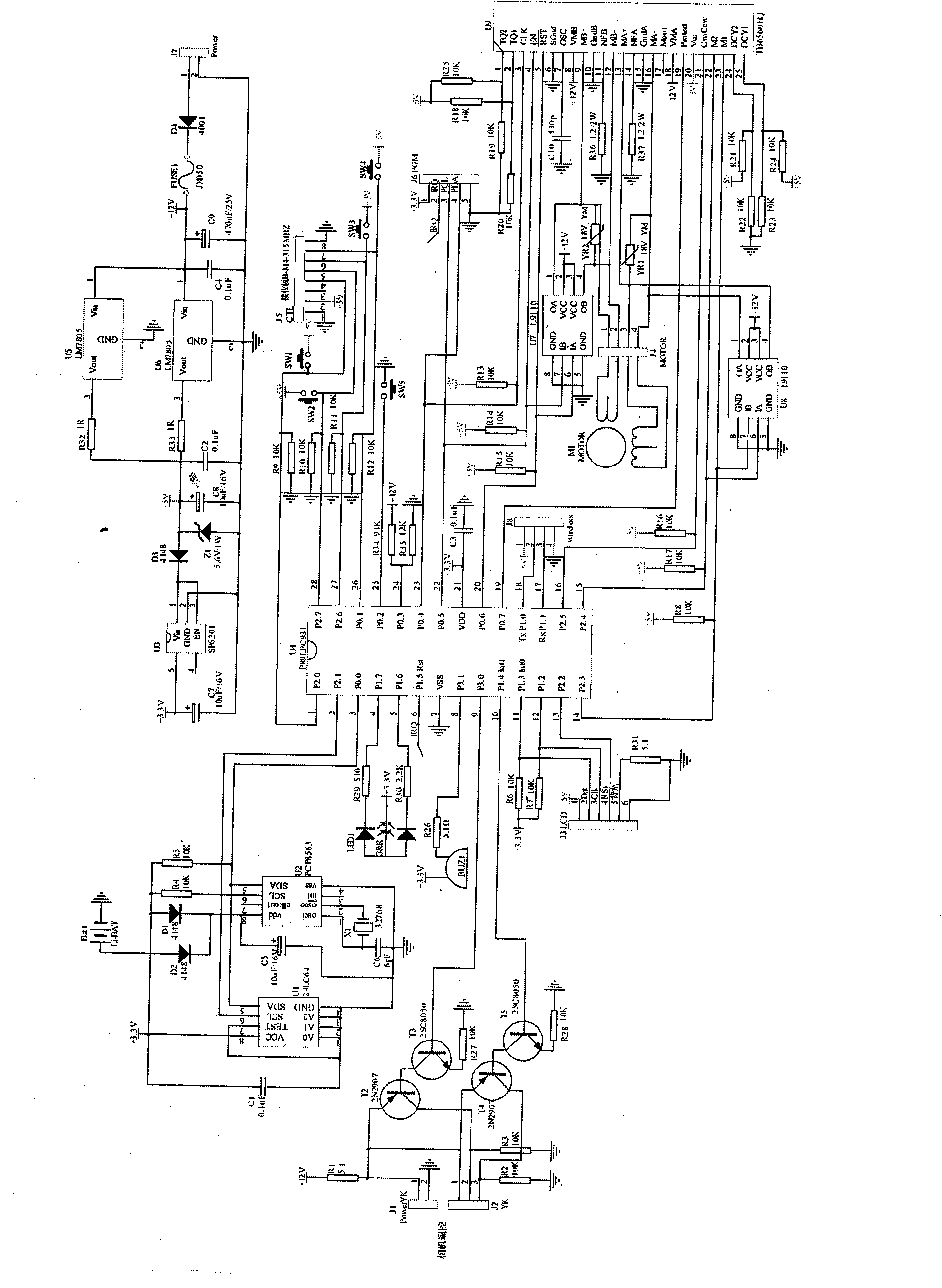

Fully automatic digital panoramic camera rotating base

InactiveCN101556423AAchieve independent rotationFully automatic operationProgramme controlTelevision system detailsDigital cameraDrive shaft

The invention discloses a fully automatic digital panoramic camera rotating base, which relates to digital camera auxiliary equipment, in particular to a camera rotating base leading a digital camera to take pictures during rotation. The fully automatic digital panoramic camera rotating base comprises a single-chip microcomputer, a camera remote control module, a stepper motor, a battery, a wireless remote control module, a camera connecting piece, operation keys and a power source; the digital camera is connected with the camera remote control module in a sensing way; the camera remote control module is connected with the single-chip microcomputer; the single-chip microcomputer is connected with a memory and the wireless remote control module; the wireless remote control module is connected with a remote controller in a sensing way; a power source charging circuit is connected with the battery; the single-chip microcomputer is supplied with power by the battery and the stepper motor is driven by a motor circuit system; the stepper motor drives a transmission shaft connected with a bearing to rotate; the transmission shaft is connected with one end of the camera connecting piece; the other end of the camera connecting piece is connected with a cradle head interface nut of the camera; and the operation keys are connecting with the single-chip microcomputer. The fully automatic digital panoramic camera rotating base has the advantages of simple and reasonable structure, and is particularly applied to fully automatic digital cameras.

