Textile Drying Rate Tester

A drying rate, textile technology, applied in the field of testing machines, can solve the problems of low testing efficiency, frequent operation, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

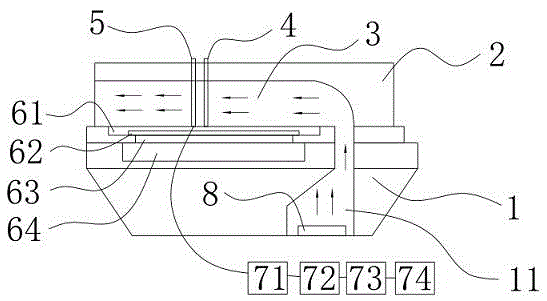

[0024] Such as figure 1 In the shown textile drying rate testing machine, the upper cover 2 and the base 1 are combined to form a drying chamber 3 for air circulation; a heating plate 62 for providing heat is installed on the side of the base 1 close to the drying chamber 3; Covering the heat conduction plate 61, the heat conduction plate 61 is used to transfer heat to the textile evenly and quickly; the water outlet of the pump 72 is installed on the upper surface of the heat conduction plate 61, and the pump 72 is used to remove the test water from the heat conduction plate 61; the water injection electromagnetic The valve 71 is installed on the outlet pipeline of the pump 72, and the water injection solenoid valve 71 is used to control the flow and timing of the pump 72 delivering water; the water outlet of the pump 72 is equipped with a temperature sensor 5, and the temperature sensor 5 is used to detect the temperature of the textile. The textile drying rate testing machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com