Plant control apparatus

A technology for equipment control and equipment, which is applied in the control of combustion, adaptive control, electrical program control, etc., to achieve the effect of improving skills, improving reliability, and deepening understanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

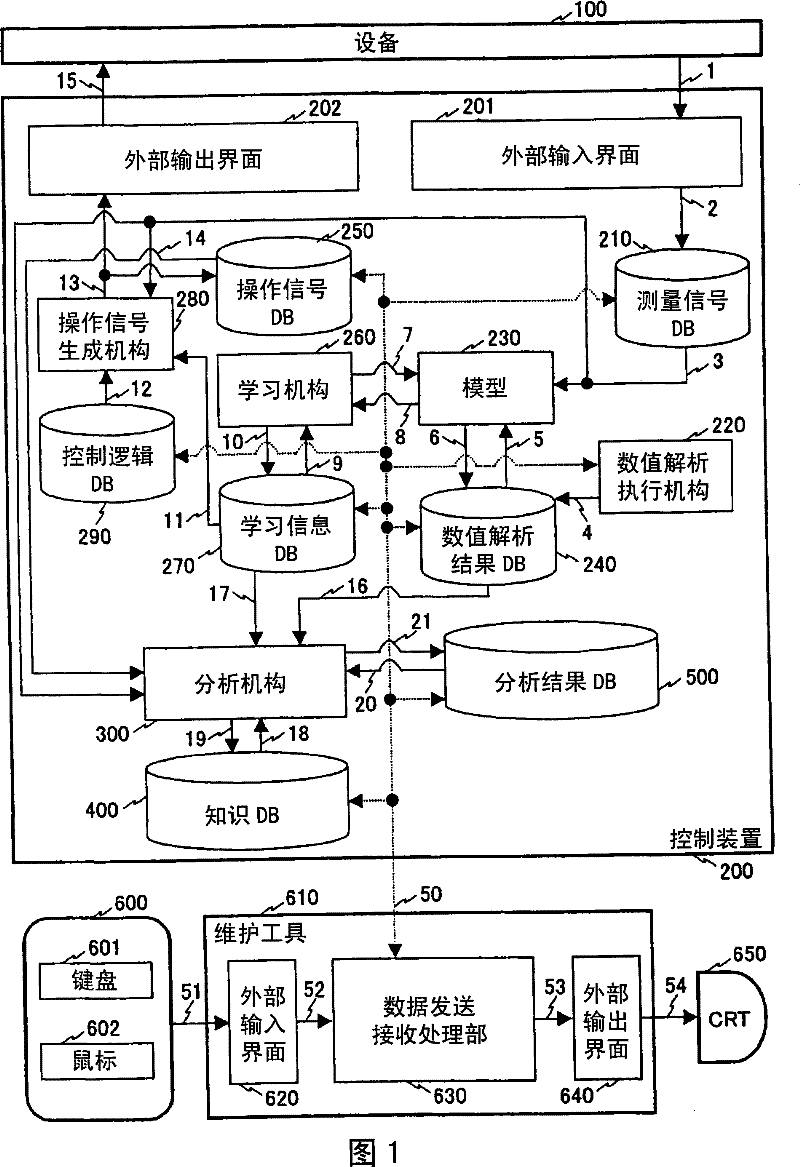

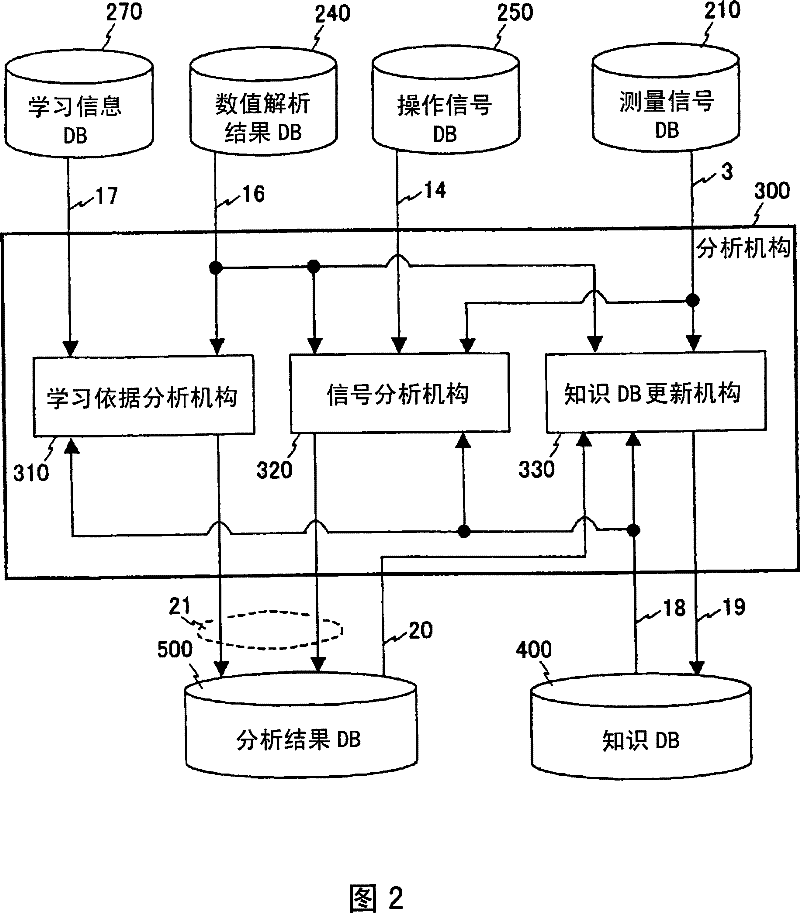

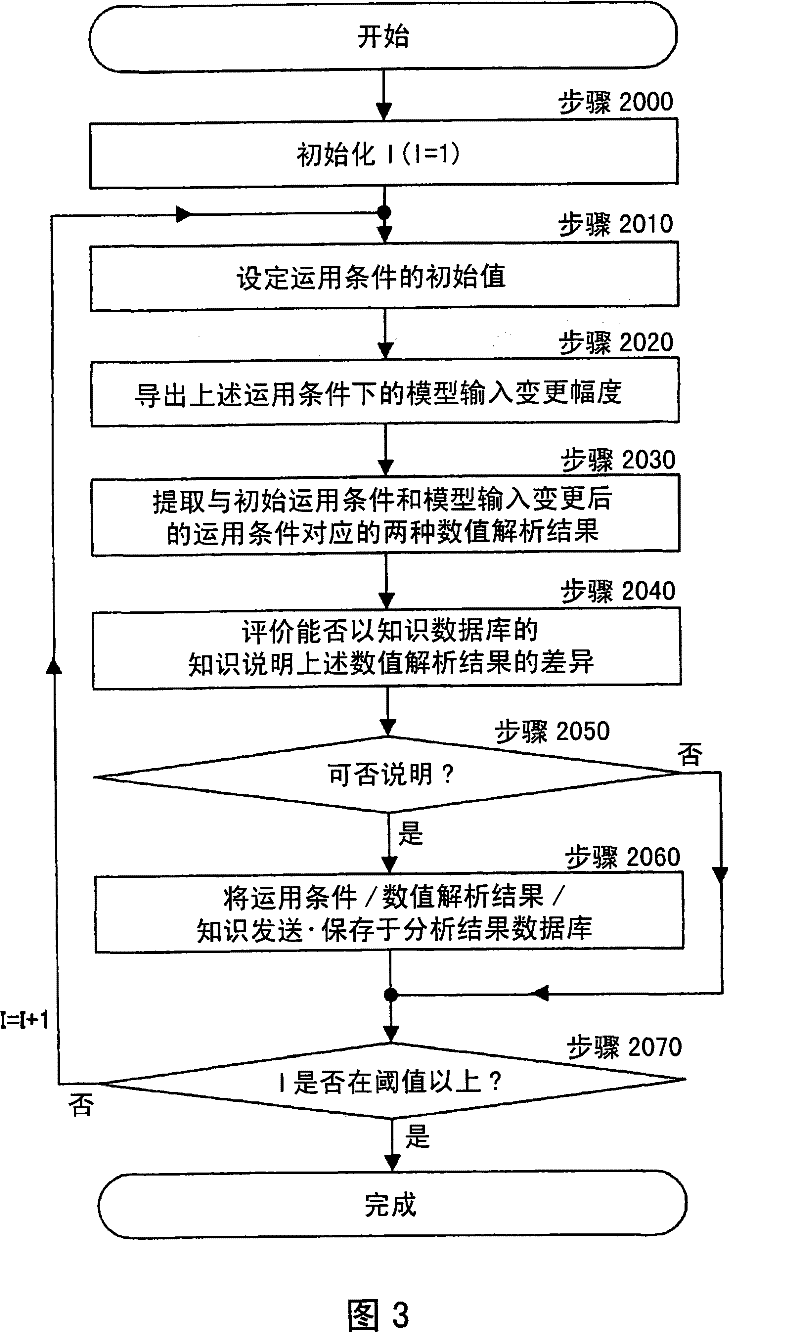

[0078] figure 1 is a block diagram showing the system configuration of Embodiment 1 of the device control device according to the present invention. figure 1 , the device 100 is controlled by the control device 200 .

[0079] In the control device 200 that controls a device to be controlled, a numerical analysis execution unit 220 , a model 230 , a learning unit 260 , an operation signal generation unit 280 , and an analysis unit 300 are provided as arithmetic units.

[0080] In addition, in the control device 200, a measurement signal database 210, a numerical analysis result database 240, an operation signal database 250, a learning information database 270, a control logic database 290, a knowledge database 400, and an analysis result database 500 are provided as databases.

[0081] In addition, an external input interface 201 and an external output interface 202 are provided in the control device 200 as interfaces with the outside.

[0082] In the control device 200 , ...

Embodiment 2

[0141] Next, Embodiment 2 in which the facility control device according to the present invention is applied to thermal power generation facilities will be described.

[0142] Furthermore, it goes without saying that the facility control device of the present invention can also be used when controlling facilities other than thermal power generation facilities.

[0143] Figure 13 It is a figure which shows the system structure of the thermal power generation facility 100.

[0144] The boiler 101 constituting thermal power generation equipment is provided with a burner 102 for supplying pulverized coal as a fuel obtained by finely pulverizing coal with a mill 110, primary air for transporting the pulverized coal, and secondary air for combustion adjustment, and uses The pulverized coal supplied through the burner 102 is burned inside the boiler 101 . Further, pulverized coal and primary air are introduced into the burner 102 through the pipe 142 , and the secondary air is int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com