Owner:陈祜

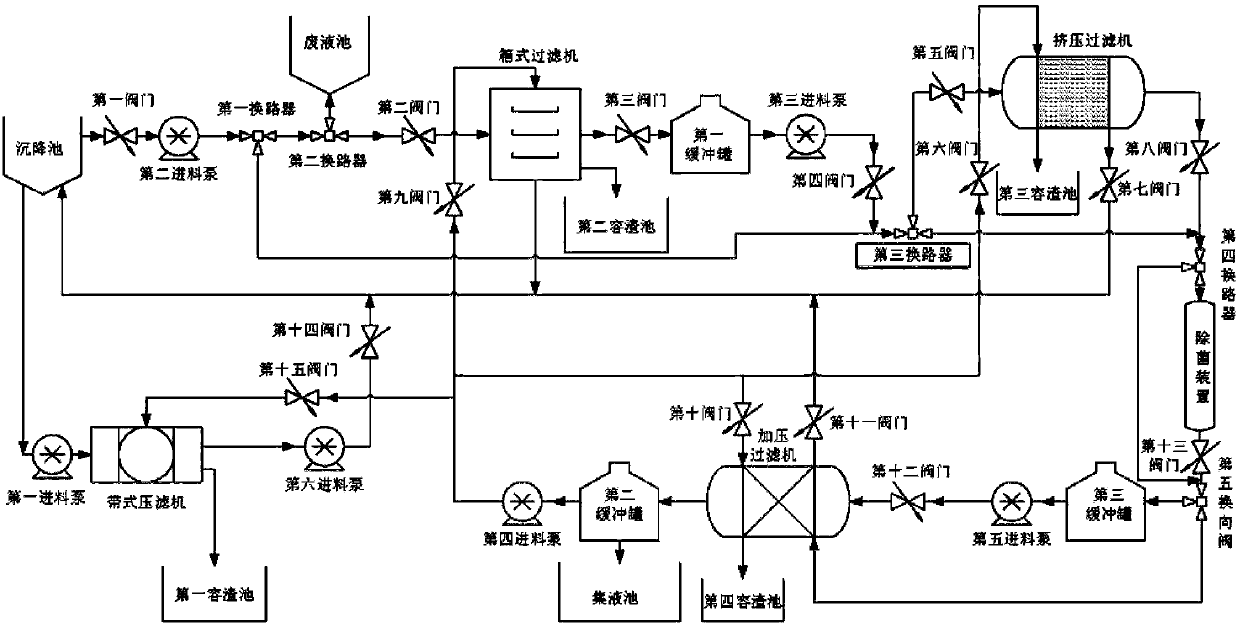

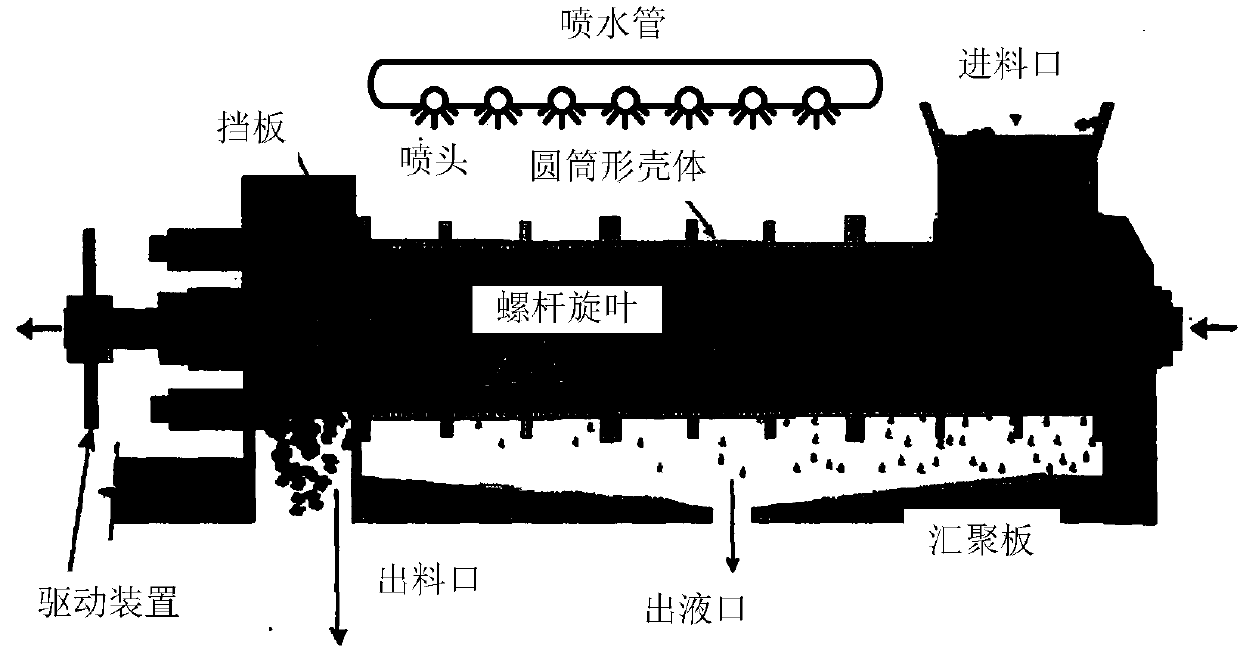

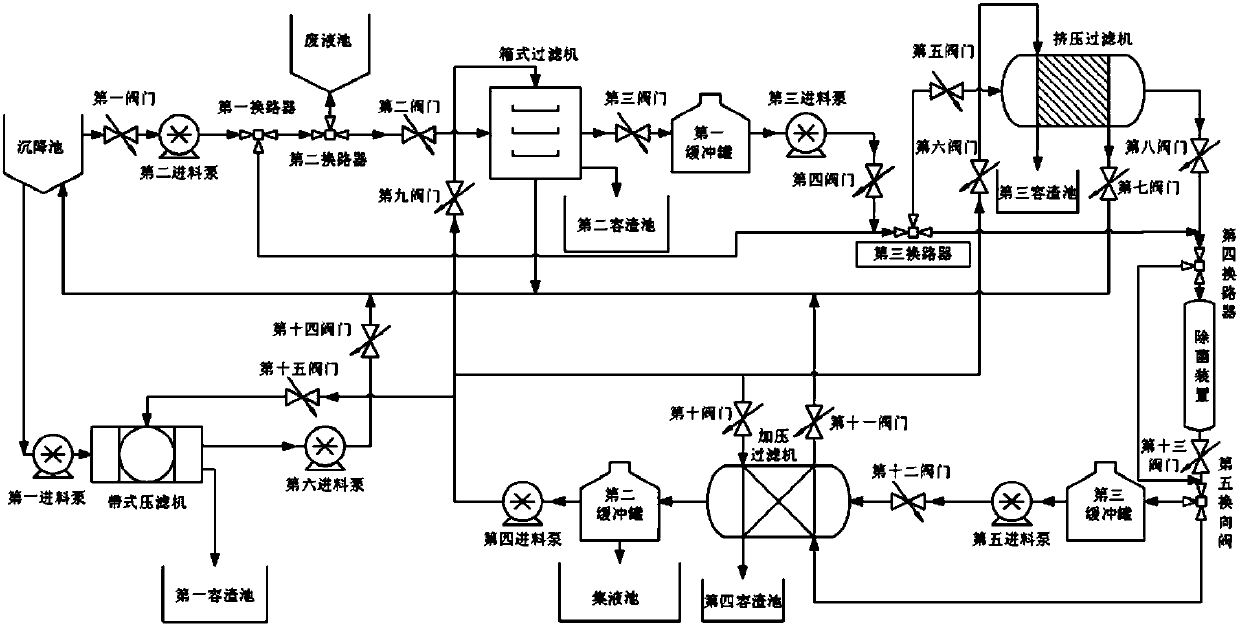

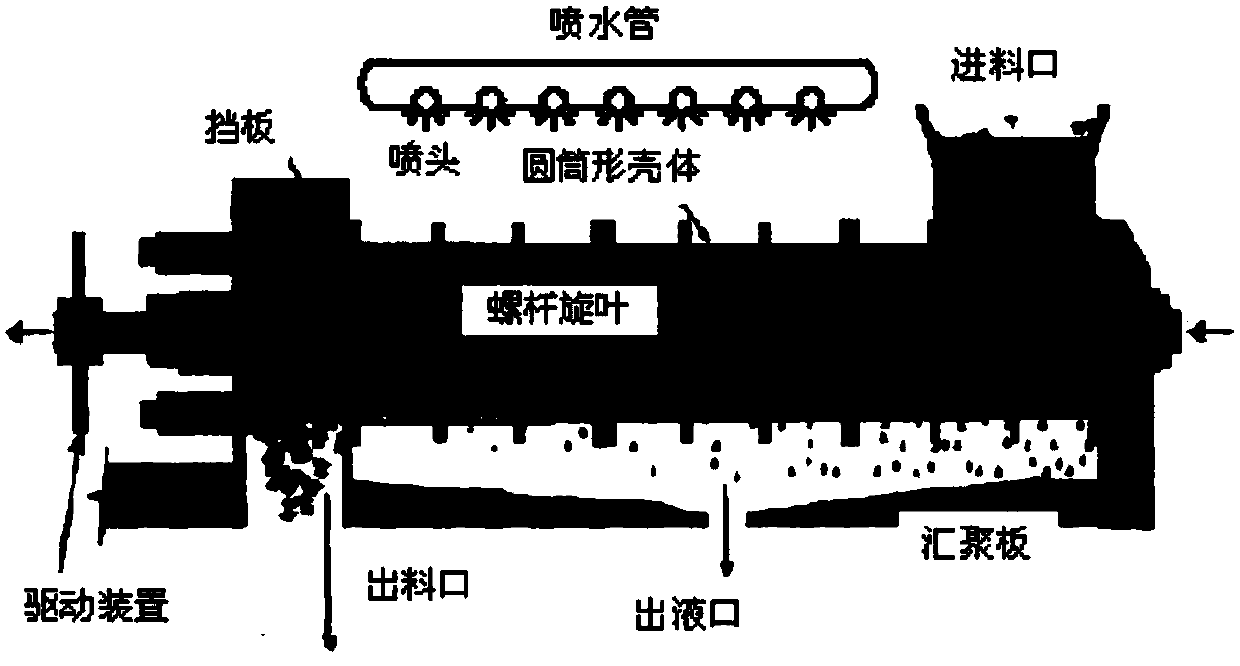

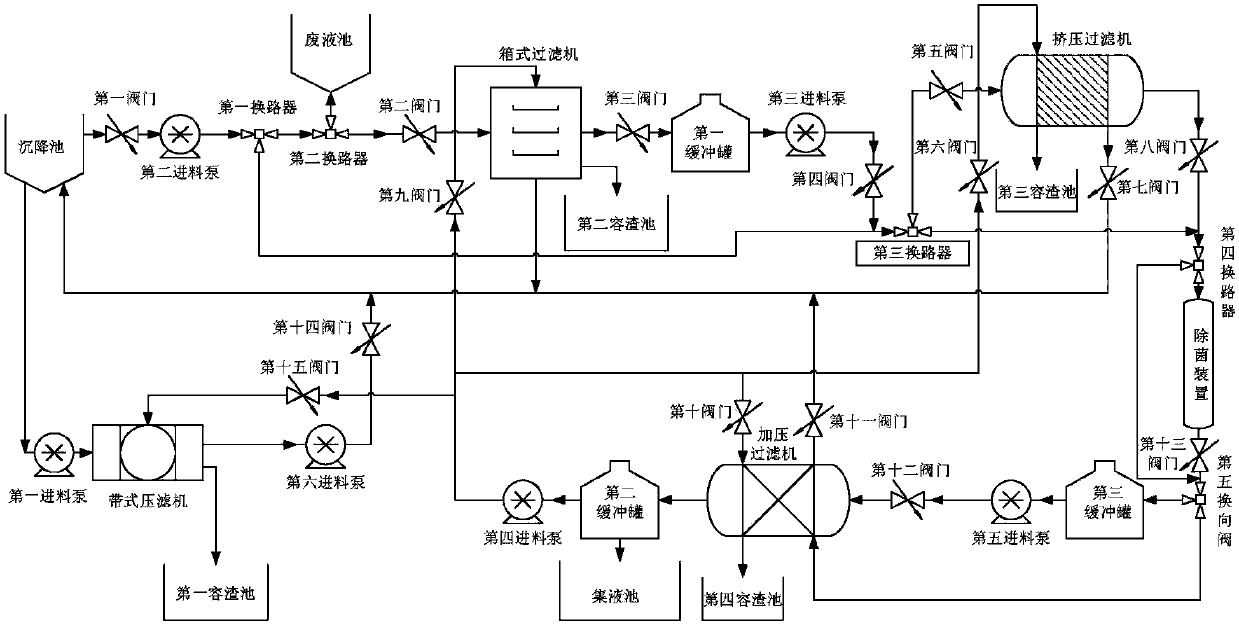

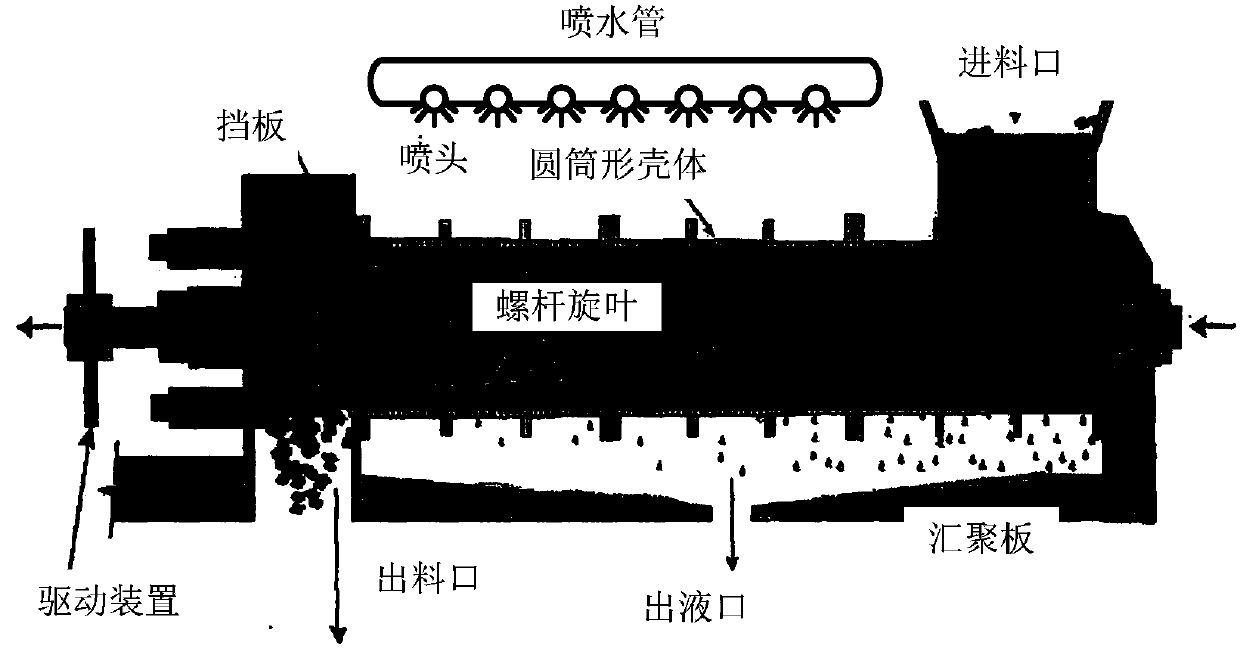

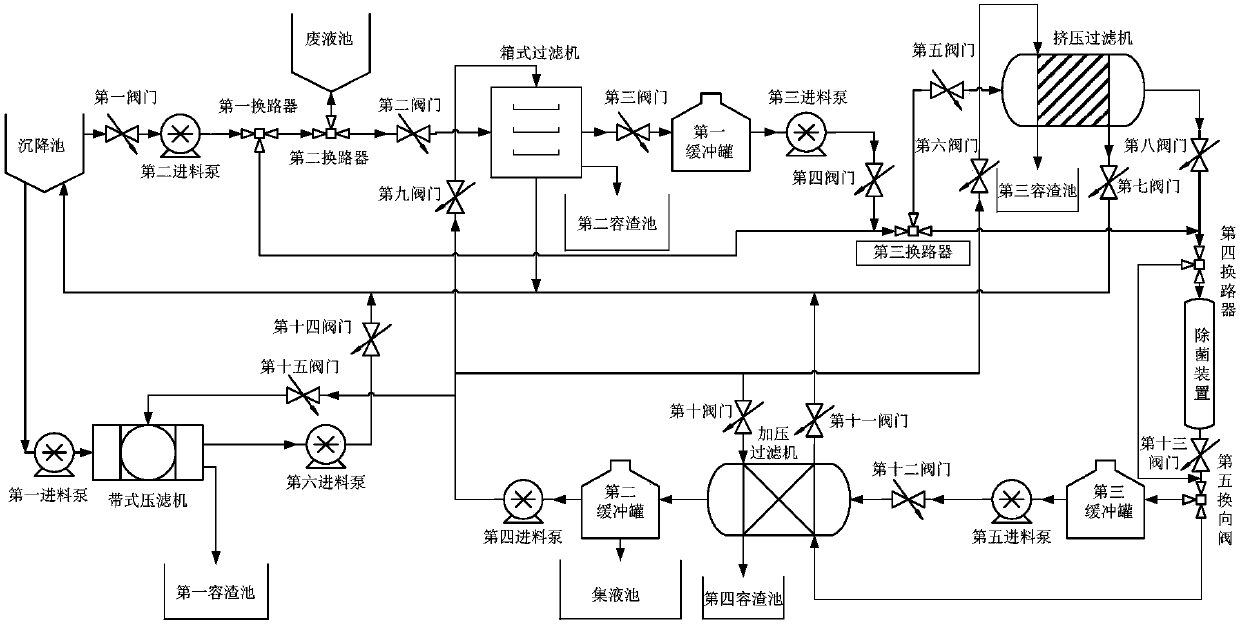

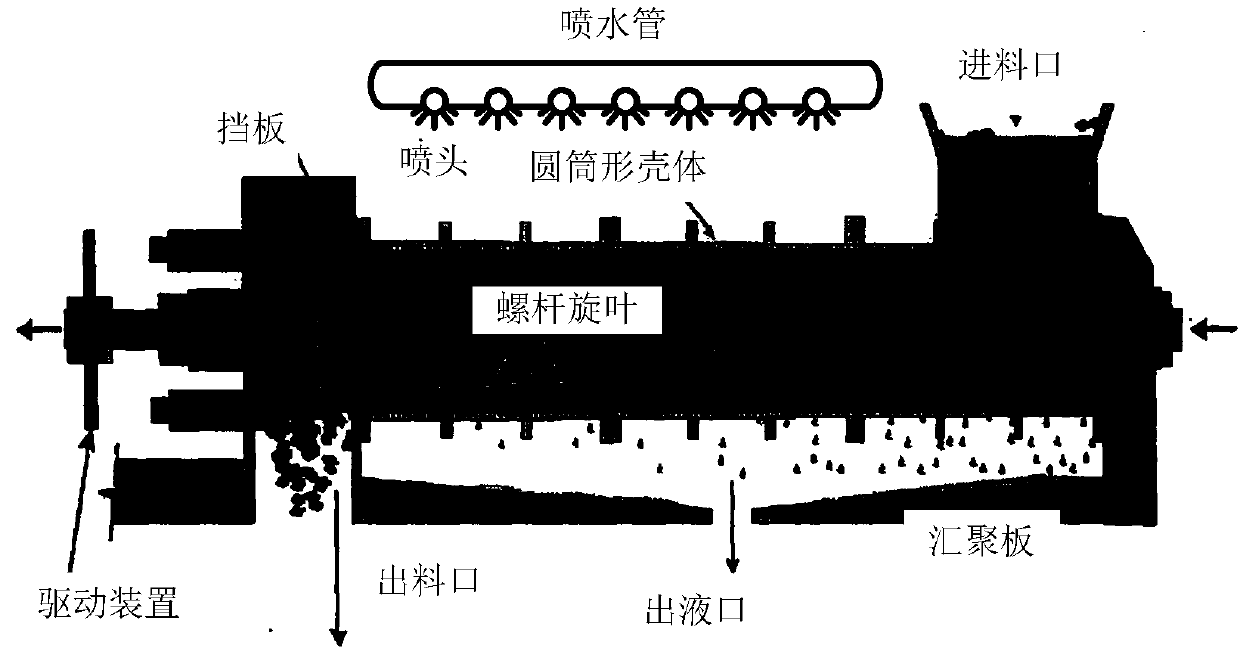

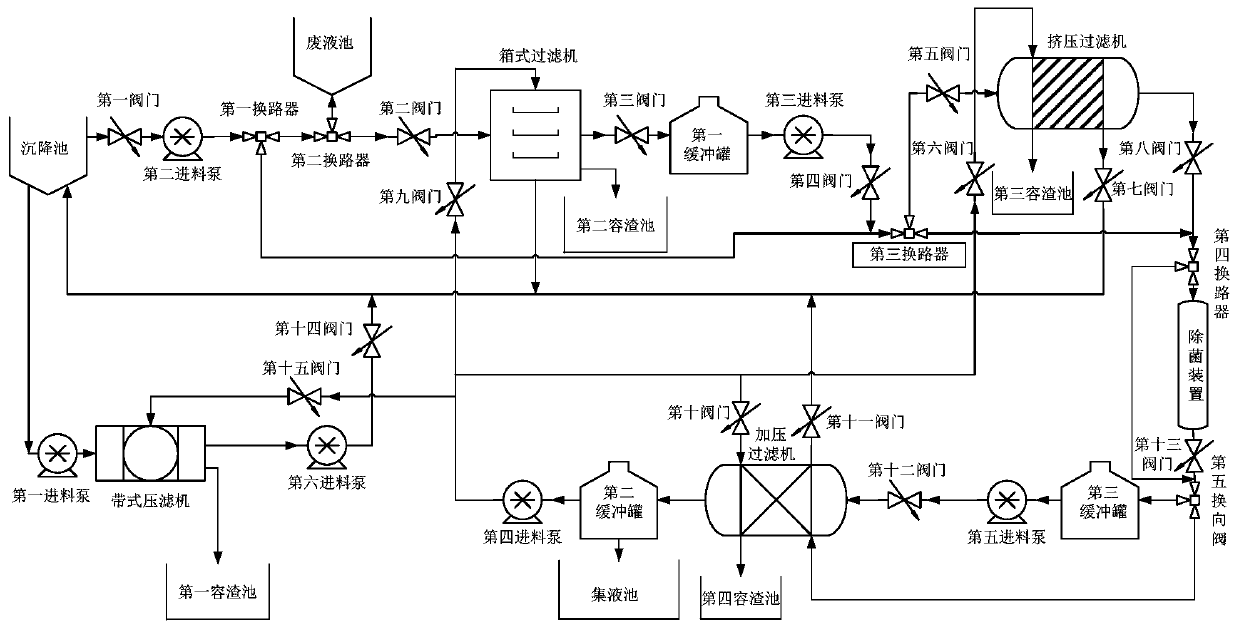

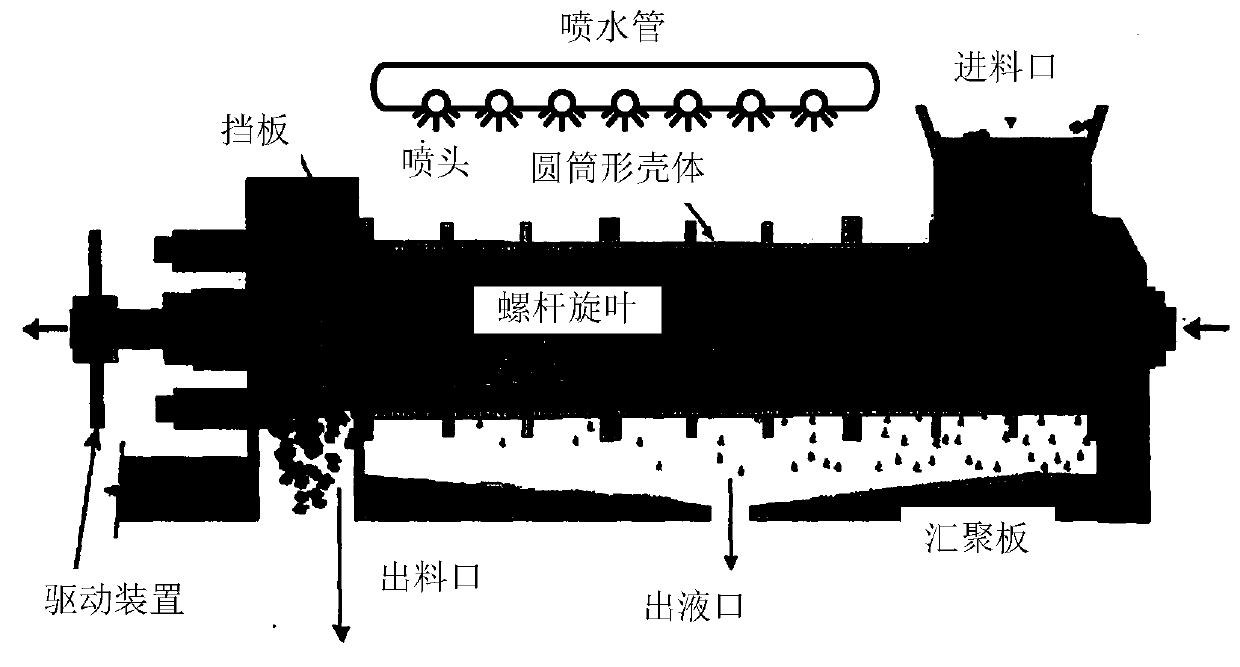

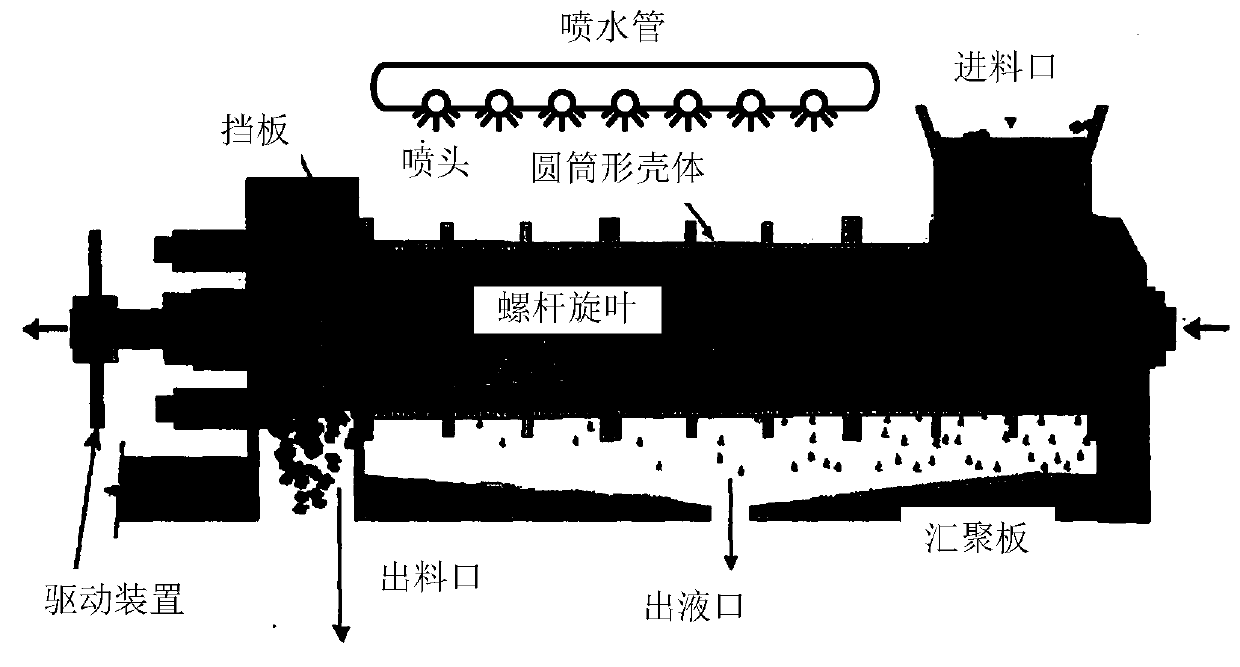

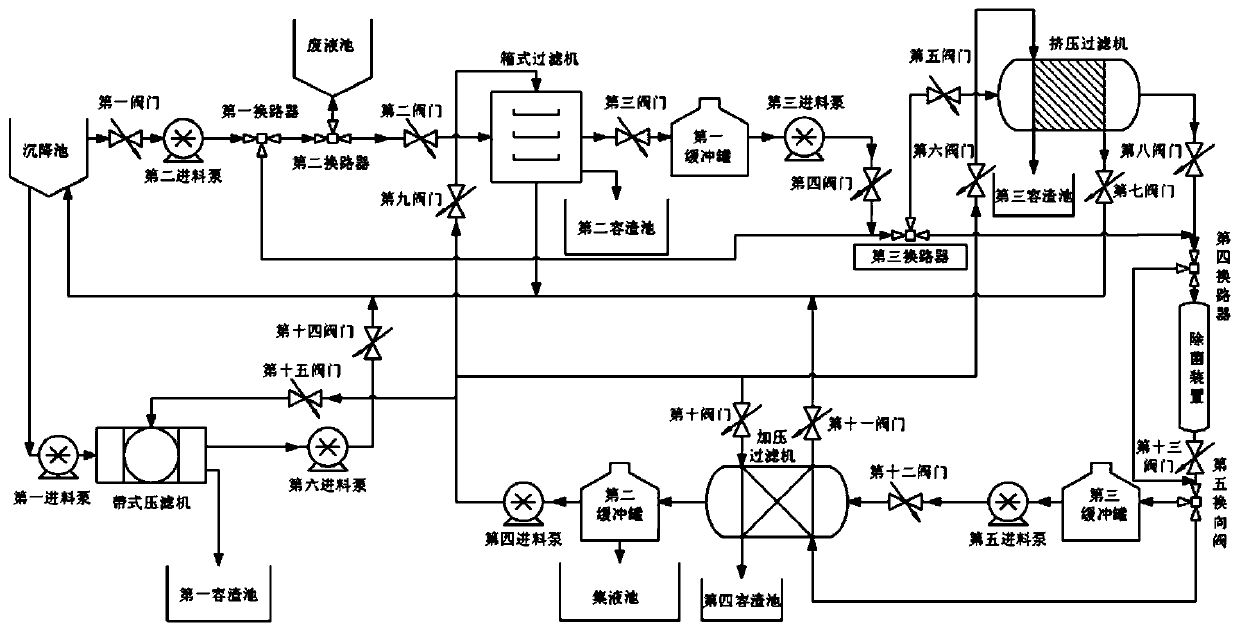

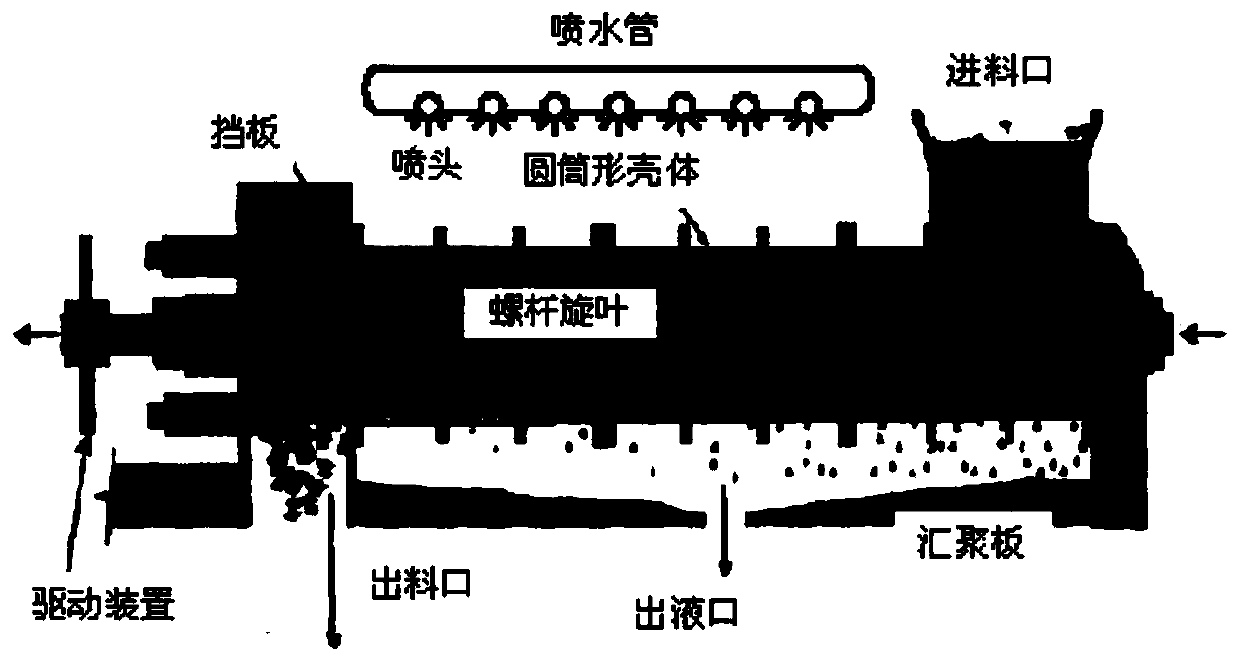

Chemical slurry squeezing filtration system

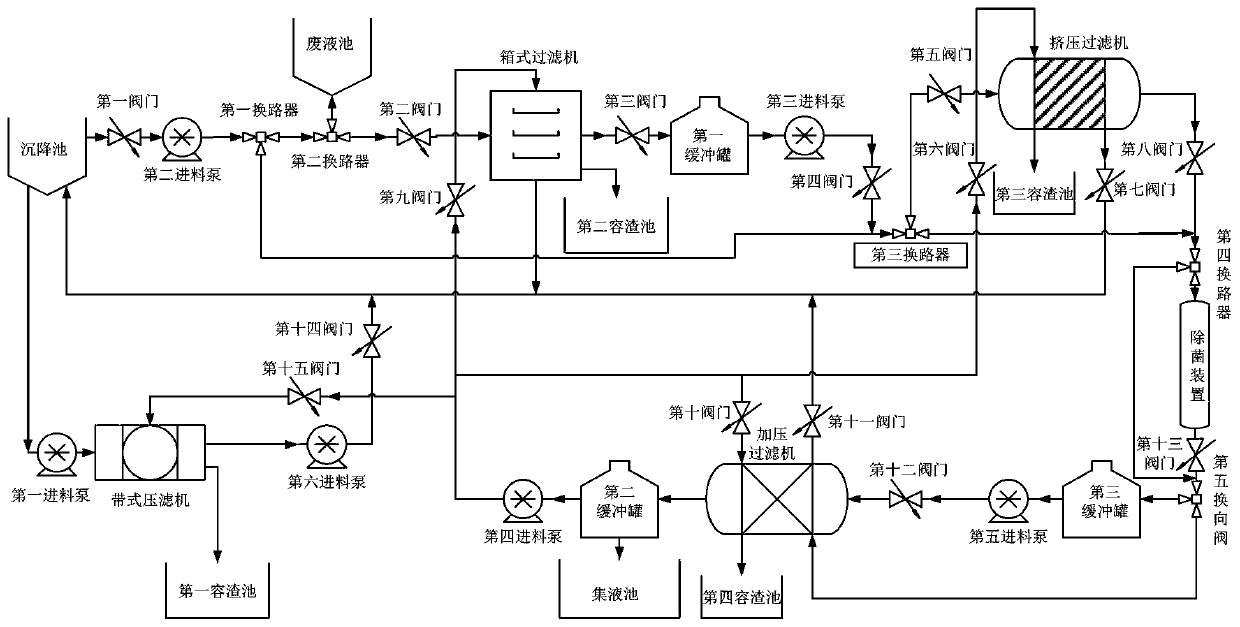

ActiveCN107670385ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagFiltration

The invention discloses a chemical slurry squeezing filtration system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device,one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The squeezing filter comprises a waster spray pipe, a cylindrical housing, screw vanes, a driving motor and a gathering plate. The screw vanes are arranged at intervals.

Owner:山东辰安化学有限公司

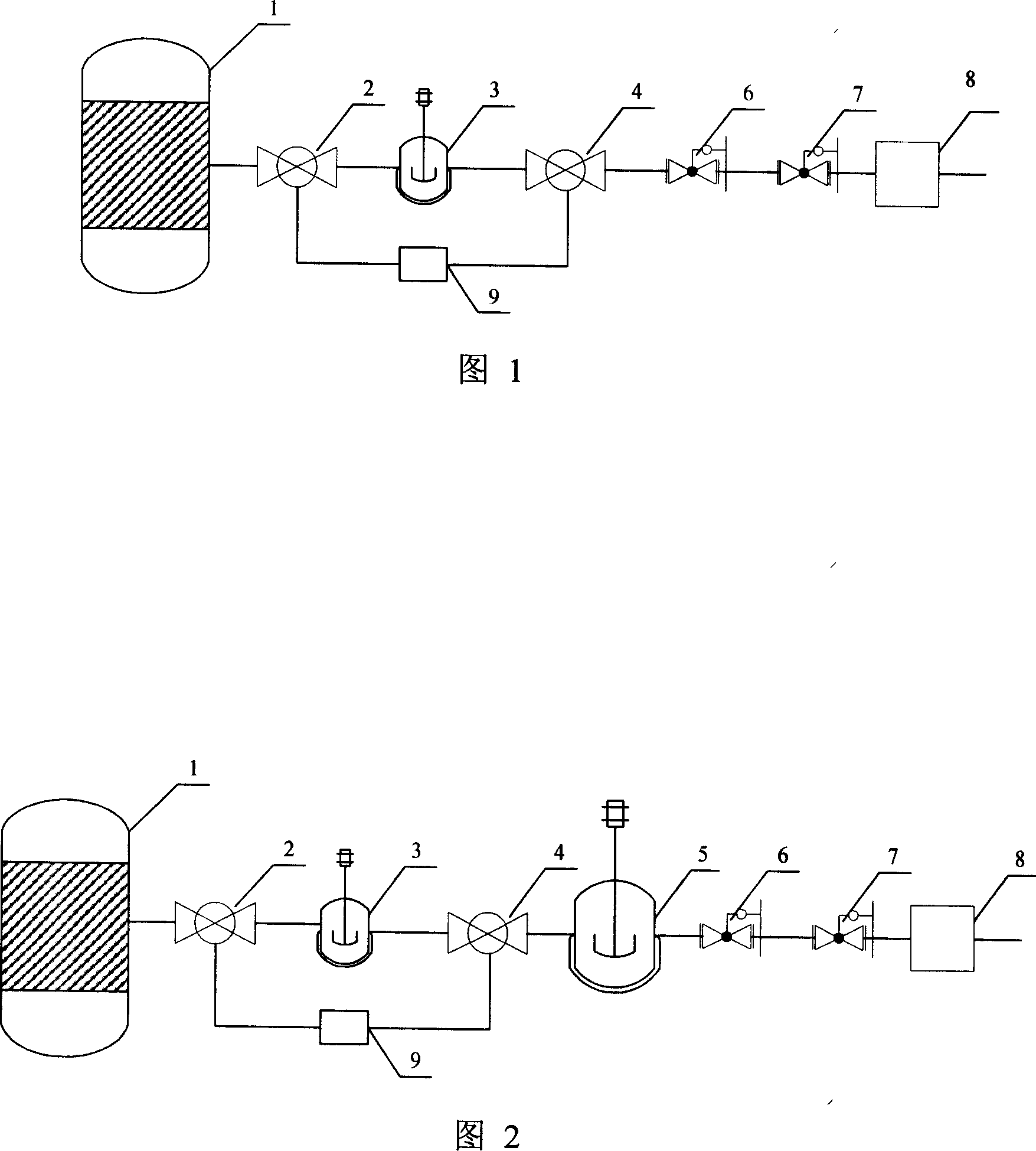

Discontinuous gas analysis method and equipment thereof

ActiveCN101008591AAutomatic analysisAutomatically analyzeWithdrawing sample devicesGas analysisProduct gas

This invention discloses one interval gas analysis method, which comprises the following steps: a, closing second valve fixed on first one and opening first one connected to the high pressure device with the gas inside filled with first and second valves capacitor as sample; b, closing first valve and opening second valve with first storage through second valve downstream; c, releasing the sample gas through second valve; d, analyzing released sample gas to get sample parameters. This invention also discloses one device to exert above method.

