Hollow forearm and wrist structure for low-load industrial robot

A technology of industrial robots and empty small arms, which is applied in the direction of claw arms, manipulators, manufacturing tools, etc., can solve problems such as unclear transmission lines, and achieve the effects of increasing the range of activities, high precision, and large transmission speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

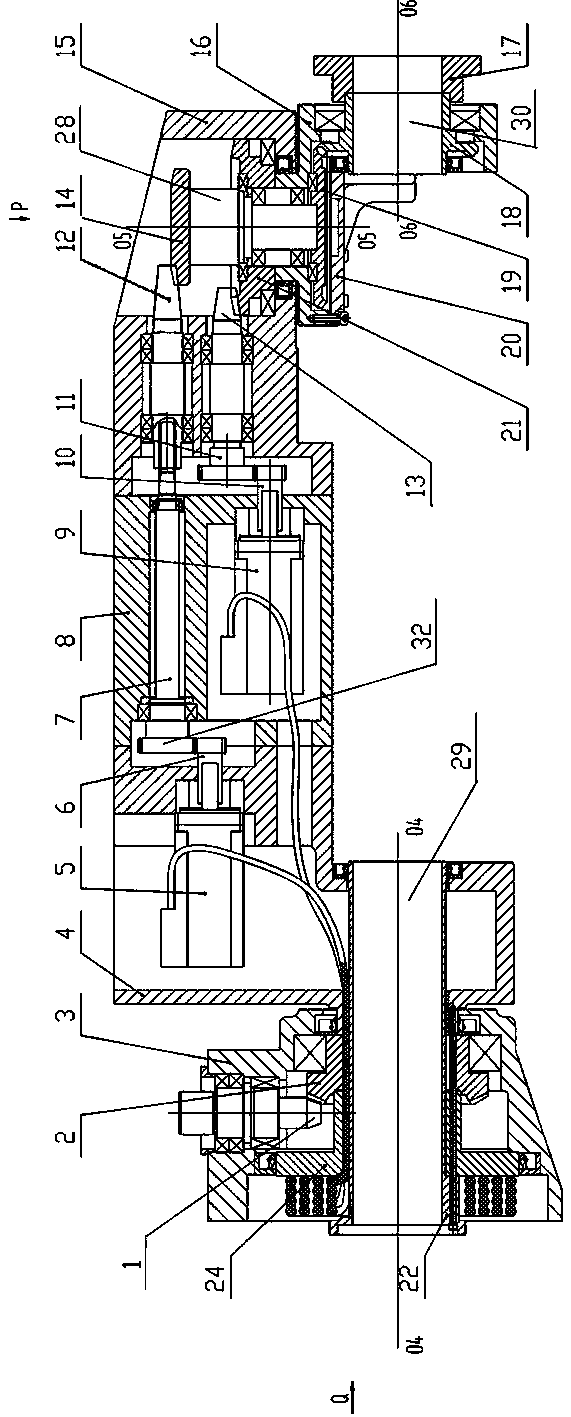

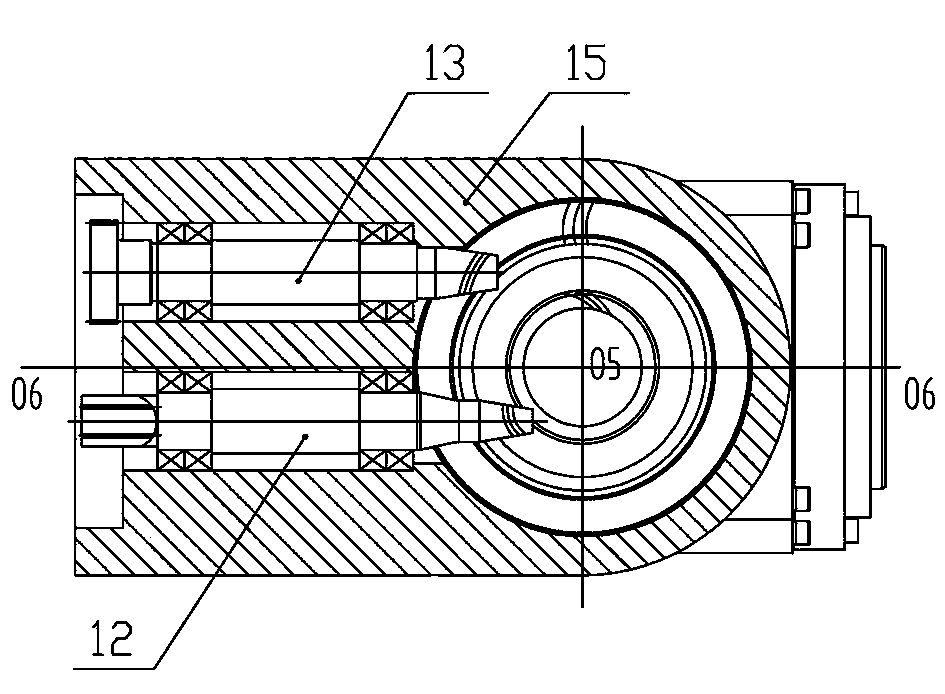

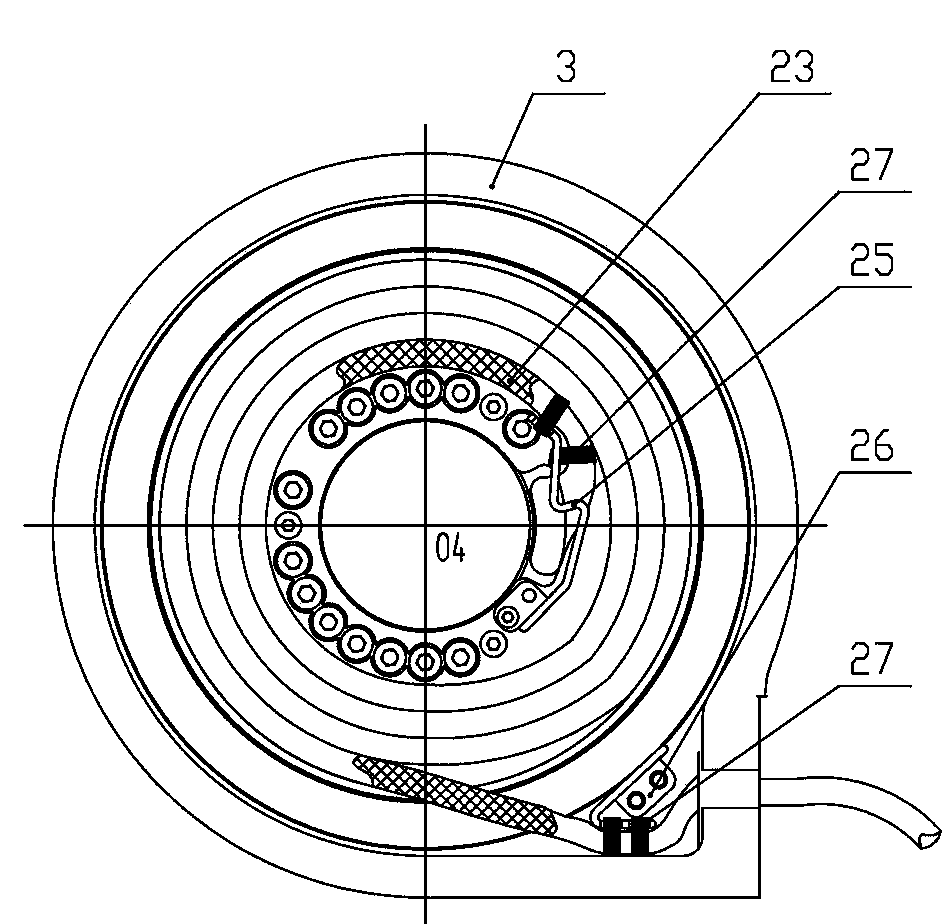

[0019] Such as figure 1 , figure 2 with image 3 The hollow forearm and wrist structure of the low-load industrial robot shown includes the J4 shaft 29, the cable turntable 24 fixed on the J4 shaft 29 from left to right, the fifth large speed ratio hypoid gear 2 and the J6 shaft Motor seat 4, one end of the J4 shaft 29 is arranged in the arm seat 3, and the J6 axis motor seat 4 is arranged in the arm seat 3 through a bearing, so that the J6 axis motor seat 4 can rotate relative to the arm seat 3. The arm seat In 3, the sixth largest speed ratio hypoid gear shaft perpendicular to the J4 axis is set by bearing rotation, and the sixth largest speed ratio hypoid gear shaft bottom is provided with the sixth largest speed ratio hypoid gear 1. The sixth The high speed ratio hypoid gear 1 meshes with the fifth high speed ratio hypoid gear 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com