Treatment process of waste liquid in the production process of dried melon reducing sugar

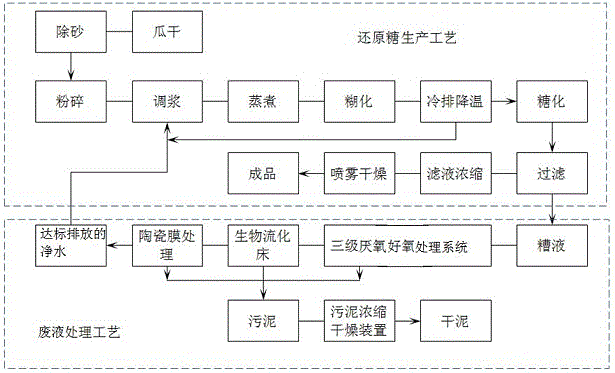

A treatment process and sugar production technology, applied in the field of reuse and treatment of high-concentration organic wastewater, can solve the problems of excessive organic load, environmental hazards, and high cost, so as to reduce water treatment costs, improve utilization efficiency, and reduce total costs. The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

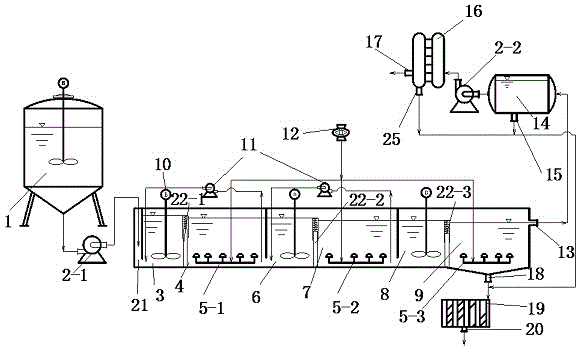

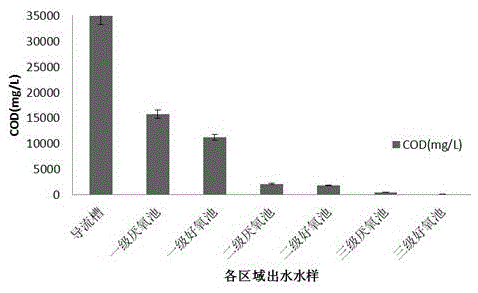

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the agitator speed in the primary anaerobic tank 3 is 5rpm, and every 40min of operation is shut down for 80min;

[0046] The aeration device at the bottom of each aerobic tank is connected to 2 fans, the flow rate is controlled at 20-500m / min, and the pressure is generally controlled at 3500-20000mmH 2 O; The operating environment temperature affects the working condition of the fan. The design temperature of the blower is 20°C. For every 1°C increase, the outlet pressure will drop by 20mmH 2 O or so. When the summer temperature is 38°C, the outlet pressure will drop by 360mmH 2 O. The parameters of the fan should be set according to the specific conditions of the use site, taking into account the influence of air temperature changes on the outlet pressure of the fan, when the daily limit temperature T of the fan is used max When >37℃, according to 20mmH 2 O / 1°C compensates the inlet pressure.

[0047] Open the valve 18 of the sludge discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com