Owner:FOCUSED PHOTONICS

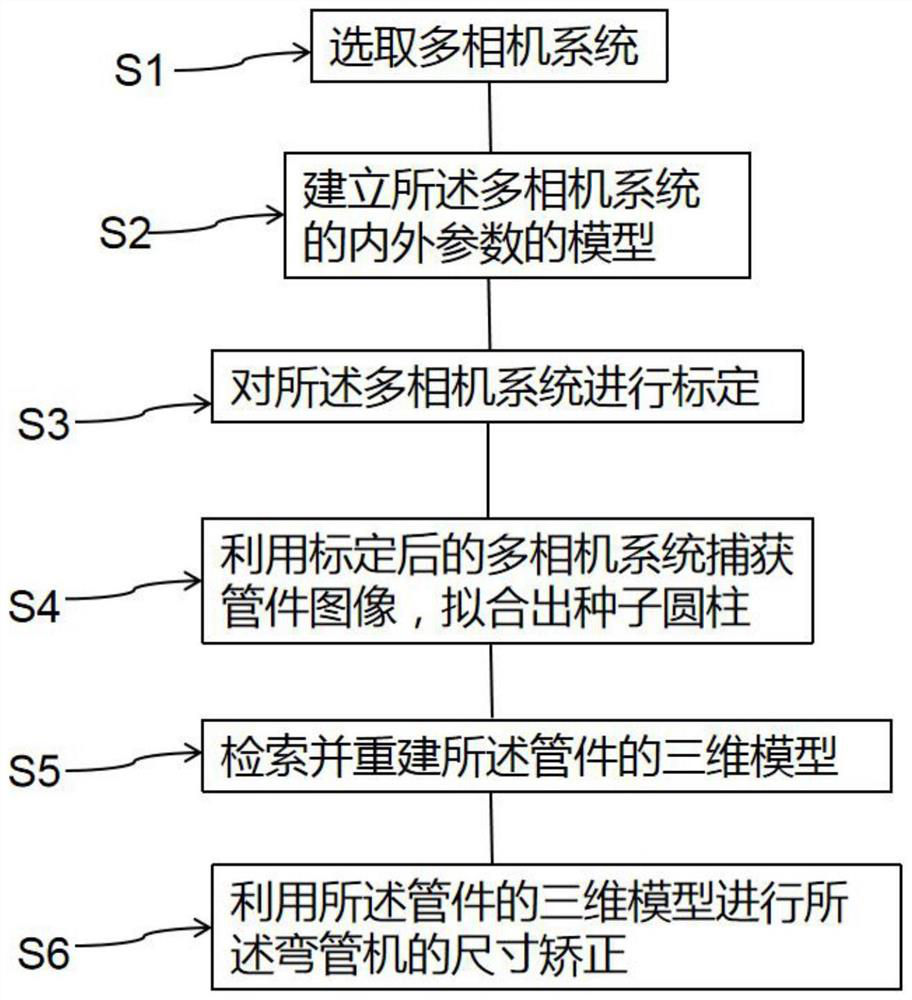

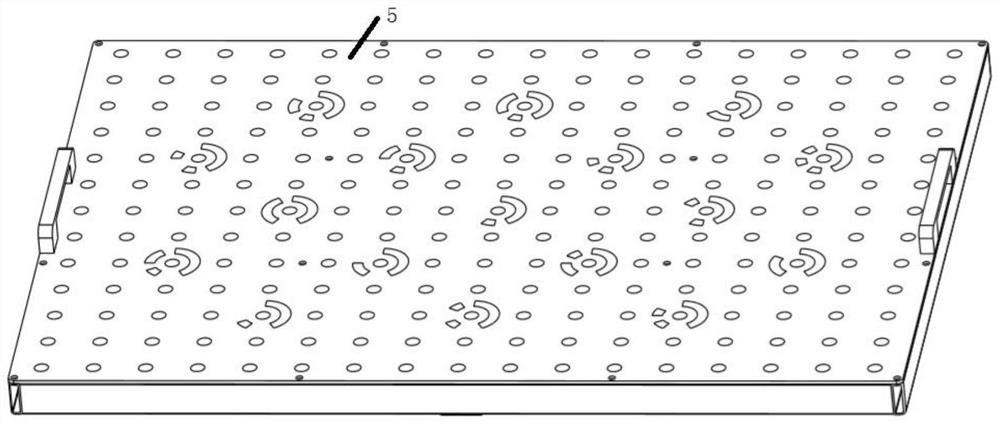

Rapid machine adjusting method and system for pipe bending machine

PendingCN112489195AFully automatic operationEasy to useImage enhancementImage analysisComputer graphics (images)Gradation

The invention discloses a rapid adjusting method and system for a pipe bender, and the method comprises the steps: firstly, selecting a multi-camera system; establishing a model of internal and external parameters of the multi-camera system; calibrating the multi-camera system by utilizing the internal and external parameter models of the multi-camera system and using a calibration plate; capturing a pipe fitting image by using the calibrated multi-camera system, and fitting a seed cylinder; retrieving and reconstructing a three-dimensional model of the pipe fitting by taking the seed cylinderas a reference and combining the pipe fitting image captured by the multi-camera system; and correcting the size of the pipe bender by utilizing the three-dimensional model of the pipe fitting. The invention provides a high-precision and high-robustness multi-camera calibration method for solving internal and external parameters of cameras by using a specific calibration plate. In the image matching process based on the seed cylinder, the edge of the seed cylinder is positioned in combination with a gray threshold. In addition, in order to minimize the deviation of the reconstruction process,a linear interpolation method is used in combination with a seed cylinder-based method.

Owner:新拓三维技术(深圳)有限公司

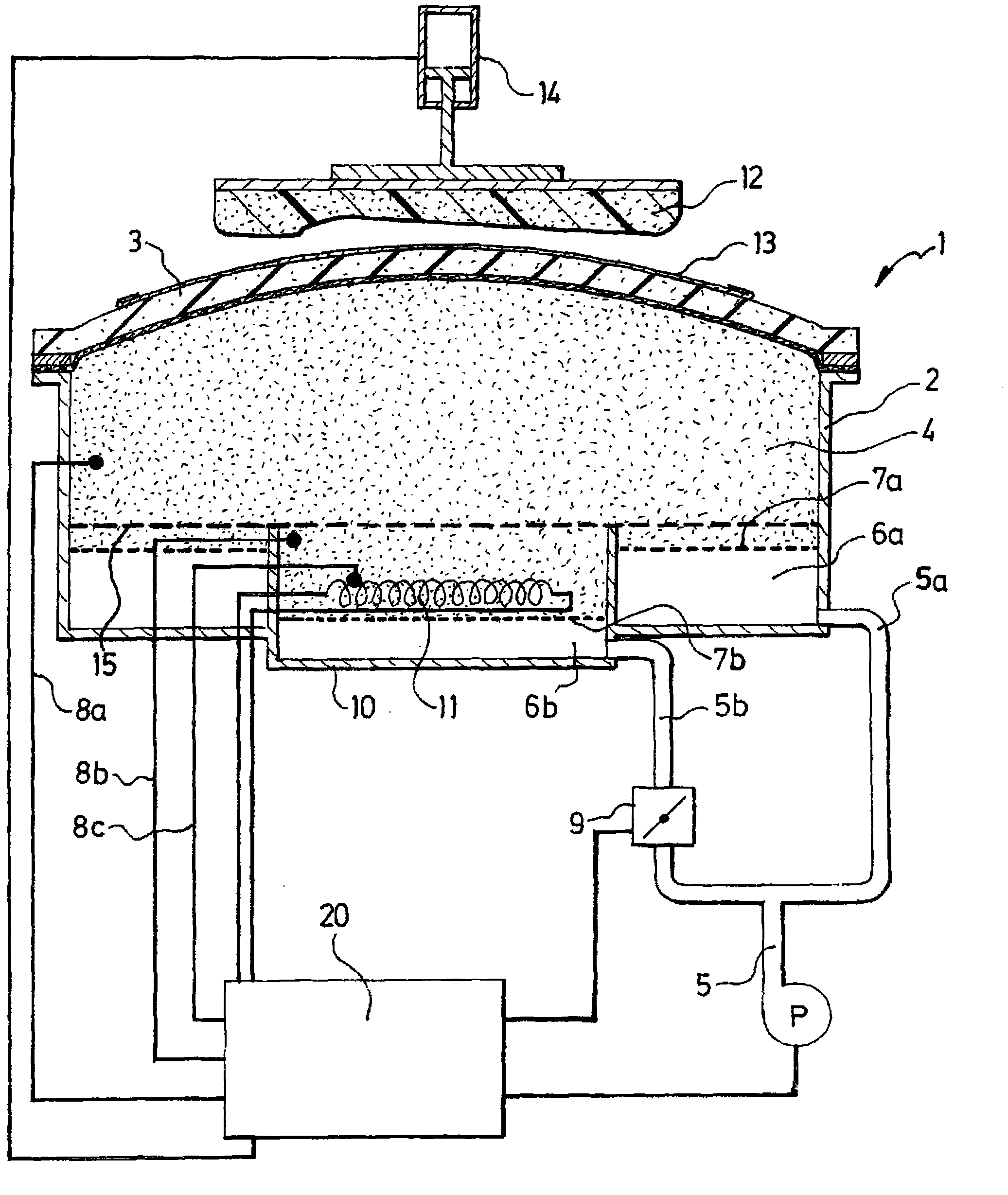

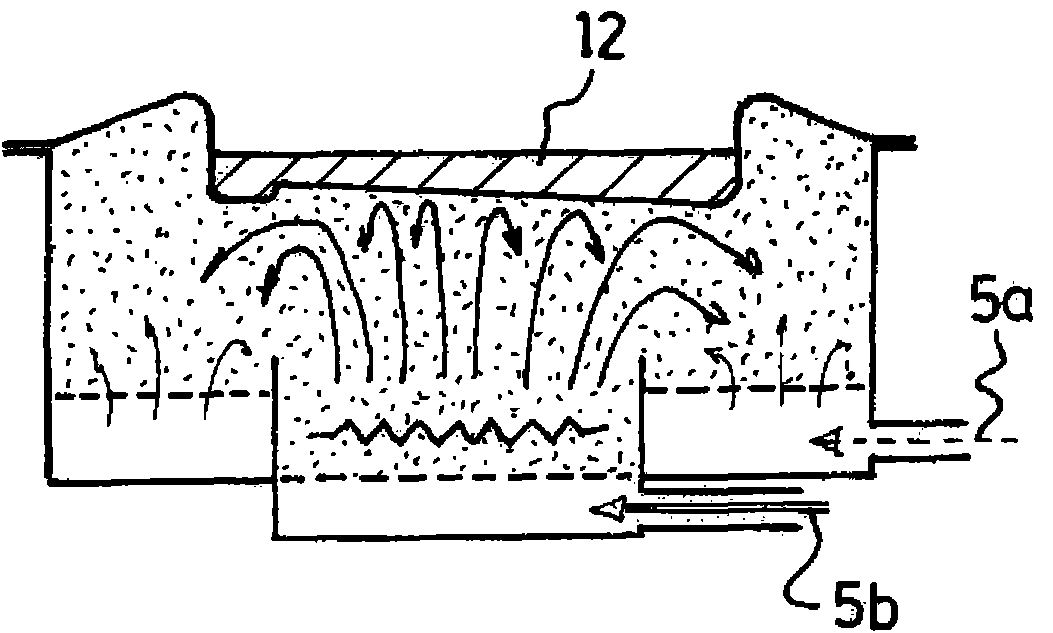

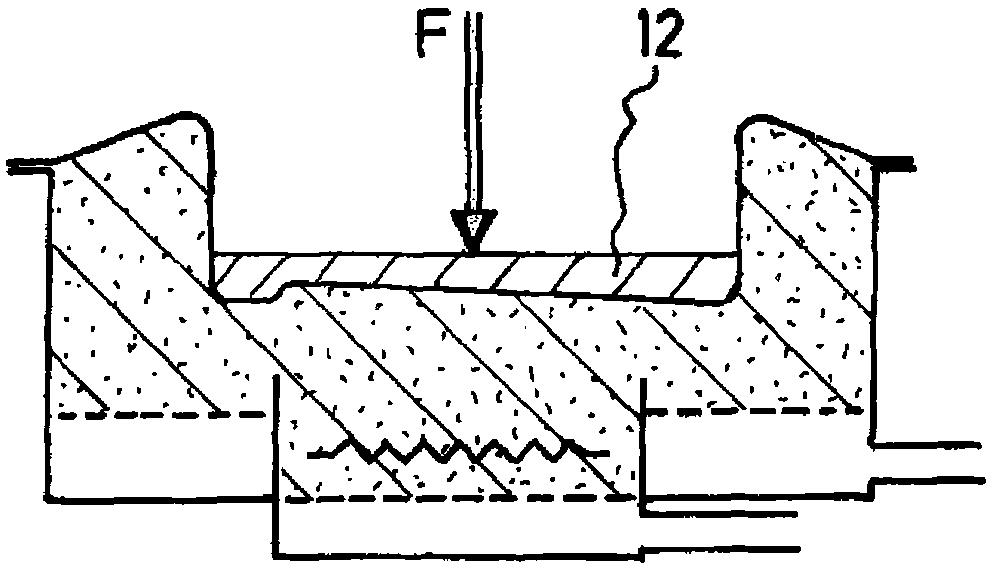

Device and method for thermally bonding a flexible coating to a support

ActiveCN102171024AInexpensive gluing operationsConstant quality or betterVehicle seatsDomestic articlesFluidized bedEngineering

The invention relates to a device for the thermal bonding of a flexible coating (13) to a support (12), using a fluidized bed of particles (4), comprising an internal zone, called a heating box (10) smaller in size than that of the enclosure (2), which is placed approximately at the centre of the latter, said heating box having a gas distributor (6b), a diffusion mesh (7b) and a gas feed system (5b, 9) that are separate and isolated from those of the enclosure, and the heating means (11) designed to be placed in the particle bed. The invention also relates to a thermal bonding method suitable for being implemented by this device.

