High-voltage switch mechanical feature tester verifying device

A technology of mechanical characteristics and high-voltage switches, which is applied in the testing of mechanical components, measuring devices, and testing of machine/structural components. The effect of high integration, powerful interrupt processing function, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

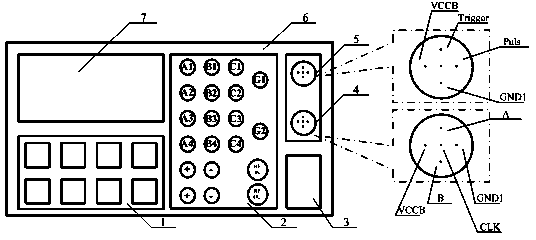

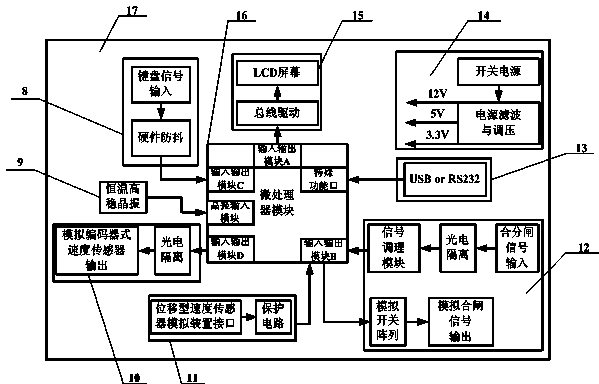

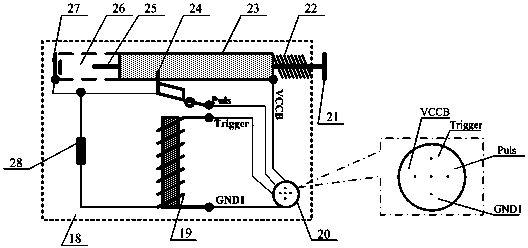

[0016] see Figure 1-Figure 3 , a high-voltage switch mechanical characteristic tester calibration device, which includes a chassis 6, a main board 17 and a displacement type speed sensor detection device 18, a keyboard 1, a power switch 3, and an LCD screen 7 are arranged on the panel of the chassis 6, and the The panel of the chassis 6 is also provided with a closing and opening signal input and output interface 2, an encoder type speed sensor analog output interface 4 and a displacement type speed sensor detection device interface 5; they are all connected to each corresponding module on the main board 17 in the chassis 6 Control connections. in:

[0017] The closing and opening signal input and output interfaces 2 include output interfaces of signals A1, B1, C1, A2, B2, C2, A3, B3, C3, A4, B4, C4, G1 and G2, signals RelayOn1, RelayOn2, RelayOff1 and The input interface of RelayOff2, these interfaces are directly connected to the input and output interfaces of the closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com