Battery core feeding equipment

A battery charging and battery technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem that the battery transmission cannot be placed and transmitted in sequence, and achieve continuity, reduce production costs, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

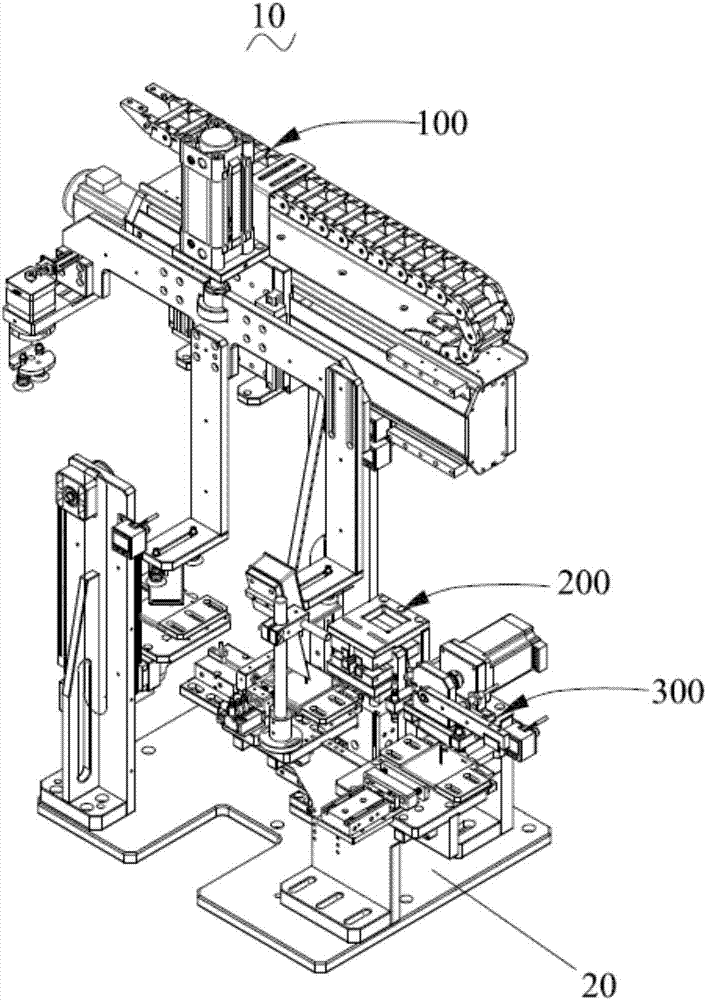

[0036] see figure 1 , the present invention provides a battery feeding device 10, comprising: a feeding platform 20, and a battery feeding and conveying mechanism 100 provided on the feeding platform 20, a battery lug leveling mechanism 200 and a battery turning over Institution 300;

[0037] The cell feeding and conveying mechanism 100 is used to absorb and transfer the cells to the cell feeding equipment. The cell tab leveling mechanism 200 is used for leveling the cell tabs. After the cells are leveled, The cell enters the flipping station, but before flipping, it is necessary to detect whether the cell needs to be flipped on the cell lug leveling mechanism. If it needs to be flipped, it will be flipped by the flipping mechanism. If it is not used, it will be directly fed by the cell. The mechanism absorbs and moves to the next station, and the battery turning mechanism 300 is used to turn over the battery.