Owner:C GEX SYSTS

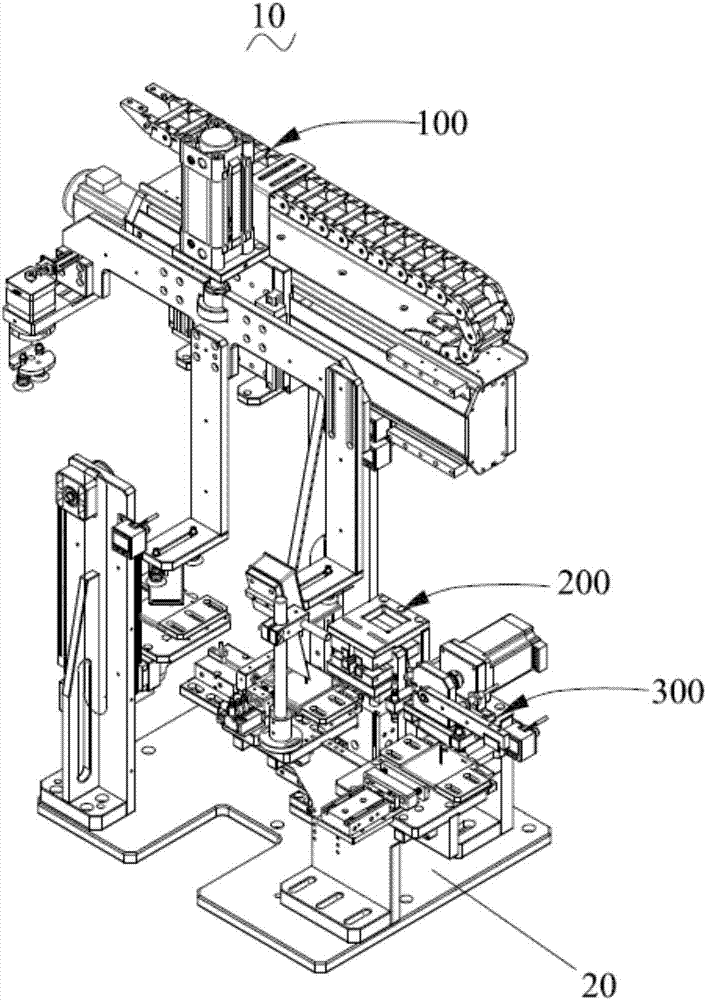

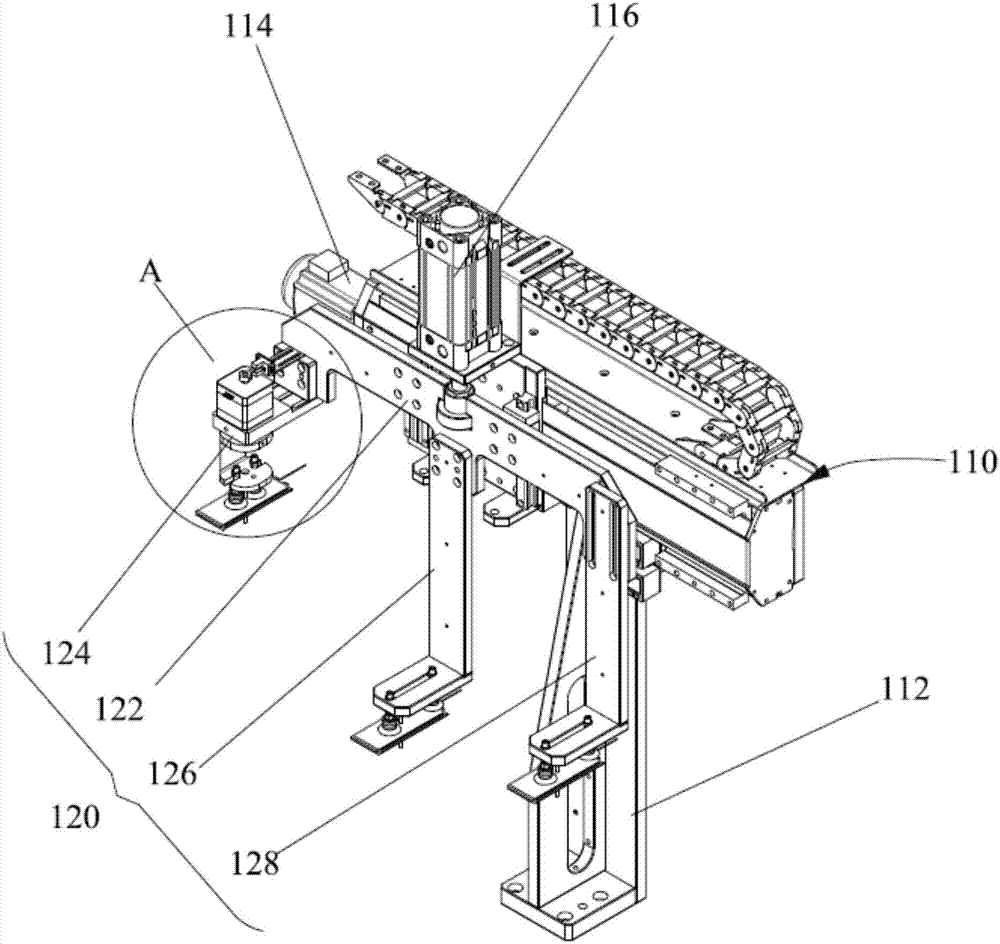

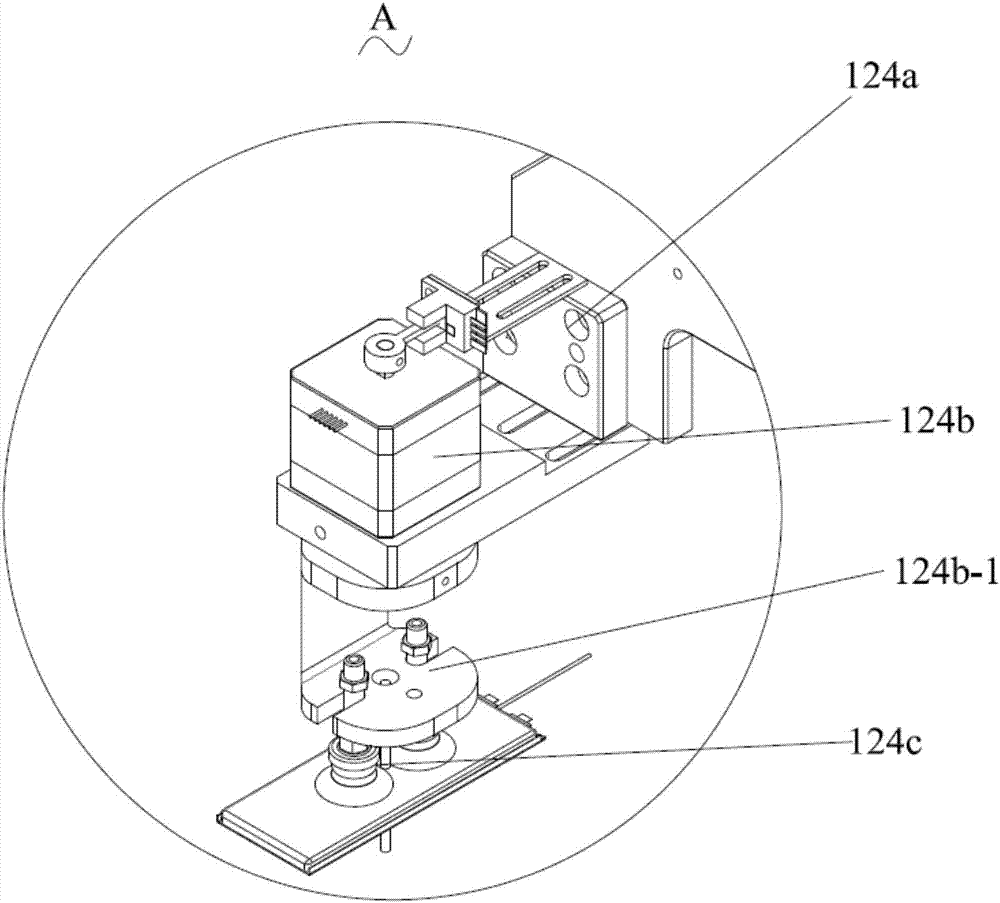

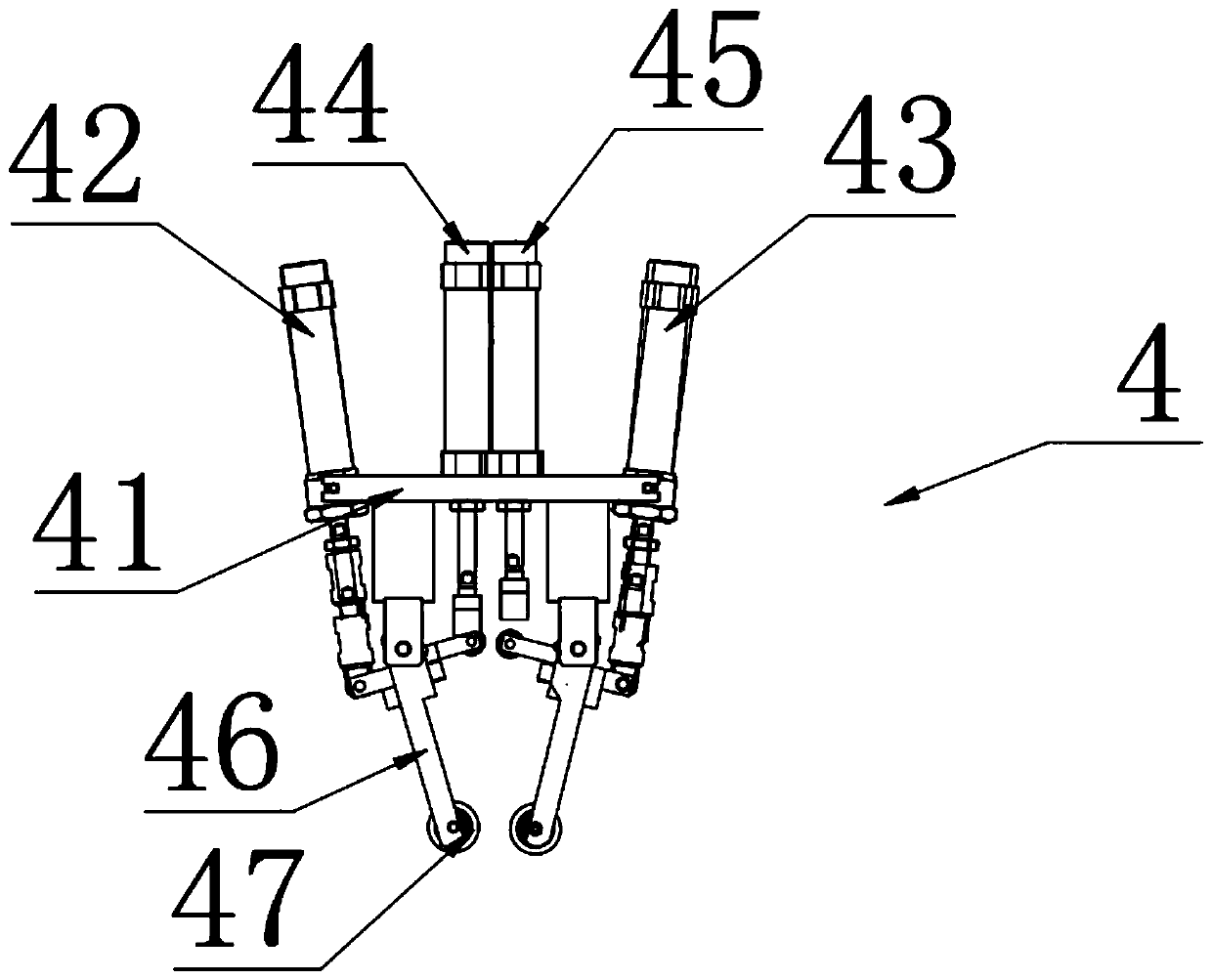

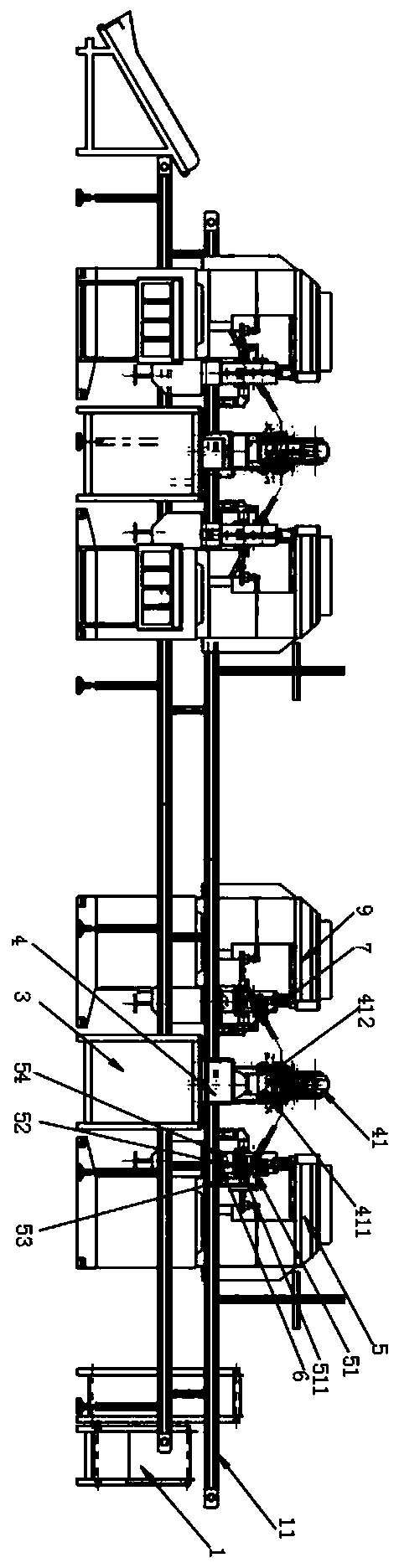

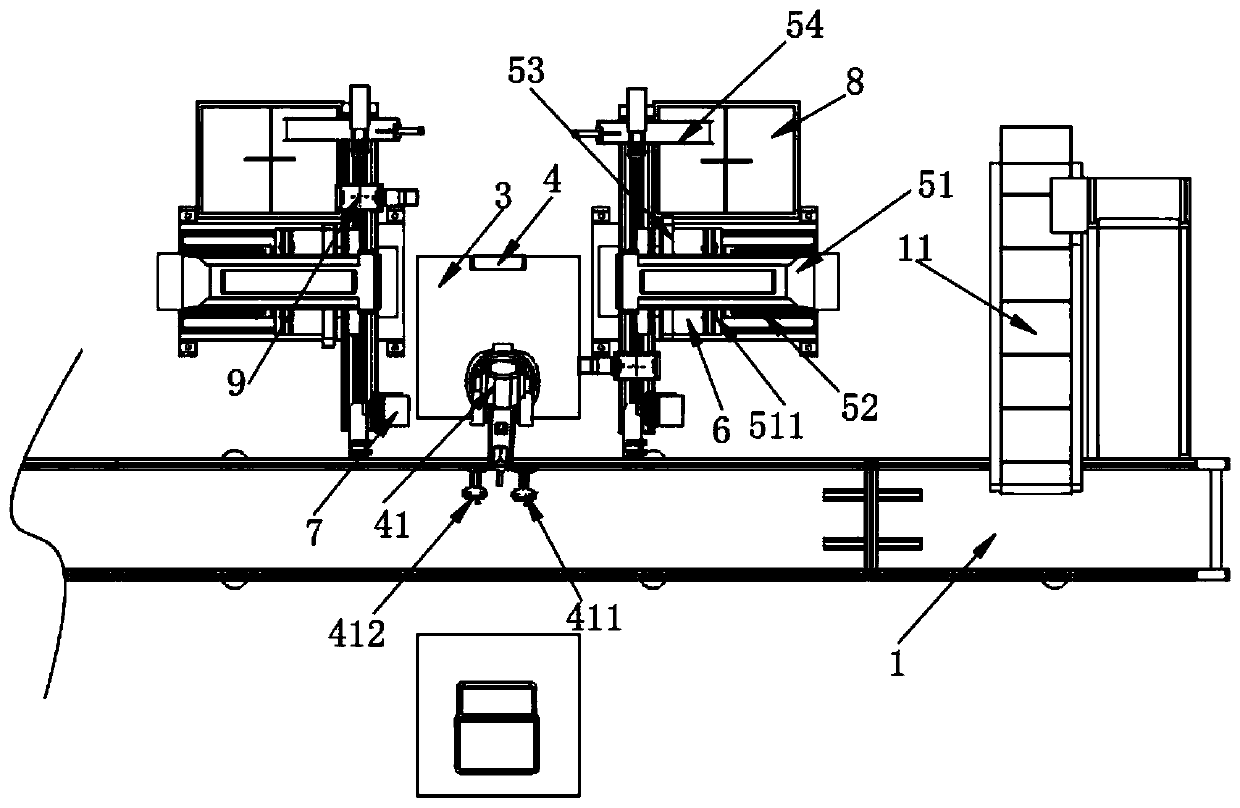

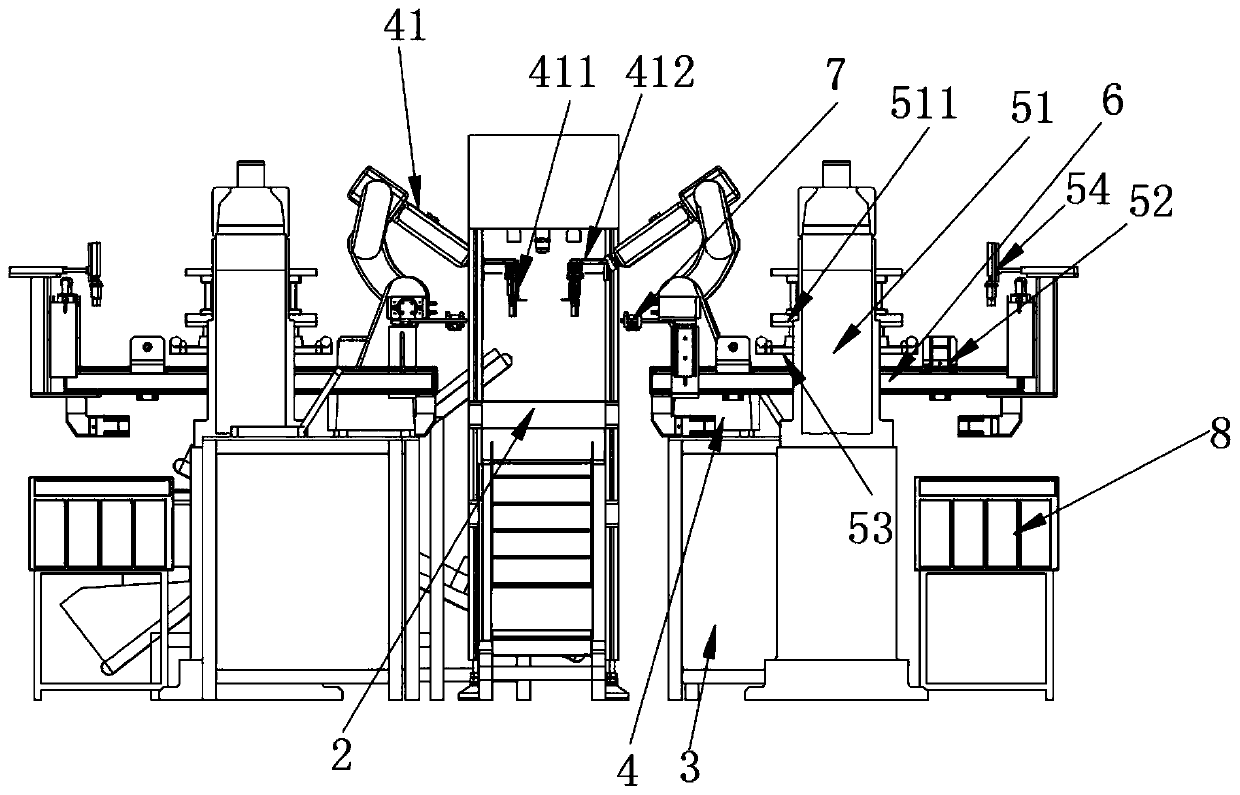

Battery core feeding equipment

ActiveCN107215667AAchieve continuityFully automatic operationFinal product manufactureConveyor partsEngineeringAssembly line

The invention discloses battery core feeding equipment. The battery core feeding equipment comprises a feeding platform, a battery core feeding and conveying mechanism, a battery core pole lug leveling mechanism and a battery core overturning mechanism, wherein the battery core feeding and conveying mechanism, the battery core pole lug leveling mechanism and the battery core overturning mechanism are arranged on the feeding platform. The battery core feeding and conveying mechanism comprises a drive device and a battery core suction device movably arranged on the drive device. The drive device comprises a drive support, a horizontal drive portion and a vertical drive portion. The horizontal drive portion is fixedly mounted on the drive support. The horizontal drive portion drives the vertical drive portion to move in a reciprocating manner in the horizontal direction. The vertical drive portion drives the battery core suction device to ascend and descend in a reciprocating manner in the vertical direction. The battery core suction device comprises a battery core suction support, a first battery core suction portion, a second battery core suction portion and a third battery core suction portion, wherein the first battery core suction portion, the second battery core suction portion and the third battery core suction portion are mounted on the battery core suction support. By the adoption of the battery core feeding equipment, the battery core conveying continuity of two equipment is achieved, the full-automatic operation on an assembly line is achieved, the work efficiency is improved, and the production cost is lowered.

Owner:SANKYO PRECISION HUIZHOU

Method for welding inconel through CMT submerged-arc welding

The invention discloses a method for welding inconel through CMT submerged-arc welding. The method comprises the following steps that (1), a grinding piece is loaded by using an electric angle grinder to grind a workpiece so as to remove impurities and oxides on the surface of the workpiece; (2), welding equipment are configured, wherein the welding equipment comprise an ABB robot, a CMT welding machine power supply, a water tank, a CMT welding gun and an inconel submerged-arc welding flux; and (3), the welding process is carried out, the welding process parameters are set, the CMT welding gun is clamped by the ABB robot, a gun head extends into the submerged-arc welding flux for CMT submerged-arc welding, and slag removing operation is carried out between the welded layers. According to the method for welding inconel through CMT submerged-arc welding, the limitation that CMT gas shielded welding cannot be welded for a narrow-gap deep groove can be solved, full-automatic operation can be realized, and the method has the characteristics of good quality stability, environmental friendliness, energy conservation, high efficiency, high material utilization rate and the like.

