Winding machine for winding metal foil type capacitor

A capacitor and winding machine technology, applied in winding capacitor machines and other directions, can solve the problems of cumbersome processes and low efficiency, and achieve the effect of optimizing the overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

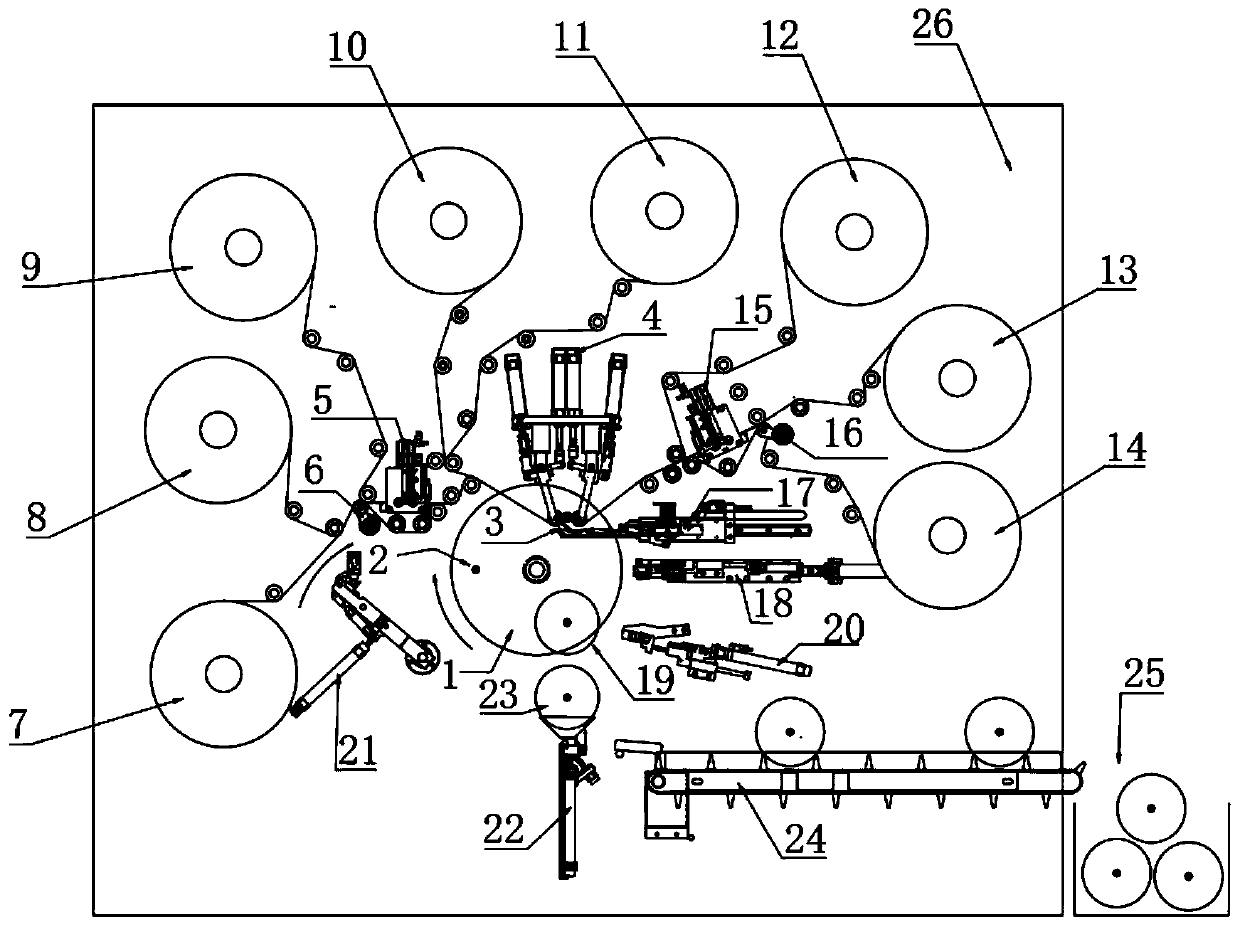

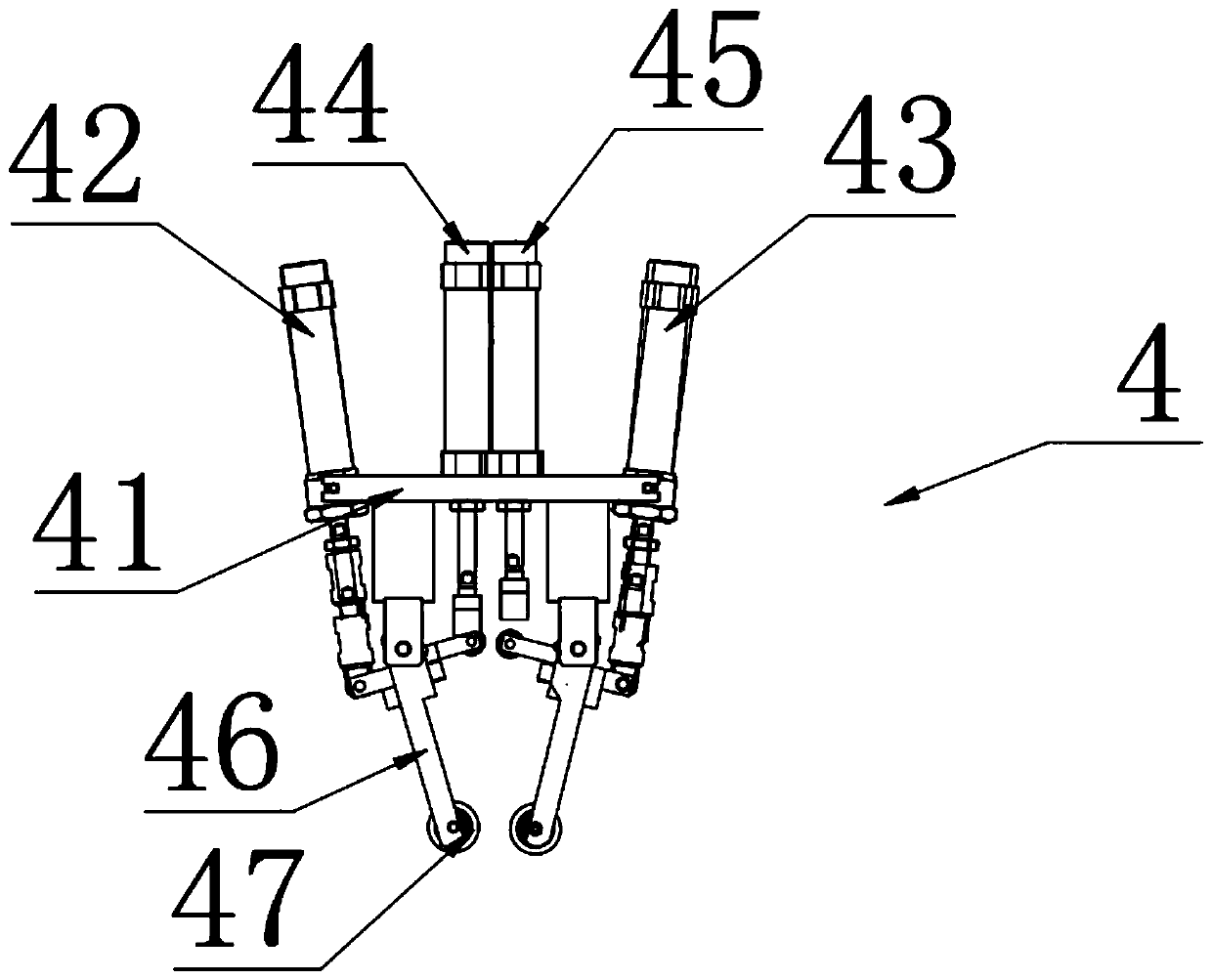

[0020] like Figure 1-2 As shown, a winding machine for winding metal foil capacitors includes a base plate 26 on which a machine head mechanism 1 is arranged, and station one 2, station two 3 and station three 19 are respectively located on the machine Circumferential direction of head mechanism 1 top, on its station all be inserted with rolling pin, the outer wall of described station two 3 is connected with the inner wall of one end of pressure roller mechanism 4, and between described station two 3 and roller mechanism 4, set There is a material insertion mechanism 17, and the end of the pressure wheel mechanism 4 away from the material insertion mechanism 17 is provided with a No. 1 hemming mechanism 5, and a No. 1 one-way wheel mechanism 6 is provided below the No. 1 hemming mechanism 5, and a material tray 7 , material disc two 8, material disc four 10, material disc five 11, material disc six 12 and material disc eight 14 are all located in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com