Discontinuous gas analysis method and equipment thereof

A gas analysis and analysis device technology, applied in the direction of sampling devices, etc., can solve the problems of low sampling frequency, measurement lag, and heavy maintenance workload, and achieve the effects of small measurement lag time, high sampling frequency, and good guidance for production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

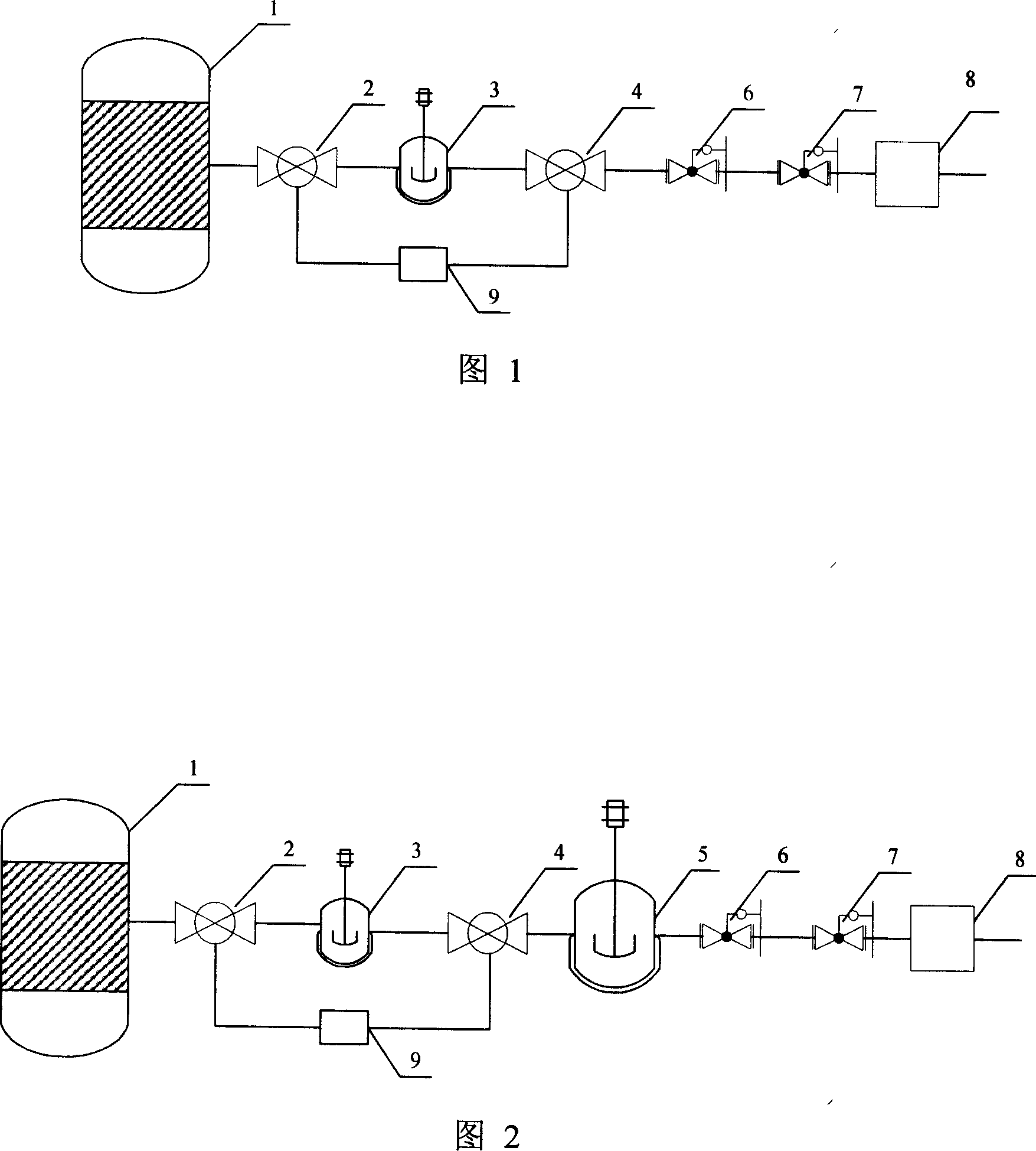

[0027] As shown in Figure 1, a discontinuous gas analysis device is applied to the analysis of high-pressure mixed gas in the urea synthesis tower to obtain the molar ratio of ammonia to carbon dioxide, that is, the ammonia-to-carbon ratio (N / C), thereby optimizing the urea production process , saving raw materials and reducing production costs. The analysis device includes an intermittent gas sampling device and a gas analysis instrument 8 .

[0028] The sampling device includes a ventilation pipeline, a control device 9 and a first-stage valve 2 , a first-stage gas storage container 3 , a second-stage valve 4 and a pressure reducing and stabilizing device sequentially installed on the ventilation pipeline. The first-stage valve 2 and the second-stage valve 4 are automatic control valves. In this embodiment, electric ball valves are used. The first-stage valve 2 is installed on the urea synthesis tower 1, and the mixed gas in the urea synthesis tower 1 The pressure is 15MPa,...

Embodiment 2

[0038] As shown in Figure 2, a kind of discontinuous gas analysis device, differs from embodiment 1, also installs the second-stage gas storage container 5 between described second-stage valve 4 and pressure reducing and stabilizing device, volume is 1L.

[0039] This embodiment also discloses a discontinuous gas analysis method, that is, the working process of the above-mentioned analysis device, and the method includes the following steps:

[0040] A. the specific process is the same as step a in Example 1;

[0041] b. The control device 9 controls to close the first-stage valve 2 and open the second-stage valve 4, and the sample gas in the first-stage gas storage container 3 passes through the second-stage valve 4 and then is filled into the In the second-stage gas storage container 5 described above, the expansion of the volume reduces the pressure of the sample gas, and then the sample gas flows downstream;

[0042] c. The sample gas flowing out from the second-stage ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com