Owner:福尼斯(南京)表面工程技术有限公司

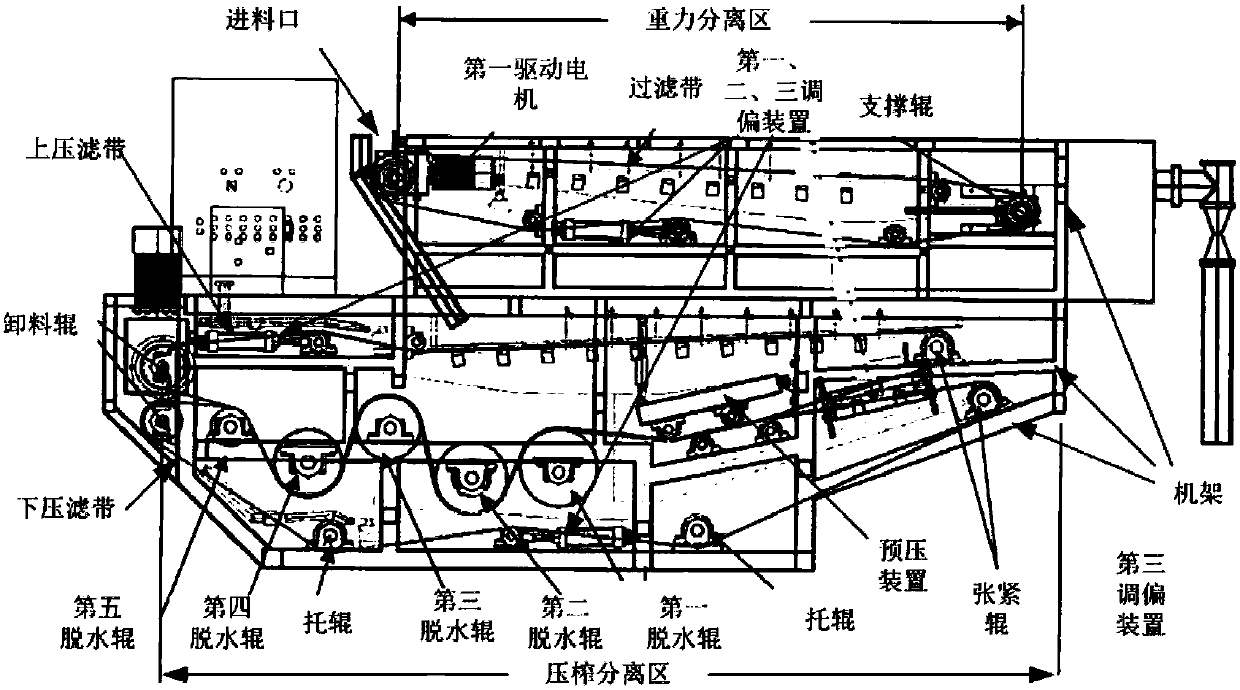

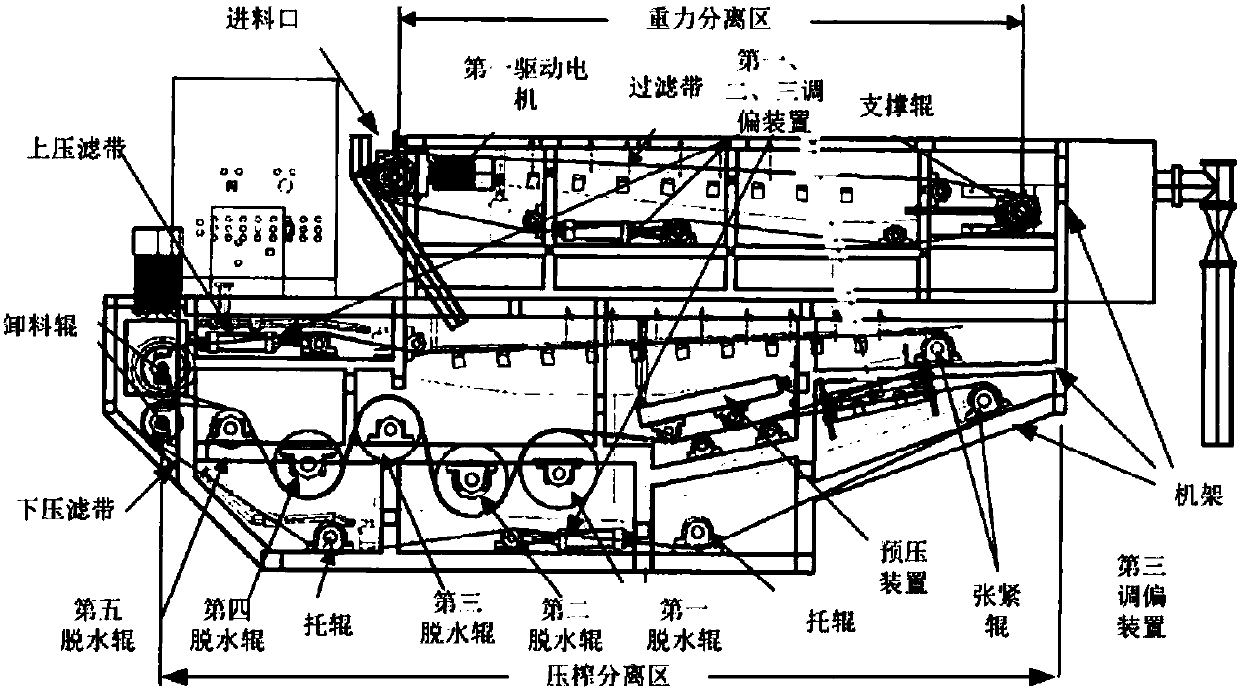

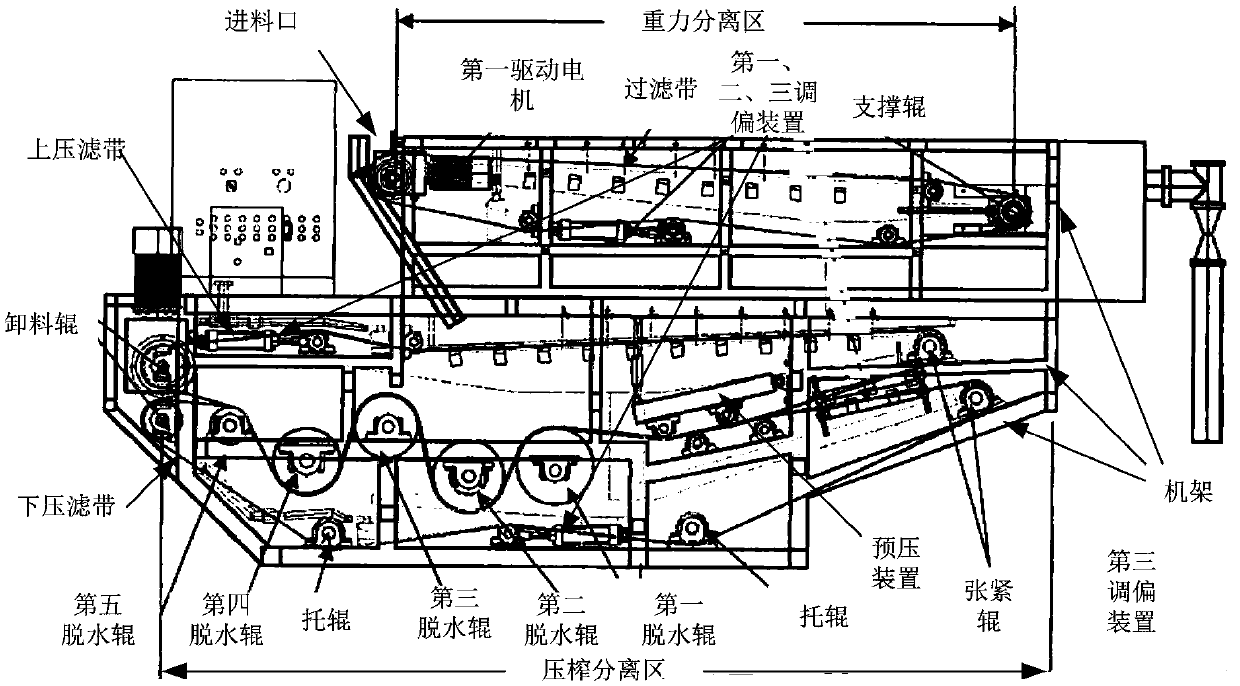

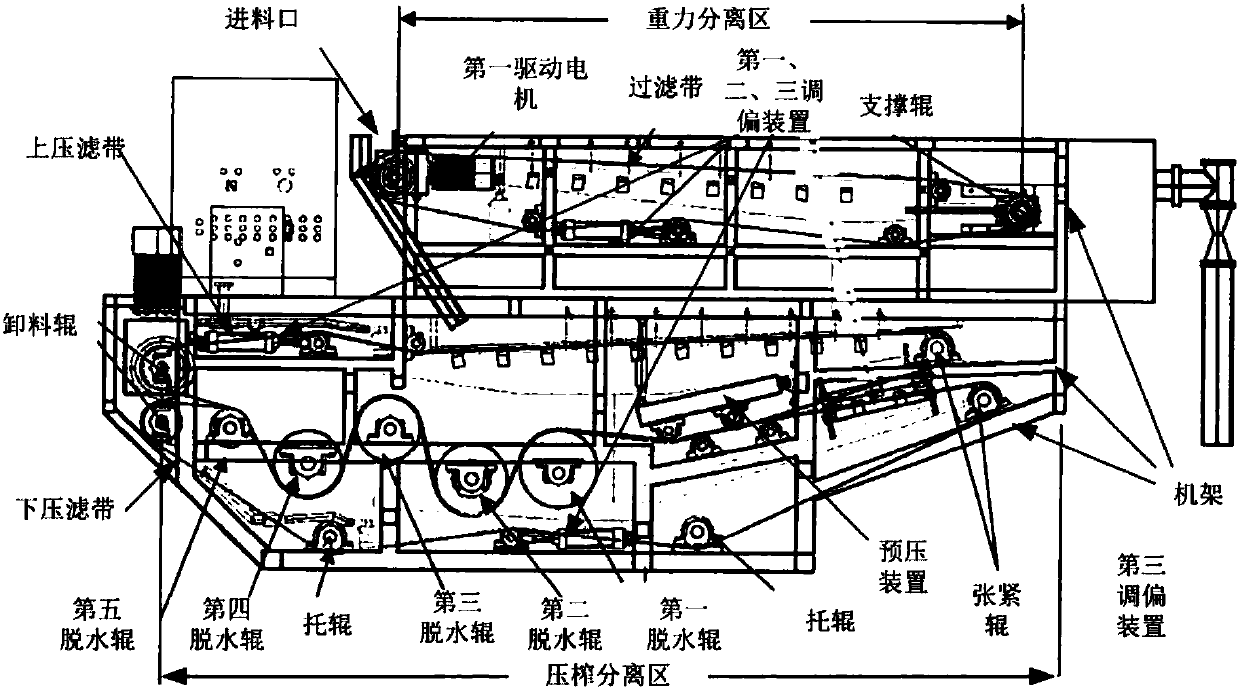

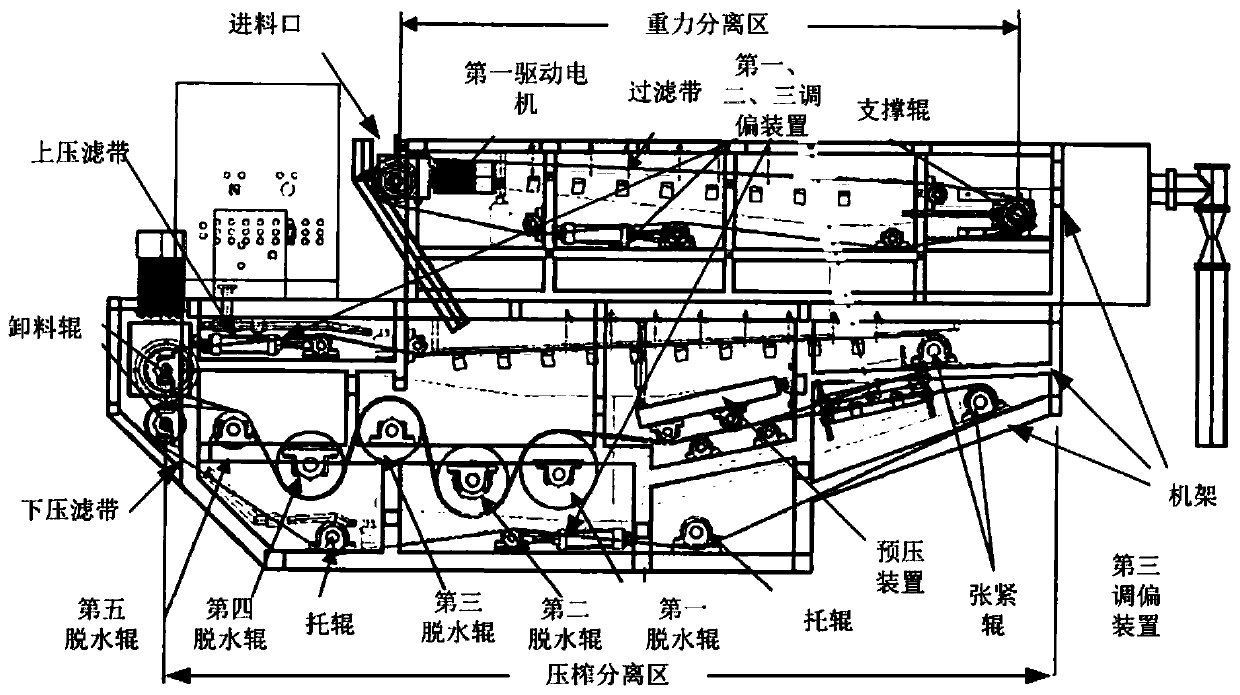

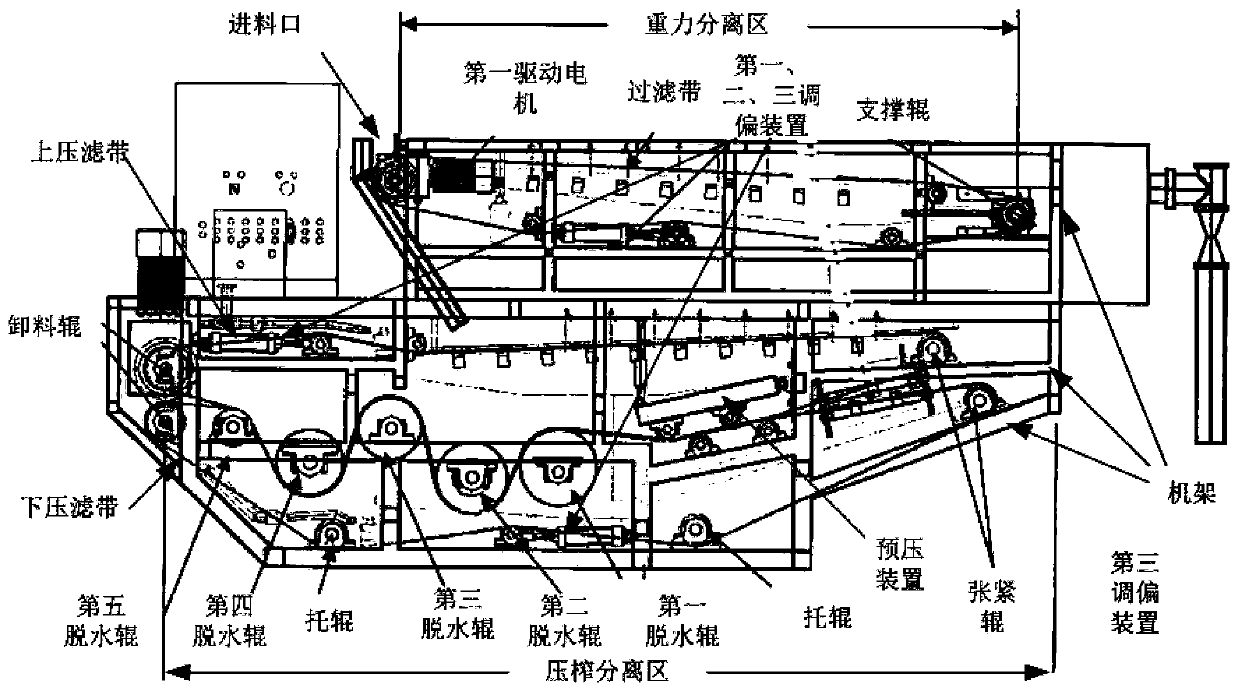

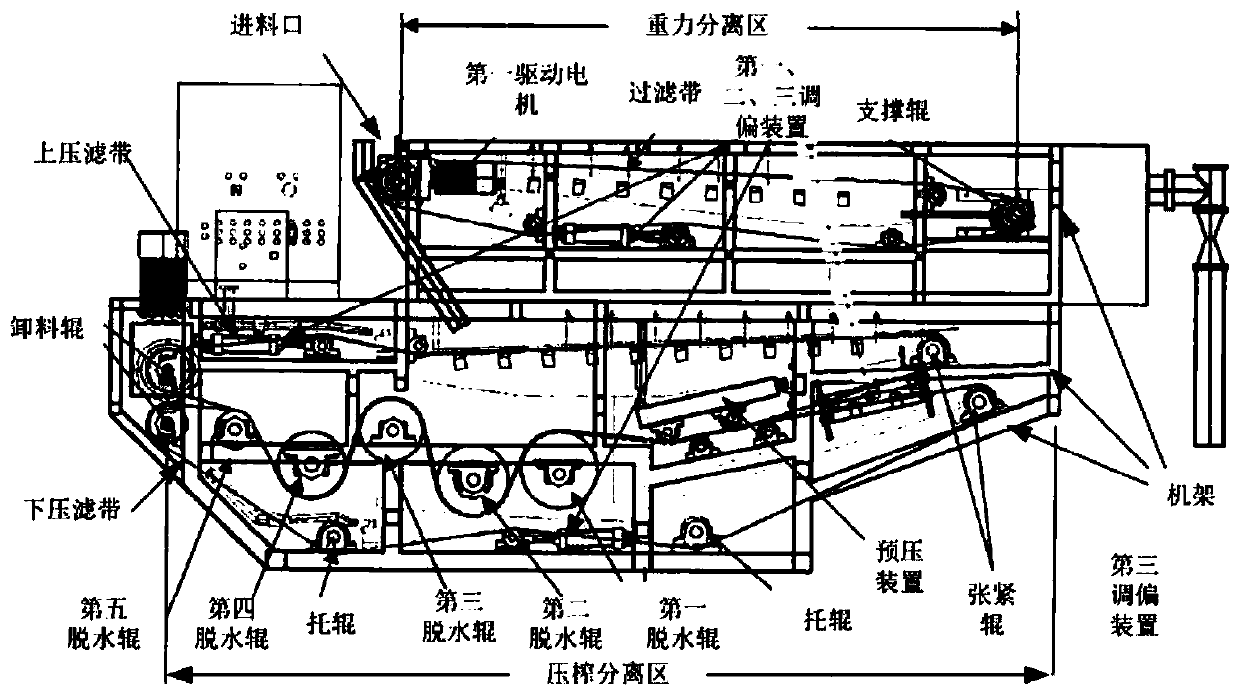

Filter press system with dewatering wheel system

ActiveCN107670387AExtended gravity separation timeFiltration pressure is highWater treatment parameter controlSpecific water treatment objectivesSlagGravity separation

The invention discloses a filter press system with a dewatering wheel system. The filter press system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves.The belt filter press comprises a frame, a gravity separation zone, a squeezing separation zone and a liquid guide device. The squeezing separation zone comprises a second driving motor, a third driving motor, a pre-pressing device, an upper pressure filtering belt, a lower pressure filtering belt, a tensioning roller, a discharge roller, a dewatering roller system, a carrier roller, a second deviation adjustment device and a third deviation adjustment device. The dewatering roller system comprises five dewatering rollers respectively arranged in the upper pressure filtering belt and the lower pressure filtering belt.

Owner:福州清河源环保科技有限公司

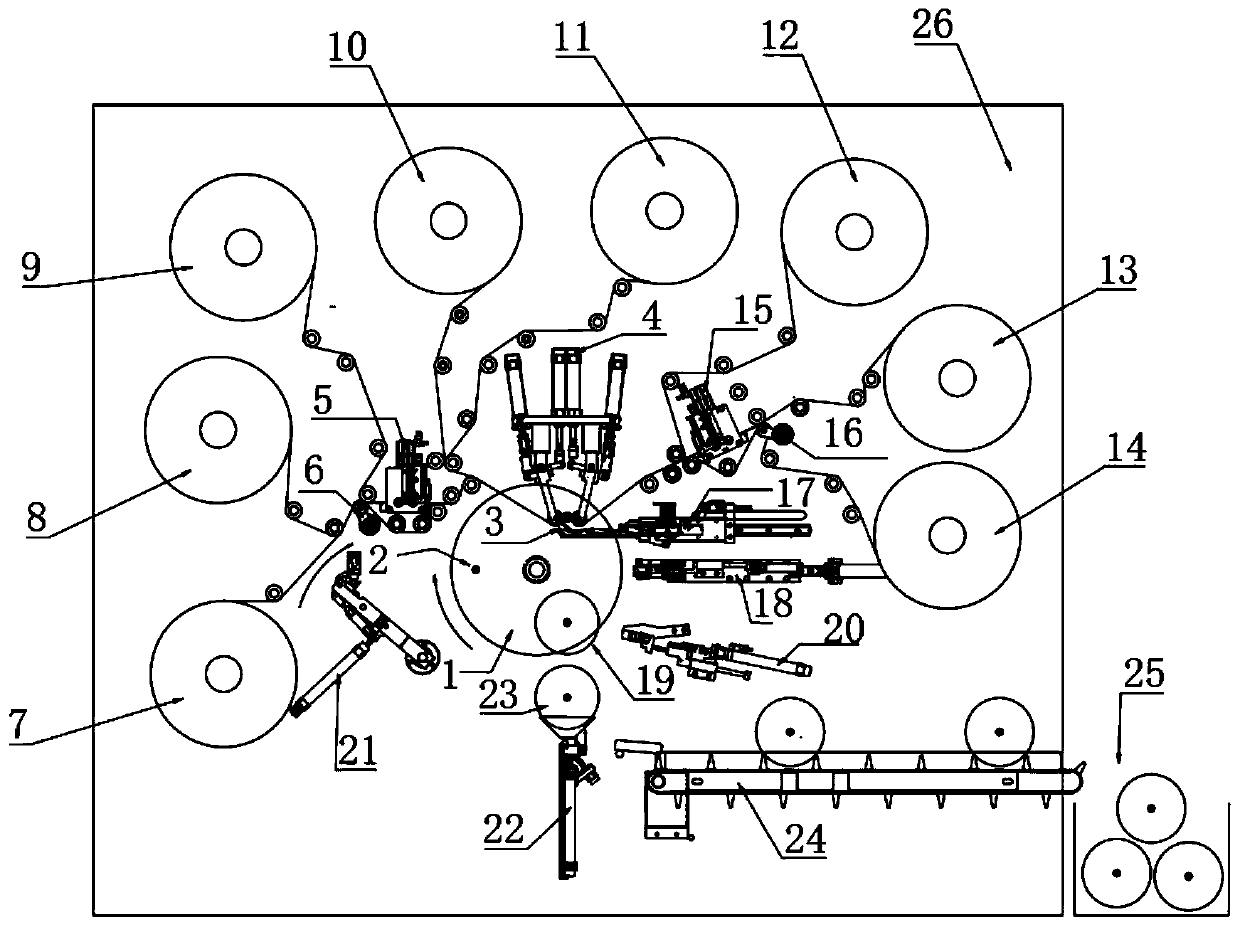

Winding machine for winding metal foil type capacitor

The invention discloses a winding machine for winding a metal foil type capacitor. The winding machine comprises a substrate, a machine head mechanism is arranged on the substrate; a first station, asecond station and a third station are located in the circumferential direction of the machine head mechanism. A winding needle is inserted into each station; a material inserting mechanism is arranged between the second station and a pressing wheel mechanism. A first edge folding mechanism is arranged at one end of the pressing wheel mechanism. A first one-way wheel mechanism is arranged below the first edge folding mechanism; all the material discs are located in the circumferential direction of the machine head mechanism, roughened films (OPP) on the material discs penetrate through pressing wheels of a pressing wheel mechanism through rolling wheels along a material film path and are wound on winding needles of a second station, and aluminum foil on a third material disc and aluminum foil on a seventh material disc pass through rolling wheels and a first edge folding mechanism and are wound into winding needles of the second station along an aluminum foil path. The overall layout of a thin film and aluminum foil winding path of the foil type capacitor winding machine is optimized, capacitors of different specifications are produced, and a mechanism for automatically feeding a hard core rod is adopted in the first station, so that the equipment can operate in a full-automatic mode.

Owner:常州联威自动化设备有限公司

Chemical slurry pressure filter system

ActiveCN107670393ARealize processing and manufacturingFilter thoroughlyLavatory sanitoryDisinfectionBall bearingSlag

The invention discloses a chemical slurry pressure filter system. The system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The pressure filter comprises a driving motor, a clutch, a transmission shaft, a distributor head, a ball bearing, a left end cover, an outer cylinder main body, a sealing cover plate, a sealing spacer block, a filter screen, an inner cylinder main body, a drainage pipe, a packing seal, a right end cover, a roller bearing, an outer cylinder support base, a side support, a scraper discharge device, an unloading box, a reducer and a lubrication device.

Owner:宝应县有机食品质量监督检验中心

Automatic control rainwater discarding and collecting device

InactiveCN107338856AEasy to useGuaranteed cleanlinessSewerage structuresAutomatic controlEngineering

The invention belongs to the technical field of rainwater treatment devices, and relates to an automatic control rainwater discarding and collecting device. An overflow pipe is arranged at the upper portion. A supporting column is arranged in a device body. A collecting water tank and a discarding water tank are arranged on the two sides of the supporting column respectively. A fulcrum is arranged on the top of the supporting column and provided with a lever. The two ends of the lever are connected with a cover plate for sealing the collecting water tank and a cover plate for sealing the discarding water tank respectively. A control bucket is hinged to the level. Overflow openings are formed in the upper side and the lower side of the bucket wall of the control bucket respectively. A spring is arranged at the bottom of the control bucket. The top of the spring is connected with a water inlet vertical pipe. The top of the water inlet vertical pipe is connected with a water inlet transverse pipe. According to the rainfall intensity and rainfall capacity, initial rainwater discarding, intermediate rainwater collecting and later automatic rainwater cleaning are automatically carried out, and the automatic control rainwater discarding and collecting device is installed beside a rainwater dry pipe underground and is convenient to use.

