Subway tunnel shaft entering construction method and construction shaft supporting structure in loess area

A technology for tunnel construction and support structure, which is applied in earth-moving drilling, shaft equipment, wellbore lining, etc., can solve problems such as tension, large construction land range, difficulty in land acquisition and demolition, etc., and achieve the effect of large construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

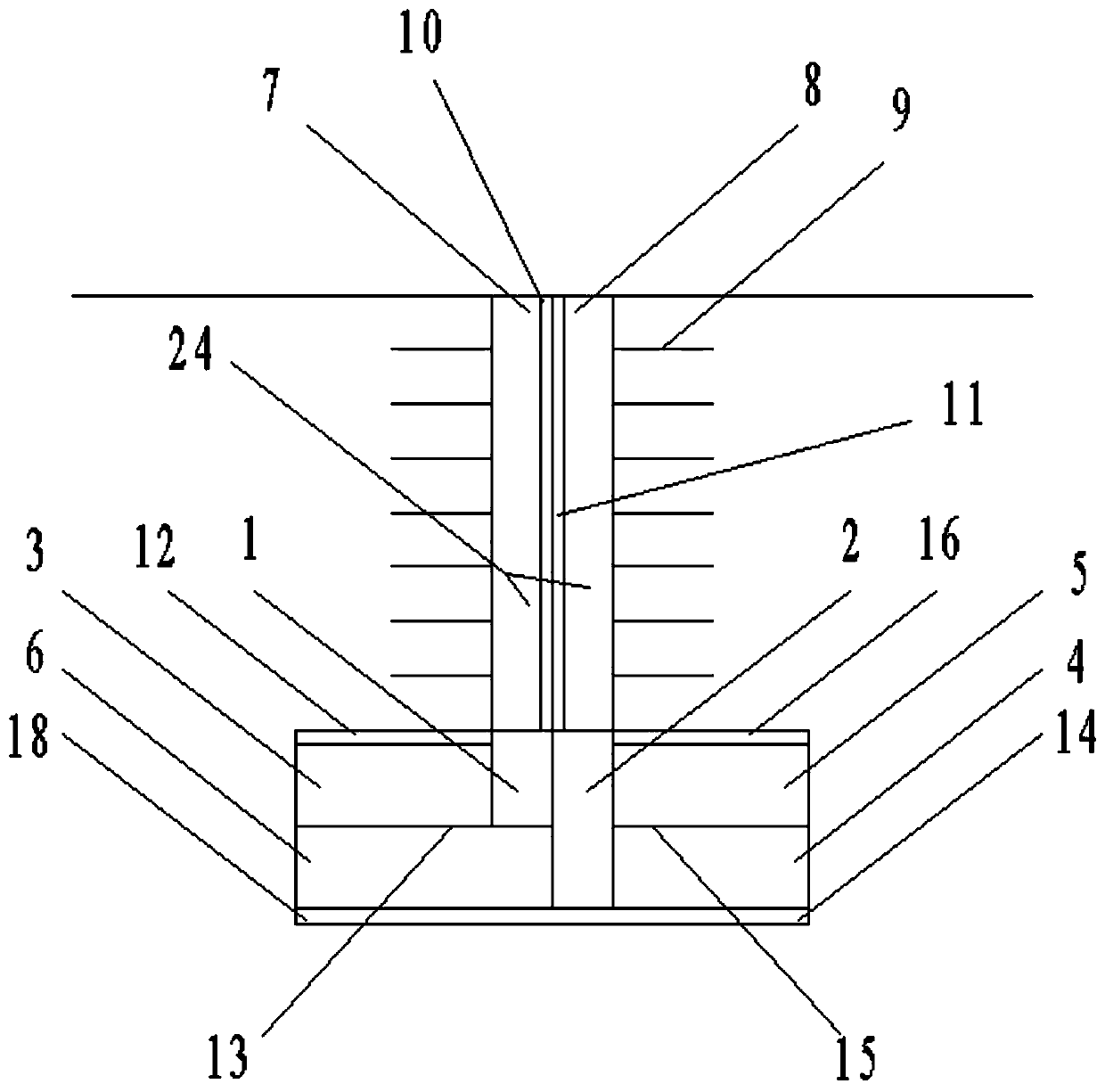

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] see figure 1 A construction method for entering a subway tunnel in a loess area, comprising the following steps:

[0042] Step 1: determine the excavation position of the shaft 24 in combination with the survey data, and set up the excavation equipment;

