Robot cleaner driving wheel mechanism

A technology for cleaning robots and driving wheels, applied to cleaning equipment, machine parts, vacuum cleaners, etc., can solve the problems of large turning radius, labor-saving, high cost, etc., and achieve the effect of small turning radius, easy steering and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

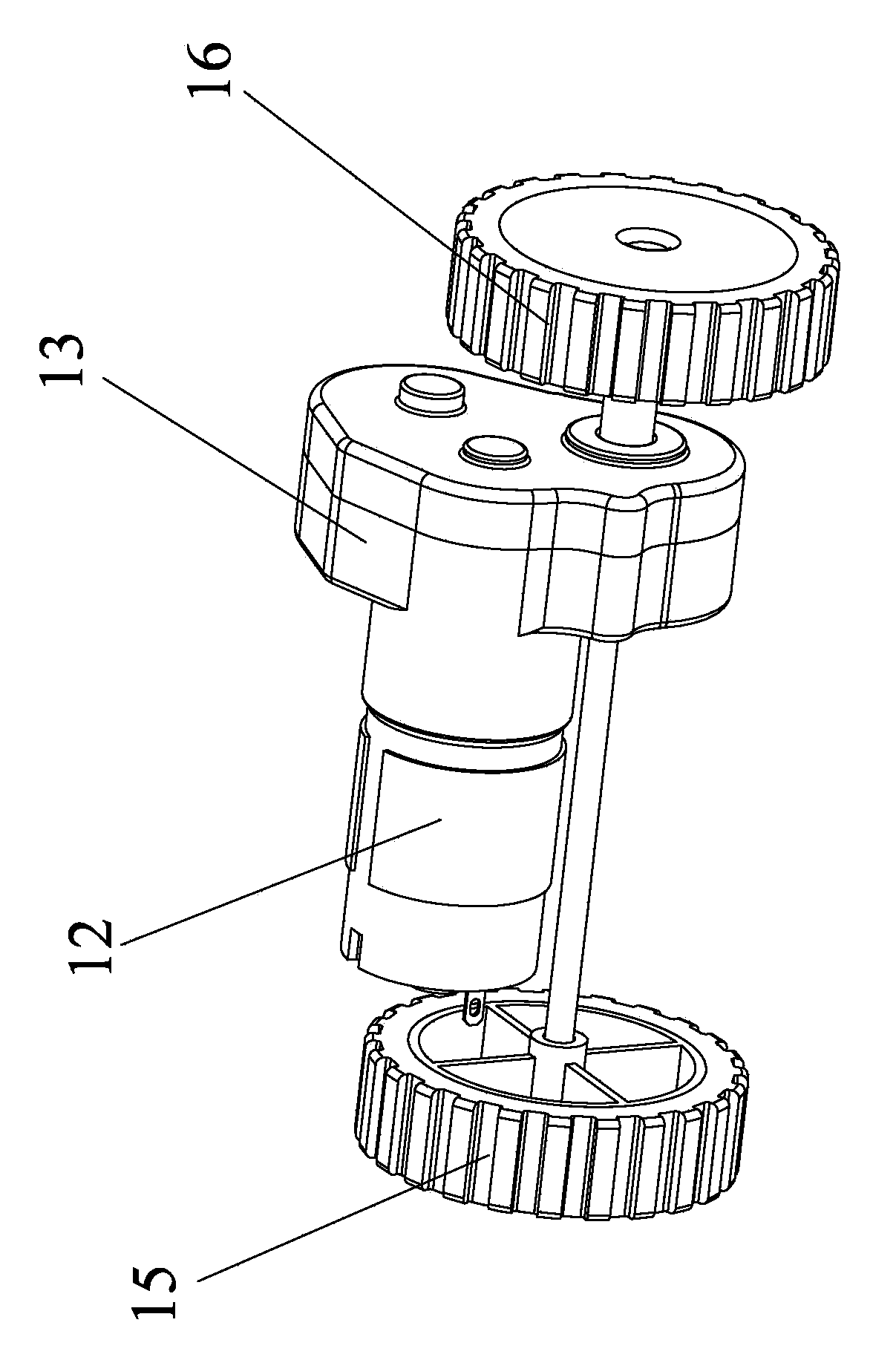

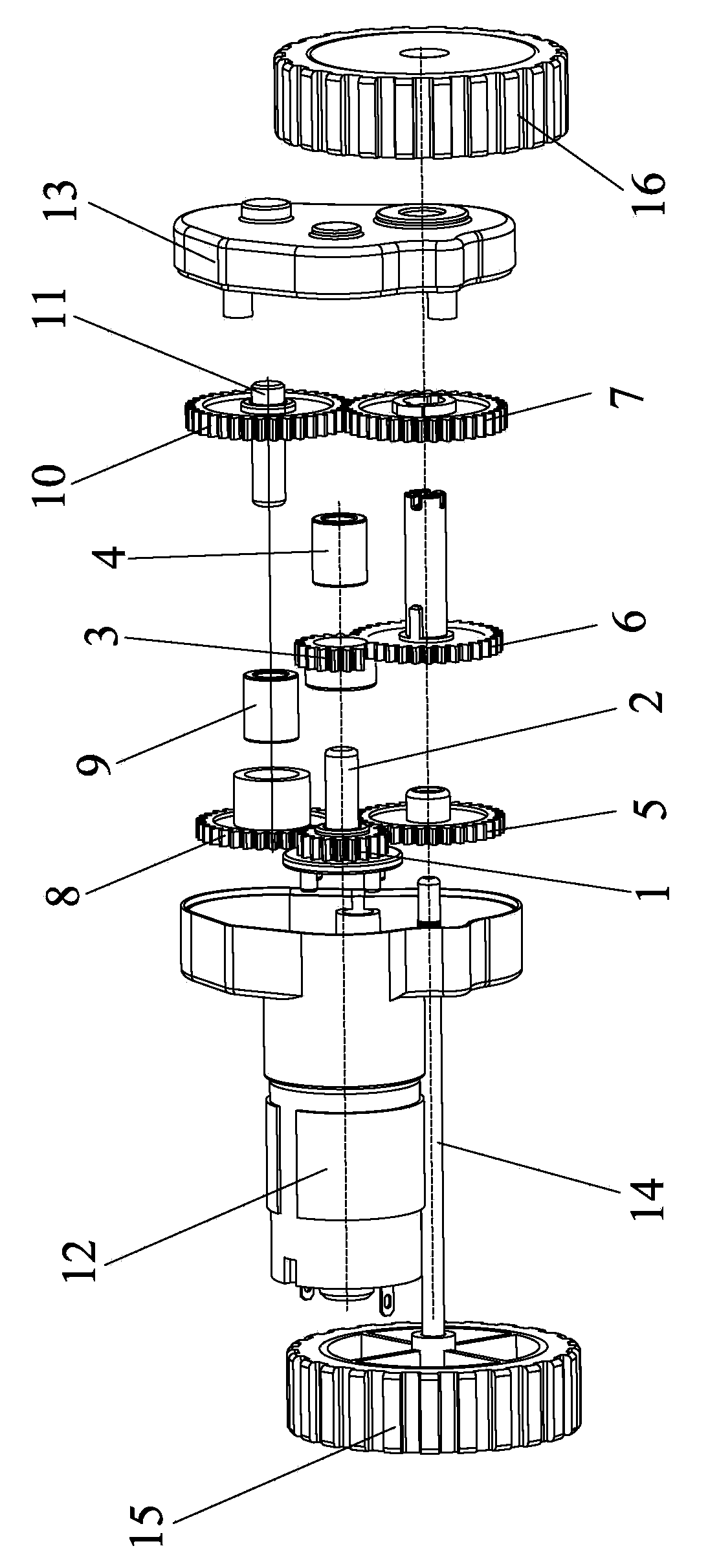

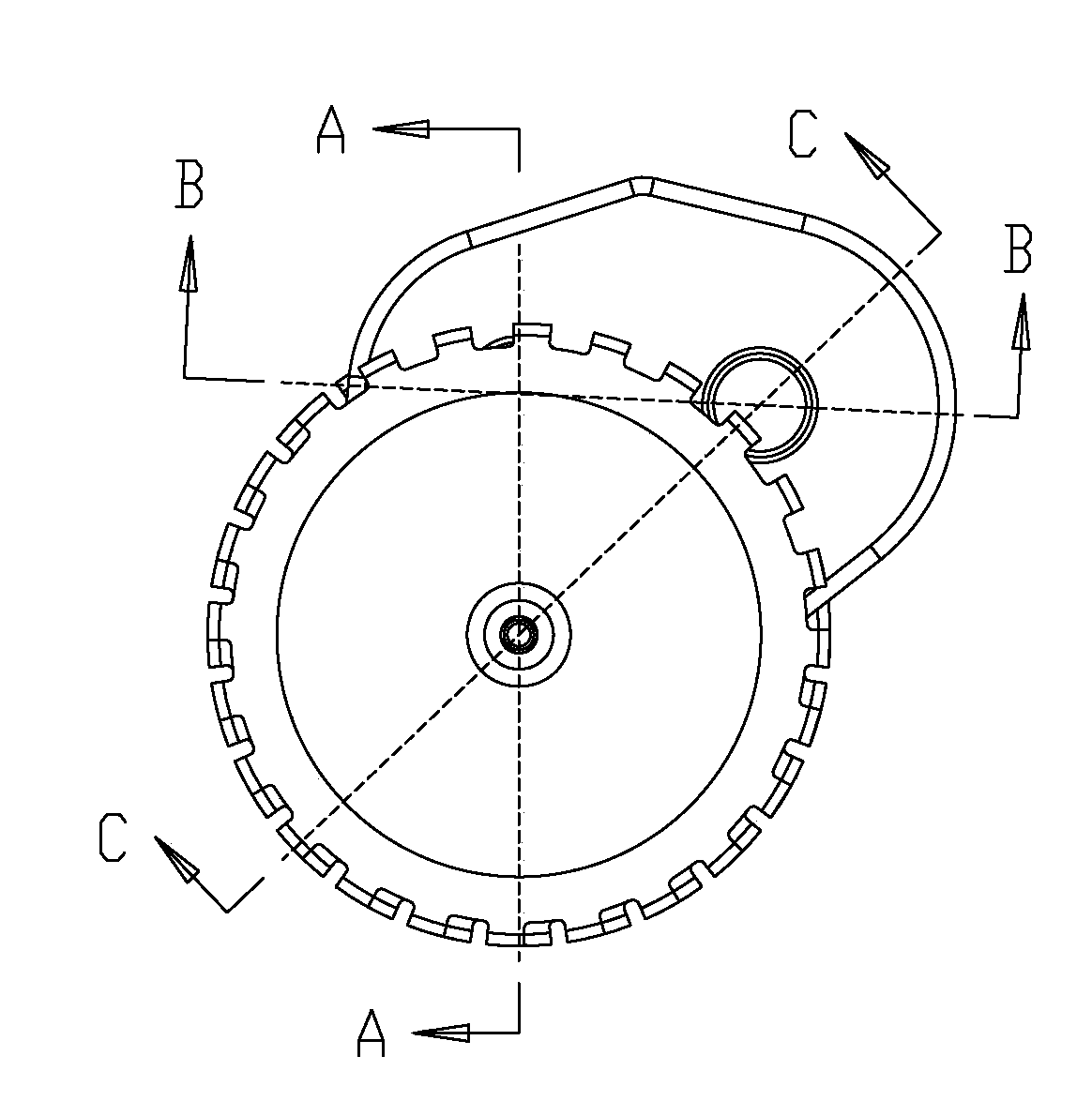

[0016] Such as Figure 1 to Figure 6 As shown, the driving wheel mechanism of the cleaning robot of the present invention includes a motor 12, a left driving wheel 15, a right driving wheel 16 and a gear box 13 connected with the motor 12. The first one-way bearing 4 and the second one-way bearing 4 are housed in the gear box 13. Bearing 9, one-way bearing can work in self-locking and free state respectively. Through the forward and reverse rotation of the motor and the control of the one-way bearing, the left and right drive wheels can work in different directions. Such as figure 2 As shown, one end of the gearbox 13 is provided with an output gear 1 of the motor 12, and the output gear 1 is closely matched with a shaft 2, and the outer edge of the shaft 2 is provided with a first one-way bearing 4, and the first one-way bearing 4 is tightly fitted. Fitted with a third gear 3, the output gear 1 transmits torque to the third gear 3 through the first one-way bearing 4; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com