Owner:TIANJIN UNIV

Full-automatic assembly line visual transfer printing system and process

PendingCN111114114ASolve worker dilemma and process capacity bottleneckIncrease productivityRotary pressesConveyor partsRobot controlProcess engineering

The invention belongs to the technical field of printing, and particularly discloses a full-automatic assembly line visual transfer printing system and process. The full-automatic assembly line visualtransfer printing system includes a conveying mechanism, one end of the conveying mechanism is provided with a feeding platform for conveying products, a robot working platform is arranged on one side of the conveying mechanism, a robot control box is arranged on one side of the robot working platform, a robot teaching box is fixed to the upper end of the robot control box, a robot arm is arranged at the upper end of the robot teaching box, and a transfer printing system is arranged on one side of the robot teaching box. The transfer printing system includes a transfer printing device, an oiling device, a transfer printing mold and a silicone deoiling device; and the robot arm controls a robot grabbing fixture A and a robot grabbing fixture B to automatically convey materials to the transfer printing system for transfer printing operation, the plight of the current lack of workers at the production line and the bottleneck of the process capacity are effectively solved, the original printing of 350 products per hour is increased to 900 pieces per hour, and the production efficiency is greatly improved.

Owner:万达工业(始兴)有限公司

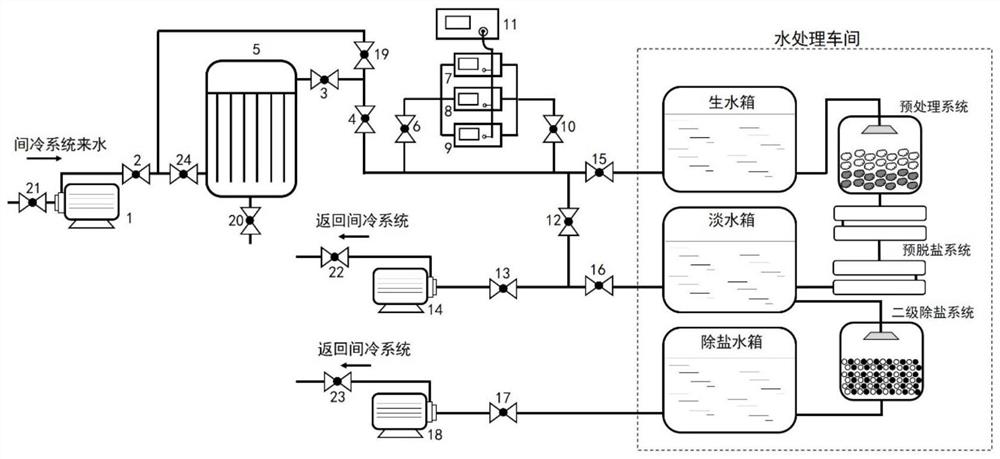

Intelligent purification system for circulating water of indirect air cooling system and use method of intelligent purification system

PendingCN111977758AEnsure water qualityImprove water qualityWater treatment parameter controlSpecific water treatment objectivesProcess engineeringAir cooling system

The invention discloses an intelligent purification system for circulating water of an indirect air cooling system and a use method of the intelligent purification system, and aims to purify indirectair cooling circulating water by using a water treatment workshop of a power plant so as to slow down and inhibit corrosion of materials in the indirect air cooling system. The intelligent purification system comprises a pipeline booster pump, a strong magnetic iron remover, a water quality monitoring device, an intelligent control device, a flow control valve and the like, wherein the water quality monitoring device comprises an online conductivity meter, an online turbidity meter and an online pH value meter. The intelligent purification system takes water from a circulating water pipeline of the indirect air cooling system, the circulating water is conveyed to the water treatment workshop through the pipeline, and the intelligent control device sets a purification scheme according to awater quality result measured by the water quality monitoring device. Under the condition of not additionally arranging water treatment equipment, the parameters such as turbidity, conductivity and pHof the indirect air cooling circulating water can be effectively controlled within the target value ranges, the water quality is kept stable, the corrosivity of the indirect air cooling circulating water is reduced, and corrosion of carbon steel and pure aluminum in the indirect air-cooling system is effectively relieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

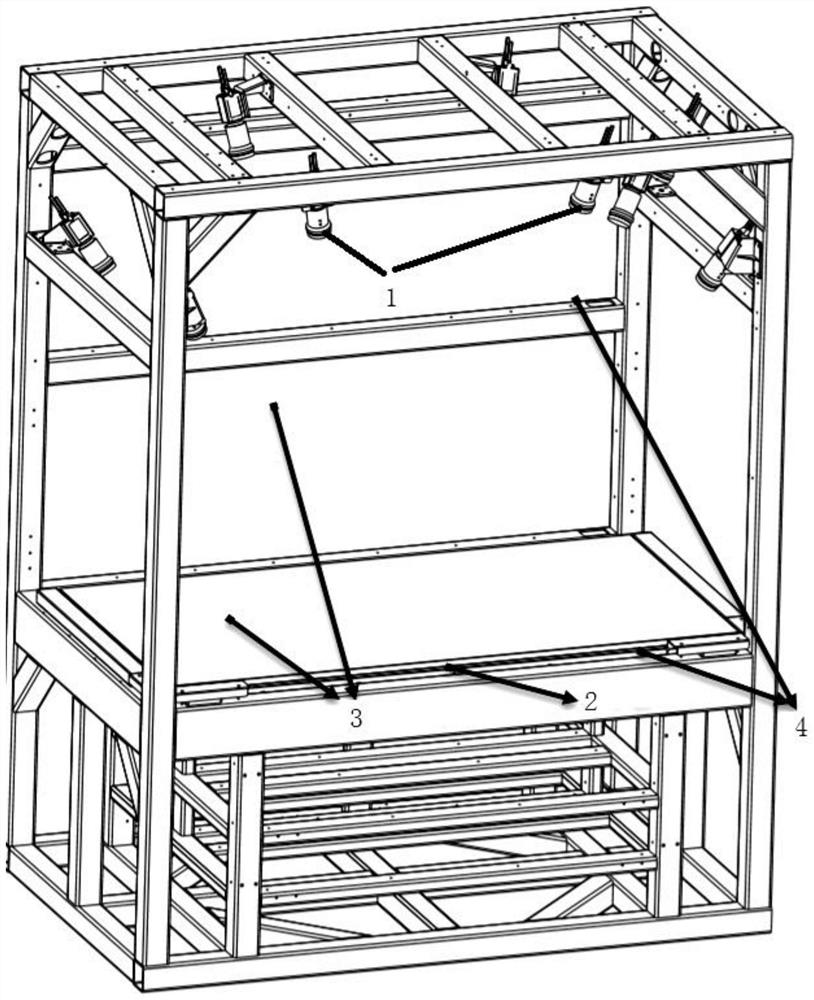

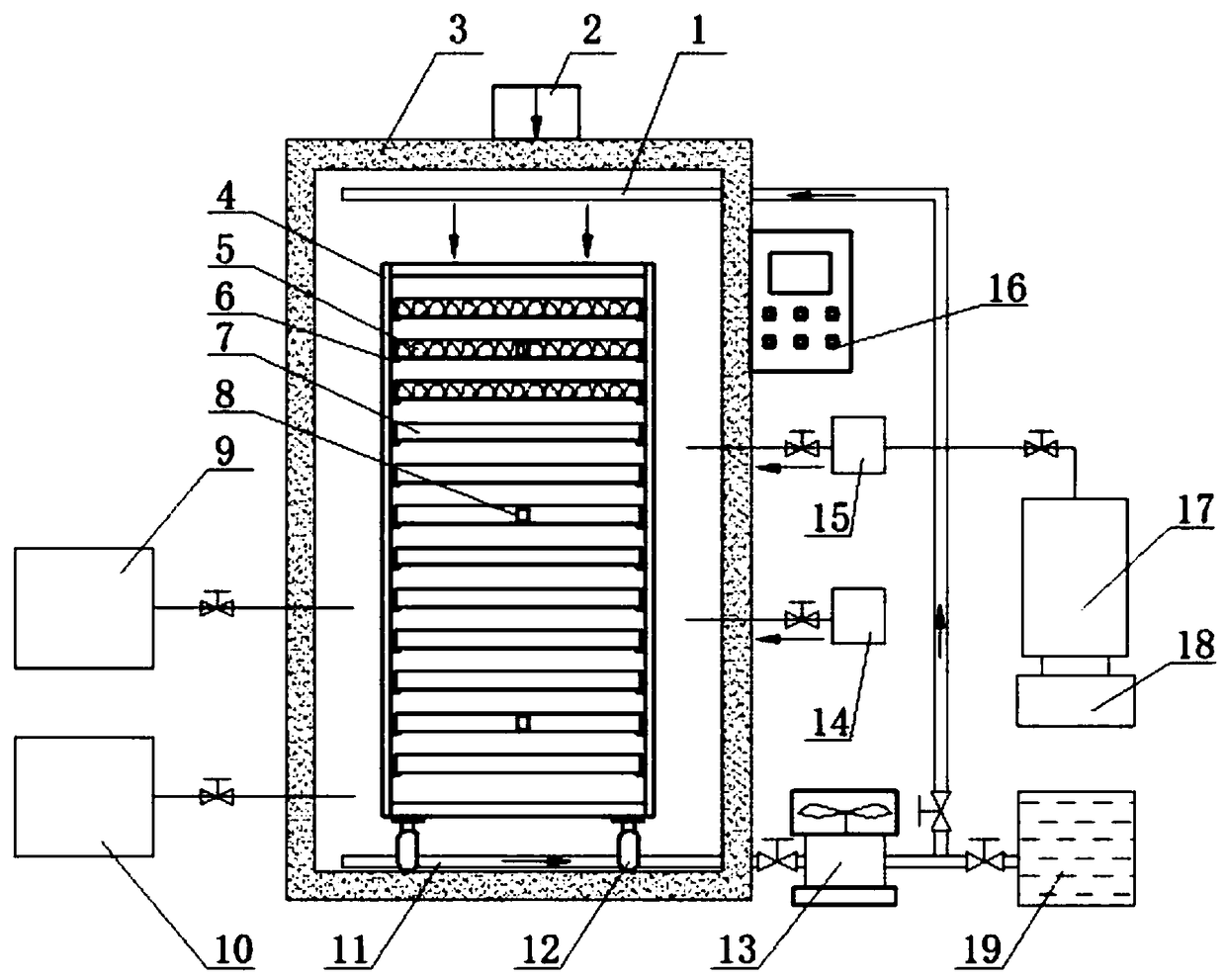

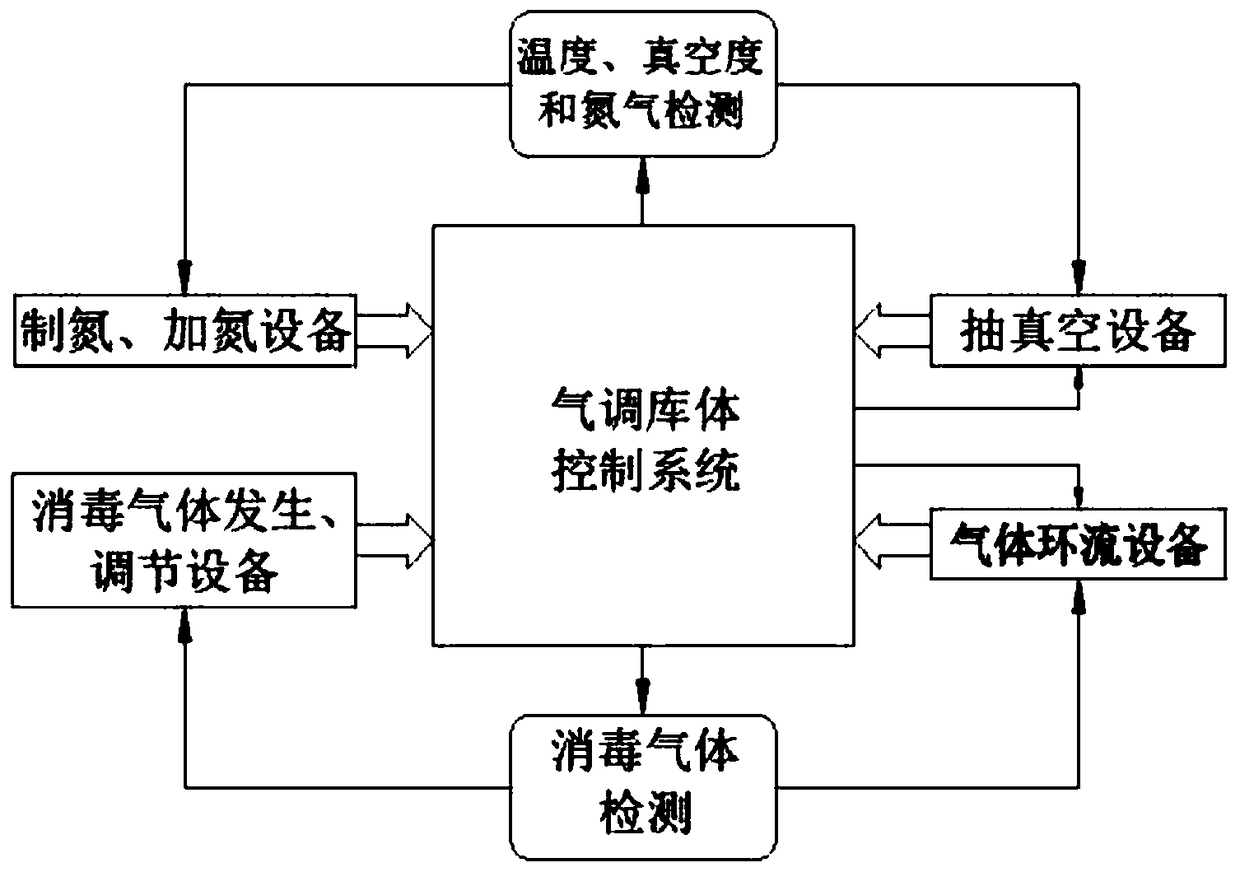

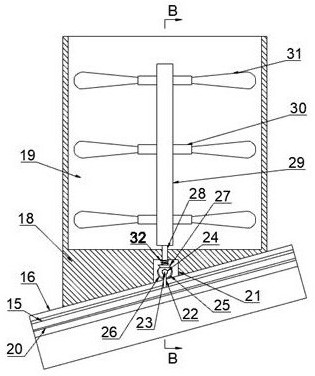

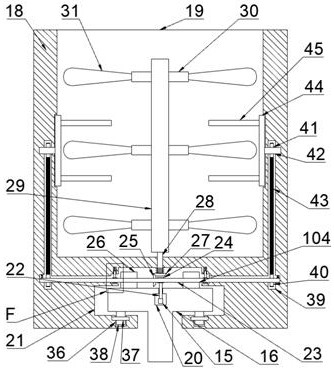

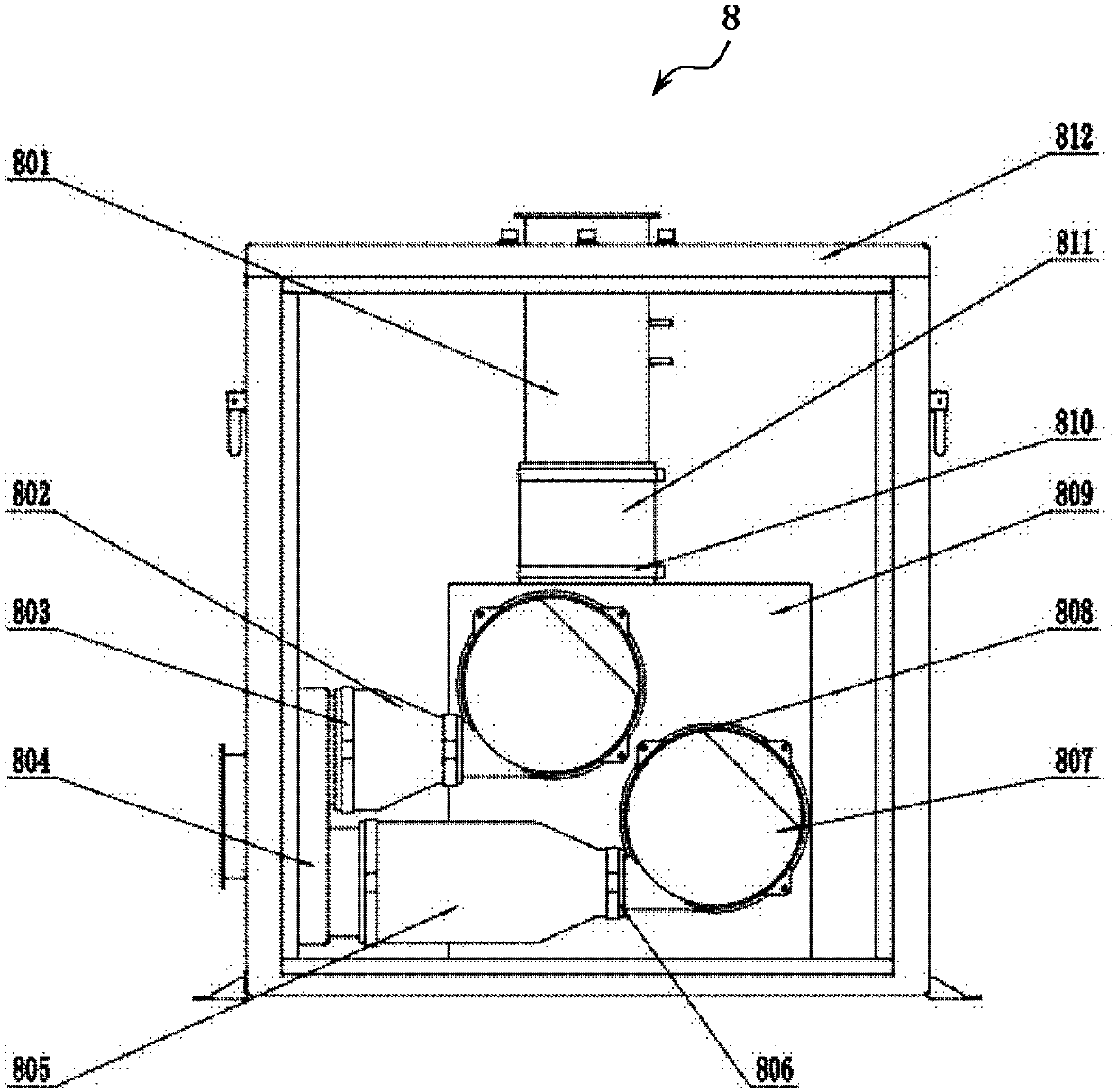

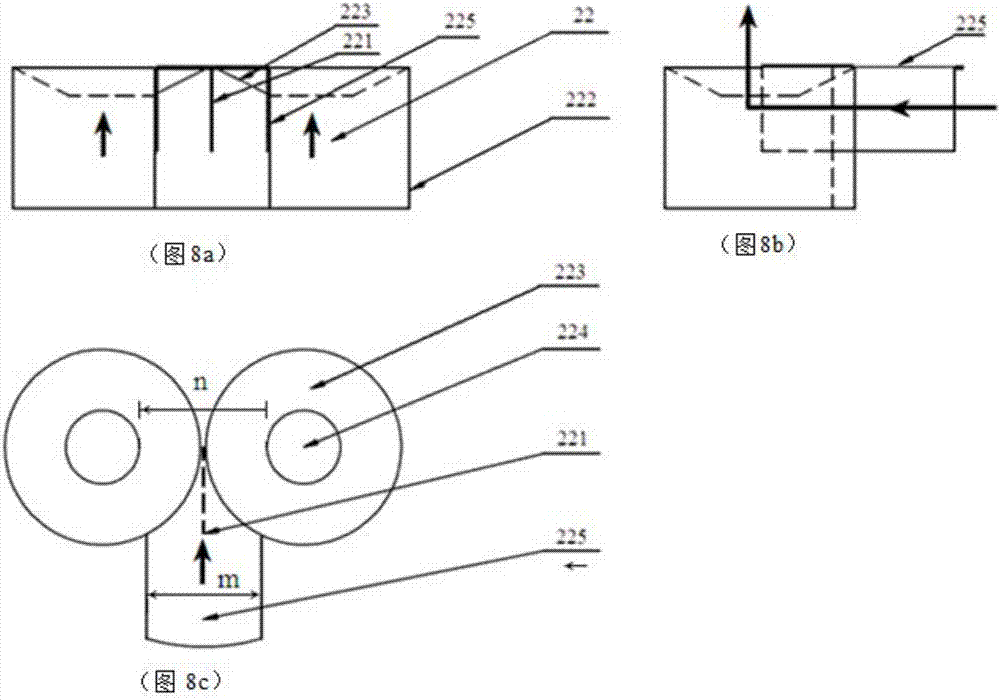

Tuber seedling modified atmosphere disinfection equipment and control method

ActiveCN109005817AThoroughly sterilizedThorough and effective sterilizationPlantingControl systemNitrogen

The invention relates to tuber seedling modified atmosphere disinfection equipment and a control method. The equipment includes a casing, a seedling tray system, a disinfecting gas circulation system,a vacuuming device, a nitrogen filling device, an ozone generating device, a disinfecting gas application system, and a modified atmosphere control system. The treatment equipment of the invention has the advantages of consistent disinfection, complete sterilization, accurate concentration control, high efficiency, and simple operation, and can meet the disinfection treatment of various tuber seedlings, and has wide adaptability. The equipment can be widely used in the treatment of high value-added seedlings such as various vegetables and Chinese herbal medicines, can effectively kill all kinds of insects, bacteria and viruses carried by seedlings, plantation can be carried out after processing, the equipment does not cause any pollution to the environment, and has good economic and social value.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Chemical slurry separation system with function of material level judgment

ActiveCN107670384ARealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesBuffer tankSlag

The invention discloses a chemical slurry separation system with a function of material level judgment. The chemical slurry separation system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches, fifteen valves, a main control computer and sensors. The main control computer receives signals from the sensors and controls the fifteen valves, five circuit switches, six feeding pumps, box filter, belt filter press, squeezing filter and pressure filter.