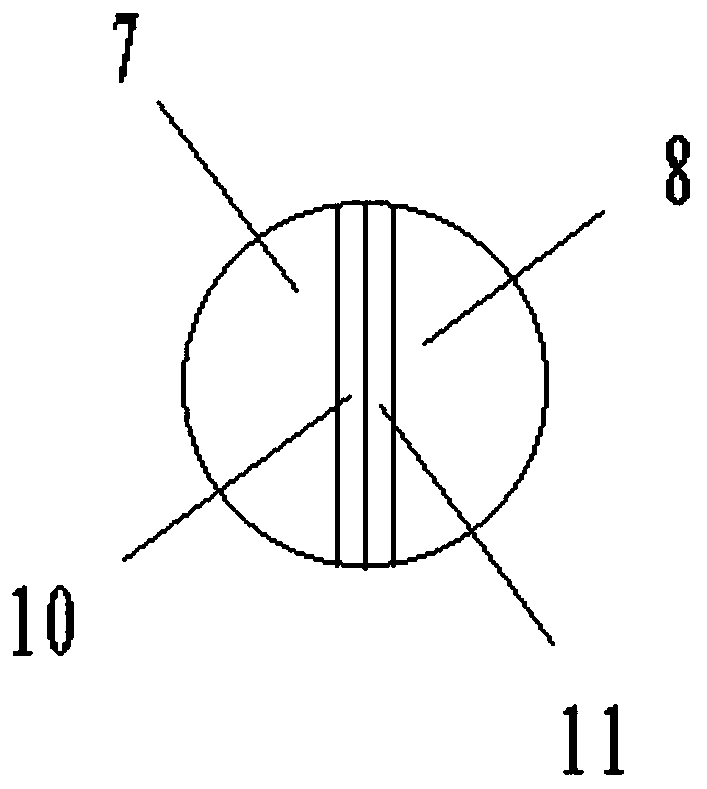

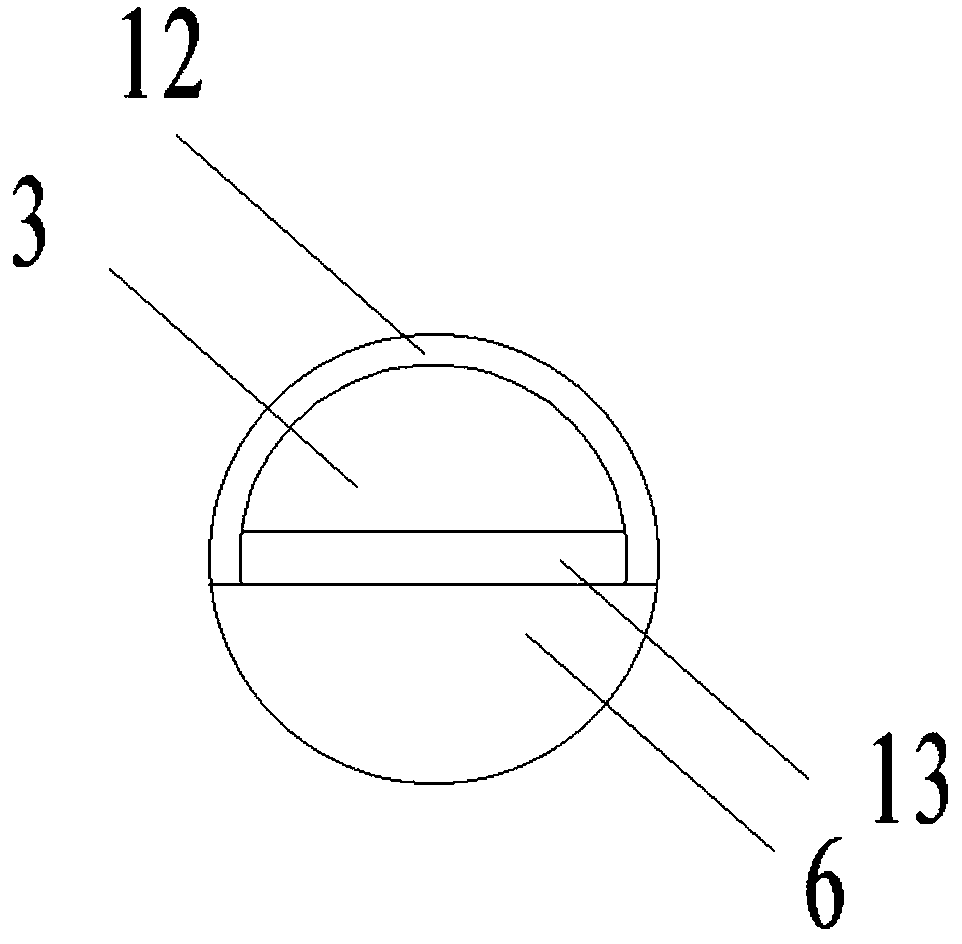

[0043] Step 2: Divide the shaft 24 into the first half area 7 and the second half area 8; excavate the first half area 7 first; during the excavation process of the first half area 7, the arc surface of the first half area 7 Anchor rods 9 are drilled into the wall, sprayed anchor support is applied, and the first concrete temporary support 10 is applied on the plane wall of the first half area 7 until reaching directly above the preset vault of the tunnel;

[0044] Step 3: Excavate the second half area 8; during the excavation process of the second half area 8, drive anchor rods 9 on the curved wall of this h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap