Bearing oiling system for disconnector bearing seats

A technology of isolating switch and bearing housing is applied in the field of bearing oiling system for isolating switch housing, which can solve the problems of large labor consumption and waste of grease, and achieve the effects of reducing manual labor, reducing labor intensity and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

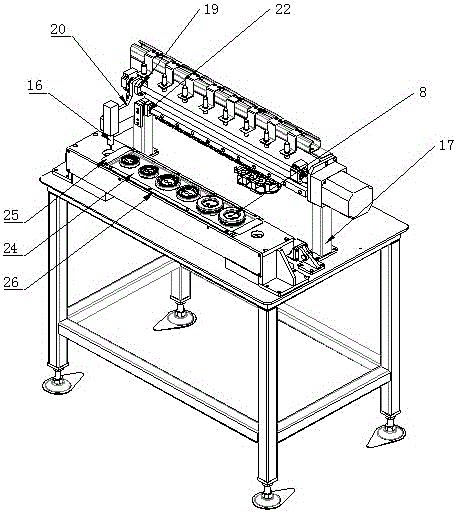

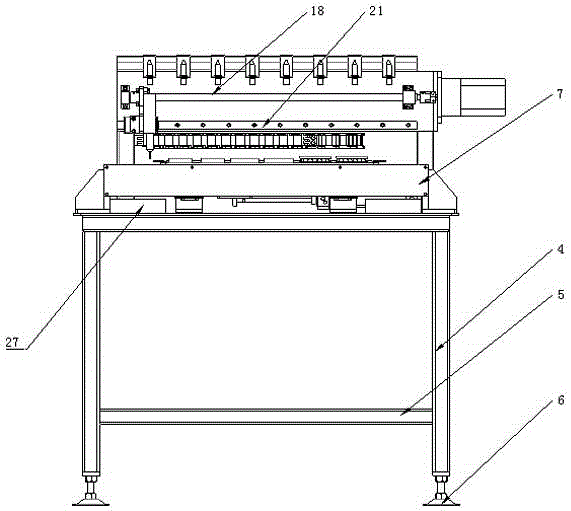

[0030] Such as Figure 2-Figure 6 A bearing lubricating system for bearing housings of disconnectors is shown, including

[0031] A frame, which is a common frame structure formed by connecting several horizontal bars 5 and vertical bars 4, a chassis 6 is also installed at the bottom of the vertical bars 4, and a coating is installed on the upper end of the frame. The oil platform 7 is provided with several bearing mounts 8 arranged side by side for bearing installation on the oiling platform 7, and the bearing mounts 8 can be driven by an independent rotating mechanism or a linkage rotating mechanism, and a Automatic oiling mechanism.

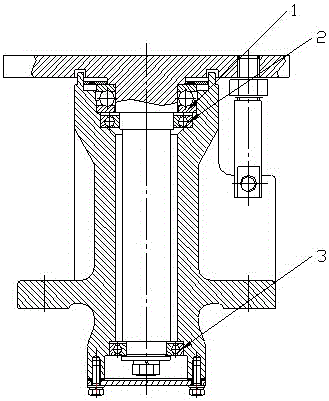

[0032] Such as Figure 4 As can be seen from the schematic diagram shown, the bearing mount 8 includes a mount body 10 which is disc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com