Owner:SHANDONG XINHUA LONGXIN CHEM

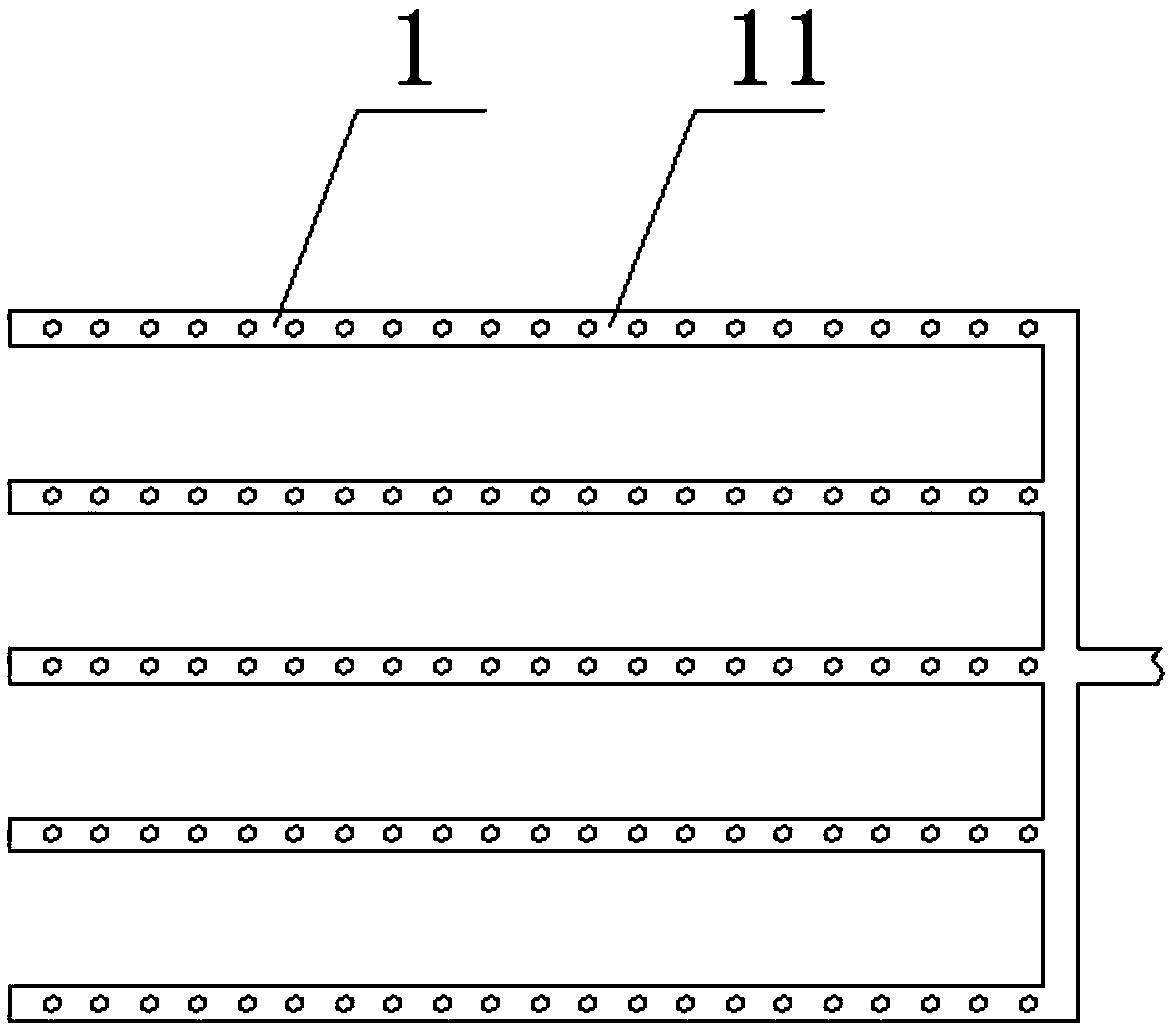

A filter box system capable of judging transmission effectiveness

InactiveCN107670378BRealize processing and manufacturingFilter thoroughlyFiltration circuitsBuffer tankSlag

The invention discloses a filter box system with a function of determining effectiveness of a transmission device. The filter box system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves. The box filter comprises multiple stacked filter boxes. A spray pipe, a movable plate, a filter plate, a fixed plate, a frame and a transmission device are arrangedin each filter box. Through comparing the transmission device power and the current driving power, it is determined if the current transmission device works normally.

Owner:冀小锋

A multi-sensor chemical slurry separation system

ActiveCN107670386BRealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagBuffer tank

The invention discloses a chemical slurry separation system with multiple sensors. The chemical slurry separation system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches,fifteen valves, a master control station and sensors. The master control station is used for receiving signals from the sensors and controlling the fifteen valves, the five circuit switches, the sixfeeding pumps, the box filter, the belt filter press, the squeezing filter and the pressure filter.

Owner:河北奥盛生物科技有限公司

Concrete conveying and mixing equipment

ActiveCN111716532BQuality improvementFully automatic operationConveyorsIngredients storageArchitectural engineeringChain link

The invention relates to the field of concrete mixing, in particular to a concrete conveying and mixing equipment, which includes a machine body and a working chamber arranged inside the machine body. A conveying device is arranged inside the working chamber. The stirring device above the conveying device moves in the working chamber. The stirring device includes a box body and a stirring chamber arranged upwardly in the opening of the box body. The first transmission chamber with a lower opening, a kind of concrete conveying and mixing equipment provided by the present invention, can automatically take materials and convey concrete to a high place, and at the same time, it can always mix the concrete during the conveying process, so that the concrete can keep Good quality of use, fully automatic operation in the whole process, no need for extra manpower, making the whole process more convenient and faster.

Owner:三亚神力混凝土有限公司

Automatic radioactive aerosol sampling measurement analysis system

ActiveCN110082166AHigh degree of intelligenceSimple structureWithdrawing sample devicesFilter paperAerosol sampling

The invention relates to an automatic radioactive aerosol sampling measurement analysis system. The system comprises a filter paper automatic conveying recovery module, an aerosol sampling module, ananalysis measurement module and a control module. The modules are modularly designed and applicable to be conveyed in a mutually independent manner.

Owner:北京方鸿智能科技有限公司

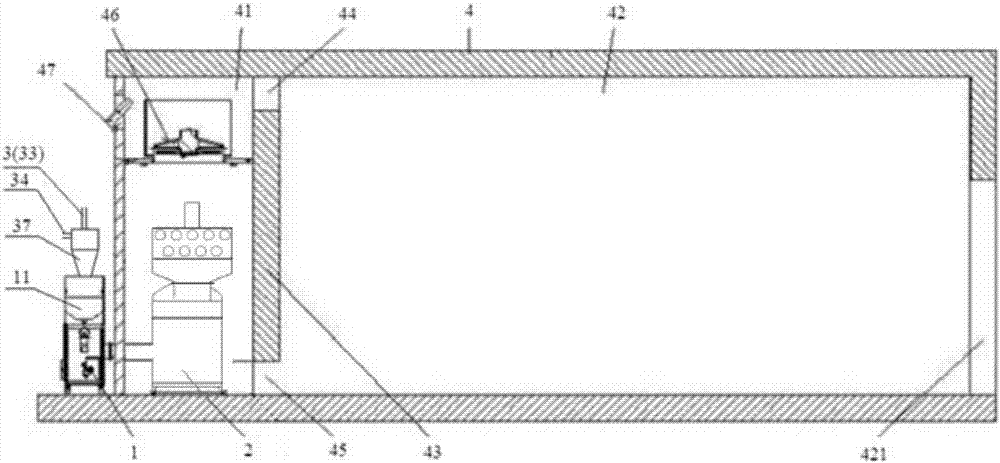

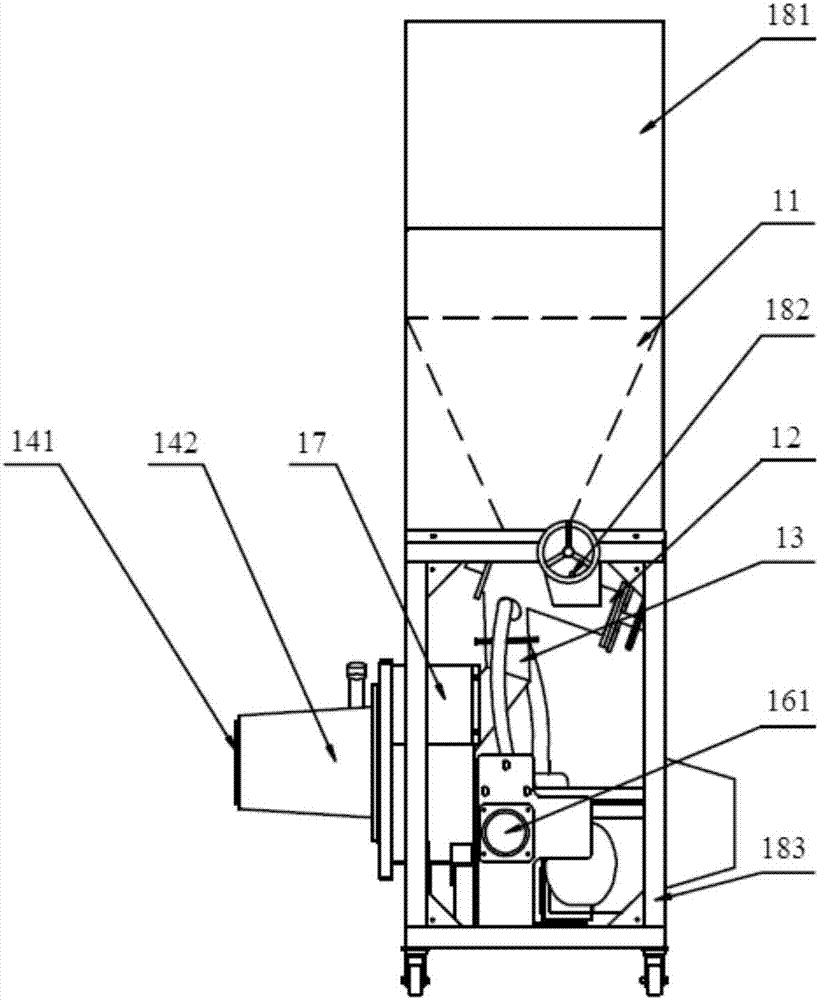

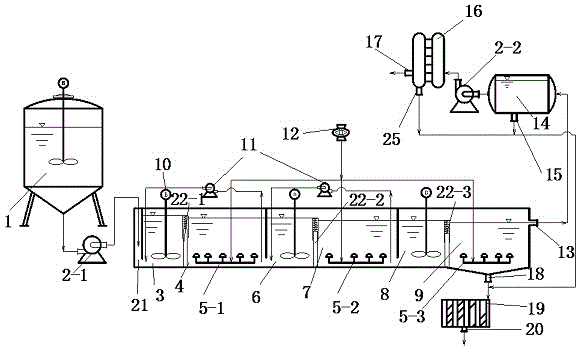

A kind of biomass pellet fuel heating equipment

ActiveCN105942568BEnsure consistencyGuaranteed versatilityTobacco preparationDrying gas arrangementsEconomic benefitsRecuperator

The invention provides a biomass pellet fuel heating appliance, comprising a combustion furnace, a heat exchanger, a central supply system for supplying biomass pellet fuel to the combustion furnace, and a barn; the heat exchanger is used for being connected to one end of a horizontal nozzle of the combustion furnace, the barn includes a heating chamber, the heat exchanger is disposed in the heating chamber, and the combustion furnace and the central supply system are disposed outside the barn; the central supply system is used for providing biomass pellet fuel centrally for more than two combustion furnaces and comprises a suction unit with a vacuum pump, a storage barrel, more than two suction pipes, more than two feed pipes, a screw feeding mechanism, a feeding distribution connector, more than two electromagnetic valves, more than two vacuum buckets and more than two gravity valves. The heating appliance provided herein is reasonable and practical in design, safe and green, and efficient and labor-saving, reduces cost, saves resources, improves work efficiency and enterprise economic benefit, and is suitable for popularization and use.

Owner:HUNAN XINDI NEW ENERGY TECH CO LTD

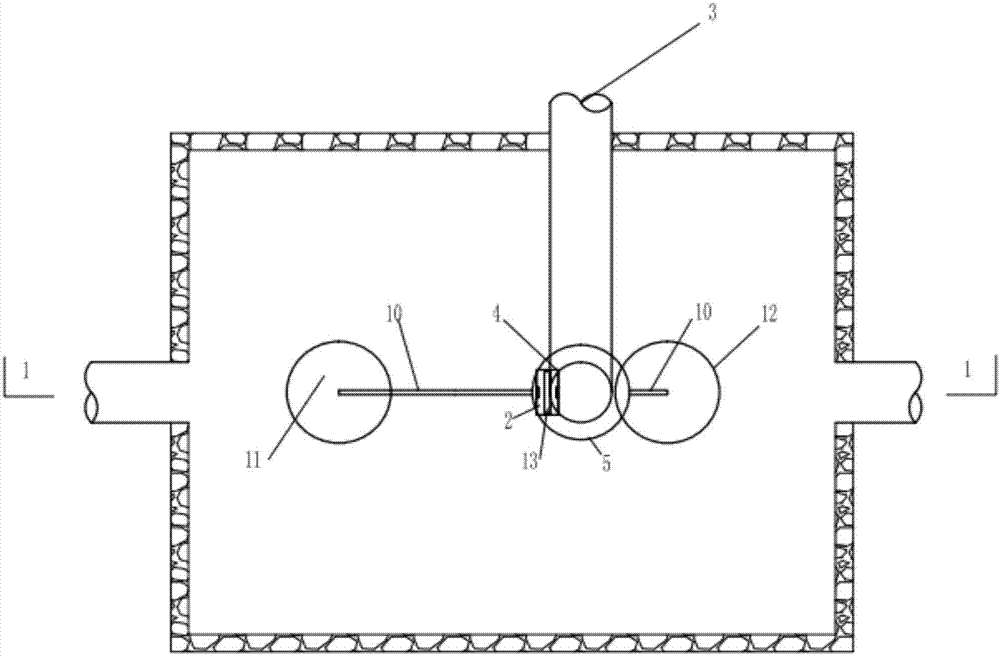

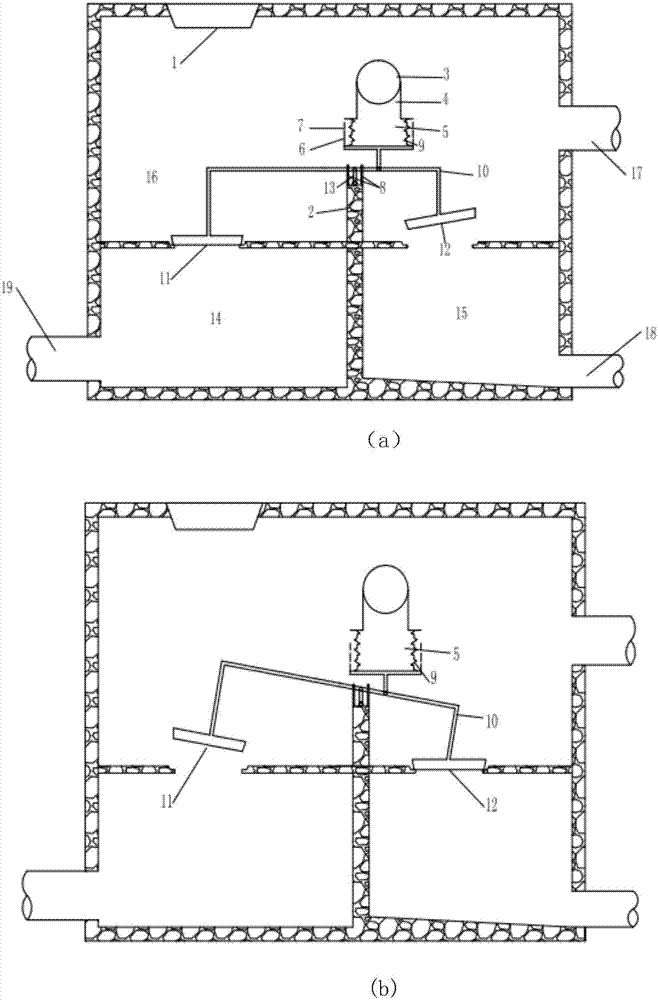

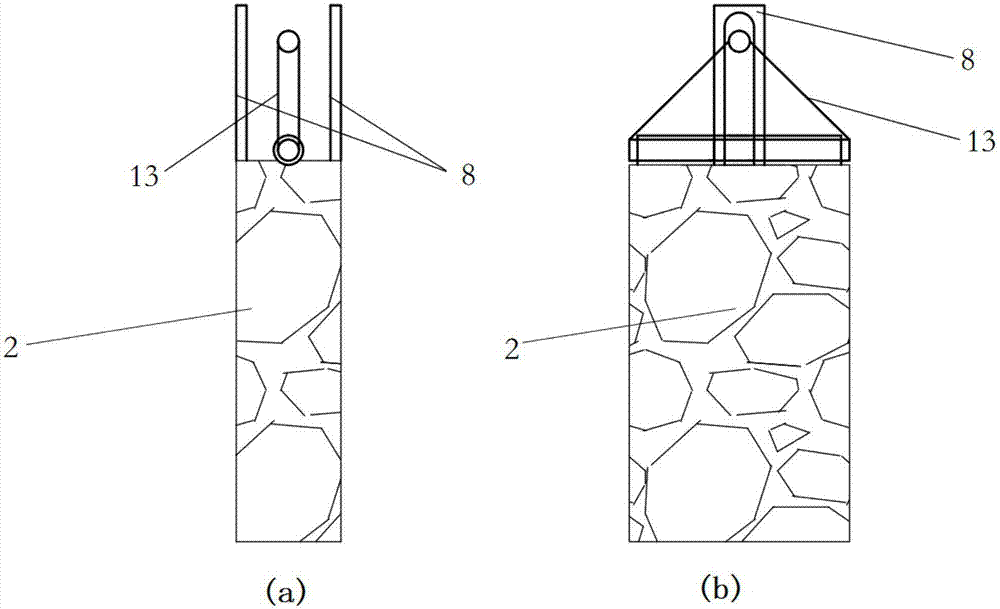

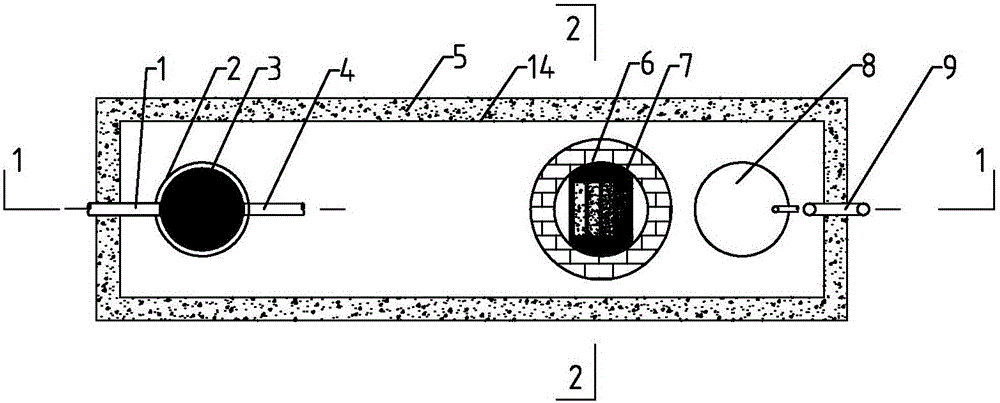

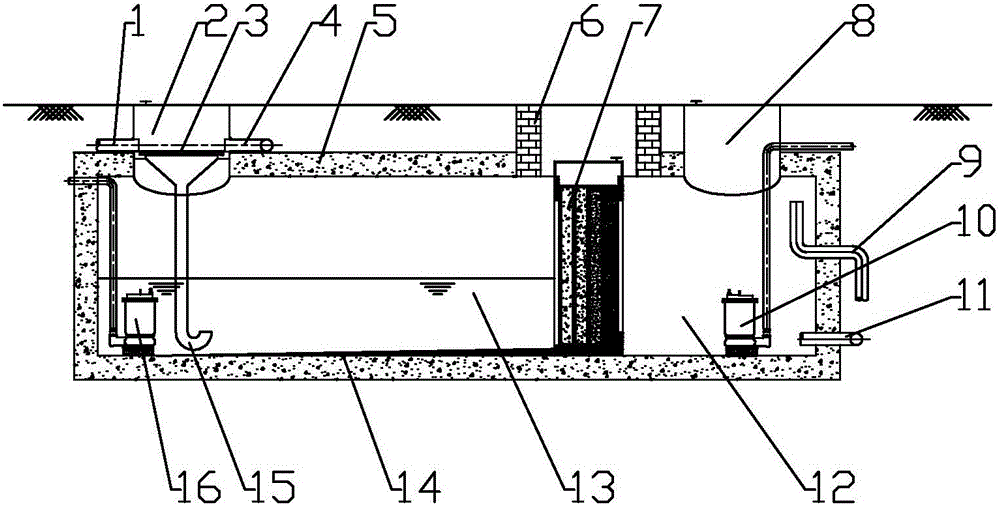

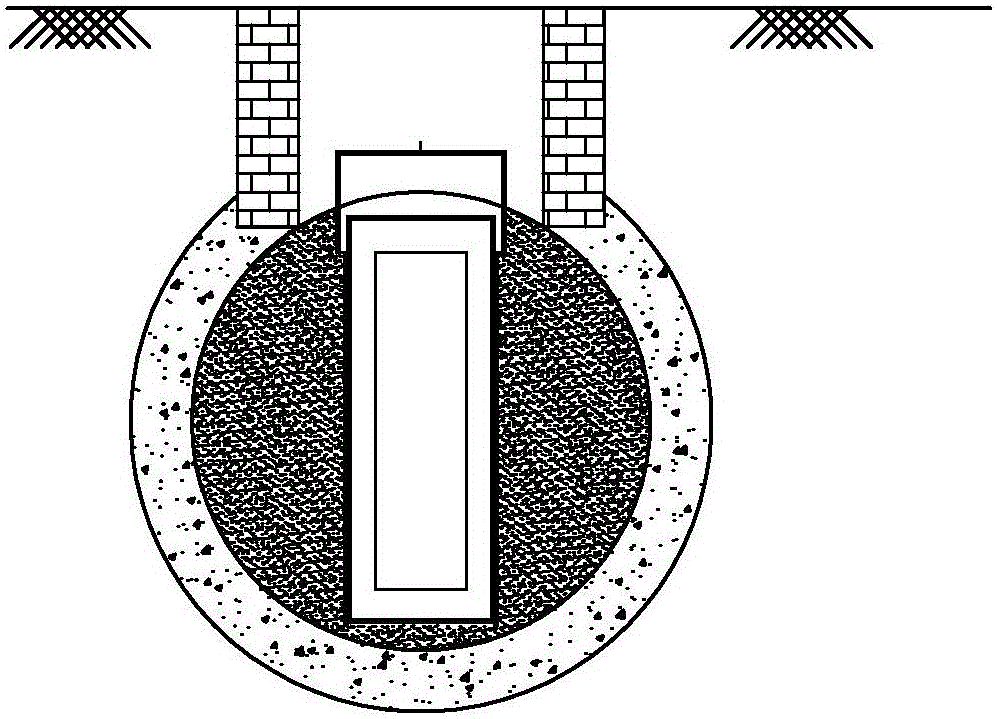

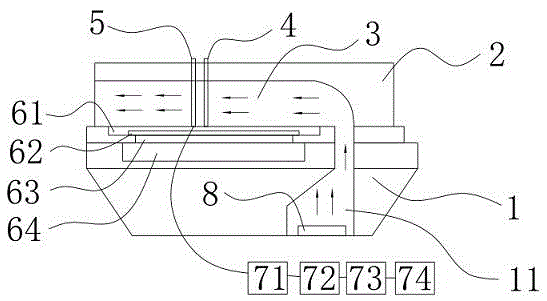

A fully automatic rainwater comprehensive utilization combined system

ActiveCN103541405BFully automatic operationImprove filtering effectGeneral water supply conservationWater supply tanksWater storage tankEngineering

An embodiment of the invention discloses a full-automatic comprehensive rainwater utilization combination system which is a device integrating a water storage tank, a filter device and a clear water tank as well as integrating rainwater collection, storage, treatment and utilization, and can be made of different materials mainly including PE (polyethylene), stainless steel and tempered glass. According to the system, roof rainwater, pavement rainwater, square rainwater and yard rainwater enter a rainwater storage pool through a rainwater pipe network, then are filtered through a filter plate, and reach the clear water tank to be extracted for utilization through a lifting device and a pipeline system. The number of the system devices can be determined according to different rainwater collection amounts, and the system devices can be mounted in a scattered manner according to collection amounts of different areas, so that effect of flexibility in application under different conditions and in different occasions is achieved, and the rainwater can be recycled more effectively.

Owner:北京雅仕格机电科技有限公司

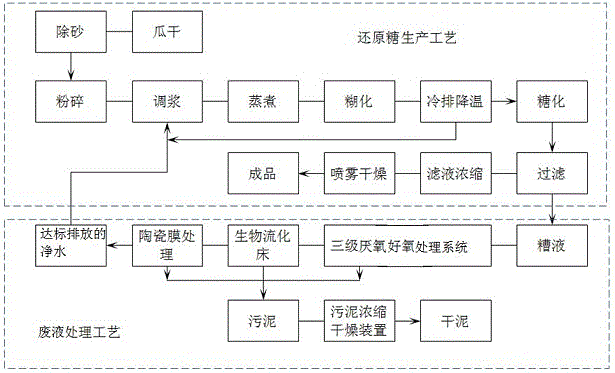

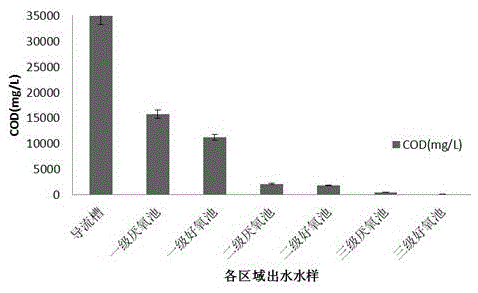

Treatment process of waste liquid in the production process of dried melon reducing sugar

InactiveCN104310586BImprove removal efficiencyEmission reductionTreatment with aerobic and anaerobic processesLiquid wasteAutomatic control

The invention relates to a treatment system and a treatment process for waste liquid in a dried melon reducing sugar production process. A waste liquid storage tank of the treatment system is connected with one end of a diversion tank, the bottom end of the diversion tank is communicated with the bottom of a multistage aerobic and anaerobic system, the top of a last-stage aerobic tank of the three-stage aerobic and anaerobic system is connected with a biological fluidized bed, the other end of the biological fluidized bed is connected with a ceramic membrane sewage treatment device, and sludge separation outlets of the biological fluidized bed, the ceramic membrane sewage treatment device and the three-stage aerobic and anaerobic system are all connected to an active sludge separation concentration device. The waste liquid flows through the diversion tank and is sequentially treated by the multistage aerobic and anaerobic system, the biological fluidized bed and the ceramic membrane sewage treatment device, then the treated waste liquid is recycled as size mixing water, and sludge produced by the system is concentrated and dried to form dried sludge. The treatment system and the treatment process have the characteristics of high environment friendliness, high resource utilization rate, high treatment effect, strong impact resistance and full-automatic control.

Owner:XUZHOU UNIV OF TECH

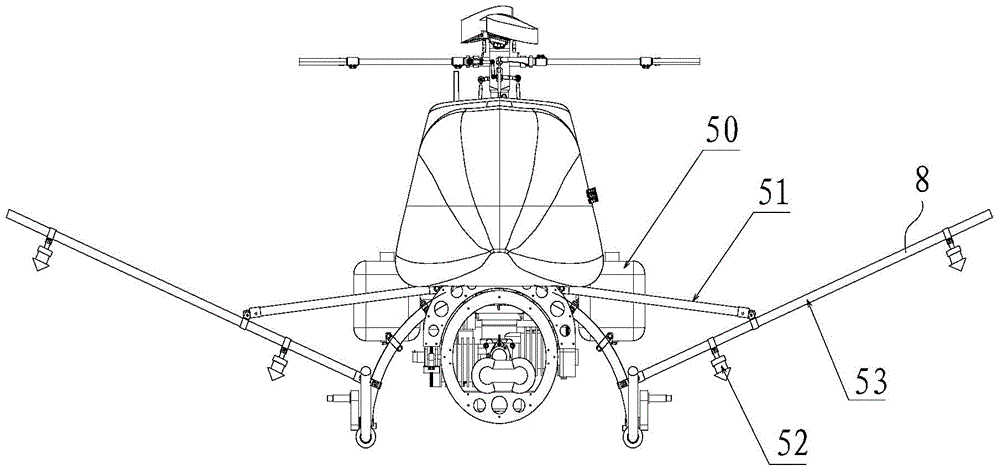

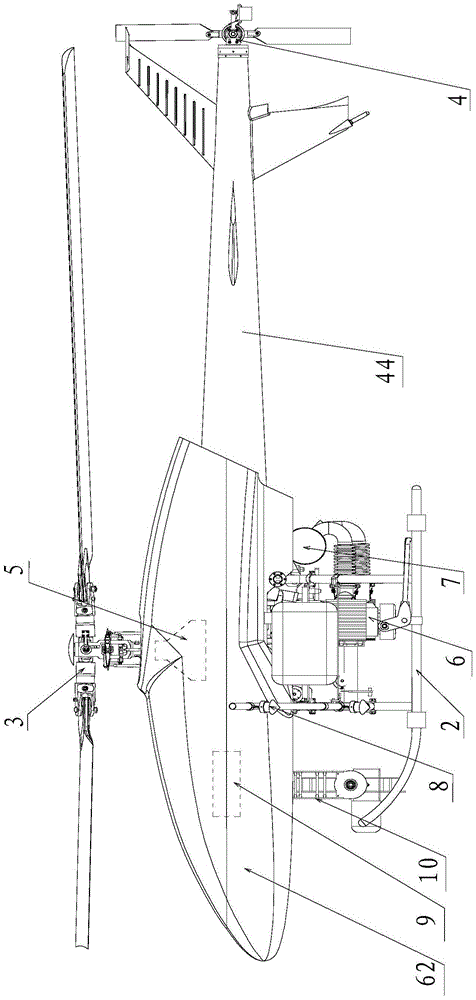

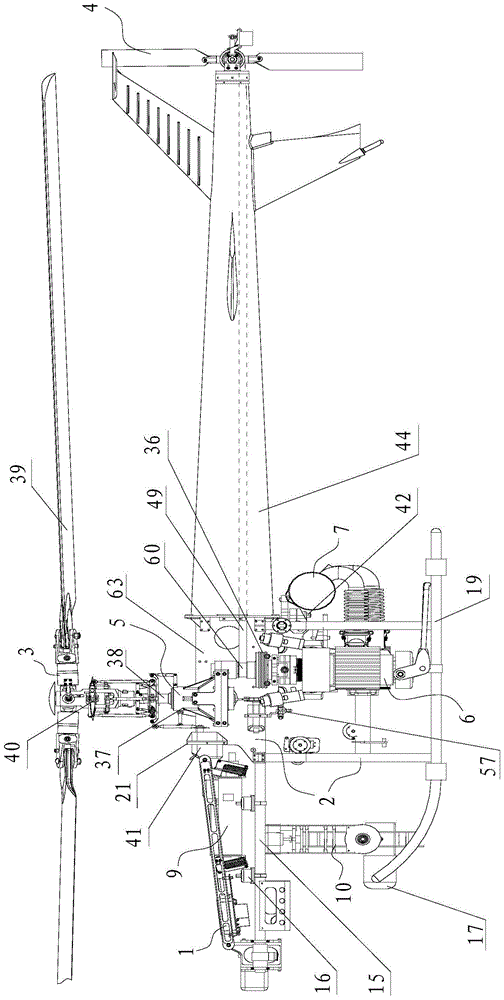

An unmanned helicopter for spraying medicine

ActiveCN104908946BRealize humanized controlAvoid wastingPower plant typeLaunching weaponsControl systemEngineering

The invention relates to an unmanned helicopter, in particular to a drug delivery unmanned helicopter which combines manual control drug delivery with automatic navigation drug delivery and has high drug delivery accuracy. The drug delivery unmanned helicopter comprises a helicopter head, a helicopter body, wings, a helicopter tail, a transmission device, a power device, an air exhausting device, a spraying device, a control system and a pan-tilt, wherein the helicopter body comprises a helicopter body support and an undercarriage; the power device is mounted on the helicopter body support; the wings above the helicopter body support are connected with the power device by the transmission device; the spraying device is mounted on the undercarriage of the helicopter body; the control system is arranged in the helicopter head; and the pan-tilt with a camera is arranged below the helicopter head. According to the drug delivery unmanned helicopter, data of crops is collected and fed back in real time by the camera, and the drug delivery time and speed of the spraying device are controlled by the control system, so that the drug delivery accuracy is realized, and the efficiency and the accuracy of drug delivery are improved greatly.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

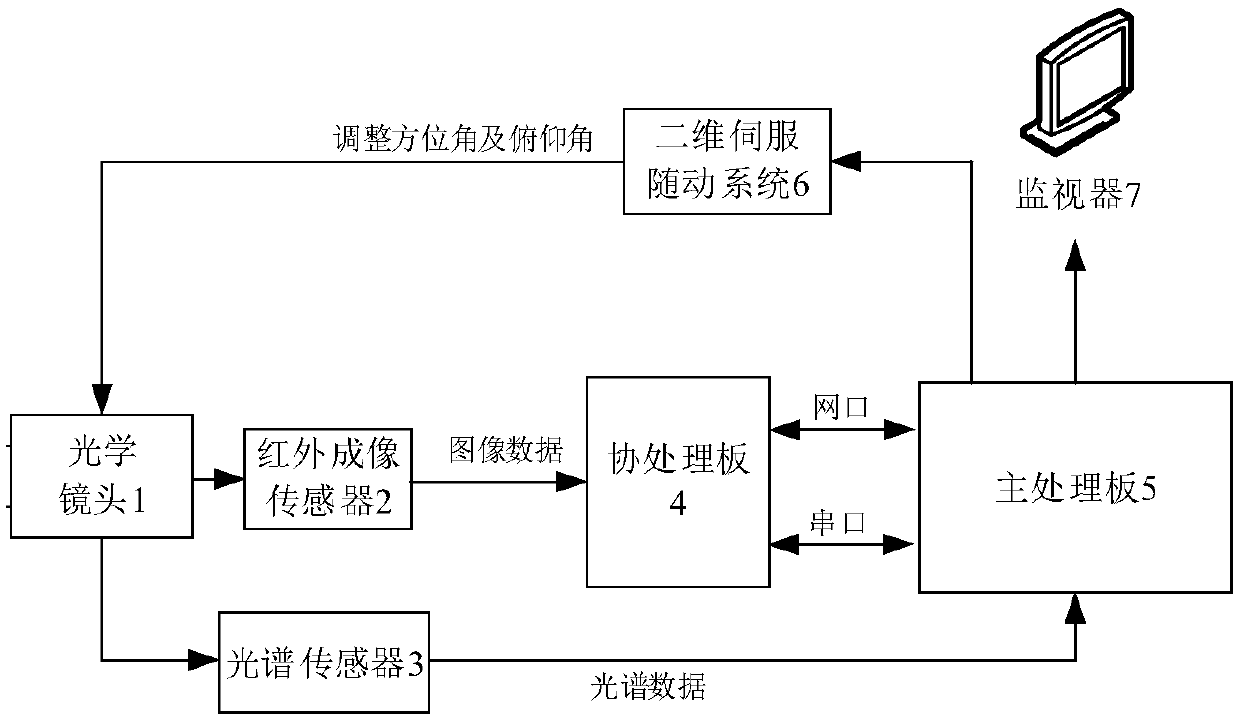

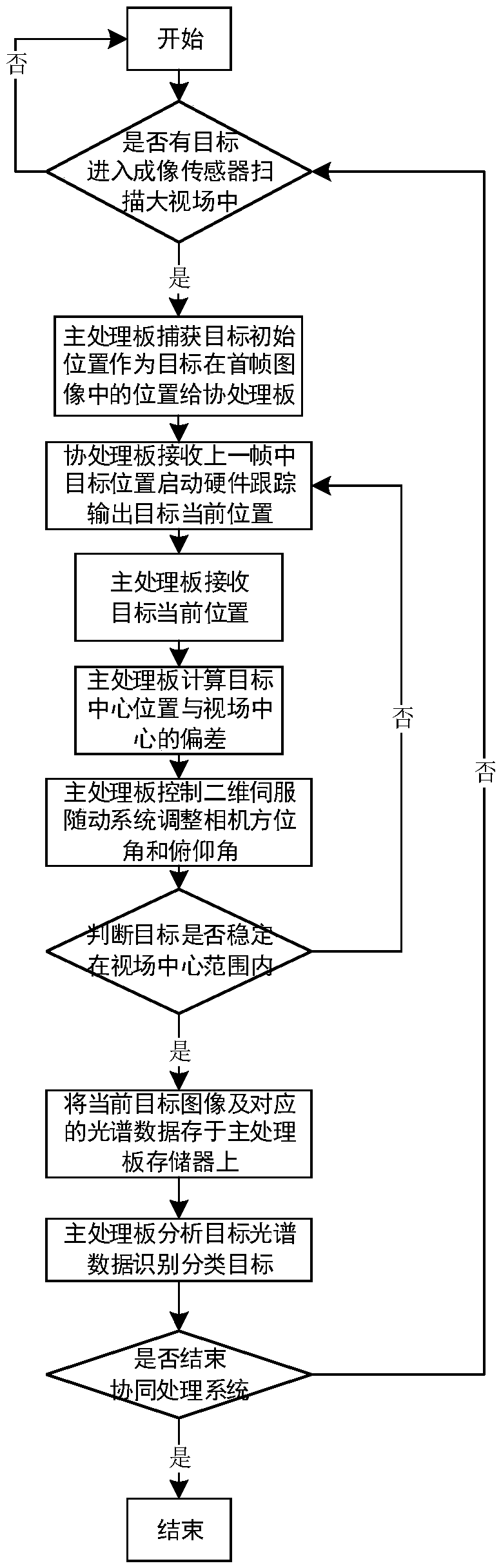

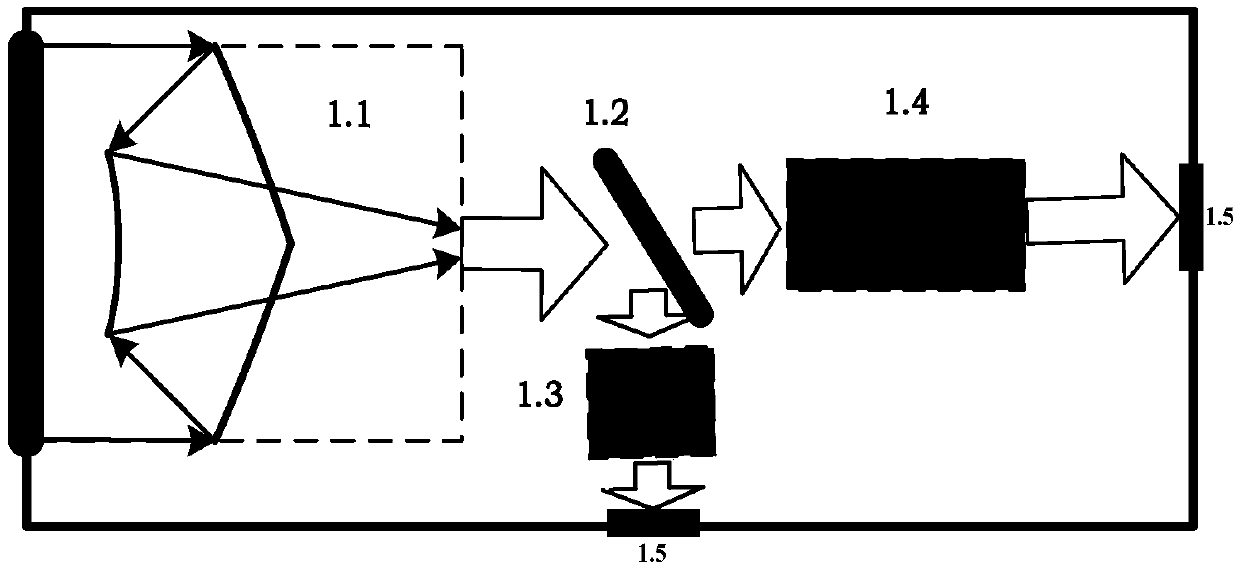

A collaborative real-time processing system for graphs

ActiveCN108335330BShorten the timeRealize fully automatic spectrum measurementProgramme controlImage enhancementProduction lineDigital image

The invention discloses a cooperative real-time image / spectrum processing system. The system comprises an optical lens, an infrared imaging sensor, a spectrum sensor, a cooperative processing plate and an upper computer, wherein the optical lens is used for obtaining visible light from a target view field and separating the visible light; the infrared imaging sensor is used for converting the received visible light into an infrared analog image, converting the infrared analog image into a digital image and providing the digital image to the cooperative processing plate; the spectrum sensor isused for obtaining spectrum data from the received visible light and providing the spectrum data to the upper computer; the cooperative processing plate is used for determining a target position fromthe digital image, sending the target position to the upper computer, determining an algorithm used by the target position and realizing the algorithm through an FPGA full-parallel production line; and the upper computer is used for continuously receiving the target position sent by the cooperative processing plate, controlling a two-dimensional servo system to adjust an optical lens, decrease a distance between a target and a view field center of the optical lens, and obtaining target spectrum information when the target is pulled to the view field center of the optical lens. According to thesystem, full-automatic spectrum measurement is realized, and finally cooperative real-time processing of images / spectrums is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

A filter press system with a dehydration train

ActiveCN107670387BRealize processing and manufacturingFilter thoroughlyWater treatment parameter controlSpecific water treatment objectivesSlagBuffer tank

The invention discloses a filter press system with a dewatering wheel system. The filter press system comprises one belt filter press, one box filter, one pressure filter, one squeezing filter, one sterilization device, one sedimentation tank, one waste liquid pool, one liquid collection pool, four slag storage tanks, three buffer tanks, six feeding pumps, five circuit switches and fifteen valves.The belt filter press comprises a frame, a gravity separation zone, a squeezing separation zone and a liquid guide device. The squeezing separation zone comprises a second driving motor, a third driving motor, a pre-pressing device, an upper pressure filtering belt, a lower pressure filtering belt, a tensioning roller, a discharge roller, a dewatering roller system, a carrier roller, a second deviation adjustment device and a third deviation adjustment device. The dewatering roller system comprises five dewatering rollers respectively arranged in the upper pressure filtering belt and the lower pressure filtering belt.

Owner:福州清河源环保科技有限公司

Textile Drying Rate Tester

ActiveCN104237487BAvoid operating errorsReduce energy consumptionTextile testingHeat conductingSolenoid valve

The invention belongs to the field of testing machines, in particular to a testing machine for testing the drying speed of textiles. The combination of the upper cover and the base forms a drying chamber for air circulation; a heating plate for providing heat is installed on the side of the base close to the drying chamber; the heating plate is covered with a heat conducting plate, which is used to transfer heat evenly and quickly to the Textiles; the water outlet of the pump is installed on the upper surface of the heat conduction plate, and the pump is used to send test water to the heat conduction plate; the water injection solenoid valve is installed on the water outlet pipeline of the pump, and the water injection solenoid valve is used to control the flow and timing of the water delivered by the pump ; A temperature sensor is installed at the water outlet of the pump, and the temperature sensor is used to detect the temperature of the textile. The textile drying rate testing machine simulates the temperature of the human body through the heating plate and the heat transfer plate. At the same time, the test water is passed into the textile through the pump and the temperature of the textile is detected through the temperature sensor, so that the textile drying speed test is completely automated.

Owner:SHENZHEN REFOND EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com