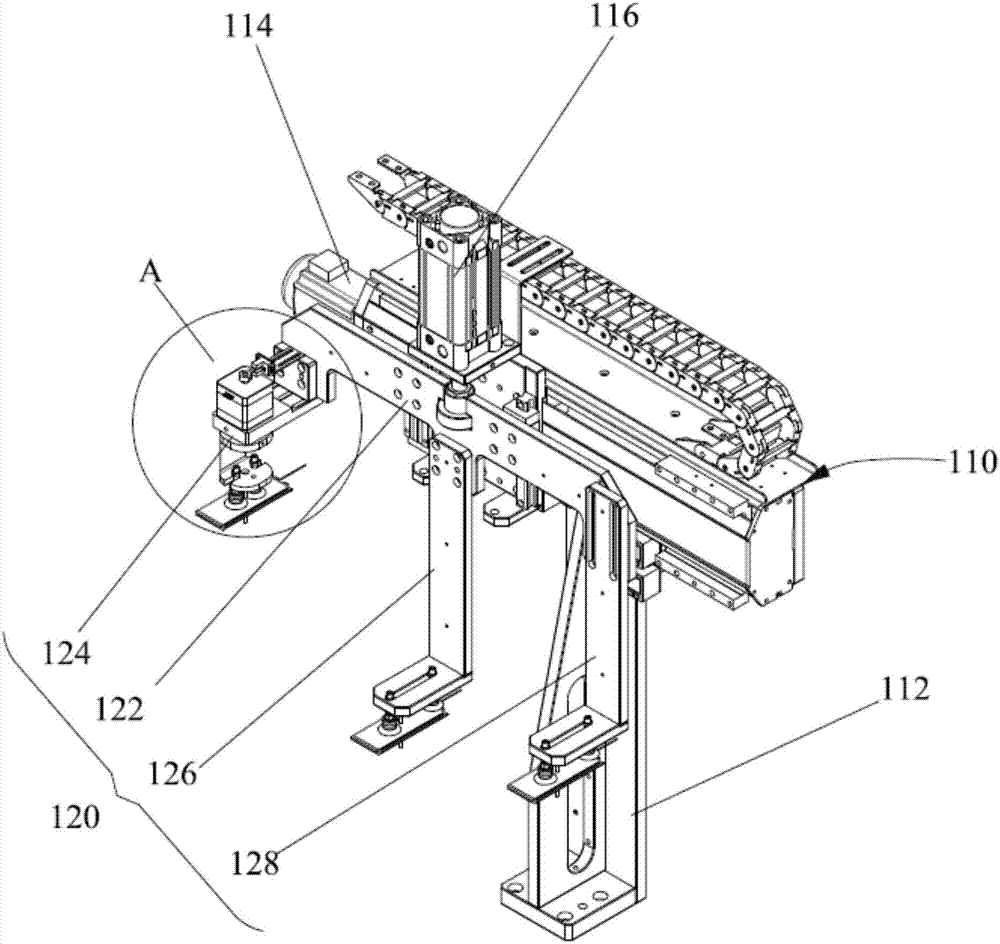

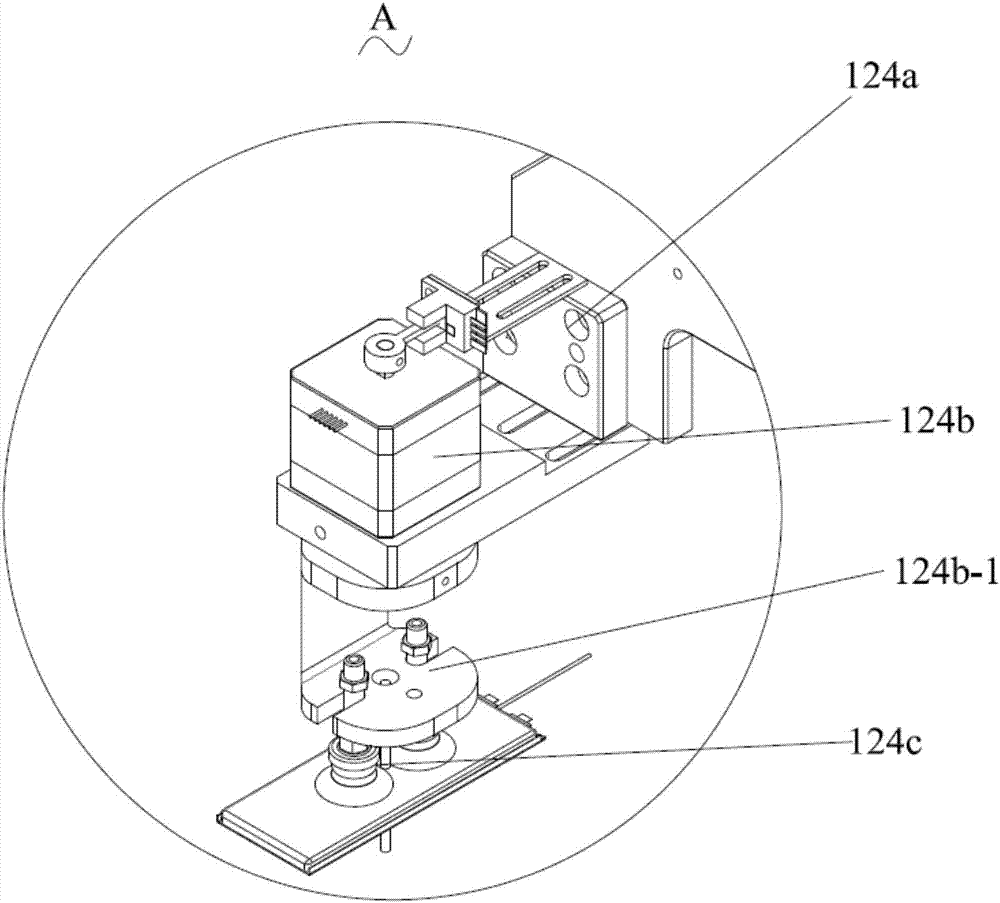

[0038] see Figure 2-3 , the cell feeding and conveying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com