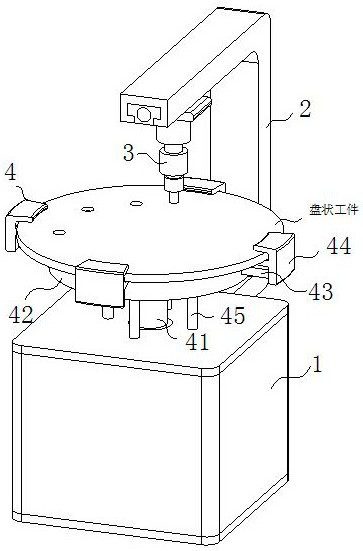

Hole punching machine for automotive parts processing using gears for precise positioning

An auto parts, precise positioning technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problem of difficult to control the clamping force of the pressing block and the accuracy of positioning, affecting the punching efficiency of the punching machine and punching accuracy, etc., to achieve the effect of improving the punching effect, improving the accuracy, and increasing the range of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

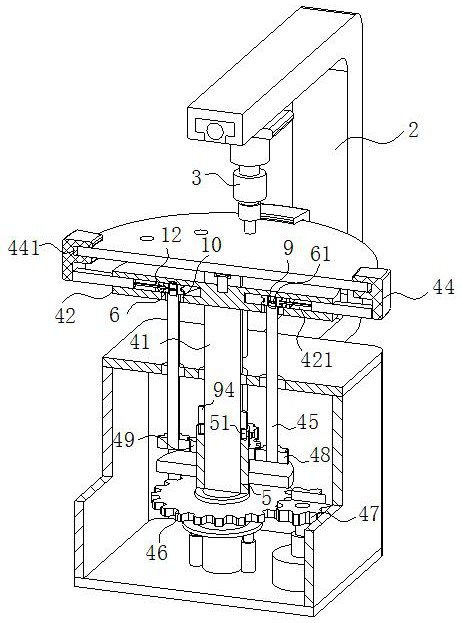

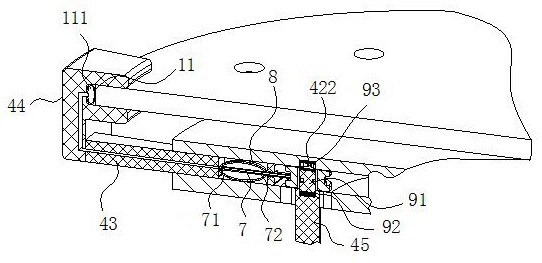

[0024] As an embodiment of the present invention, the rotating winch 6 is flexibly connected to the rotating column through a limit sliding mechanism 9; the outer wall of the support shaft is provided with a plurality of limit inserts 94; The top is provided with a plurality of limiting slots 51, and the limiting inserts 94 are slidably inserted into the plurality of limiting slots 51; the thickness of the driving gear 47 is greater than the overall thickness of the driven gear 46 and the meshing wheel 49; The bottom end of the fixed disk 42 is rotated with a rotating ring 10, and a plurality of rotating rods 45 are inserted into the rotating ring 10 through bearings;

[0025] During work, when the fixed disc 42 needs to be rotated, and then when the different positions of the disc-shaped workpiece are punched, it is necessary to rotate the capstan 6 to be disconnected from the rotating rod 45, and then it is convenient for the fixed disc 42 to rotate; Control the rotating cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com